Adipic acid production device tail gas treatment device and method

A production device and tail gas treatment technology, which is applied in the field of tail gas treatment devices of adipic acid production devices, can solve problems such as large amount of nitric acid, and achieve the effects of environmental friendliness, reduction of production costs, and maximization of economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

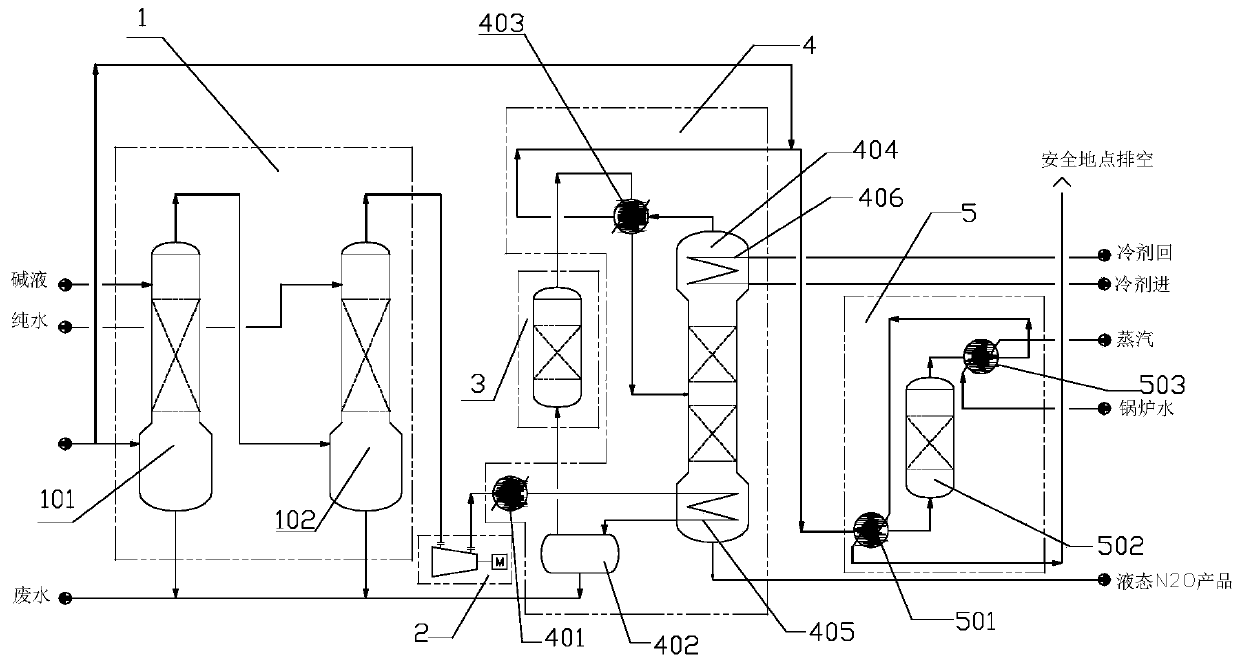

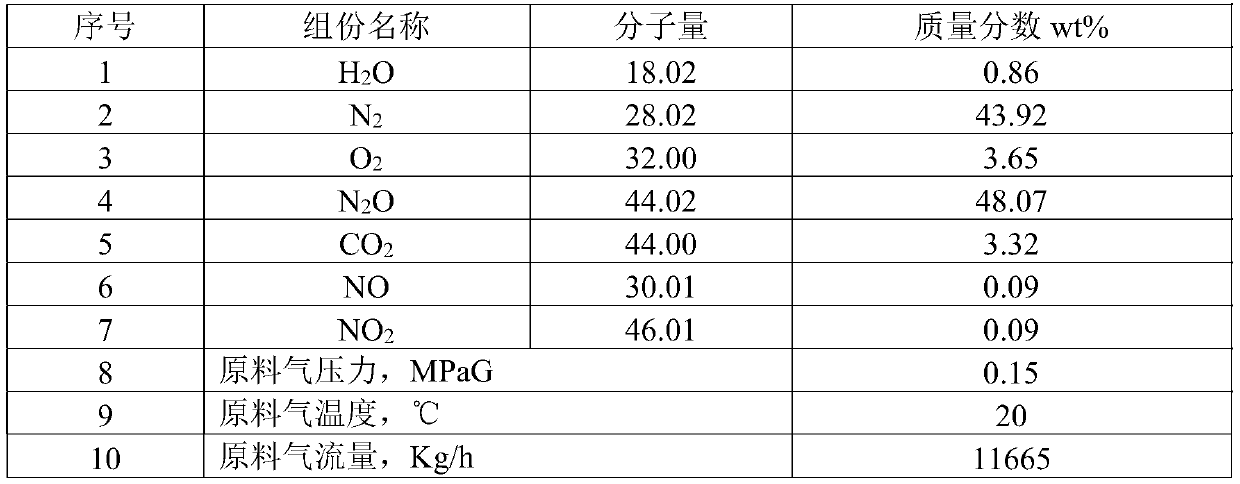

[0068] The tail gas composition of an adipic acid plant is shown in the following table:

[0069]

[0070] The 583kg / h raw material tail gas of the above components is washed by a 20% lye circulating alkali, and then washed twice by a water washing tower to prevent the lye from entering the pretreated raw material gas.

[0071] The pretreated raw gas enters the separator, after metering, component detection and pressure adjustment, it enters the raw gas compressor (the set pressure of the tail gas pressurization system is 0.7MPaG), and enters the dehydration process (dehydration until the water content is lower than 0.4 ppm).

[0072] Cryogenic rectification adopts single-column rectification process to extract N 2 O. The top of the tower adopts partial condensation, and the gas phase is throttled to 0.2MPaG, and then the gas phase discharge is discharged to the waste gas treatment system. The raw material gas (10°C) after dehydration and purification is exchanged with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com