Patents

Literature

130results about How to "Improve anti-sulfur poisoning performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and preparation thereof

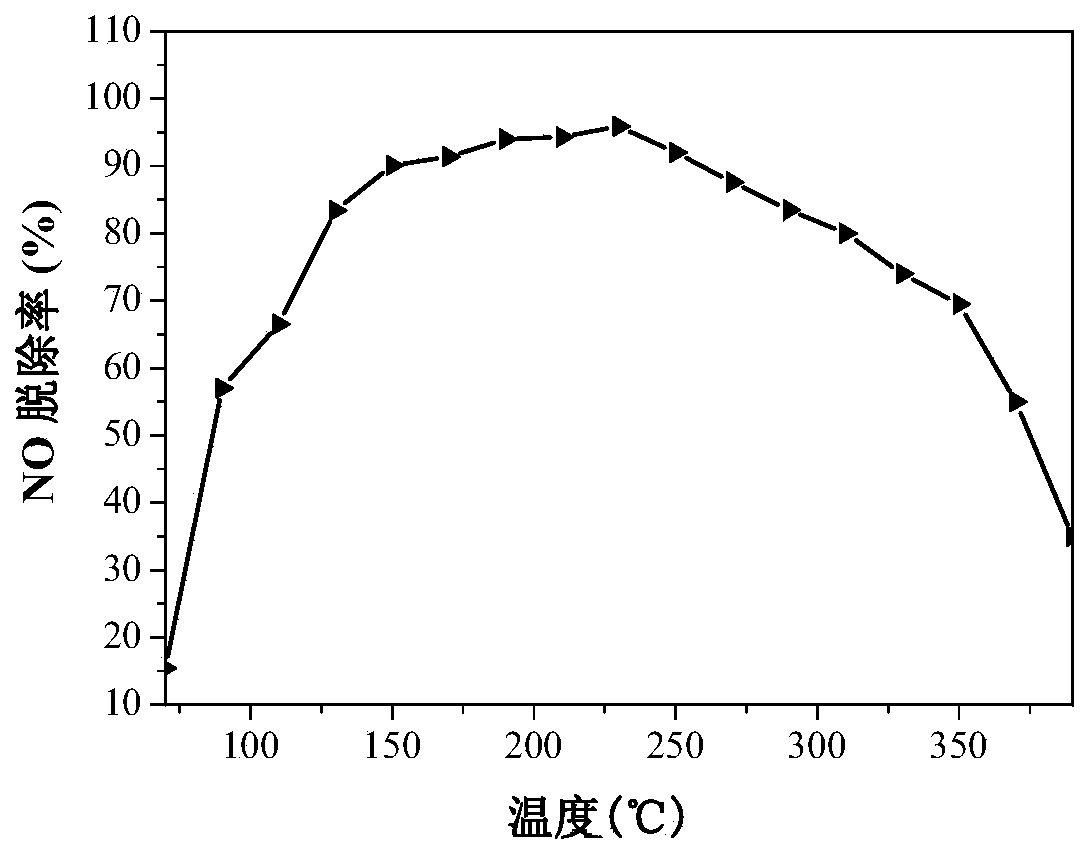

ActiveCN102240543AImprove anti-sulfur poisoning performanceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurWorking temperature

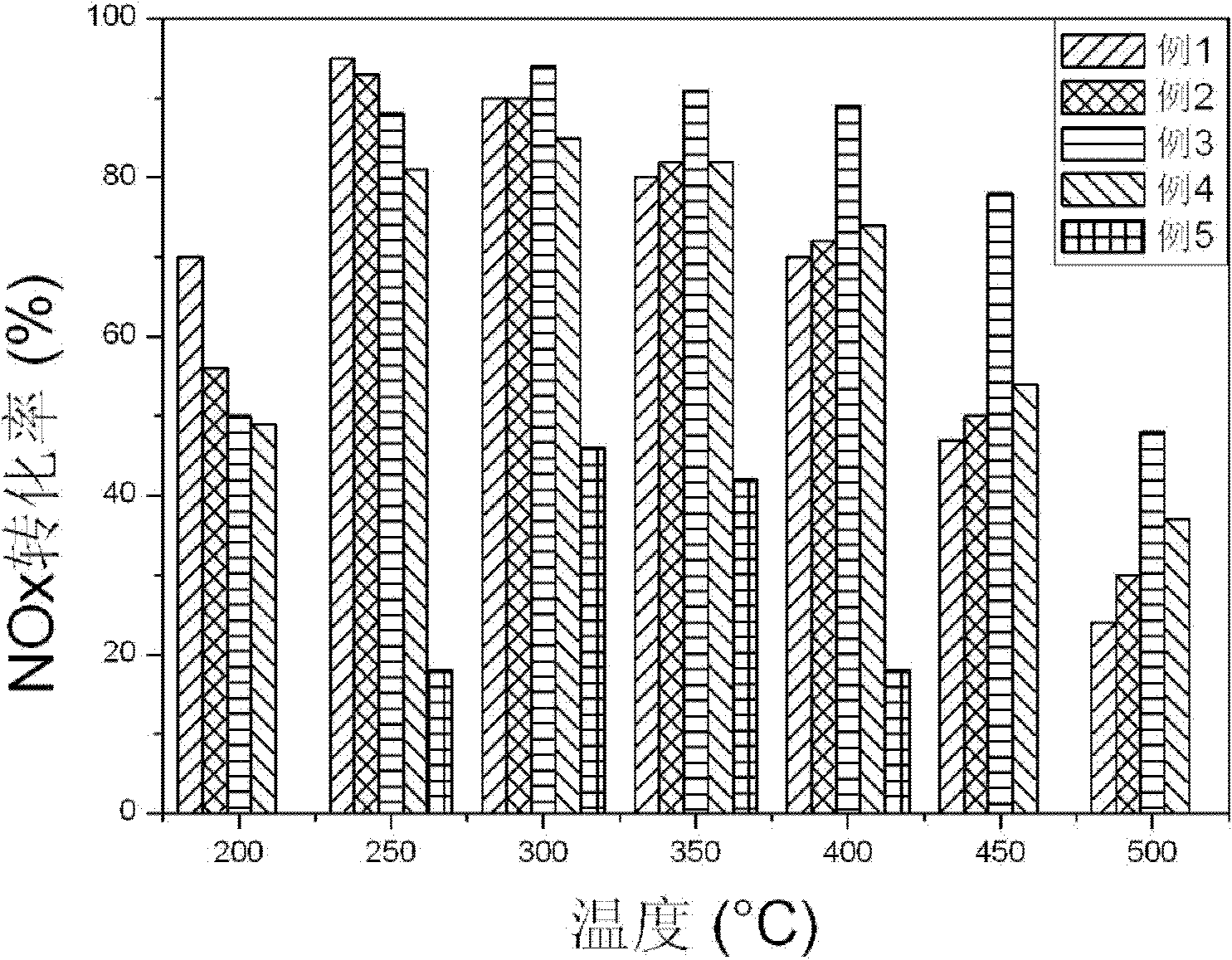

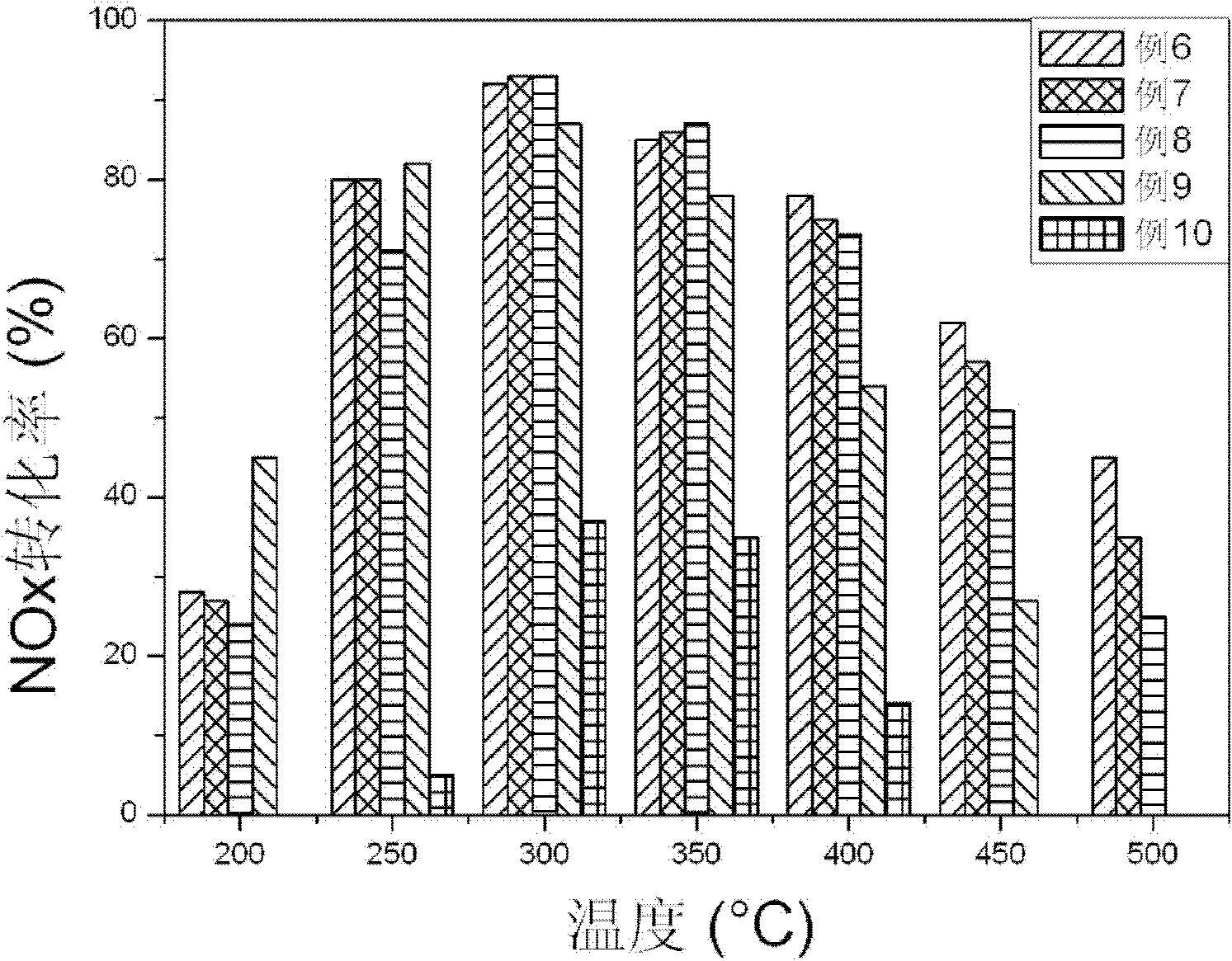

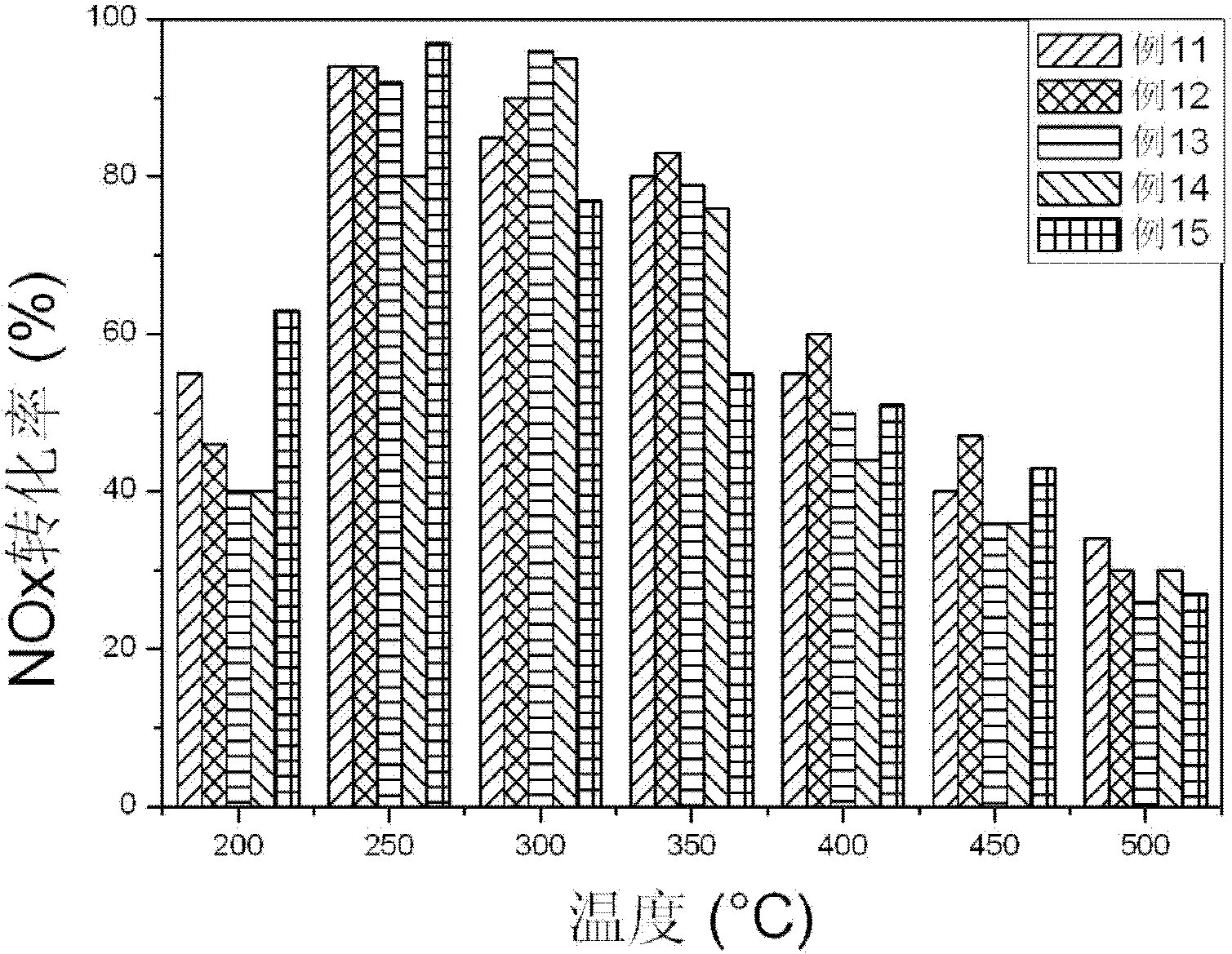

The invention discloses a CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and a preparation thereof and belongs to the field of nitric oxide post-processing purification. The catalyst has a three-layer structure, wherein cordierite honeycomb ceramic is used as a carrier; an active coating is loaded on the carrier; a modifying coating is loaded on the active coating; the cordierite carrier has a skeleton carrying function; the active coating of the catalyst mainly has a function of activating NOx and NH3; and the modifying coating mainly has functions of storing NH3, avoiding deep oxidation of NH3 on the surface of the catalyst when the catalyst is used at a high temperature and increasing the sulfur poisoning resistance of the catalyst. The preparation process of the catalyst is simple and can be easily industrialized. A working temperature window of the optimized catalyst can reach 250-450 DEG C, and denitration efficiency is above 80%. The catalyst has the significant advantage of being nontoxic and has excellent heat stability and excellent SO2 poisoning resisting property.

Owner:TSINGHUA UNIV +1

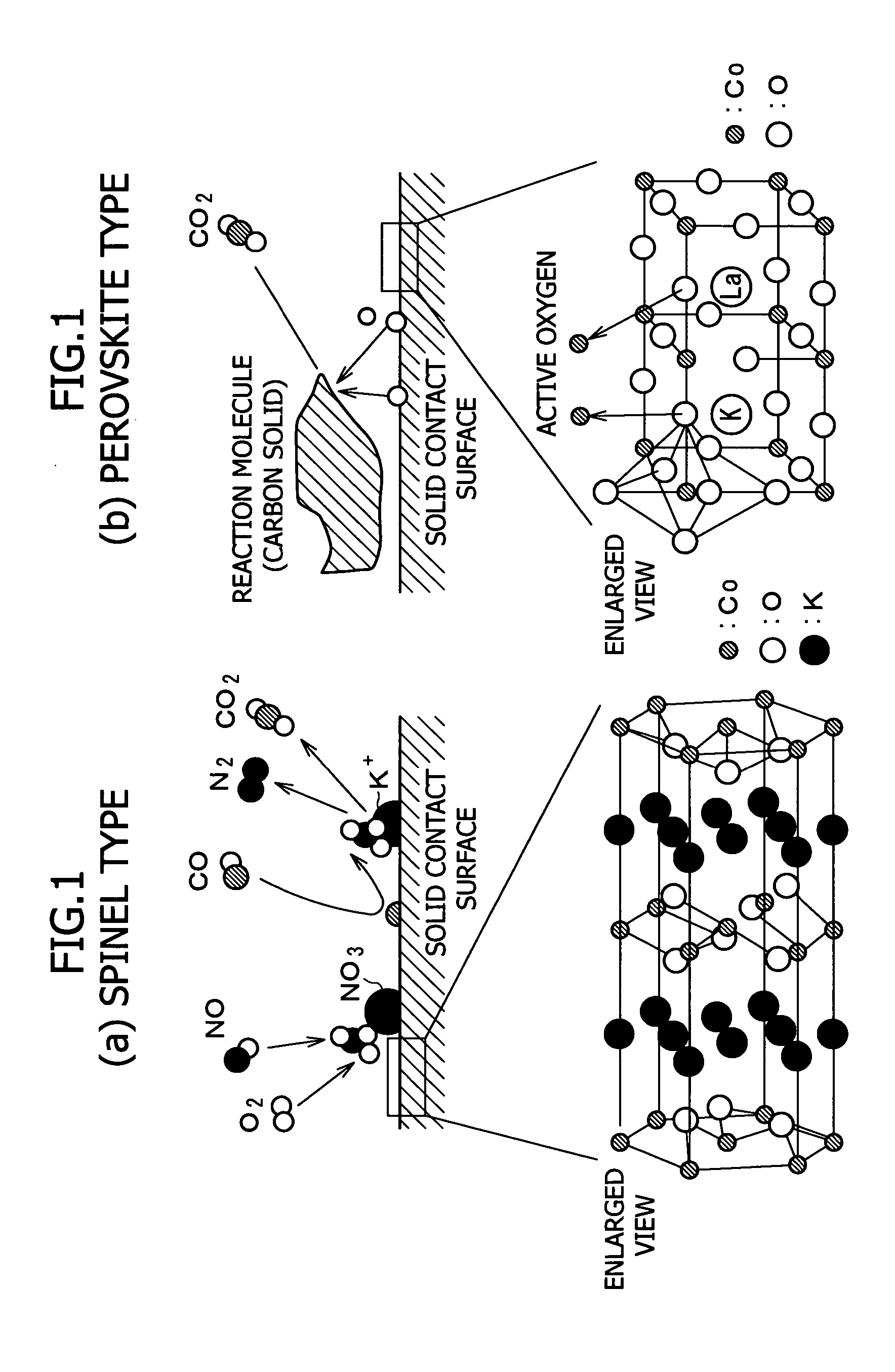

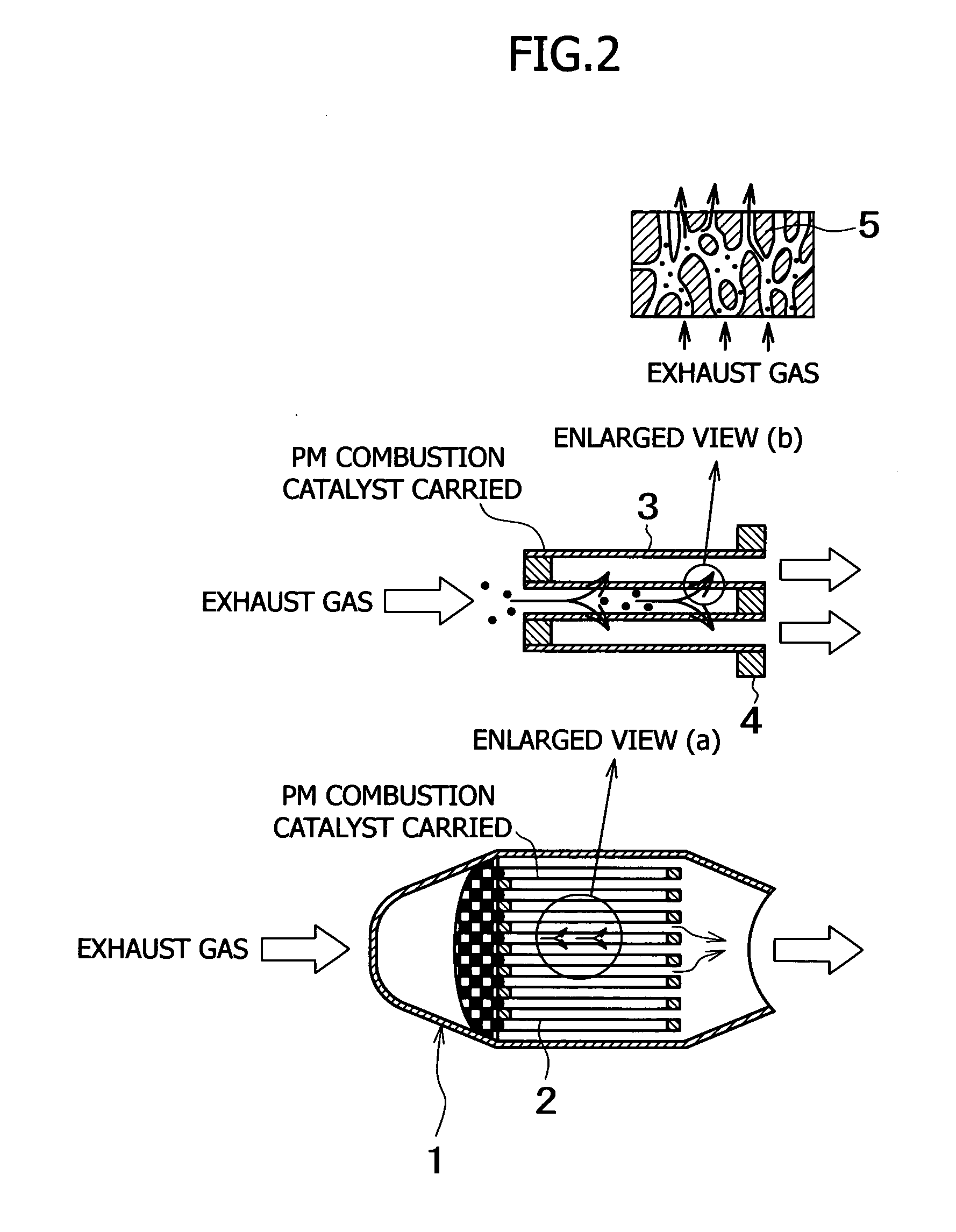

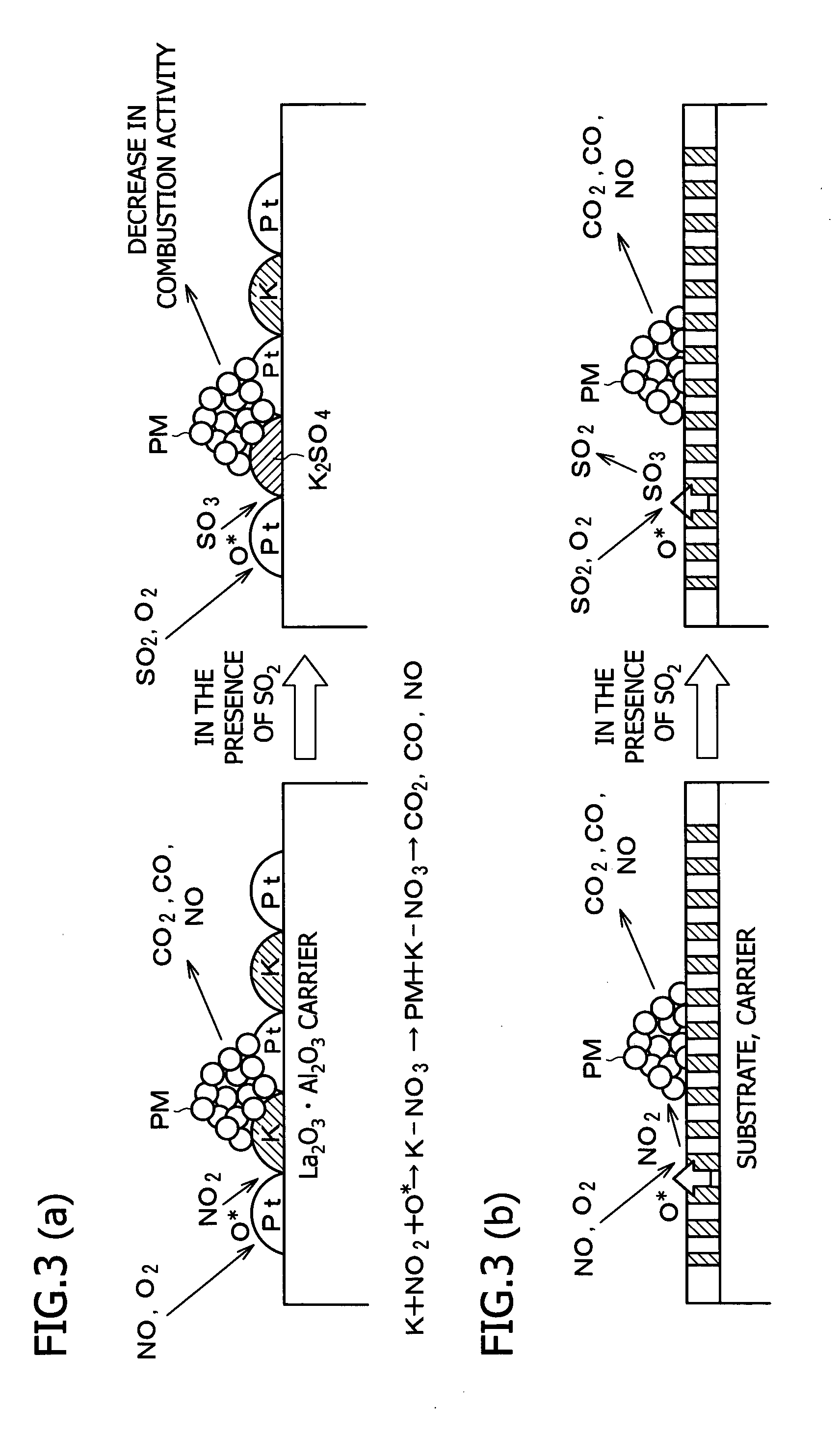

Exhaust gas treatment catalyst and exhaust gas treatment method

ActiveUS20050049143A1Efficient removalImprove anti-sulfur poisoning performanceFluid couplingsExhaust apparatusParticulatesAlkaline earth metal

The present invention provides an exhaust gas treatment catalyst characterized by containing a compound oxide expressed by the following general formula (1),AMxOy (1)(wherein A represents an alkali metal or alkaline earth metal, M represents Cr, Mn, Fe, Co or Ni, O represents oxygen, and 0<x≦4 and 0<y≦8) and an exhaust gas treatment method using the said catalyst. According to the present invention, there can be provided an exhaust gas treatment compound oxide that can effectively remove particulates and NOx contained in exhaust gas with a high oxygen concentration that is discharged from a diesel engine etc., and also has excellent resistance to sulfur poisoning.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

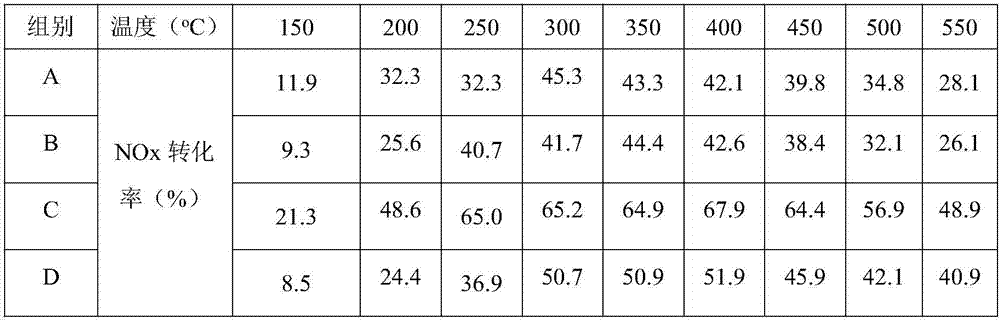

Low-temperature flat plate type denitration catalyst and preparation method thereof

ActiveCN106268784AEasy to removeImprove wear resistanceHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsMass ratioCerium

The invention discloses a low-temperature flat plate type denitration catalyst and a preparation method thereof. According to the catalyst, tin-samarium-manganese compound oxide serves as the catalyst active component, one or more of vanadium, cerium, lanthanum, nickel, zirconium, copper, molybdenum and tungsten serve as the promoters, TiO2 and SiO2 serve as the carriers, glass fiber, binder, lubricant and pore forming material are added as functional auxiliaries, and the uniform catalyst is prepared and smeared and spread on a supporting body; the mass ratio of the carriers to the active component to the promoters to the functional auxiliaries in catalyst paste is 100:(1-18):(0.1-10):(0.1-15). The prepared catalyst has an excellent NOX removal effect in smoke at 70-280 DEG C, has good wear resistance, and is simple in preparation process and low in cost. The catalyst is suitable for low-temperature denitration of coal-fired power plants, garbage incinerators, ceramic kilns, cement kilns and the like and has quite good application prospects.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

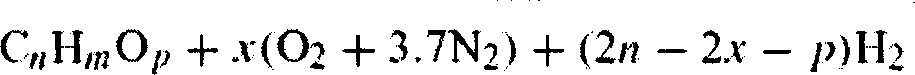

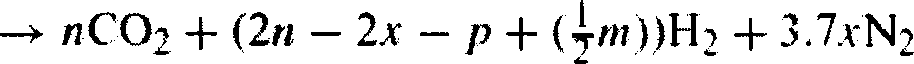

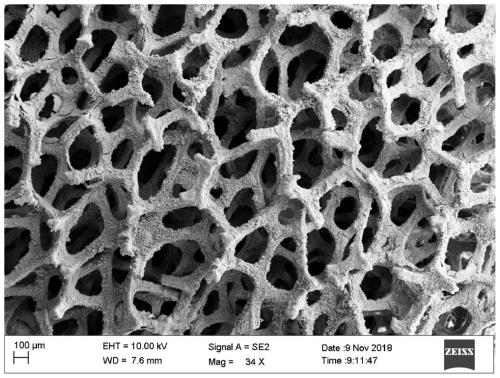

Hydrocarbon-decomposing porous catalyst body and process for producing the same, process for producing hydrogen-containing mixed reformed gas from hydrocarbons, and fuel cell system

ActiveUS20110038775A1Increase contact areaHigh catalytic activityMaterial nanotechnologyHydrogenDecompositionComposite oxide

The present invention aims at providing a catalyst as a porous catalyst body for decomposing hydrocarbons which comprises at least magnesium, aluminum and nickel, wherein the catalyst has an excellent catalytic activity for decomposition and removal of hydrocarbons, an excellent anti-sulfur poisoning property, an excellent anti-coking property even under a low-steam condition, a sufficient strength capable of withstanding crushing and breakage even when coking occurs within the catalyst, and an excellent durability. The above aim of the present invention can be achieved by a porous catalyst body for decomposing hydrocarbons which comprises at least magnesium, aluminum and nickel in such a manner that the magnesium and aluminum are present in the form of a composite oxide of magnesium and aluminum, and the nickel is present in the form of metallic nickel; and which porous catalyst body has a magnesium element content of 10 to 50% by weight, an aluminum element content of 5 to 35% by weight and a nickel element content of 0.1 to 30% by weight, a pore volume of 0.01 to 0.5 cm3 / g, an average pore diameter of not more than 300 Å and an average crushing strength of not less than 3 kgf.

Owner:TODA IND

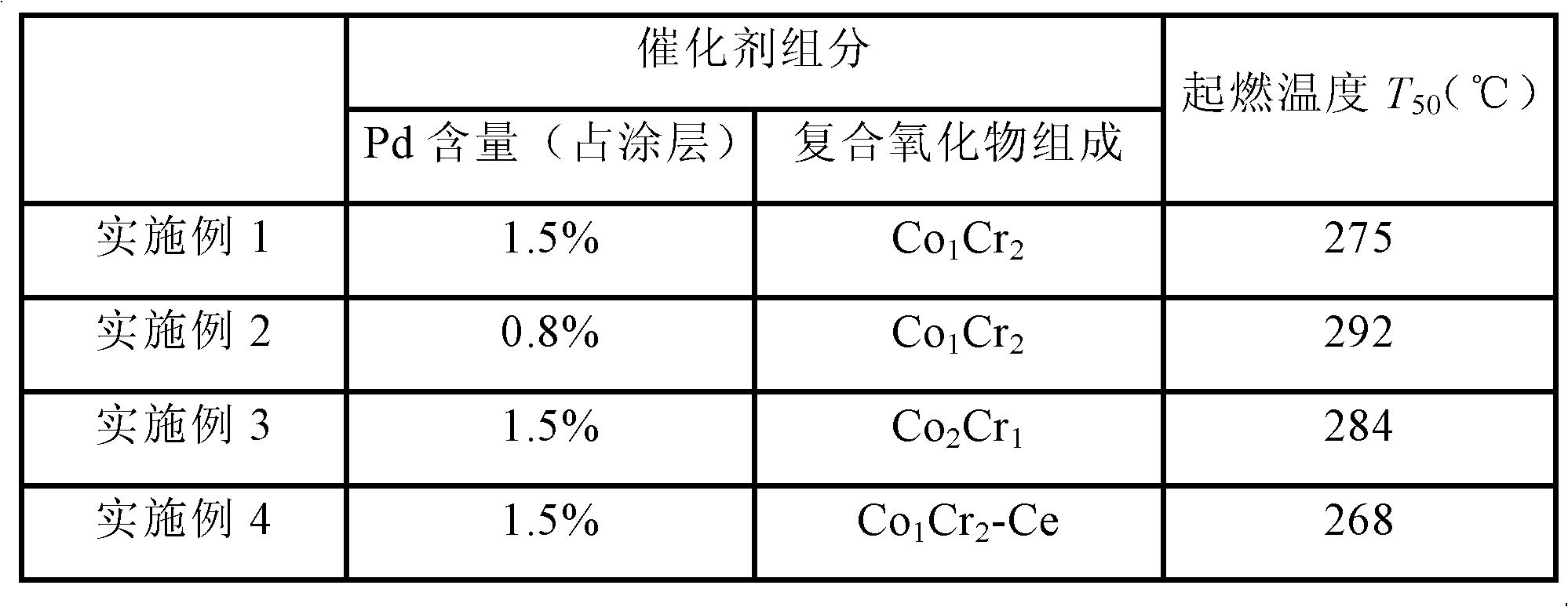

Monolithic catalyst for low temperature oxidation of methane and preparation thereof

ActiveCN102626640AAbundant raw materialsLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChromium CompoundsCerium

A monolithic catalyst for low temperature oxidation of methane comprises cordierite honeycomb ceramic carrier and a coating thereon. The coating has an expression of Pd / CoxCry-M / Al2O3, wherein Pd is noble metal palladium; CoxCry is cobalt chromium compound oxide, and a molar ratio of cobalt to chromium is between 0.001-100; M represents one or more doped metal selected from cerium, zirconium, iron, lanthanum, nickel and manganese, and a dopping amount (molar ratio) of M to (Co+Cr+M) is less than 0.10; and Al2O3 is gamma-Al2O3 with high thermal stability. The preparation method includes the following steps: step one, preparing the composite metal oxide CoxCry-M; step two, preparing the coating slurry; step three, dipping; step four, drying and calcining to obtain the monolithic catalyst. The catalyst of the invention can be used in methane purification of natural gas and vehicle tail gas and has good methane oxidation activity and thermal stability.

Owner:TSINGHUA UNIV

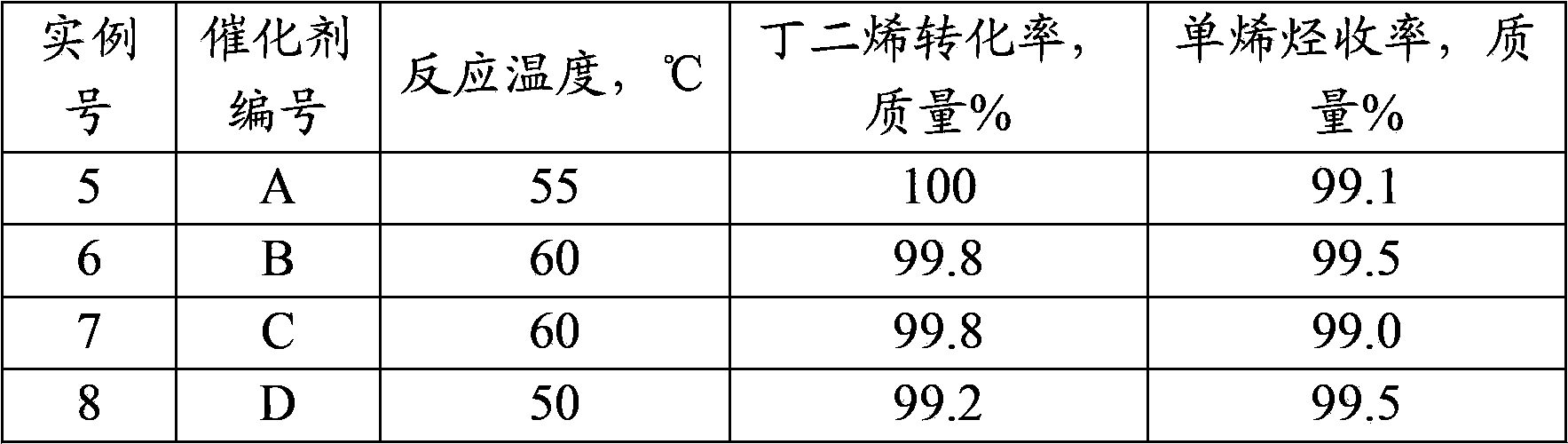

Catalyst for removing alkadiene in C4 and preparation method thereof

ActiveCN103418379AGood choiceHigh monoolefin yieldHydrocarbon purification/separationHydrocarbonsAlkadieneActive component

A catalyst for removing alkadiene in mixed C4. The catalyst comprises a composite carrier and the following active components, calculated by using the composite carrier as a basis: 0.05-1.0 wt% of Pd and 0.1-5.0 wt% of WO3; and the composite carrier comprises 90-99 wt% of alumina and 1-10 wt% of oxygen calcium. The catalyst is used for removing alkadiene in mixed C4 through selective hydrogenation, and has high activity, selectivity and resistance to sulfur poisoning, and excellent service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Light hydrocarbon distillate selective dediene catalyst and method for preparing the same

InactiveCN1485411AReduce carbon depositionExtended service lifeRefining by selective hydrogenationActive componentSolid solution

A catalyst for selectively hydrogenating and dediolefinating for light hydrocarbon fractions, comprises 0.05í½1.0 wgtúÑ Pd as the active component and the carrier of magnesium aluminum oxide solid solution. In the magnesium aluminum oxide, the mol ration of Mg / Al is 1.0í½12.0. the catalyst also contains auxiliary agents selecting from Co, Mo, Ni and Wu. The catalyst is suitable for selectively hydrogenating and dediolefinating for light C4-C6 hydrocarbon fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

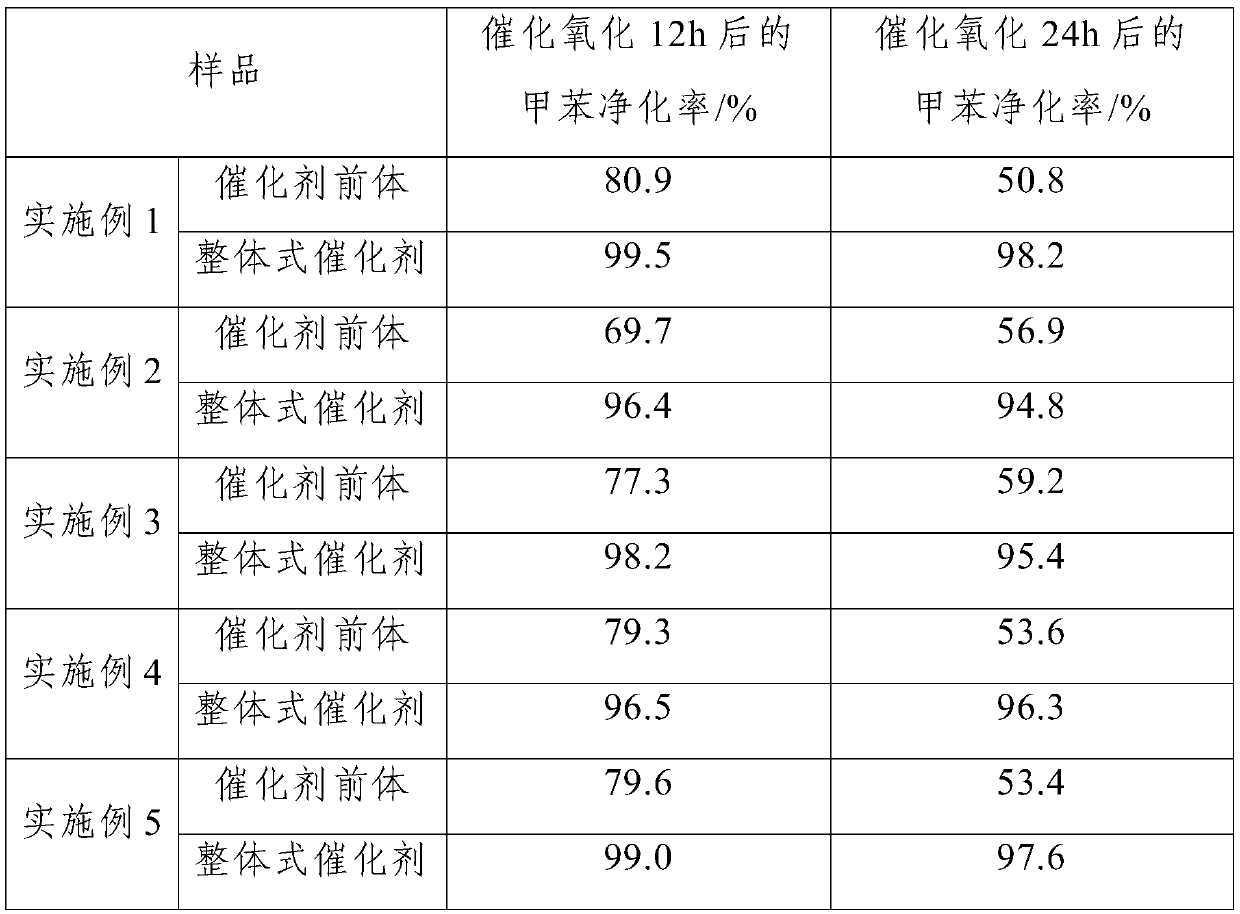

Catalyst for catalytic combustion of VOCs as well as preparation method and application thereof

ActiveCN110479317AGood oxygen mobilityImprove redox abilityPhysical/chemical process catalystsIncinerator apparatusCatalytic oxidationOxygen

The invention provides a catalyst for catalytic combustion of VOCs and a preparation method and application thereof, and belongs to the field of catalyst preparation. The invention particularly provides a core-shell type catalyst which is formed by covering, with a SiO2 shell, a catalyst taking a sulfuric acid modified TiO2-CeO2 composite oxide as a carrier and loaded with noble metal ruthenium oxide and / or transition metal vanadium oxide as active components. The CeO2 has good oxygen mobility and can significantly enhance the oxidation-reduction performance of the catalyst, so that the catalyst has efficient VOC catalytic oxidation activity; the carrier is soaked in sulfuric acid; the surface acidity is enhanced to inhibit adsorption of acidic impurity components such as SO2, HCl and H2S,the active components RuO2 and V2O5 also have sulfur resistance, so that the sulfur poisoning resistance of the catalyst is remarkably improved, the silicon shell can inhibit contact between chlorideand the active components, and inactivation of the active components of the catalyst due to chlorine poisoning is avoided; or honeycomb ceramic can be used as a matrix to prepare a coated type catalyst.

Owner:KUNMING UNIV OF SCI & TECH

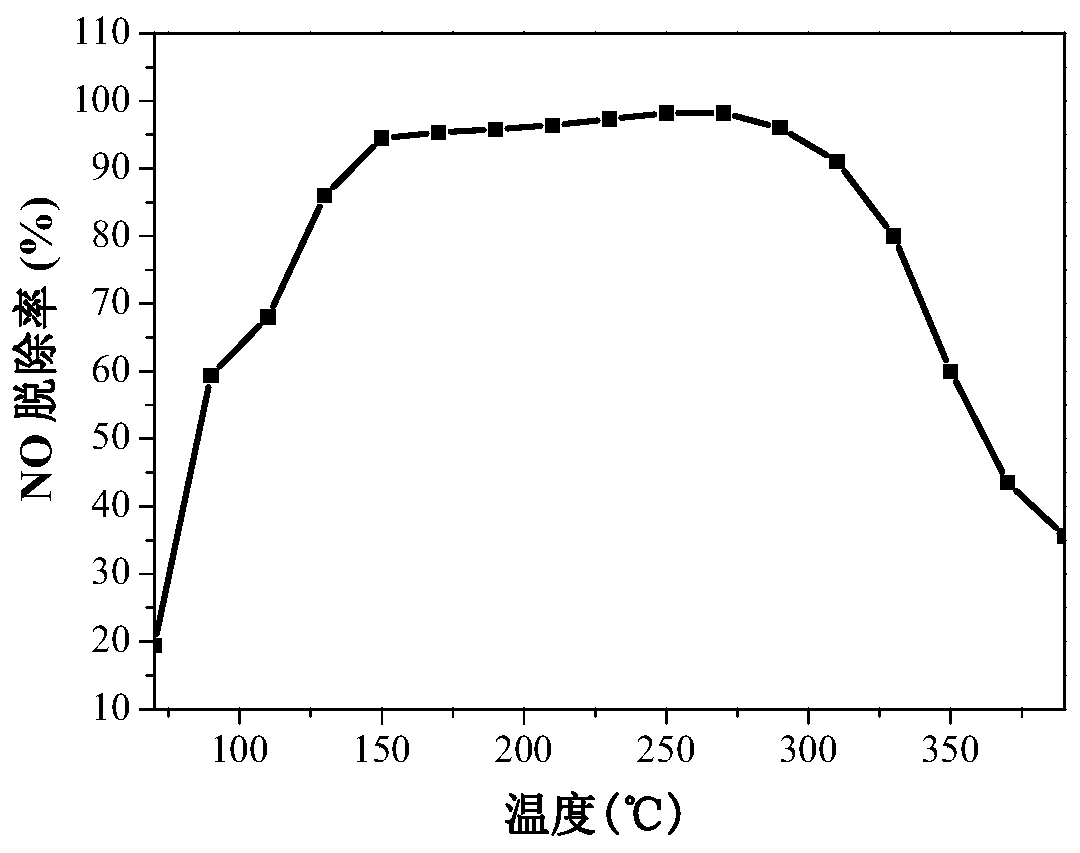

Plate type denitration catalyst and preparation method thereof

InactiveCN107224979AWide active temperature rangeLow costGas treatmentDispersed particle separationSulfurActive component

The invention relates to a plate type denitration catalyst and a preparation method of the catalyst and belongs to the field of environment-friendly catalysis material and air pollution control. A cerium-antimony-molybdenum composite oxide serves as a catalytic active component; a tungsten, cobalt or lanthanum oxide serves as a promoter; a titanium dioxide and argil mixing component serves as a major carrier; mass percentages of the cerium-antimony-molybdenum composite oxide and the promoter oxide are 8-20% and 1-3% respectively by taking the mass of the titanium dioxide and argil mixing component carrier as a reference. The denitration activity of the catalyst reaches 98.5% or above, and the catalyst has excellent sulfur poisoning resistance.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

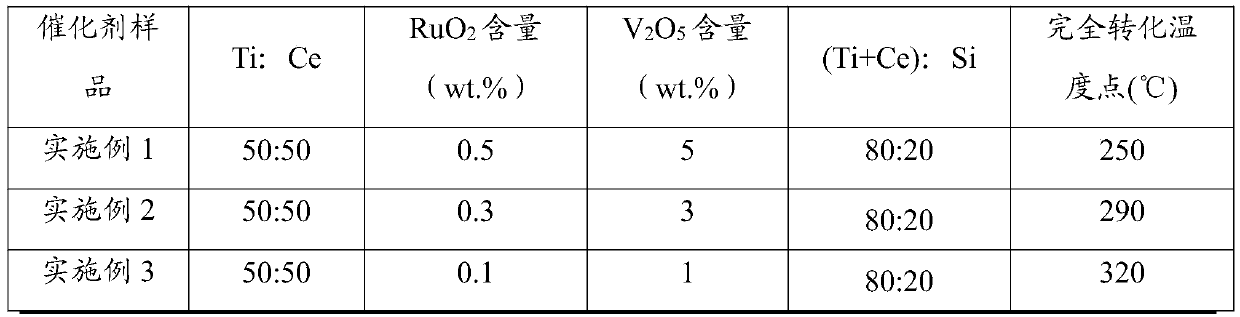

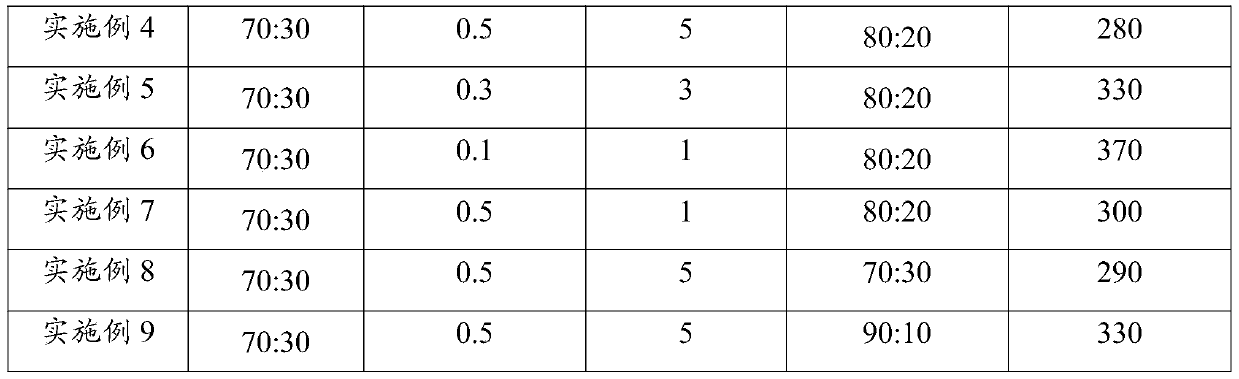

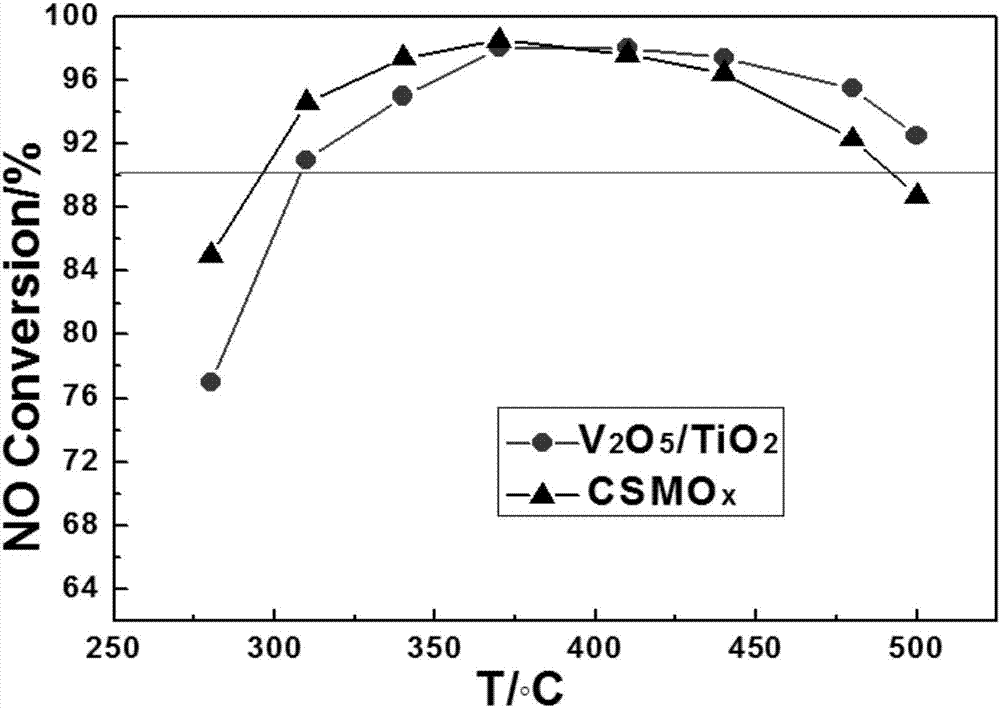

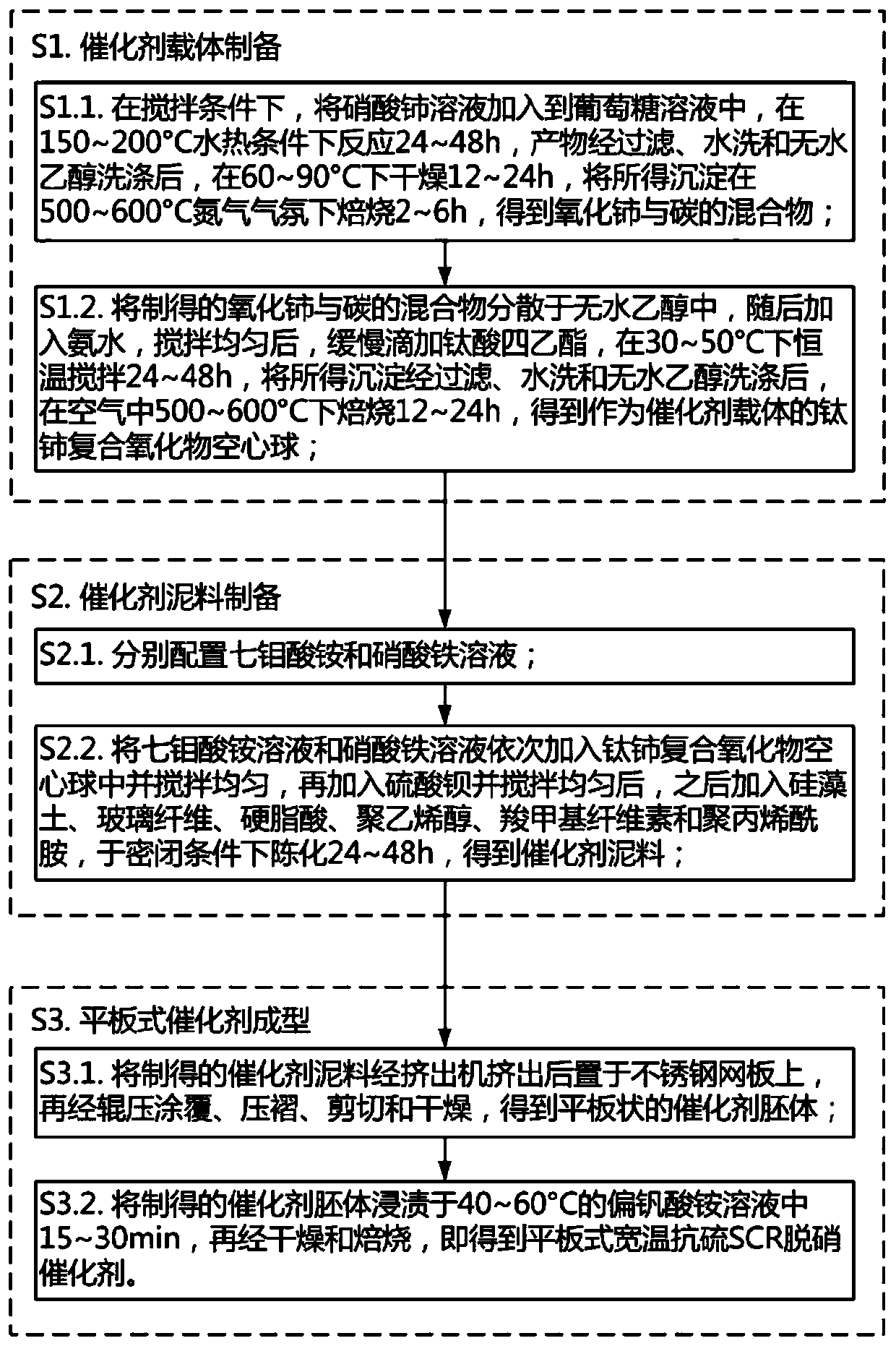

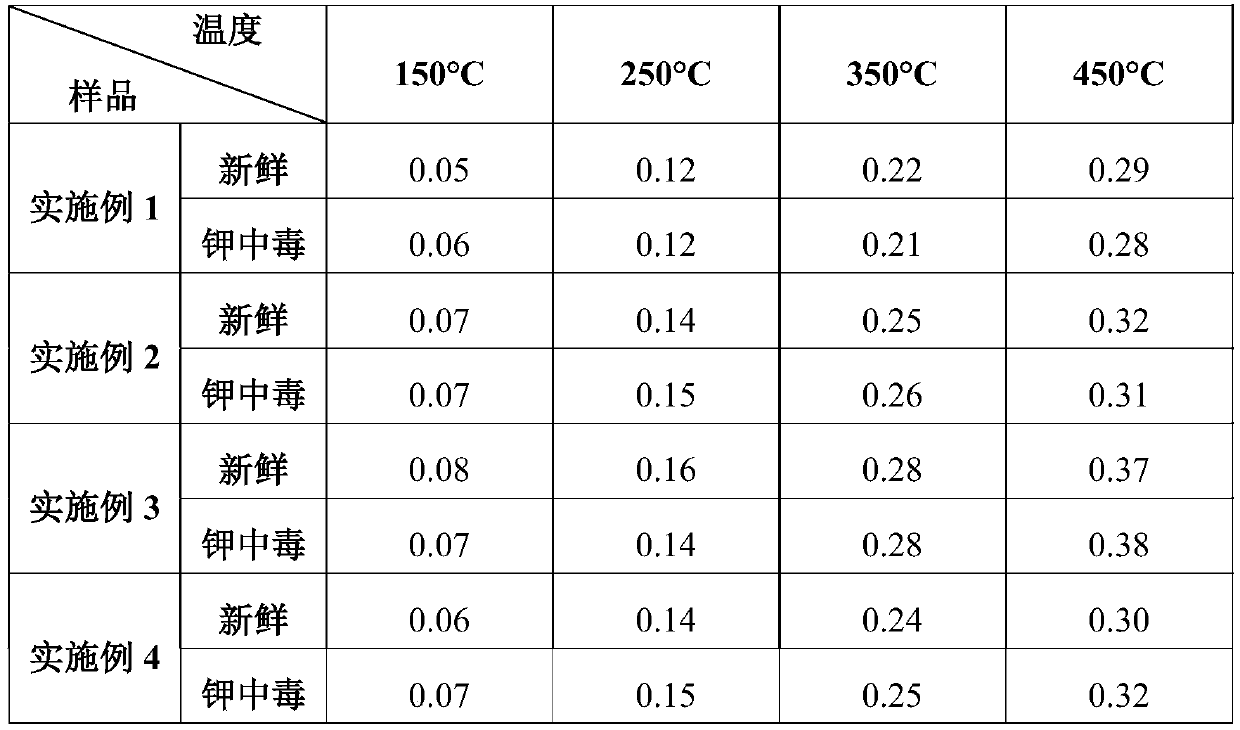

Flat-plate wide-temperature sulfur-resistant selective catalytic reduction (SCR) denitration catalyst and preparation method thereof

ActiveCN110801848AHigh activityImprove anti-sulfur poisoning performanceCatalyst carriersGas treatmentPtru catalystMolybdenum trioxide

The invention belongs to the field of environmental protection technology and denitration catalysis, and particularly relates to a flat-plate wide-temperature sulfur-resistant selective catalytic reduction (SCR) denitration catalyst and a preparation method thereof. A carrier of the catalyst provided by the invention is a titanium-cerium composite oxide hollow sphere, an active component of the catalyst is vanadium pentoxide, and catalytic auxiliary agents are ferric oxide, molybdenum trioxide and barium sulfate. A two-step rolling molding process is adopted, wherein the catalytic auxiliary agents are loaded on the surface of the titanium-cerium composite oxide hollow sphere by adopting an incipient-wetness impregnation method; then the catalyst active component vanadium pentoxide is loaded on the surface of the carrier; and the catalyst is molded into a flat plate shape through a rolling molding process, so that the flat-plate SCR denitration catalyst with a wide temperature and sulfur poisoning resistance is prepared. The catalyst has good catalytic activity and sulfur poisoning resistance in a range of 150-450 DEG C, can solve the problems of low activity and sulfur poisoning ofa catalyst in low-temperature flue gas and high SO2 oxidation rate in medium-temperature flue gas, and is suitable for denitration of wide-temperature sulfur-containing flue gas.

Owner:北京华电光大环境股份有限公司

Flat-plate type sulfur-resistant low-temperature SCR denitration catalyst and preparation method thereof

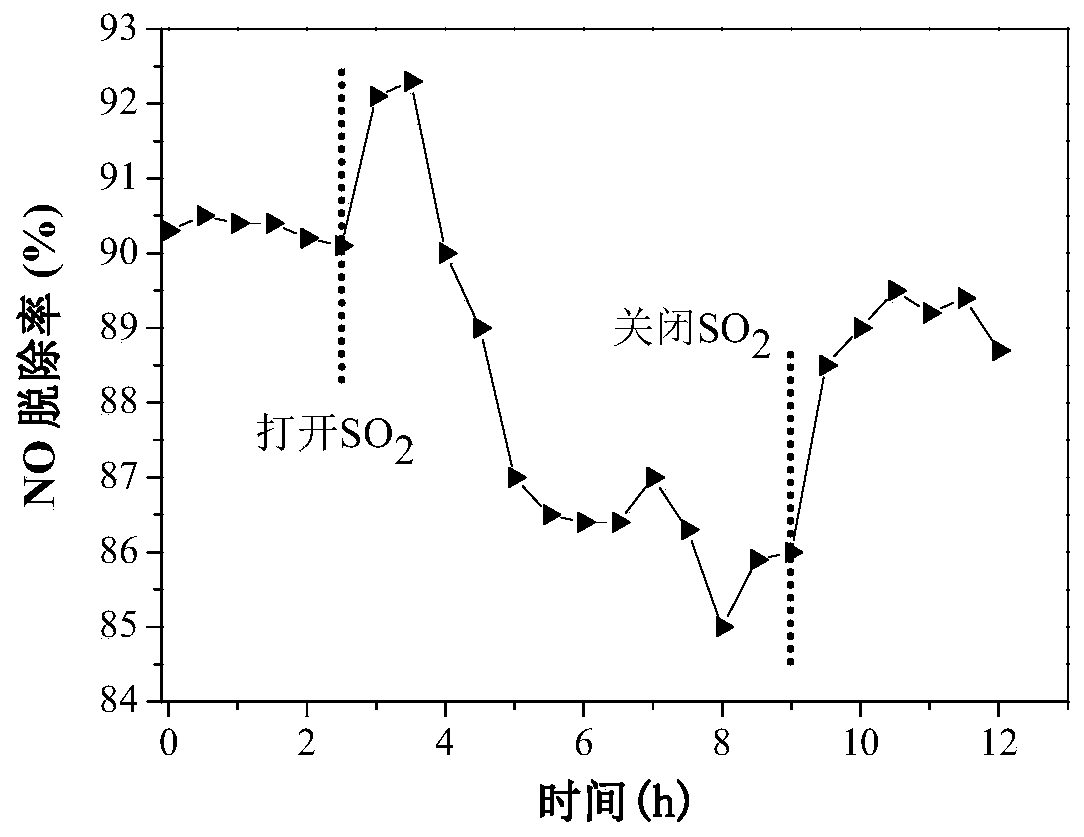

ActiveCN105289644AStrong mechanical propertiesExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurActive component

The invention specifically relates to a flat-plate type sulfur-resistant low-temperature SCR denitration catalyst and a preparation method thereof, belonging to the fields of environmental protection and environmental catalysis. The method comprises the following steps: with nanometer composite oxide Ce-ZrO2 as a carrier, manganese oxide as an active component and iron oxide and molybdenum oxide as cocatalysts, carrying out equivalent-volume impregnation, drying, roasting and crushing so as to prepare a powdery catalyst; and subjecting the prepared powdery catalyst to acidification by sulfuric acid and then carrying out mixing, rolling coating, fold pressing, shearing, drying and roasting so as to obtain the flat-plate type sulfur-resistant low-temperature SCR denitration catalyst. The prepared catalyst has denitration activity of 85 to 98% in a temperature range of 80 to 150 DEG C and has excellent resistance to sulfur dioxide poisoning.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

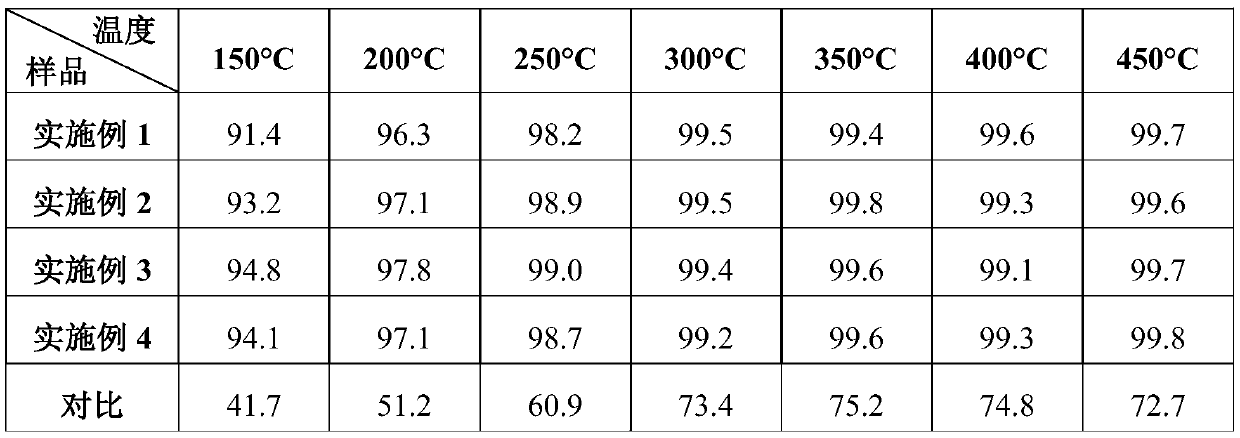

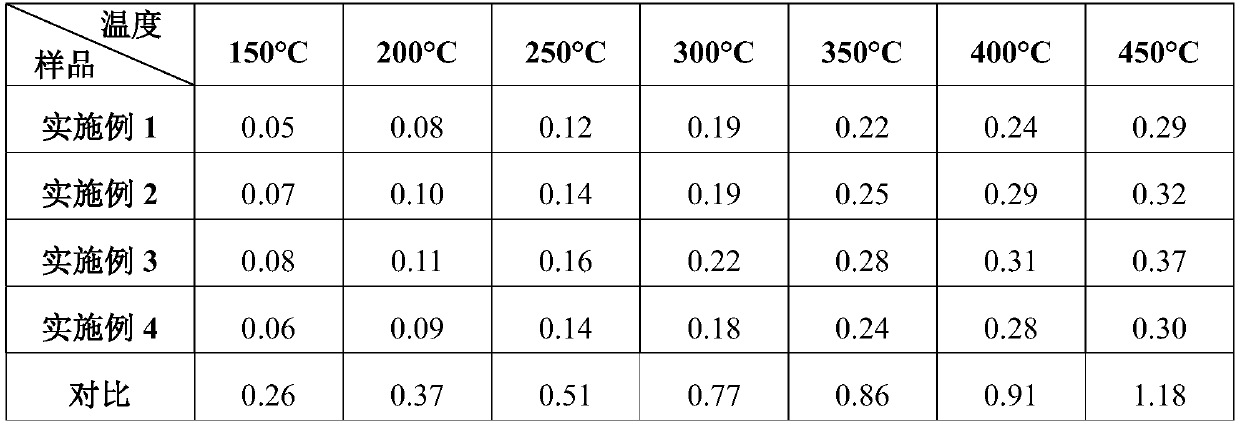

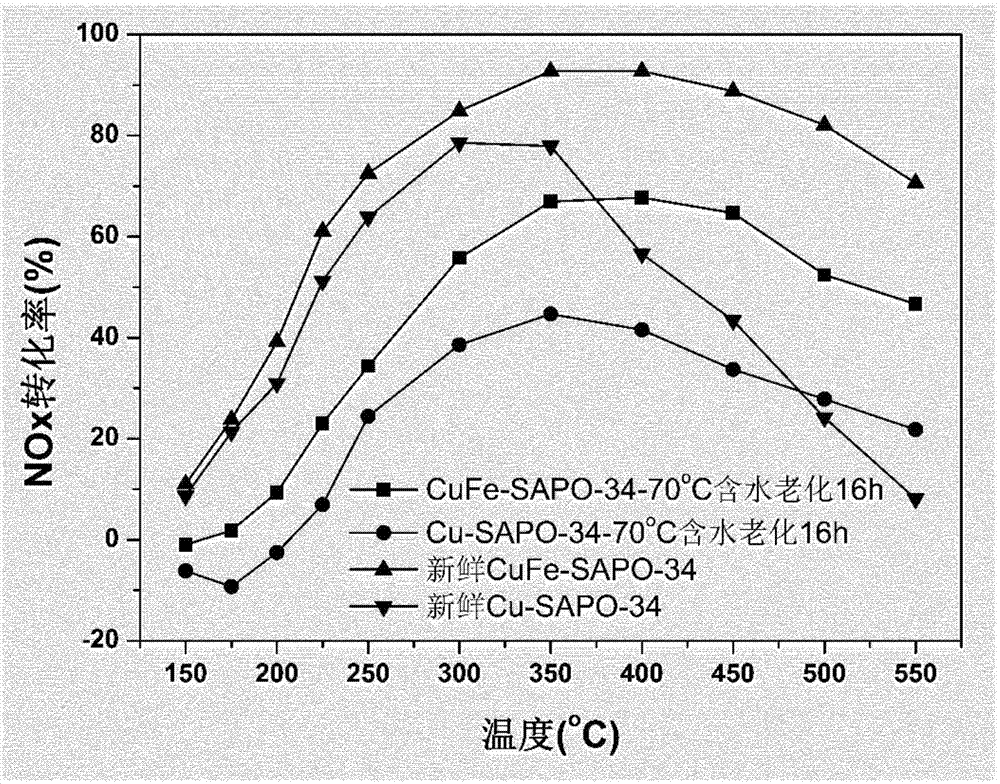

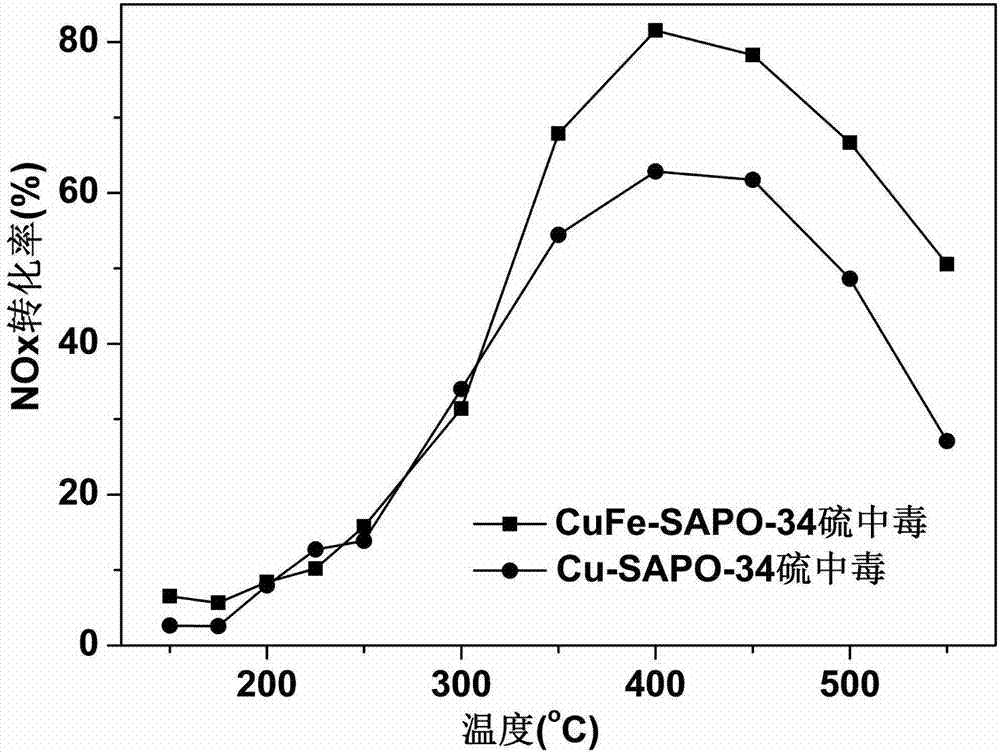

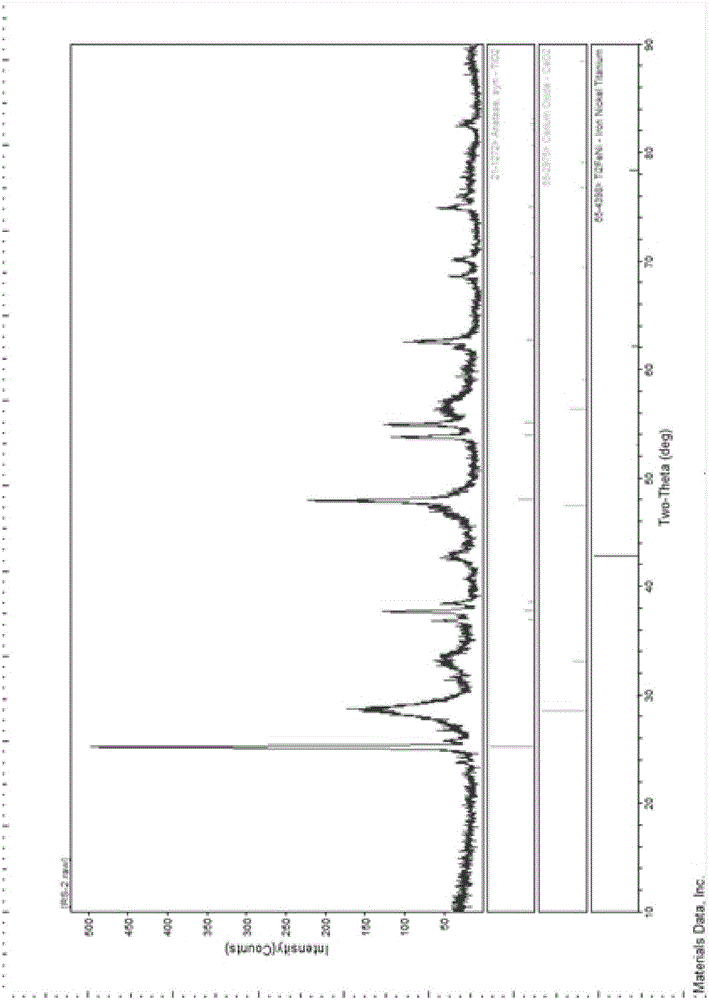

In-situ synthesis method and applications of CuFe-SAPO-34 catalyst

InactiveCN107126973ASave resourcesWide temperature windowGas treatmentMolecular sieve catalystsIonMolecular sieve

The invention discloses an in-situ synthesis method and applications of a CuFe-SAPO-34 catalyst, and belongs to the technical field of catalysis. The method comprises the following steps: adding pseudo-boehmite into deionized water, stirring to dissolve pseudo-boehmite, then adding ortho-phosphoric acid and fumed silica, evenly mixing, then adding copper salts and tetraethylene pentamine, fully stirring, then adding Fe salts and n-propylamine; adding fully stirred gel into a hydrothermal reactor to carry out crystallization, after crystallization reactions, cooling to the room temperature, separating solid crystals from the mother liquor, washing the solid crystals by deionized water until the solid crystals become neutral, drying, and finally burning the solid crystals in the air to obtain the CuFe-SAPO-34 microporous molecular sieve catalyst. The CuFe-SAPO-34 catalyst is synthesized in one step; the loading amount of Fe is optimized; and the catalytic performance and low temperature water resisting performance of the CuFe-SAPO-34 catalyst are prominently improved.

Owner:JIANGNAN UNIV

Wide-temperature denitration catalyst and preparation method thereof

ActiveCN108620058AImprove bindingImprove wear resistanceGas treatmentDispersed particle separationReaction temperatureBULK ACTIVE INGREDIENT

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

SCR denitration catalyst for resisting alkali metal poisoning and preparation method thereof

InactiveCN108160087AUnique lumen structureAvoid inactivationPhysical/chemical process catalystsDispersed particle separationBULK ACTIVE INGREDIENTAntimony trioxide

The invention belongs to the field of environmental protection technology and denitration catalysis, and particularly relates to an SCR denitration catalyst for resisting alkali metal poisoning and apreparation method thereof. The catalyst carrier provided by the invention is a titanium nano-tube, the active ingredient is vanadium pentoxide, and the catalytic assistants are tungsten trioxide, antimony trioxide and copper sulfate. A flat-plate type or honeycomb type SCR denitration catalyst with alkali metal poisoning resistance is prepared by adopting a rolling coating or extrusion molding process. The catalyst provided by the invention has the advantages of simple production process, easy implementation of industrial production, and very good alkali metal poisoning resistance and mechanical performance, can solve the problem of alkali metal poisoning of the denitration catalyst, and is suitable for flue gas with high alkali metal content.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst and preparation method thereof

ActiveCN110354843ALarge specific surface areaImprove denitrification activityGas treatmentHeterogenous catalyst chemical elementsChromium trioxideSilicon dioxide

The embodiment provides a thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst. A catalyst carrier is a titanium dioxide-coated silicon dioxide composite nanotube, an active component is vanadium pentoxide, and a catalytic assistant is molybdenum trioxide and chromium trioxide. The thin-wall honeycomb SCR denitration catalyst with low-temperature sulfur resistance performance is prepared by adopting an extrusion molding process. The catalyst has good low-temperature activity and sulfur poisoning resistance, can solve the problems of low activity and sulfur poisoning of the catalyst in low-temperature flue gas, and is suitable for low-temperature sulfur-containing flue gas; by adding various inorganic and organic forming additives and optimizing the drying androasting processes, the wall thickness of the catalyst is reduced on the basis of maintaining the mechanical strength of the catalyst, the sulfur poisoning resistance of the catalyst is improved, theproduction cost is reduced, and the thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst has good economic benefits. The embodiment also provides a preparation method ofthe thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Low-temperature anti-sulfur denitration catalyst by taking organic porous material as carrier and preparation method thereof

InactiveCN107029800AGood activity at low temperatureSolve easy poisoningGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsFlue gasReactive site

The invention provides a low-temperature anti-sulfur SCR denitration catalyst by taking an organic porous material as a carrier and a preparation method thereof. The method is characterized in that an immersion method is employed, one or more than two of metal element oxides of Mn, Fe, Cu, Co, Ce, and Zr can be loaded on the organic porous material, the material is subjected to silicatization, and the operating temperature of the catalyst is 120-250 DEG C. The catalyst takes the organic porous material with large specific surface area as the carrier, disperse optimization of the active components and catalysis cooperation among the components are realized, so that good low temperature denitration activity can be obtained, after silicatization, active site contact of SO2 and the catalyst can be effectively isolated, problem of easy SO2 poisoning of the low temperature denitration catalyst can be effectively solved, and the method has good prospect in denitration industrialization application of low temperature sulfur-containing flue gas.

Owner:江苏万德环保科技有限公司 +1

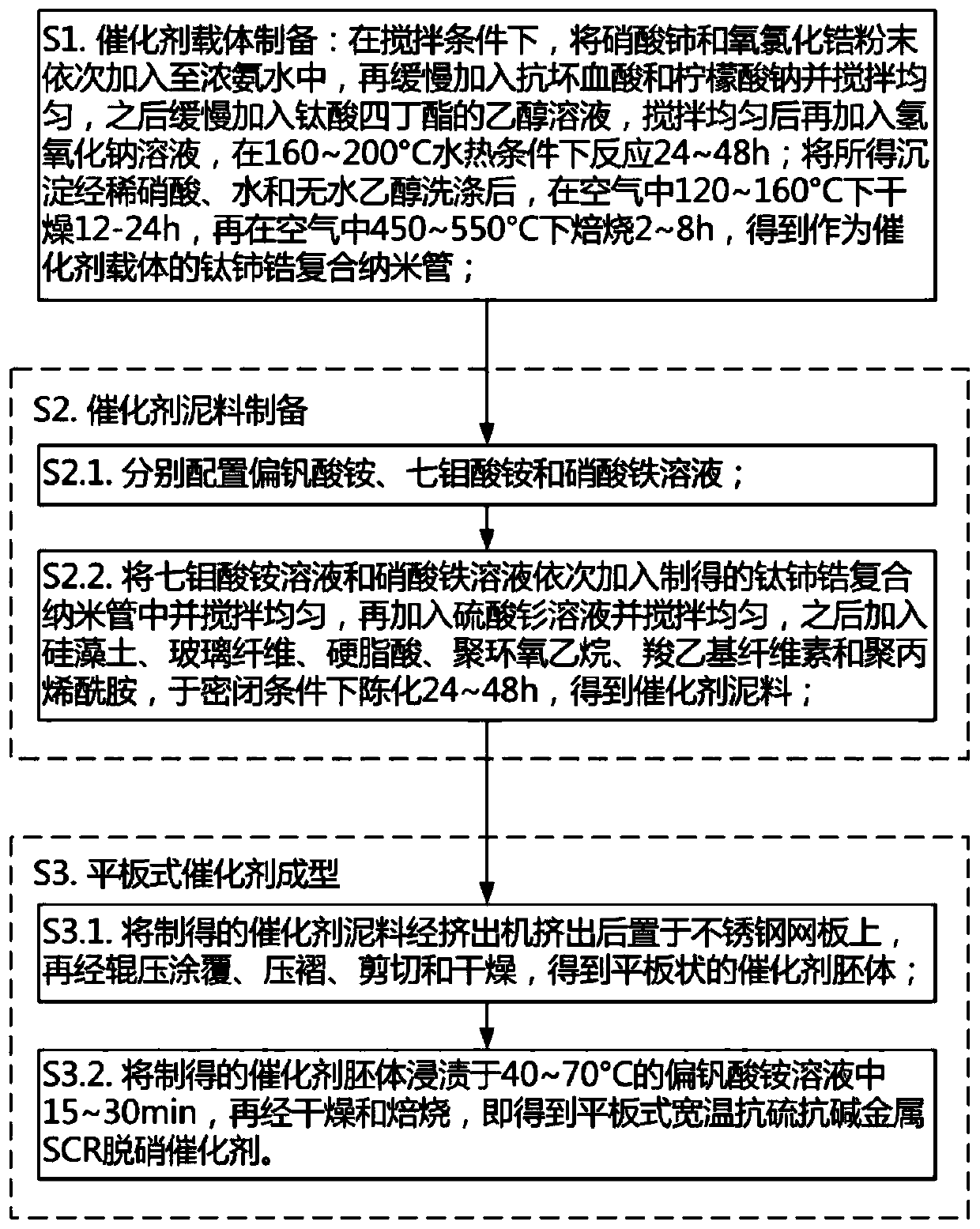

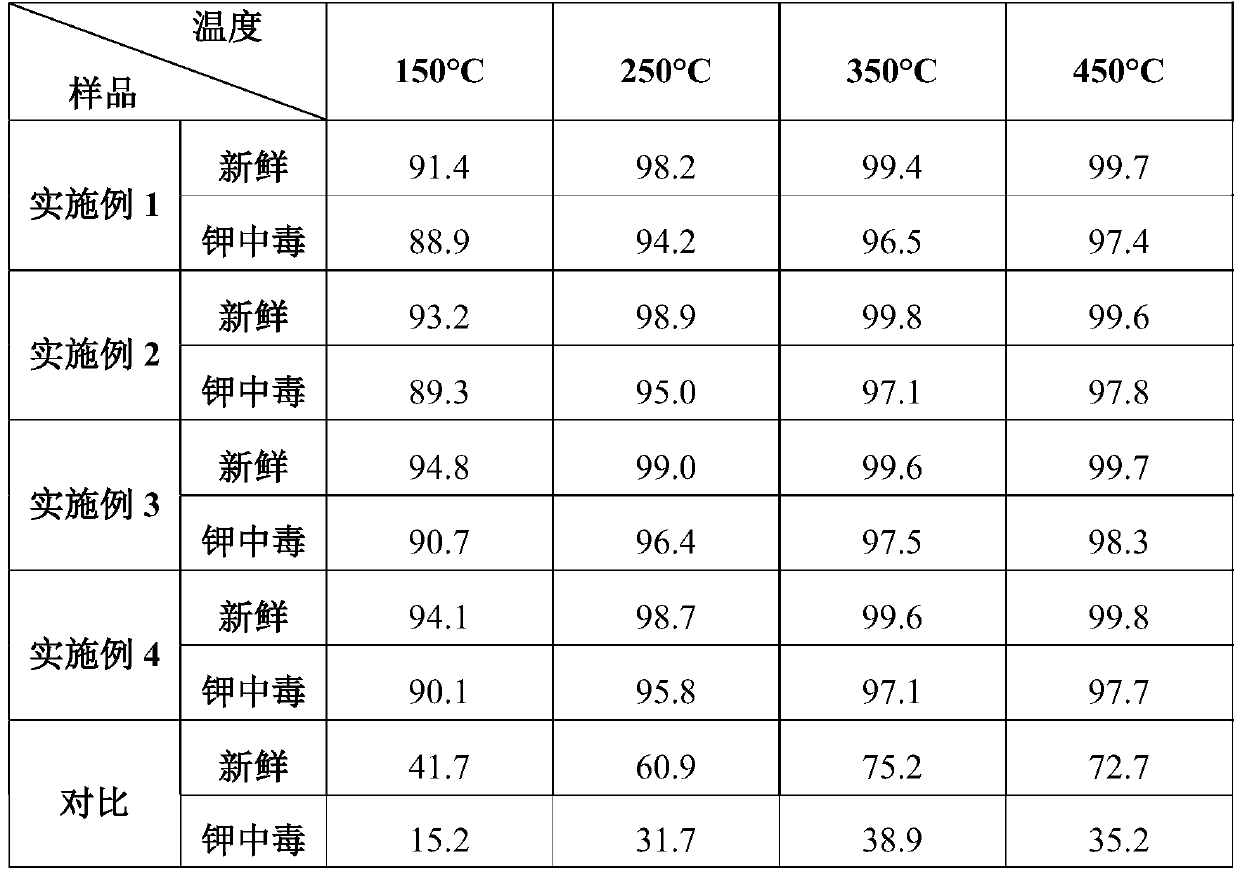

Flat-plate wide-temperature sulfur-resistant alkali-metal-resistant SCR denitrification catalyst and production method thereof

ActiveCN110801849ALarge specific surface areaImprove low temperature denitrification activityCatalyst carriersGas treatmentPtru catalystPhysical chemistry

The invention belongs to the technical fields of environmental protection and denitrification catalysis, and particularly relates to a flat-plate wide-temperature sulfur-resistant alkali-metal-resistant SCR denitrification catalyst and a production method thereof. A carrier of the catalyst is titanium-cerium-zirconium compound nanotubes, an active component of the catalyst is vanadium pentoxide, and catalytic additives are ferric oxide, molybdenum trioxide and samarium sulphate. A two-step roll forming technology is adopted, and comprises the steps of firstly, loading the catalytic additives onto surfaces of the titanium-cerium-zirconium compound nanotubes by adopting an incipient-wetness impregnation method, then loading the active component of the catalyst onto surfaces of the carrier, and forming the catalyst into a flat plate through the roll forming technology to produce the flat-plate SCR denitrification catalyst with wide-temperature activity and performance of resistance to sulfur poisoning and alkali metal poisoning. The catalyst has excellent catalytic activity and performance of resistance to sulfur poisoning and alkali metal poisoning at a range of 150-450 DEG C, the problems of a narrow activity temperature range, sulfur poisoning, alkali metal poisoning and the like of a conventional catalyst in sulfur-containing alkali-metal-containing flue gas can be solved, andthe flat-plate wide-temperature sulfur-resistant alkali-metal-resistant SCR denitrification catalyst is suitable for wide-temperature denitrification of sulfur-containing alkali-metal-containing complex flue gas.

Owner:北京华电光大环境股份有限公司

Hydrogen production catalyst, preparation and its uses

InactiveCN1788841AHigh activityHigh selectivityHydrogenCatalyst activation/preparationPtru catalystPhysical chemistry

The present invention relates to hydrogen producing catalyst, is especially reforming hydrogen-making catalyst and its preparation process and application in reforming hydrogen-making reaction, and belongs to the field of energy source and petrochemical technology. The hydrogen-making catalyst is oxide carrier with oxygen conducting property, Ce-containing compound oxide or CeO2, and active metal component. It is used in reforming hydrogen-making reaction. It has high activity, high selectivity, high sulfur toxin resistance, easy preparation and low cost.

Owner:EAST CHINA NORMAL UNIV

SCR low-temperature denitration catalyst based on ZIF-67 porous carbon skeleton modification, and preparation method of SCR low-temperature denitration catalyst

ActiveCN110368991AIn situ growth achievedIncrease the areaNitrous oxide captureGas treatmentFlue gasPorous carbon

The invention discloses a SCR low-temperature denitration catalyst based on ZIF-67 porous carbon skeleton modification, and relates to the field of flue gas catalytic denitration, and the technical problems of great damage and poor low-temperature activity of a traditional denitration catalyst are solved. Carbonized Co-MOF (ZIF-67) is in situ grown on the surface of TiO2, in particular, the surface of the TiO2 is non covalently functionalized by PVP, the problem of insufficient growth sites on the surface of the TiO2 is overcome, amino groups are uniformly modified on the surface of the TiO2,then through the method that ligands are added after adsorption of Co2+, the in-situ growth of the ZIF-67 is realized, the surface of the TiO2 is evenly coated with the ZIF-67, and a novel TiO2 carrier coated with highly dispersed CoOx porous carbon is obtained by carbonization. The invention further discloses a preparation method of the SCR low-temperature denitration catalyst based on the ZIF-67porous carbon skeleton modification, and the reaction condition of the method is simple and mild.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

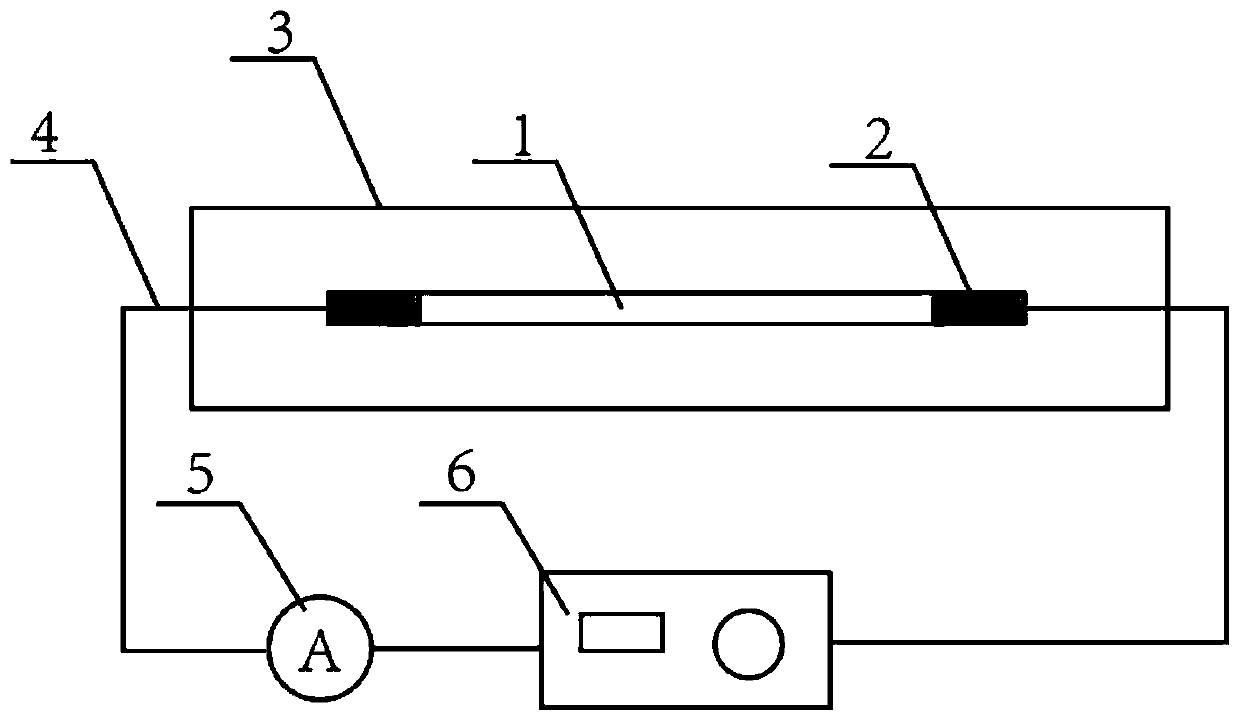

Method for intensifying carbon dioxide catalytic hydrogenation reaction

ActiveCN110368945AEvenly heatedHigh activityProductsHydrocarbon from carbon oxidesHydrogenation reactionBULK ACTIVE INGREDIENT

The invention discloses a method for intensifying a carbon dioxide catalytic hydrogenation reaction. The method for intensifying the carbon dioxide catalytic hydrogenation reaction mainly comprises the following steps that active ingredients having capacity for catalyzing CO2 hydrogenation are loaded on a porous conductive framework to prepare a structural catalyst; the structural catalyst is plugged into a circuit to conduct a current; and the structural catalyst is placed in raw material gas containing CO2 and hydrogen, a power source is turned on to apply the current on the circuit, joule heat generated on the structural catalyst of the current can heat the structural catalyst to a temperature at which CO2 hydrogenation reaction can be carried out, and CO2 and hydrogen react on the structural catalyst. The current is applied on the structural catalyst of the conductive framework to realize electric internal heating, so that the catalyst is heated more uniformly, activity and sulfurpoisoning capacity of the catalyst are improved, and the conversion performance of CO2 is obviously improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Preparation method and application of catalyst containing low-silicon composite metal Beta molecular sieve

ActiveCN111617800AImprove performanceImprove denitrification performanceGas treatmentMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a preparation method and application of a catalyst containing a low-silicon composite metal Beta molecular sieve. The Fe-Beta molecular sieves with different morphologies are prepared by a one-step method by controlling the composition of synthesis raw materials and a structure-directing agent under the condition of no template agent, so that the acidity and pore channels of the molecular sieves are optimized, and the purpose of optimizing the performance of the molecular sieves is achieved. Lanthanum salt is used for further modifying the Fe-Beta molecular sieve for the first time by adopting an impregnation method, so that the denitration temperature interval of the Fe-Beta molecular sieve is greatly widened, the denitration performance and hydrothermal stabilityof the Fe-Beta molecular sieve are improved, and the Fe-Beta molecular sieve is relatively good in sulfur poisoning resistance and relatively low in cost. The low-silicon composite metal Beta molecular sieve catalyst disclosed by the invention is mainly used for treating NOx-containing tail gas and flue gas, and has excellent NOx selective reduction capability, good hydrothermal stability and HC carbon deposition resistance and sulfur poisoning resistance in a low-temperature range.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

Catalyst for flue gas denitrification and preparation method of catalyst

InactiveCN106732624AReduce the cost of denitrificationImprove catalytic performanceGas treatmentHeterogenous catalyst chemical elementsHigh resistanceFlue gas

The invention provides a catalyst for flue gas denitrification. The catalyst is multi-component metal oxide comprising Fe2O3, CeO2, NiO and TiO2. The Fe2O3-CeO2-NiO / TiO2 multi-component metal oxide serving as an SCR (selective catalytic reduction) flue gas denitrification catalyst has the advantages of high resistance to H2O and SO2 poisoning, low denitrification cost and the like and also has higher thermal stability, wider temperature window and better low-temperature denitrification activity.

Owner:JILIN ELECTRIC POWER RES INST LTD

Catalyst for purifying soluble organic matter in diesel exhaust and preparation method of catalyst

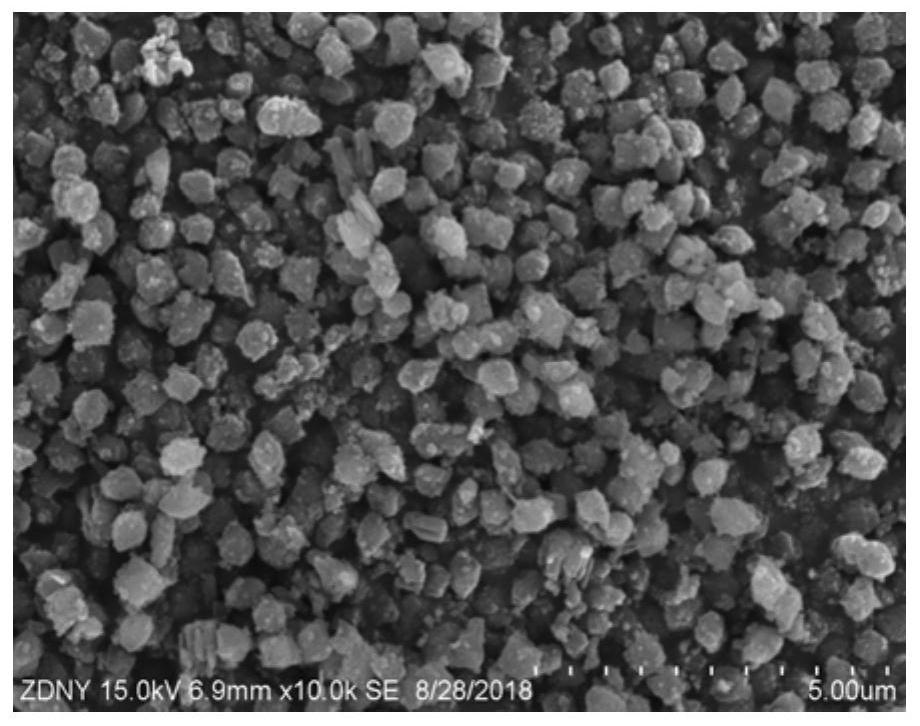

ActiveCN104138754AImprove performanceHigh catalytic oxidation activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNanoparticle

The invention relates to a catalyst for purifying soluble organic matter (SOF) in diesel exhaust and a preparation method of the catalyst. The catalyst is a composite oxide catalyst; especially, the catalyst is formed by mixing oxides of cerium, vanadium and silicon. The catalyst is nano particle and is suitable for processing SOF in the diesel exhaust; the process of catalyzing and oxidizing SOF by using the catalyst is simulated by using a TG-DTA combination method; due to the adoption of the catalyst, SOF can begin to convert at 133 DEG C; the activity on catalytic combustion of SOF is equivalent to that of a loaded noble metal catalyst; the catalyst has good sulfur resistance; and meanwhile, the catalyst does not contain noble metal and is low in cost.

Owner:SOUTHWEST PETROLEUM UNIV

NO*storage-reduction catalyzer for vehicle vent gas process and preparation method thereof

ActiveCN101172229AImprove storage-recovery capacityHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalSodium Bentonite

The invention relates to automobile exhaust purification catalyst and a preparation method thereof, in particular to the automobile exhaust purification catalyst with the NOx storing-restoring function, and the preparation method thereof. The NOx storing-restoring catalyst provided by the invention consists of a bentonite carrier and at least one precious metal active component carried on the carrier and selected from the group composed of Pt, Pd and Rh. The content of the precious metal is 0.01 to 1.0 percent of the total weight of the catalyst. The catalyst can also include at least one transition metal taken as an auxiliary active component and selected from Ti, Mn, Fe, Co, Ni, Cu, Zn and Zr, and the content of the transition metal is 0 to 5 percent of the total weight of the catalyst. The bentonite can be modified by alkali metal and or alkaline earth metal compound. The NOx storing-restoring catalyst of the invention can effectively improve the NOx storing-restoring capability, and improve the capabilities of sulfur poisoning resistance and heat aging resistance and so on, and has simple preparation.

Owner:BYD CO LTD

Preparation method of sulfur poisoning-resistant palladium-carbon catalyst

InactiveCN106378130AIncrease oxygen-containing groupsImprove hydrophilicityMetal/metal-oxides/metal-hydroxide catalystsActivated carbonSulfur

The invention provides a preparation method of a sulfur poisoning-resistant palladium-carbon catalyst. The preparation method comprises the following steps: 1, performing acid pickling treatment on activated carbon, then washing the activated carbon subjected to acid pickling treatment with water until the activated carbon is neutral, and drying the washed activated carbon; 2, putting the activated carbon into saline solution to obtain activated carbon slurry; 3, uniformly mixing a palladium compound with deionized water to obtain a palladium solution; 4, dripping the palladium solution into the activated carbon slurry for soaking, then adjusting the pH value of the system, and filtering to obtain a filter cake; 5, pulping the filter cake with pure water, adding a reducing agent for reduction, and washing with water to obtain the palladium-carbon catalyst. The preparation process is simple; the sulfur poisoning resistance of the palladium-carbon catalyst prepared by the preparation method is obviously improved, and the service life of the catalyst is substantially prolonged.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

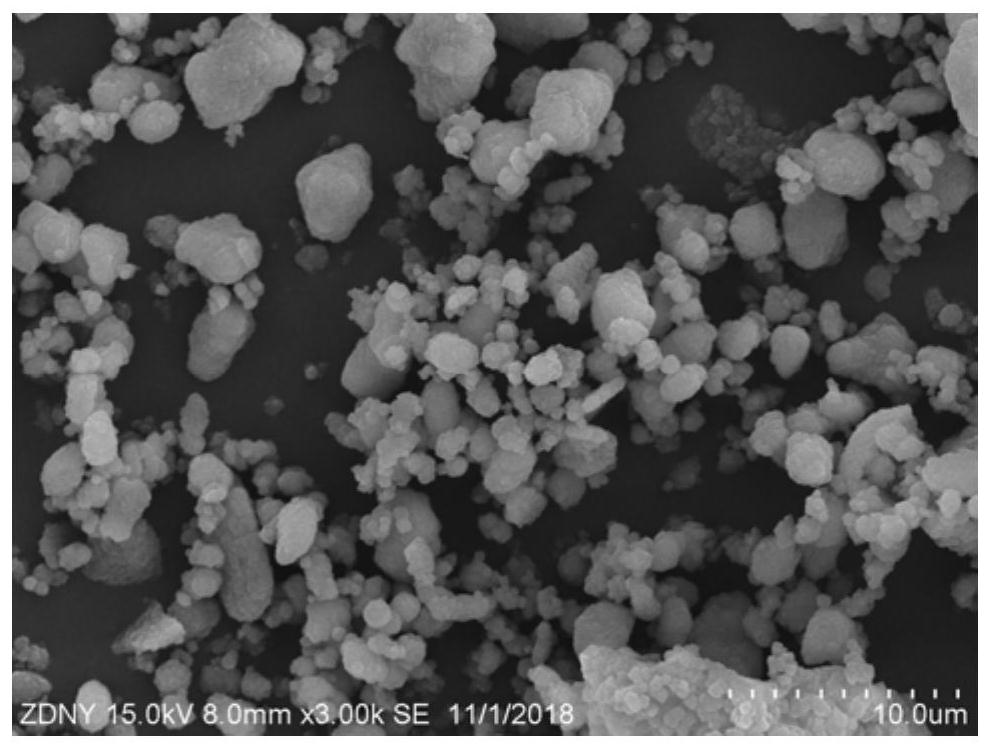

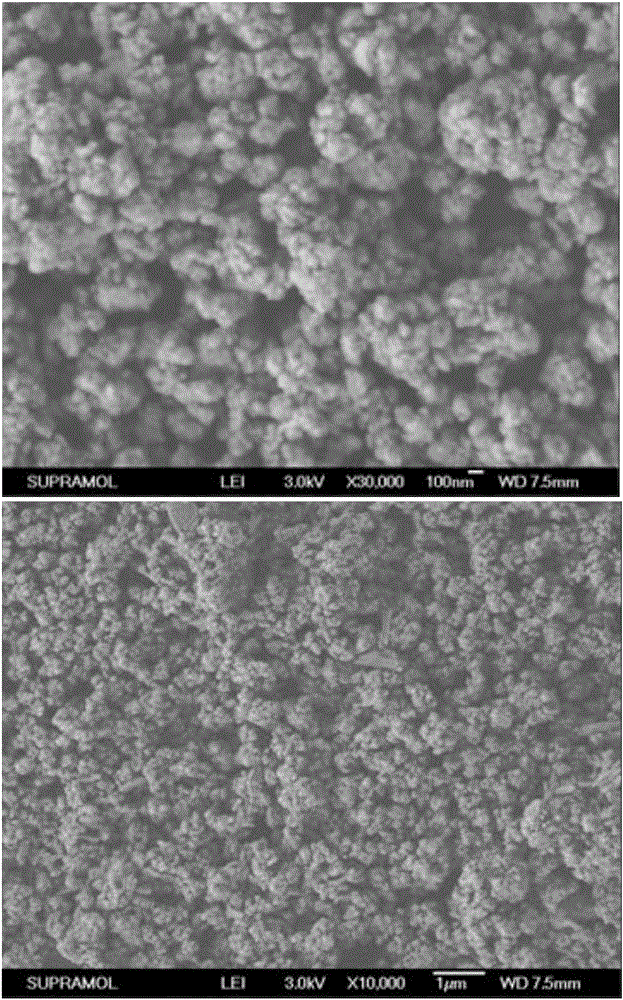

Layered manganese oxide with water resistance and sulfur poisoning resistance and preparation method and application thereof

InactiveCN109956502ALow ignition temperatureLarge specific surface areaNanotechnologyManganese oxides/hydroxidesAlcoholSulfur

The invention discloses layered manganese oxide with water resistance and sulfur poisoning resistance and a preparation method and application thereof, and belongs to the technical field of catalyticmaterials. The preparation method comprises the following steps: adding a KMnO4 solution into chain alcohol, or adding chain alcohol into a KMnO4 solution, and then reacting at the condition of 10-38DEG C for 6-48 h; and filtering after the reaction, washing a precipitate and drying to obtain layered manganese oxide. The carbon atom number of the chain alcohol is less than or equal to 4; and theraw materials are continuously stirred or vibrated during the addition process and the reaction process. The chain alcohol is preferably methanol or ethanol. When applied to catalytic combustion of volatile organic compounds, the prepared layered manganese oxide has advantages of high specific surface area, high catalytic activity, strong catalytic stability, excellent water resistance, sulfur poisoning resistance and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

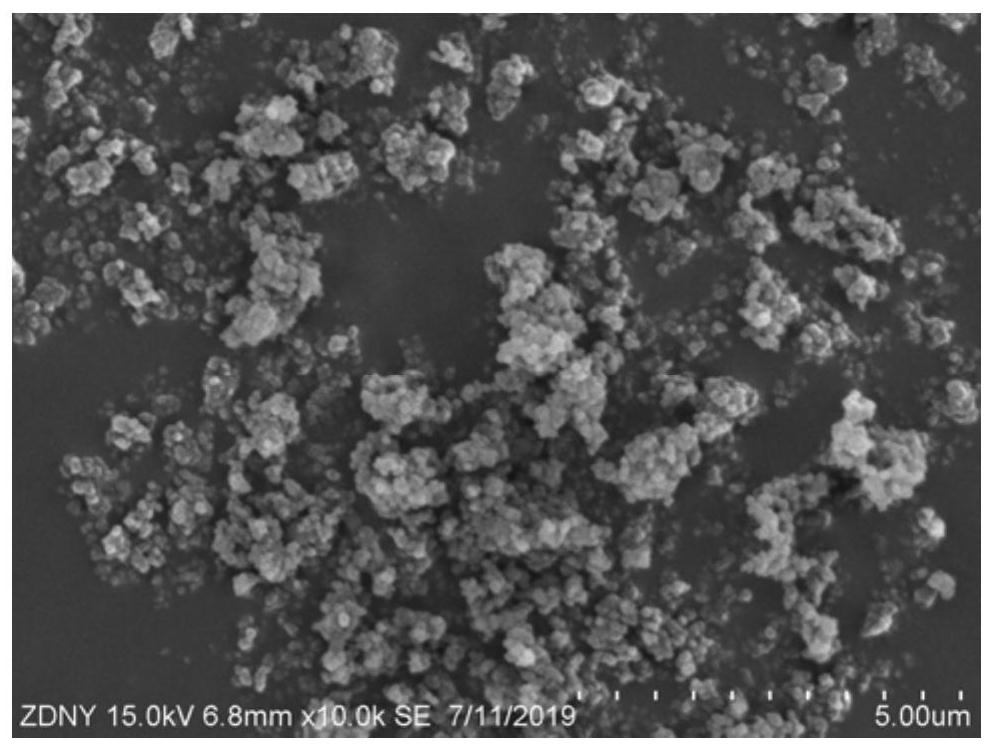

Rare earth doped ZIF-8 nanoporous carbon catalyst, and preparation method and application thereof

PendingCN111203205ALarge specific surface areaGood choiceGas treatmentHeterogenous catalyst chemical elementsOxideNanoporous carbon

The invention discloses a preparation method of a rare earth doped ZIF-8 nanoporous carbon catalyst, and relates to the field of environment-friendly catalytic materials. The method is provided against the problems of poor sulfur resistance and low-temperature catalytic performance of an existing denitration catalyst. The preparation method comprises the following steps: taking ZIF-8 as a precursor, impregnating a rare earth metal salt in the pore channels of the precursor, carrying out heat treatment in the presence of an inert gas to make the ZIF-8 form nanoporous carbon and make rare earthsalt converted into an oxide attached to the interior of the porous carbon in order to obtain the rare earth oxide modified nanoporous carbon (NPC), grinding and fully mixing the rare earth oxide modified nanoporous carbon (NPC) and nanoscale gamma-Al2O3 to obtain a composite carrier, and finally impregnating and loading a MnOx active component to obtain the target catalyst. The invention also discloses an application of the rare earth doped ZIF-8 nanoporous carbon catalyst. The catalyst has the advantages of excellent NOx removal efficiency under the low-temperature condition, the denitrationefficiency at 150 DEG C reaches 95%, and the overall specific surface area and SO2 poisoning resistance of the catalyst are improved through a special composite structure.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH +1

Monolithic catalyst for catalytic oxidation of wet VOCs-containing tail gas and preparation method and application thereof

InactiveCN110116009AHigh activityReduced activityHeterogenous catalyst chemical elementsCatalyst activation/preparationWater vaporCatalytic oxidation

The invention discloses a monolithic catalyst for catalytic oxidation of wet VOCs-containing tail gas. The catalyst comprises a cordierite honeycomb carrier, a composite zirconia coating doped with rare earth components and supported on the carrier, active components loaded on the coating, and hydrophobic components covering the surface of the catalyst. The invention further discloses a preparation method of the catalyst and application of the catalyst in catalytic oxidation of the wet VOCs-containing tail gas. The composite zirconia coating doped with the rare earth components, an active component coating and a hydrophobic component coating are sequentially prepared on the carrier through a step-by-step impregnation method. The rare earth components in the catalyst improve the oxygen supply capacity of the composite zirconia coating and the activity of the catalyst, and the hydrophobic components on the surface of the catalyst avoid the activity decrease of the catalyst and improve the water vapor resistance of the catalyst. The preparation method of the catalyst is simple and easy to achieve, and the catalyst has high catalytic efficiency and a wide use range and is suitable forcatalytic oxidation of the wet VOCs-containing tail gas at low temperature.

Owner:陕西省煤化工工程技术研究中心

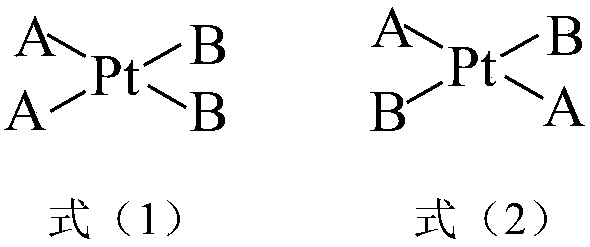

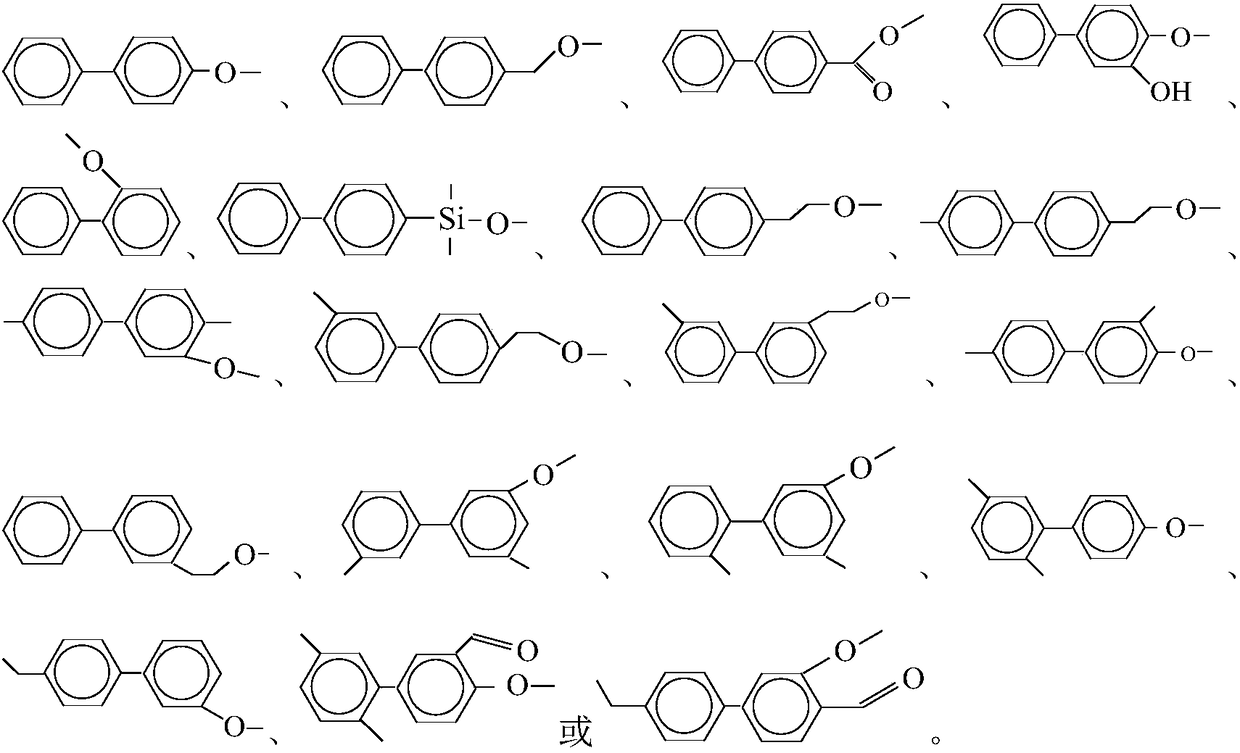

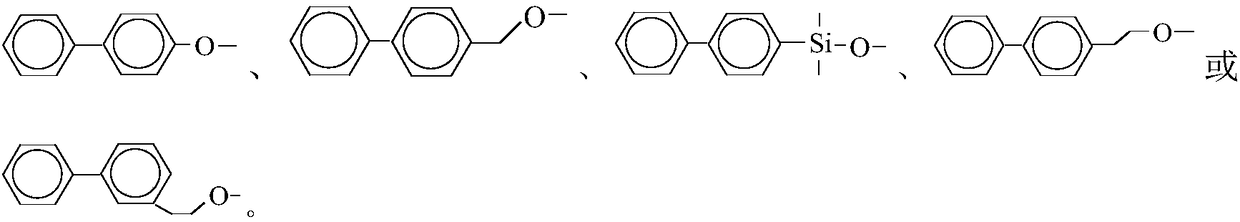

Platinum catalyst resistant to sulfur poisoning and preparation method of platinum catalyst

ActiveCN108273553AImprove barrier propertiesImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPlatinum organic compoundsSulfurEther

The invention belongs to the technical field of organosilicon polymer, and discloses a platinum catalyst resistant to sulfur poisoning and a preparation method of the platinum catalyst. The platinum catalyst comprises the following molecular structural formulas (1) and (2), wherein the A group is an ether structural group containing double protonated biphenyl or derivatives of the double protonated biphenyl, and the B group is a nitrogen-containing six-membered ring pyridine structure or a derivative structural group of the nitrogen-containing six-membered ring pyridine structure. Through theprepared catalyst which is resistant to sulfur poisoning and has a specifically designed structure, not only can the defects of short storage time, inconvenient use and sufficiently sealed harsh storage conditions of of a current platinum catalyst be overcome, but also an effect of resistance to sulfur poisoning can be achieved; therefore, in a system in the presence of sulfur compounds, a strongcatalytic effect can still be achieved, and the platinum catalyst has no harsh synthesis conditions, a simple preparation process, simple steps, high production efficiency, stable products and low cost, so that industrial production of the platinum is realized.

Owner:GUANGDONG UNIV OF TECH

Loaded nickel-based catalyst and preparation method and application thereof

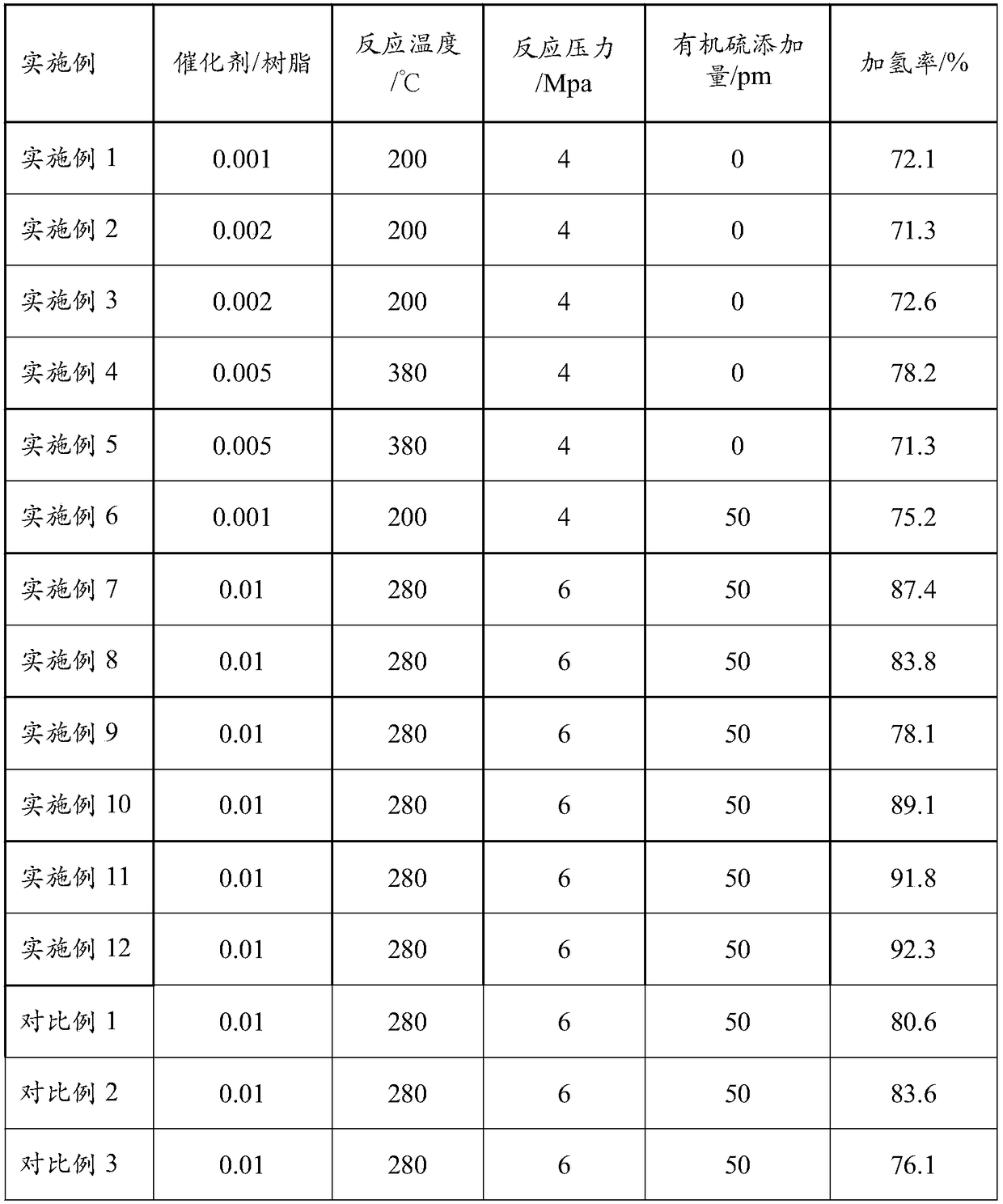

PendingCN108126702AObvious price advantageImprove hydrogenation reactivityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentPetroleum resin

The invention discloses a loaded nickel-based catalyst. The loaded nickel-based catalyst comprises an active component and a composite carrier, wherein the active component comprises nickel, zinc, iron and cobalt; the active component is loaded on the composite carrier to form the loaded nickel-based catalyst of which the structure is shown as Ni-Zn-Fe-Co / SiO2-TiO2; the loaded nickel-based catalyst comprises 30-80% by mass of nickel, 0.1-15% by mass of zinc, 0.1-5% by mass of iron, 0.1-15% by mass of cobalt, 10-50% by mass of silica, and 1-30% by mass of titanium dioxide. The prepared Ni-Zn-Fe-Co / SiO2-TiO2 loaded nickel-based catalyst is obvious in petroleum resin hydrogenation decoloring effect; the preparation processes and equipment are simple; the industrial production can be easilycarried out; and the loaded nickel-based catalyst has a good application prospect and has huge economic benefit.

Owner:SHANGHAI XUNKAI NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com