High-efficiency and energy-saving caprolactam recovery technology

A caprolactam and aqueous solution technology, applied in caprolactam production, chemical industry, multi-effect evaporation, etc., can solve the problems of high energy consumption and high operating cost, and achieve the effect of small required space, small footprint and compact evaporation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

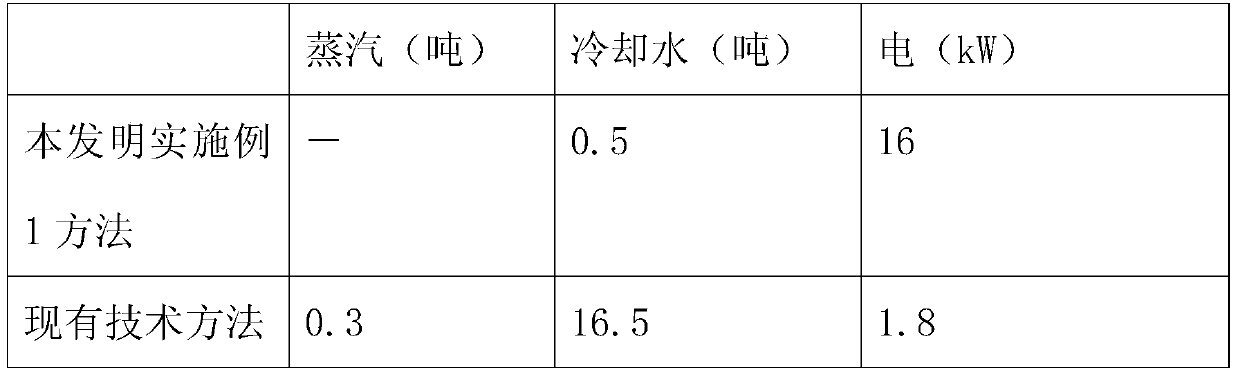

Embodiment 1

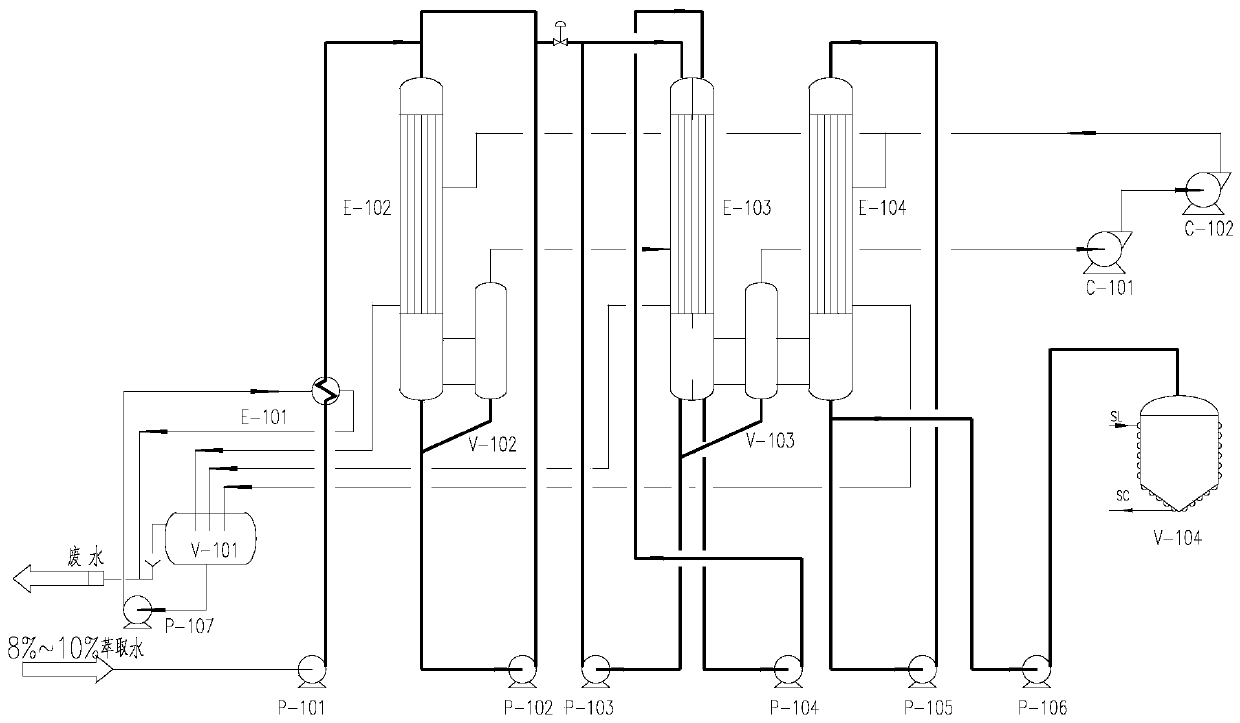

[0027] A method of extracting water containing caprolactam and its oligomers obtained after concentrated production of nylon 6 slices, the method, the steps are as follows:

[0028] 1) The extraction water is preheated to about 110°C by the pump (P-101) through the heat exchanger (E-101), and enters the evaporation tube from the top inlet of the first-effect falling film evaporator (E-102).

[0029] 2) The extraction water is distributed through the liquid distributor in the (E-102) tower, and distributed into the heat exchange tube in the form of a film. When it enters the tube cavity by gravity flow, it is heated by the steam outside the tube to evaporate the film, and together with the secondary steam It flows down from the pipe to the bottom of the effect body and enters the first-effect separation tank (V-102) for liquid-vapor separation.

[0030] 3) The concentration at the bottom of the effect body and the bottom of the separation tank reaches 12% to 15%. (E-103) The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com