Preparation method and application of nitrous oxide decomposition reaction catalyst

A catalyst and catalytic decomposition technology, applied in the direction of nitrous oxide capture, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as exhaust gas pollution, reduce emissions and reduce costs , the effect of low activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

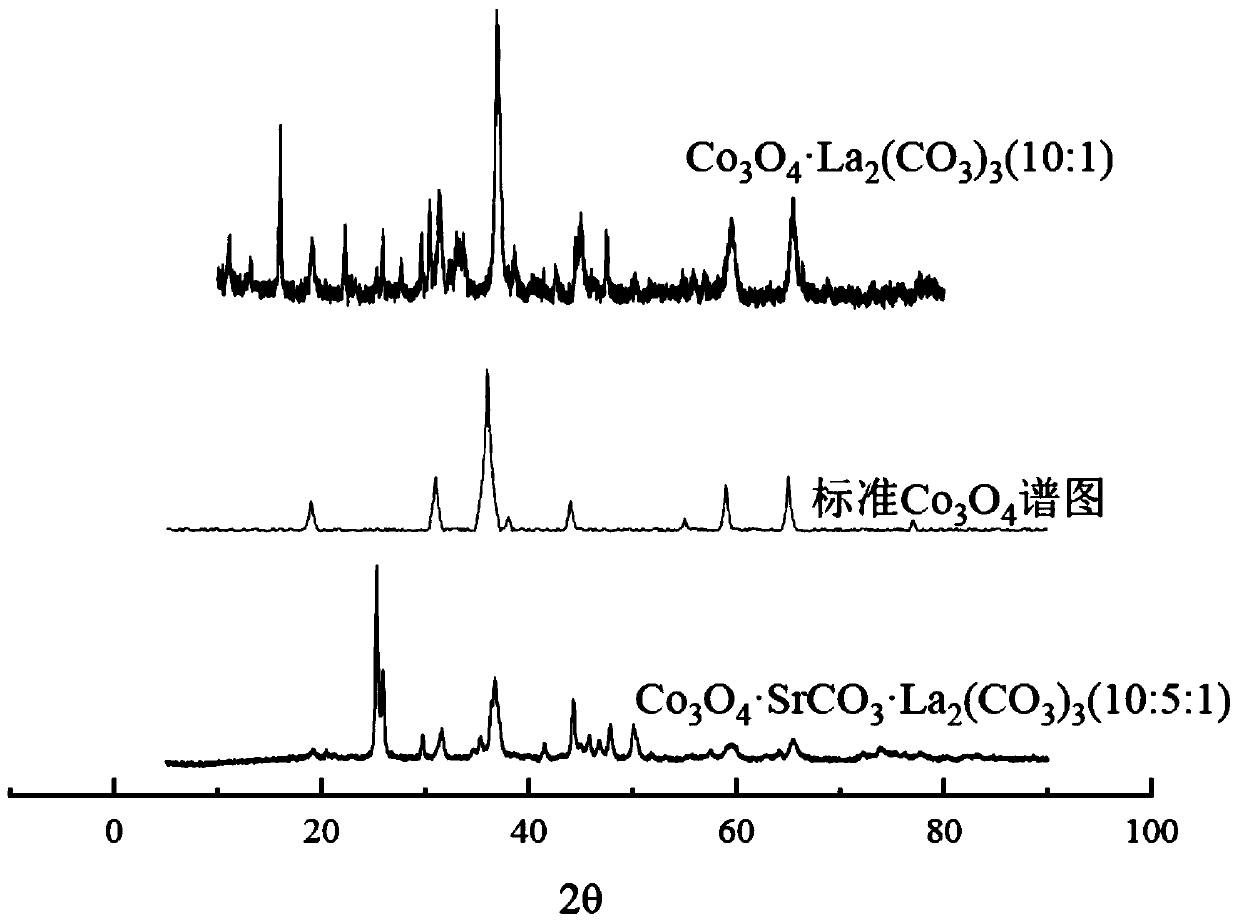

Image

Examples

Embodiment 1

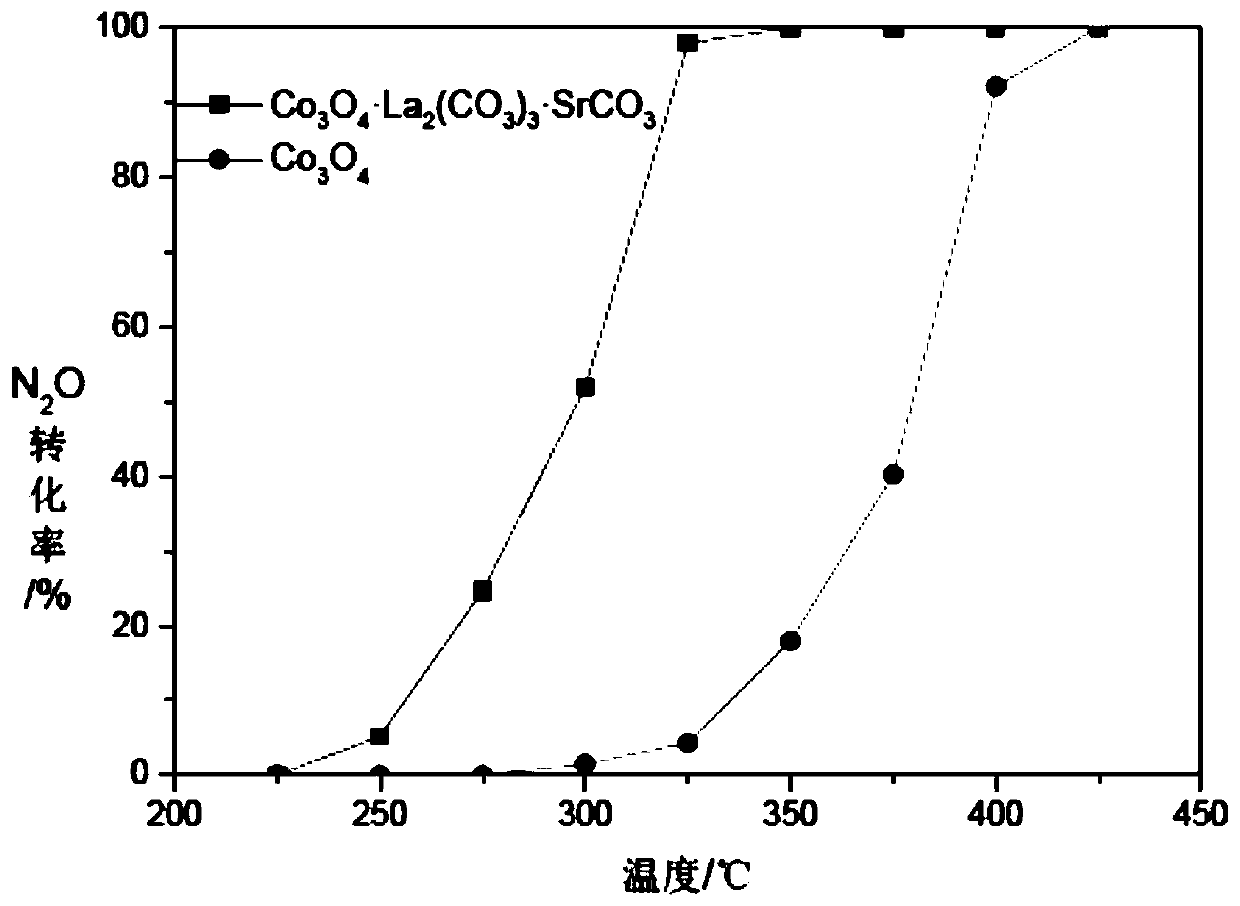

[0023] Example 1: Take 1000mL of deionization and pour it into a 2000mL beaker, add a magnetic stirring bar, stir and heat in a constant temperature magnetic stirrer, and set the temperature at 65°C. Add 157g of cobalt nitrate hexahydrate and 85g of strontium acetate into the beaker, stir and dissolve evenly; measure 1500mL of deionized water and add it to a 2000mL beaker, add a magnetic stirring bar, stir and heat in a constant temperature magnetic stirrer, set the temperature at 65°C, weigh Get 157g of anhydrous sodium carbonate and put it into a beaker; under the condition of heating and stirring in a water bath at 65°C, the rotating speed of the stirring paddle is 400r / min, and the precipitant Na 2 CO 3 Add the solution drop by drop to the metal nitrate solution, and control the mixing time for 1 hour. At the same time, the reaction kettle is controlled at 65°C through a water bath, and the pH of the suspension is adjusted to about 9. Then stop the dropwise addition, and c...

Embodiment 2

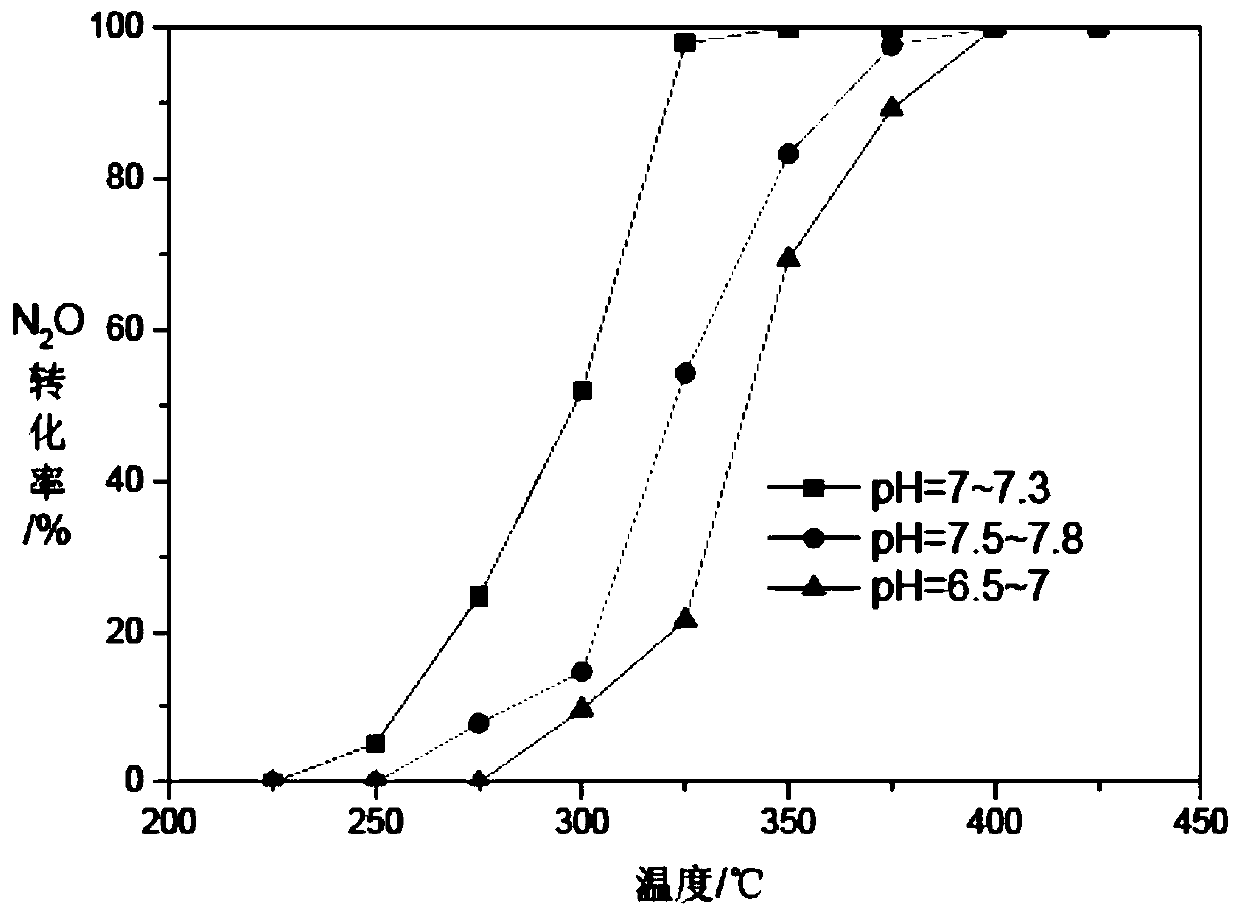

[0025] Embodiment 2: the Co obtained by changing the pH of washing in catalyst preparation in embodiment 1 is 7.5~7.8 3 o 4 ·SrCO 3 , carry out activity evaluation under the same conditions, other conditions are all the same as embodiment 1, gained experimental result sees image 3 .

Embodiment 3

[0026] Embodiment 3: Co 3 o 4 ·SrCO 3 , carry out activity evaluation under the same conditions, other conditions are all the same as embodiment 1, gained experimental result sees image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com