Preparation method of cerium-based sulfate catalyst for SCR (selective catalytic reduction) reaction

A catalyst and sulfate technology, which is applied in the field of preparation of cerium-based SCR catalysts to achieve good application prospects and good catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

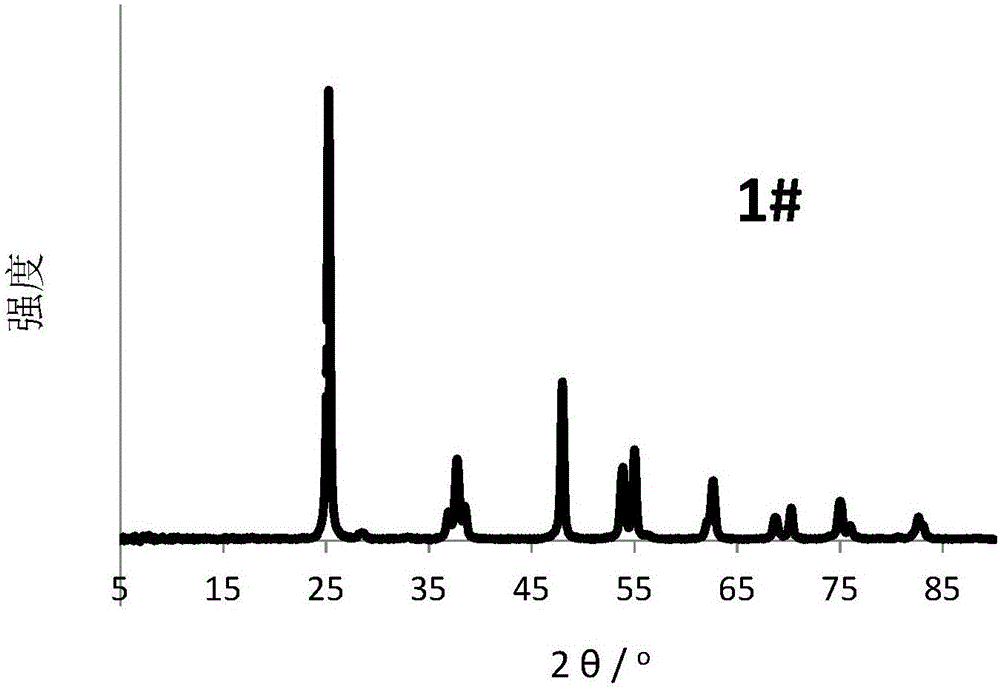

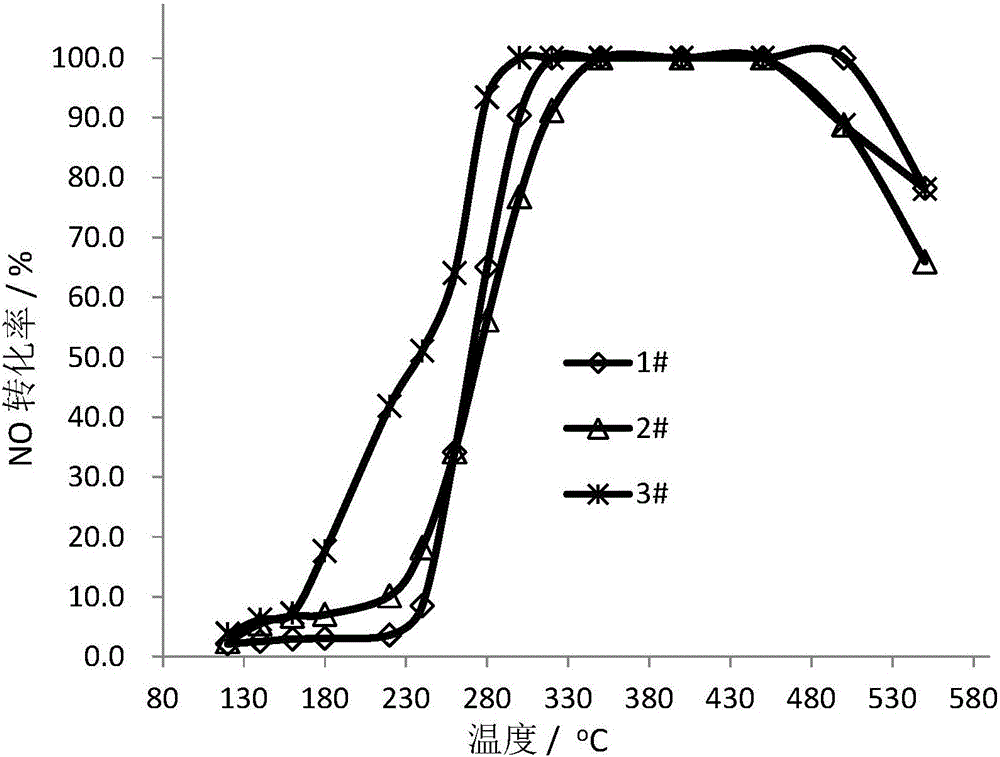

[0026] Accurately weigh 1.93g of Ce(SO 4 ) 2 , adding 9g of titanium dioxide, grinding and mixing at room temperature to obtain a mixture. The above mixture was added into a crucible with a lid, kept in a muffle furnace at 200°C for 2h, and then heated to 580°C for 3h to obtain 1# catalyst.

Embodiment 2

[0028] Accurately weigh 1.93g of Ce(SO 4 ) 2 , adding 18g of titanyl sulfate powder, grinding and mixing at room temperature to obtain a mixture. The above mixture was added into a crucible with a lid, kept in a muffle furnace at 200°C for 2h, and then heated to 400°C for 3h to obtain 2# catalyst.

Embodiment 3

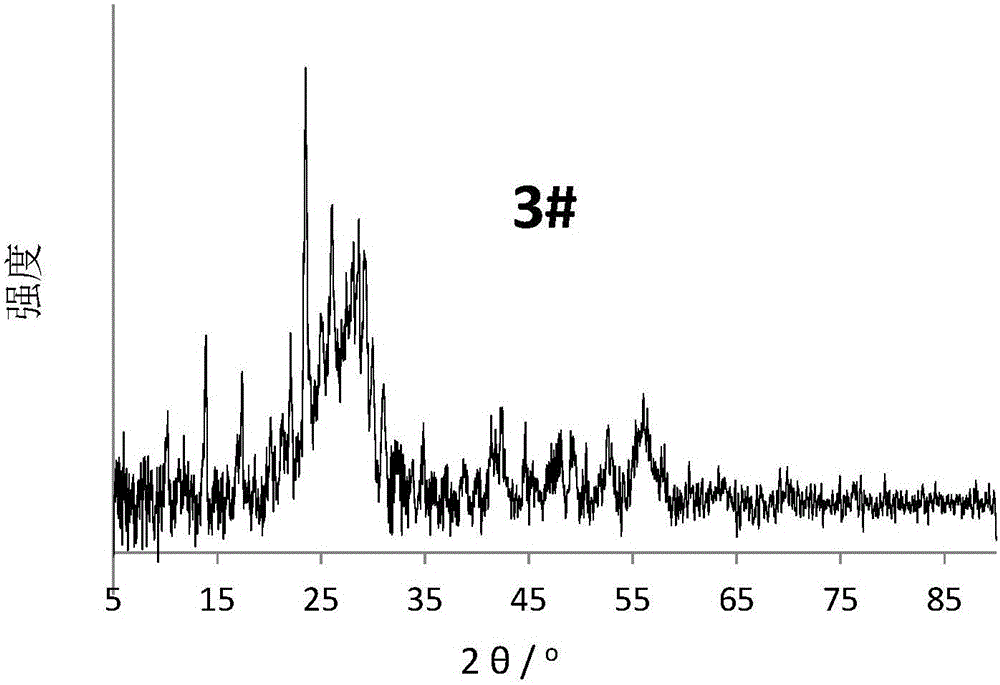

[0030] Accurately weigh Ce with a mass of 3.16g 2 (C 2 o 4 ) 3 , adding 18g of titanyl sulfate powder, grinding and mixing at room temperature to obtain a mixture. The above mixture was added into a crucible with a lid, kept in a muffle furnace at 200°C for 2h, and then heated to 400°C for 3h to obtain 3# sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com