Method for intensifying carbon dioxide catalytic hydrogenation reaction

A technology for catalytic hydrogenation and carbon dioxide, which is used in carbon compound catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. problem, to achieve the effect of increasing CO2 conversion rate, improving activity, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

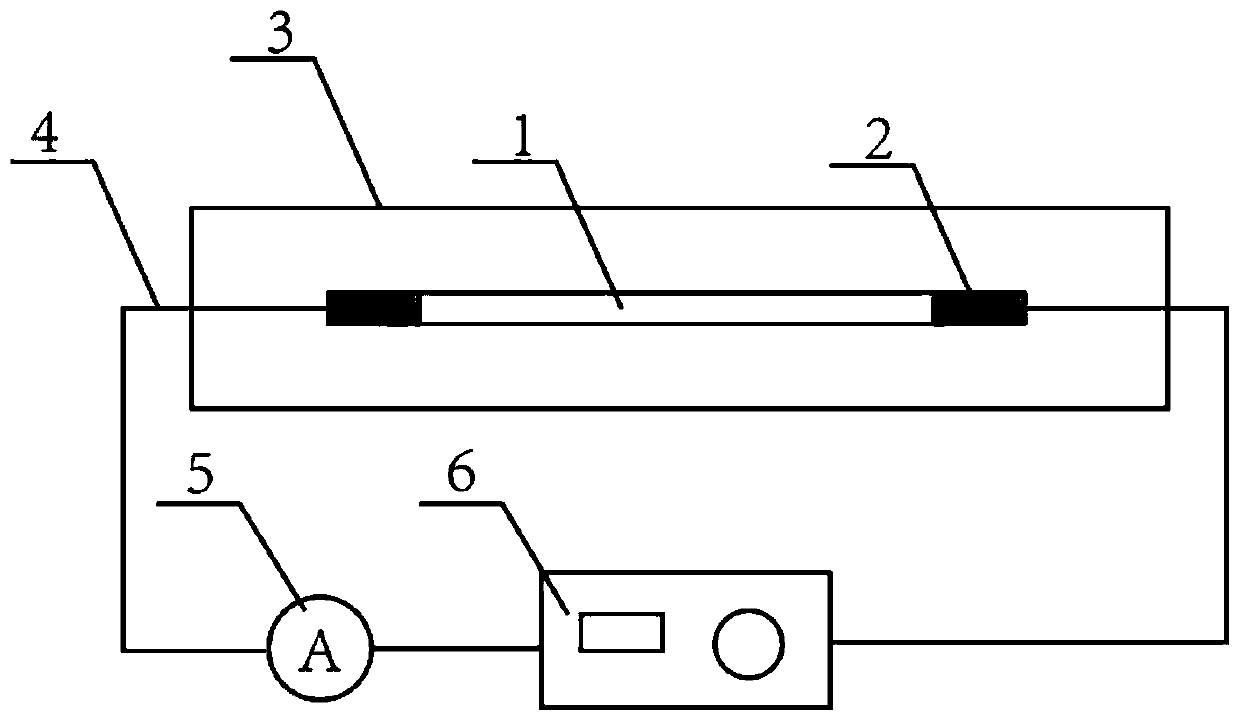

[0053] This embodiment provides a method for strengthening the catalytic hydrogenation reaction of carbon dioxide with a nickel foam structured catalyst, the method is as follows figure 1 shown, including the following steps:

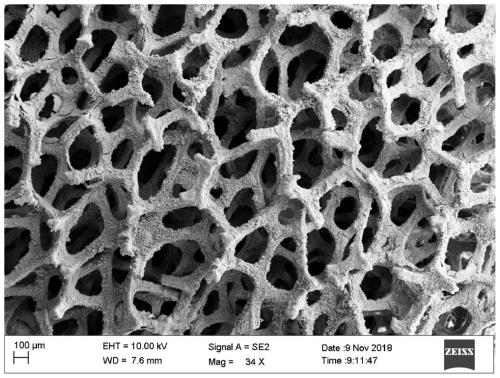

[0054] 1. Put the nickel foam material with a length of 70mm, a width of 4mm, a thickness of 1.5mm, and a pore density of 100ppi in 6mol / L hydrochloric acid for ultrasonic cleaning for 5 minutes, rinse repeatedly with deionized water and ethanol, and then put it in a constant temperature In a drying oven, dry at 60°C for 3 hours to obtain a nickel foam structured catalyst skeleton, as shown in the physical picture figure 2 shown.

[0055] 2. Mix 0.009mol Ni(NO 3 ) 2 ·6H 2 O, 0.003mol Al(NO 3 ) 3 9H 2 O and 0.04mol urea are added in 75ml deionized water, and the gained solution is moved in the autoclave;

[0056] 3. Immerse the nickel foam material in the solution, seal the reaction vessel, react at 110°C for 8 hours, take out the reaction produ...

Embodiment 2

[0061] This embodiment provides a method for strengthening the catalytic hydrogenation reaction of carbon dioxide with a nickel foam structured catalyst, the method is as follows figure 1 shown, including the following steps:

[0062] 1. Put the foamed nickel material with a length of 80mm, a width of 3mm, a thickness of 1mm, and a pore density of 90ppi in 7mol / L sulfuric acid for ultrasonic cleaning for 4min, rinse it repeatedly with deionized water and ethanol, and then dry it at a constant temperature In an oven, dry at 60° C. for 2.5 h to obtain a nickel foam structured catalyst framework.

[0063] 2. Mix 0.007mol Ni(NO 3 ) 2 ·6H 2 O, 0.003mol Al(NO 3 ) 3 9H 2 O and 0.035mol urea are added in 80ml deionized water, and the gained solution is moved in the autoclave;

[0064] 3. Immerse the nickel foam material in the solution, seal the reaction vessel, react at 100°C for 7h, take out the reaction product and rinse it with deionized water and dry it at 70°C for 2.5h to...

Embodiment 3

[0069] This embodiment provides a method for strengthening the catalytic hydrogenation reaction of carbon dioxide with a nickel foam structured catalyst, the method is as follows figure 1 shown, including the following steps:

[0070] 1. Put the foamed nickel material with a length of 90mm, a width of 3mm, a thickness of 1mm, and a pore density of 90ppi in 5mol / L nitric acid for ultrasonic cleaning for 5 minutes, rinse repeatedly with deionized water and ethanol, and dry at a constant temperature In an oven, dry at 50° C. for 3.5 h to obtain a nickel foam structured catalyst framework.

[0071] 2. Mix 0.01mol Ni(NO 3 ) 2 ·6H 2 O, 0.003mol Al(NO 3 ) 3 9H 2 O and 0.045mol urea are added in 85ml deionized water, and the gained solution is moved in the autoclave;

[0072] 3. Immerse the nickel foam material in the solution, seal the reaction vessel, react at 110°C for 7 hours, take out the reaction product, rinse it with deionized water and dry it at 70°C for 3 hours, and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com