Catalyst for catalytic decomposition of nitrous oxide and a preparation method

A nitrous oxide and catalyst technology, which is applied in molecular sieve catalysts, nitrous oxide capture, physical/chemical process catalysts, etc., can solve problems such as catalyst deactivation, achieve simple preparation process, broad application prospects, and nitrous oxide catalysis The effect of high decomposition activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

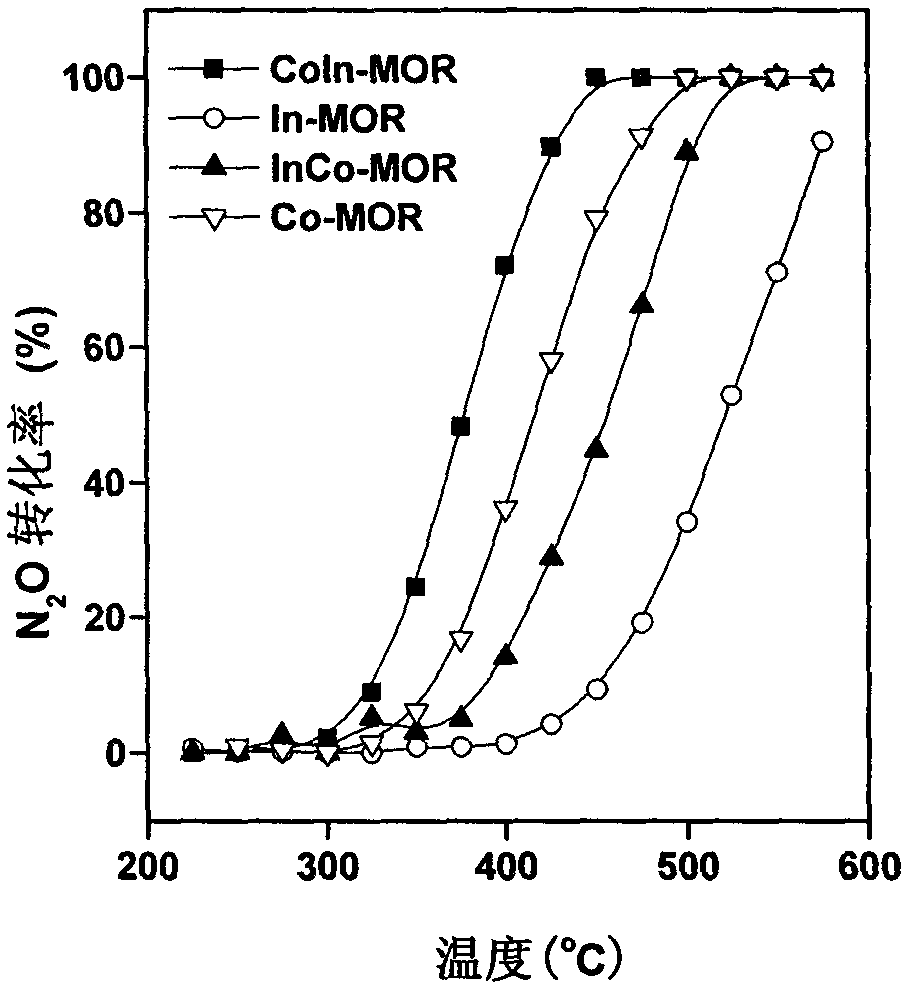

[0013] Example 1: CoIn-MOR catalyst, space velocity is 30,000h -1 , N 2 O concentration is 0.5%, N at different temperatures 2 O decomposition reaction activity. The initial reaction temperature is 300°C, and the total conversion temperature is 450°C.

[0014] Preparation of CoIn-MOR: 1) Under the condition of pH 6, use 0.1 mol / L of Co 2+ Exchange the aqueous solution with MOR for 24 hours, repeat 3 times, dry at 80°C for 24 hours, and then heat to 500°C and calcine in air at a constant temperature for 4 hours to obtain Co-MOR;

[0015] 2) Under the condition of pH 6, use 0.1mol / L containing In 3+ The aqueous solution was exchanged with Co-MOR for 24 hours, repeated 3 times, dried at 80°C for 24 hours, and then heated to 500°C and calcined in air at a constant temperature for 4 hours to obtain CoIn-MOR catalyst.

[0016] The catalytic reaction adopts a fixed-bed continuous flow reaction evaluation device. 2 The initial concentration of O is 0.5%, and the space velocity is 30,000h -1 ...

Embodiment 2

[0017] Example 2: Indium-cobalt-supported mordenite (InCo-MOR) catalyst prepared in different exchange sequences, with a space velocity of 30,000h -1 , N 2 O concentration is 0.5%, N at different temperatures 2 O decomposition activity. The initial reaction temperature is 325°C, and the total conversion temperature is 525°C.

[0018] Preparation of InCo-MOR: 1) Under the condition of pH 6, use 0.1mol / L of In 3+ The aqueous solution was exchanged with MOR for 24 hours, repeated 3 times, dried at 80°C for 24 hours, and then heated to 500°C and calcined in air at a constant temperature for 4 hours to obtain indium-supported mordenite (In-MOR);

[0019] 2) Under the condition of pH 6, use 0.1mol / L containing Co 2+ The aqueous solution was exchanged with In-MOR for 24 hours, repeated 3 times, dried at 80°C for 24 hours, and then heated to 500°C and calcined in air at a constant temperature for 4 hours to obtain InCo-MOR catalyst.

[0020] The catalytic reaction adopts a fixed-bed continuo...

Embodiment 3

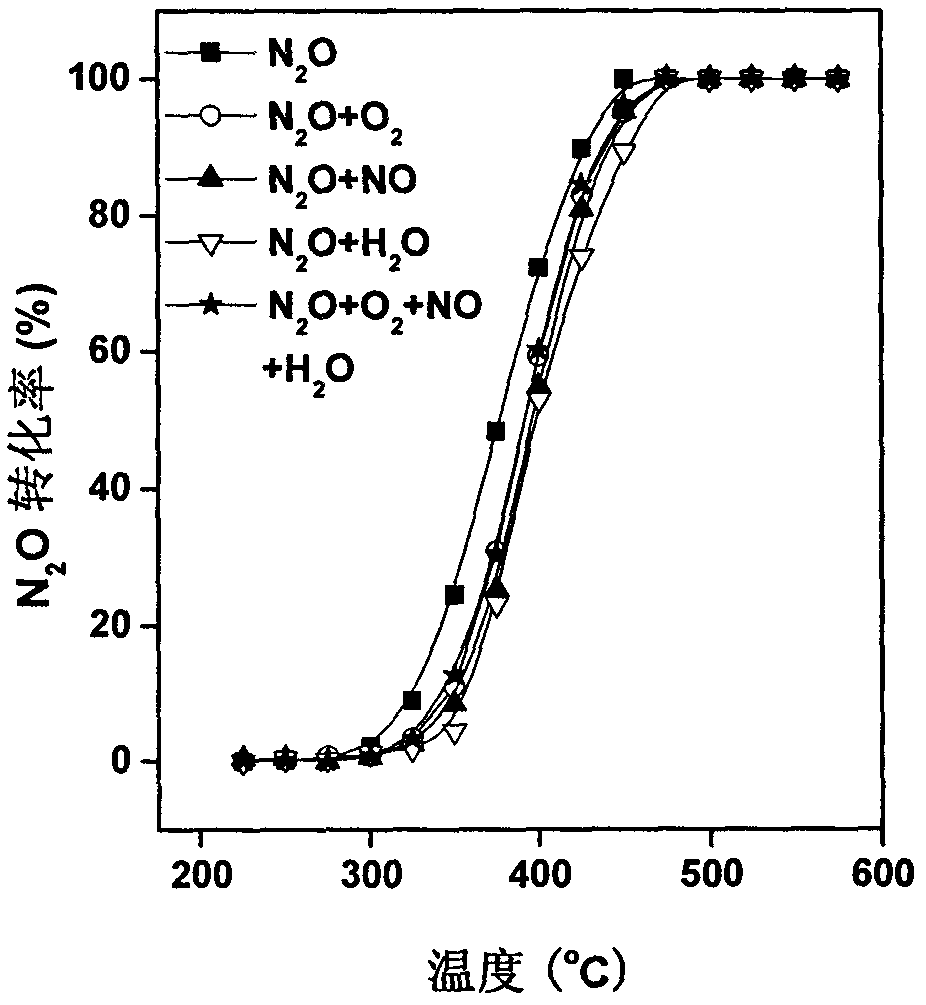

[0021] Example 3: CoIn-MOR catalyst, space velocity is 30,000h -1 , N 2 O concentration is 0.5%, under different interference atmosphere (NO, O 2 , H 2 O), different temperatures N 2 O's decomposition activity. The results show that in NO, O 2 , H 2 When O exists alone and together, N 2 The 50% conversion temperatures of O are 395, 390, 400 and 395°C, respectively.

[0022] The catalyst was the CoIn-MOR catalyst in Example 1, and the evaluation was performed on the device in Example 1. The amount of catalyst is 0.1g, and the space velocity is 30,000h -1 , Adjust various gas flow and balance gas He gas flow to make the initial concentration N 2 O is 0.5%, O 2 Is 5%, NO is 0.1%, H 2 O is 2%. Program temperature rise from 200-600℃, investigate N 2 O conversion rate. The results show that in NO, O 2 , H 2 When O exists alone and together, N 2 The 50% conversion temperatures of O are 395, 390, 400 and 395°C, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com