Monolithic catalyst for catalytic oxidation of wet VOCs-containing tail gas and preparation method and application thereof

A monolithic catalyst and catalytic oxidation technology, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of few research literatures, and achieve a simple and efficient method. Ease of implementation, effects of enhanced migration properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

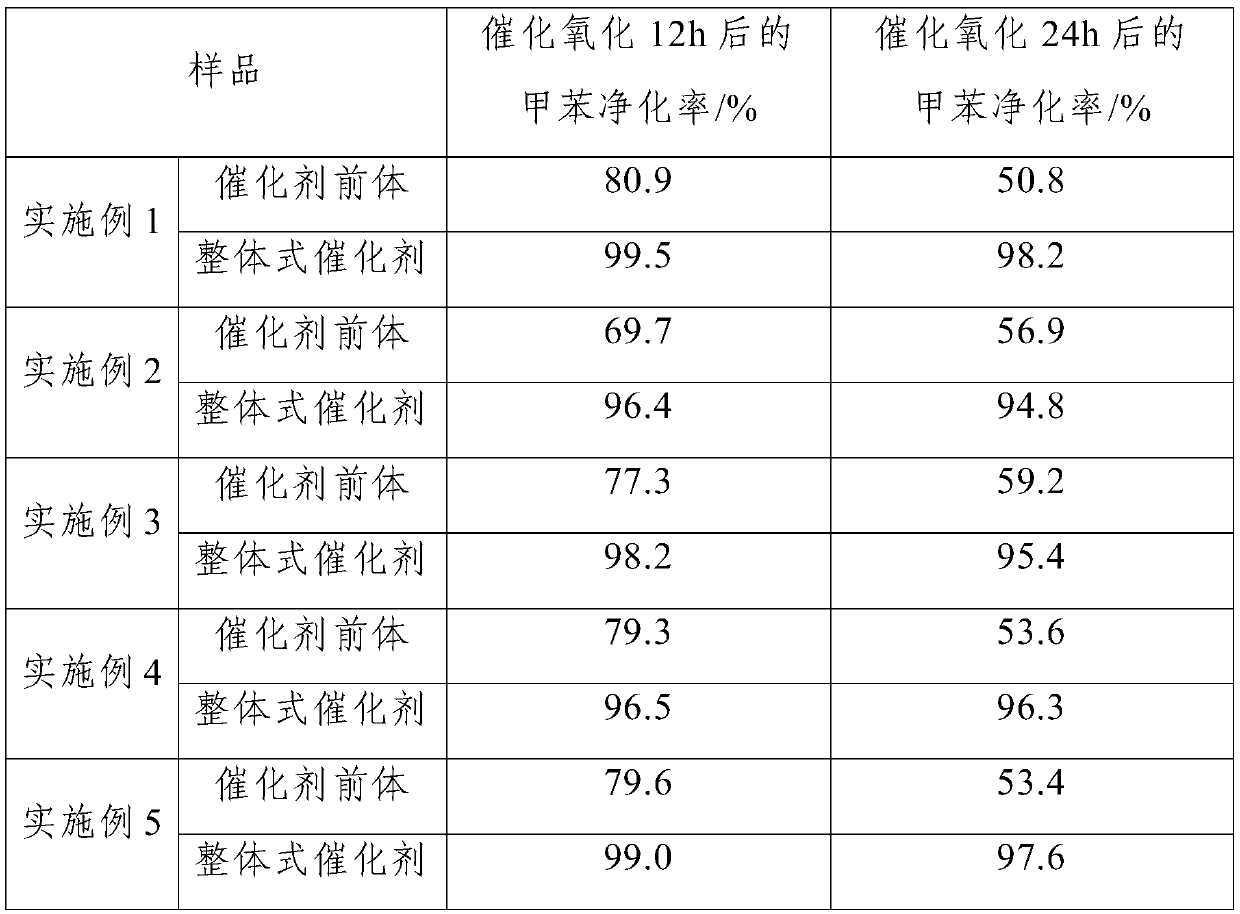

Embodiment 1

[0036] The wet VOCs catalytic oxidation monolithic catalyst of this embodiment consists of a honeycomb carrier, a composite rare earth oxide coating loaded on the honeycomb carrier, an active component loaded on the composite rare earth oxide coating, and a catalyst covered on the The composition of hydrophobic components on the surface, the honeycomb carrier is a cordierite honeycomb carrier, the mesh density of the cordierite honeycomb carrier is 200 holes / square foot, and the wall thickness is 0.25mm, and the composite rare earth oxide coating is doped oxide A composite zirconia coating of cerium, the active component includes CuO and PdO, the hydrophobic component is a hydrophobic silicon material, and the loading mass of the composite zirconia coating doped with cerium is the mass of a cordierite honeycomb carrier The loading mass of CuO is 4% of the mass of the cordierite honeycomb carrier, and the loading mass of PdO is 0.35% of the mass of the cordierite honeycomb carri...

Embodiment 2

[0047] The wet VOCs catalytic oxidation monolithic catalyst of this embodiment consists of a honeycomb carrier, a composite rare earth oxide coating loaded on the honeycomb carrier, an active component loaded on the composite rare earth oxide coating, and a catalyst covered on the The composition of hydrophobic components on the surface, the honeycomb carrier is a cordierite honeycomb carrier, the mesh density of the cordierite honeycomb carrier is 200 holes / square foot, and the wall thickness is 0.25mm, and the composite rare earth oxide coating is doped oxide A composite zirconia coating of yttrium, the active component includes MnO and PdO, the hydrophobic component is a hydrophobic silicon material, and the loading mass of the composite zirconia coating doped with yttrium oxide is the mass of a cordierite honeycomb carrier The loading mass of the MnO is 1% of the mass of the cordierite honeycomb carrier, and the loading mass of the PdO is 1% of the mass of the cordierite ho...

Embodiment 3

[0057] The wet VOCs catalytic oxidation monolithic catalyst of this embodiment consists of a honeycomb carrier, a composite rare earth oxide coating loaded on the honeycomb carrier, an active component loaded on the composite rare earth oxide coating, and a catalyst covered on the The composition of hydrophobic components on the surface, the honeycomb carrier is a cordierite honeycomb carrier, the mesh density of the cordierite honeycomb carrier is 200 holes / square foot, and the wall thickness is 0.25mm, and the composite rare earth oxide coating is doped oxide A composite zirconia coating of cerium and yttrium oxide, the active component includes CuO and PtO, the hydrophobic component is a hydrophobic silicon material, and the loading mass of the composite zirconia coating doped with cerium oxide and yttrium oxide 8% of the mass of the cordierite honeycomb carrier, the loading mass of CuO is 5% of the mass of the cordierite honeycomb carrier, and the loading mass of PtO is 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com