Patents

Literature

192results about How to "High catalytic oxidation activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ti-Si molecular sieve modifying method

InactiveCN1421389AImprove selectivity and activity stability andIncrease the content of titanium in the frameworkMolecular sieve catalystsCrystalline aluminosilicate zeolitesSide productMolecular sieve

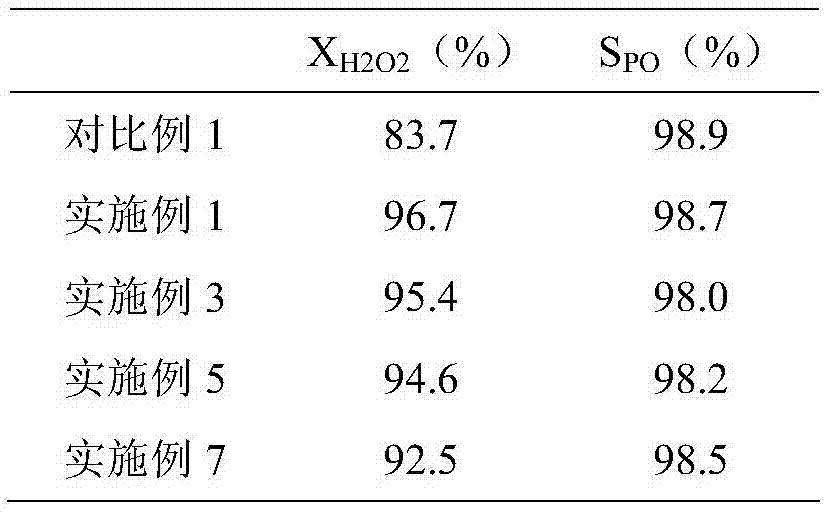

The preparation process of modified Ti-Si molecular sieve TS-1 with MFI structure includes mixing water solution of Si and synthesized TS-1 molecular sieve, the reaction of the mixture at 80-190 deg.c in the reactor for 0.1-150 hr, filtering, washing and drying. The modified Ti-Si molecular sieve TS-1 has certain amount of inert component Si covering the surface and pores and less Ti content in the surface and pores and thus less side reaction in the said places, and these results in raised catalytic oxidation activity, prolonged service life and less side product.

Owner:CHINA PETROLEUM & CHEM CORP +1

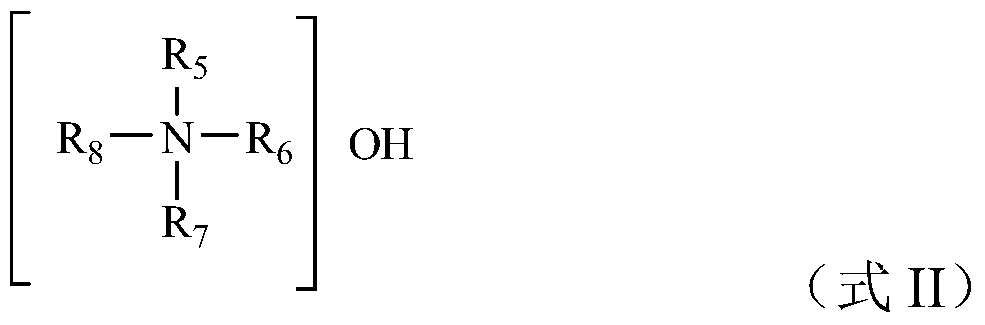

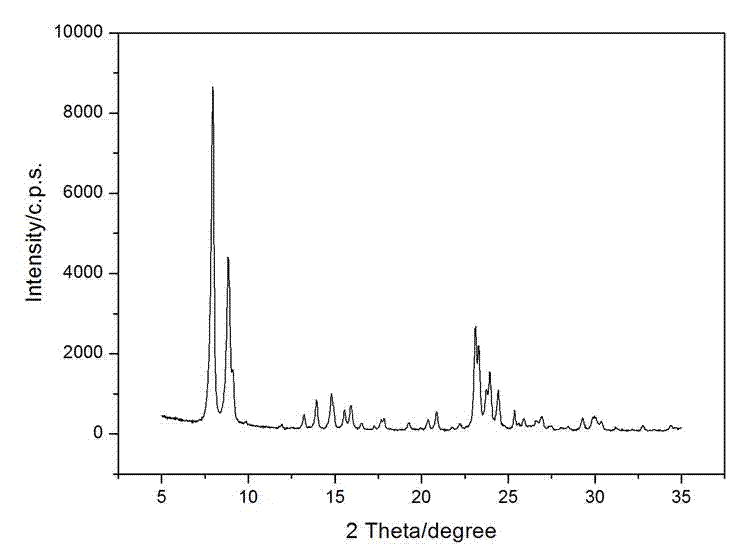

Tin-silicon molecular sieve and synthetic method and application thereof, and phenol hydroxylation method

ActiveCN105271294AHigh crystallinityReduce dosageOrganic chemistryMolecular sieve catalystsMolecular sieveCatalytic oxidation

The invention provides a method for synthesizing a tin-silicon molecular sieve. The method comprises: (1) hydrolyzing an organic silicon source, a tin source and an alkali source template agent to obtain a mixture A and carrying out first crystallization on the obtained mixture A; and (2) mixing the material obtained by first crystallization with an inorganic silicon source to obtain a mixture B and carrying out second crystallization on the obtained mixture B. The invention provides the tin-silicon molecular sieve synthesized through the method and an application of the molecular sieve. The invention provides a phenol hydroxylation method. By taking the inorganic silicon source which is relatively low in price as a part of, or even, a main silicon source, the use level of organosilicone esters is reduced, and the synthetic benefit is improved to a great extent. Moreover, the synthesized tin-silicon molecular sieve is high in relative crystallinity, high in catalytic oxidation activity and high in selectivity, and shows the characteristics of being high in catalytic oxidation activity and high in selectivity on hydroquinone in a probe reaction, i.e. a phenol hydroxylation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

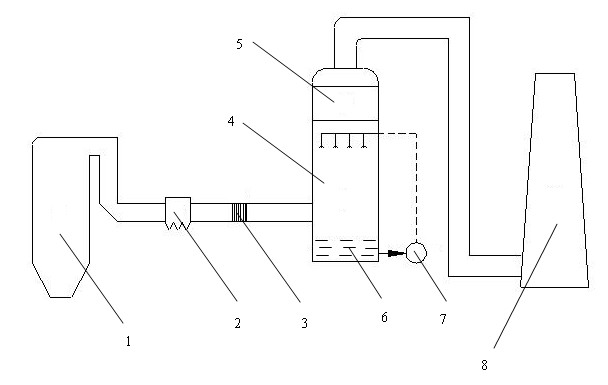

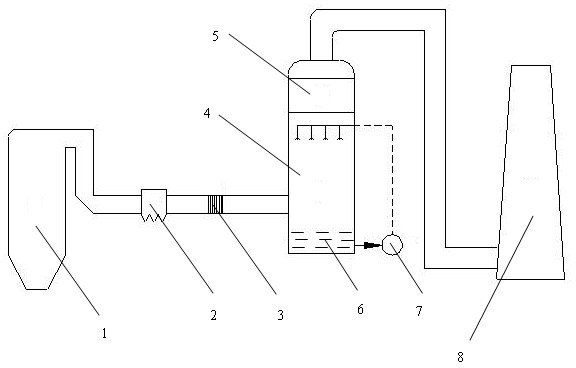

Method and system for simultaneously removing sulfur, niter and mercury from smoke based on catalytic oxidation

ActiveCN102527205AAvoid preparationImprove safety and economyDispersed particle separationEnvironmental chemistryDust control

The invention discloses a method for simultaneously removing sulfur, niter and mercury from smoke based on catalytic oxidation. The method is characterized by comprising the following steps of: (1) arranging a catalytic reactor in a dust-removed smoke duct, wherein a catalyst for promoting oxidizing reaction of NO and HgO is filled in the catalytic reactor; (2) allowing the dust-removed smoke to pass through the catalytic reactor, wherein under catalysis of the catalyst, the reaction speed of the NO, the HgO and O2 is increased and the NO and the HgO are oxidized into NO2 and Hg<2+>; and (3) introducing the smoke subjected to catalytic oxidation into an absorber with an absorption solution, wherein the absorption solution is used for absorbing NO2, Hg<2+> and SO2 from the smoke. The invention also discloses a system applicable to the method. According to the method and the system, the sulfur, the niter and the mercury are removed from the smoke; external oxidant is not required to be added; preparation, transportation and storage of strong oxidant are avoided; operating cost is reduced; and economy and safety of the system are improved.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Tin-silicon molecular sieve and preparation method thereof

ActiveCN103964461AImprove catalytic oxidation performanceHigh catalytic oxidation activityCrystalline aluminosilicate zeolitesMolecular sieveCatalytic oxidation

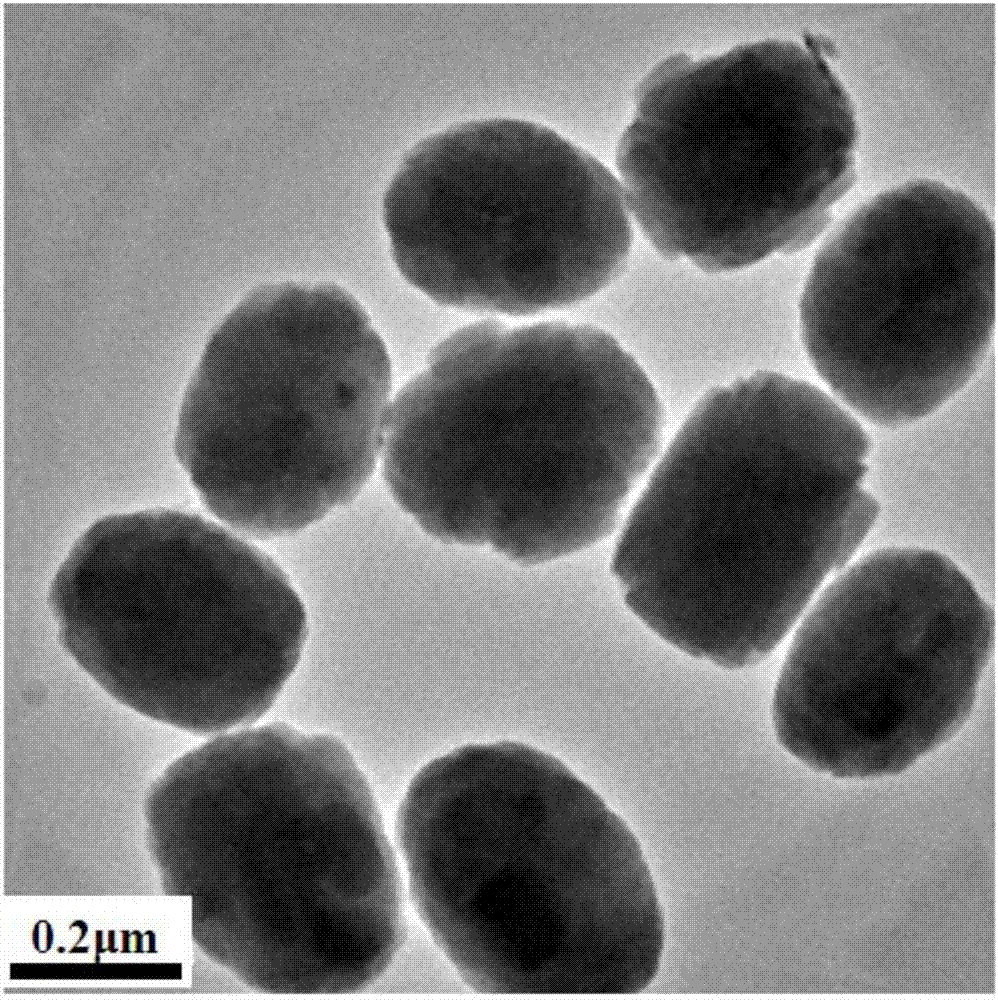

The invention provides a tin-silicon molecular sieve. The tin-silicon molecular sieve contains silicon, tin and oxygen elements. All or a part of crystal grains have internal cavities or cavity structures, a total specific surface area is greater than or equal to 300m<2> / g, and a ratio of an external specific surface area to the total specific surface area is greater than or equal to 10%. The tin-silicon molecular sieve has good catalytic oxidation effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

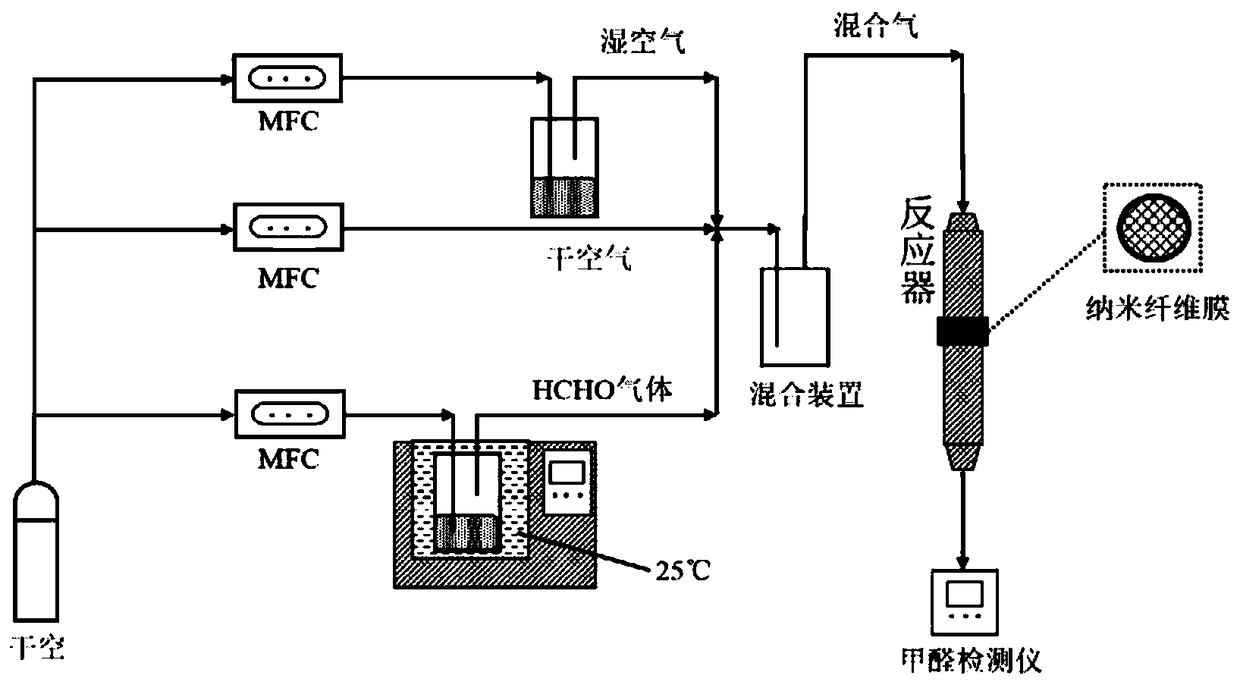

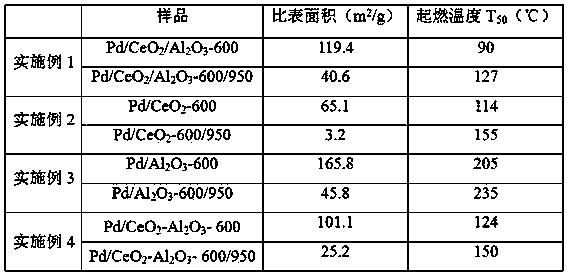

Normal-temperature high-effective formaldehyde catalytic-oxidizing catalyst, preparation method, and application thereof

InactiveCN107096527ASimple preparation stepsShort cycleGas treatmentDispersed particle separationCatalytic oxidationManganese oxide

A high-effective catalyst used for removing indoor formaldehyde at normal temperature includes a carrier, a noble active component, and an additive. The carrier is a mesoporous oxide including at least one of Al2O3, TiO2, SiO2, cerium oxide, cobalt oxide and manganese oxide; the active component includes a less amount of at least one of noble metals Pd, Pt, Au and Ag; the additive is at least one of Na, K, Fe, Co, Ce and Ni. The catalyst can completely convert the formaldehyde into CO2 and H2O at normal temperature under relative humidity of 50-90%. The catalyst has high catalytic-oxidizing activity and strong anti-moisture capability and is suitable for removal of the formaldehyde in a sealed or a semi-sealed space.

Owner:XI'AN PETROLEUM UNIVERSITY

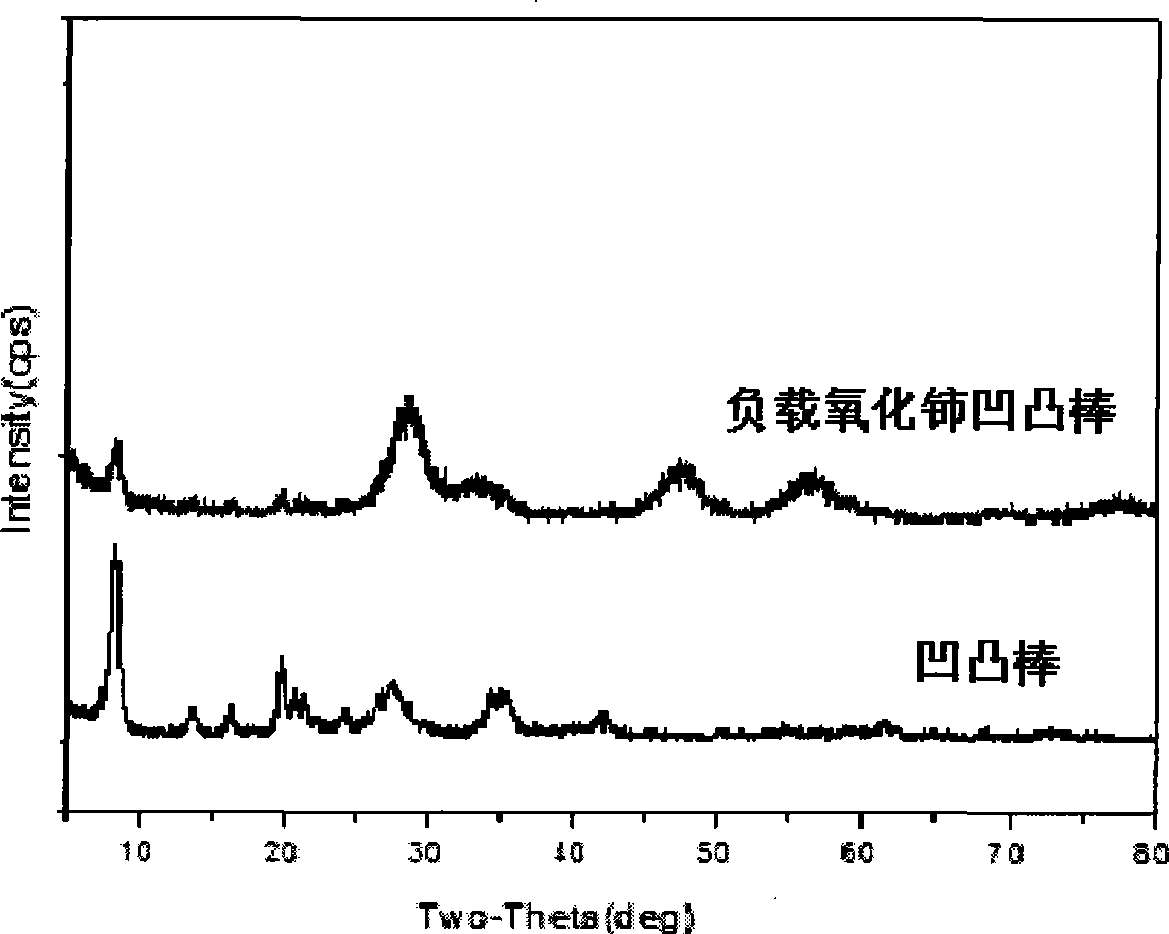

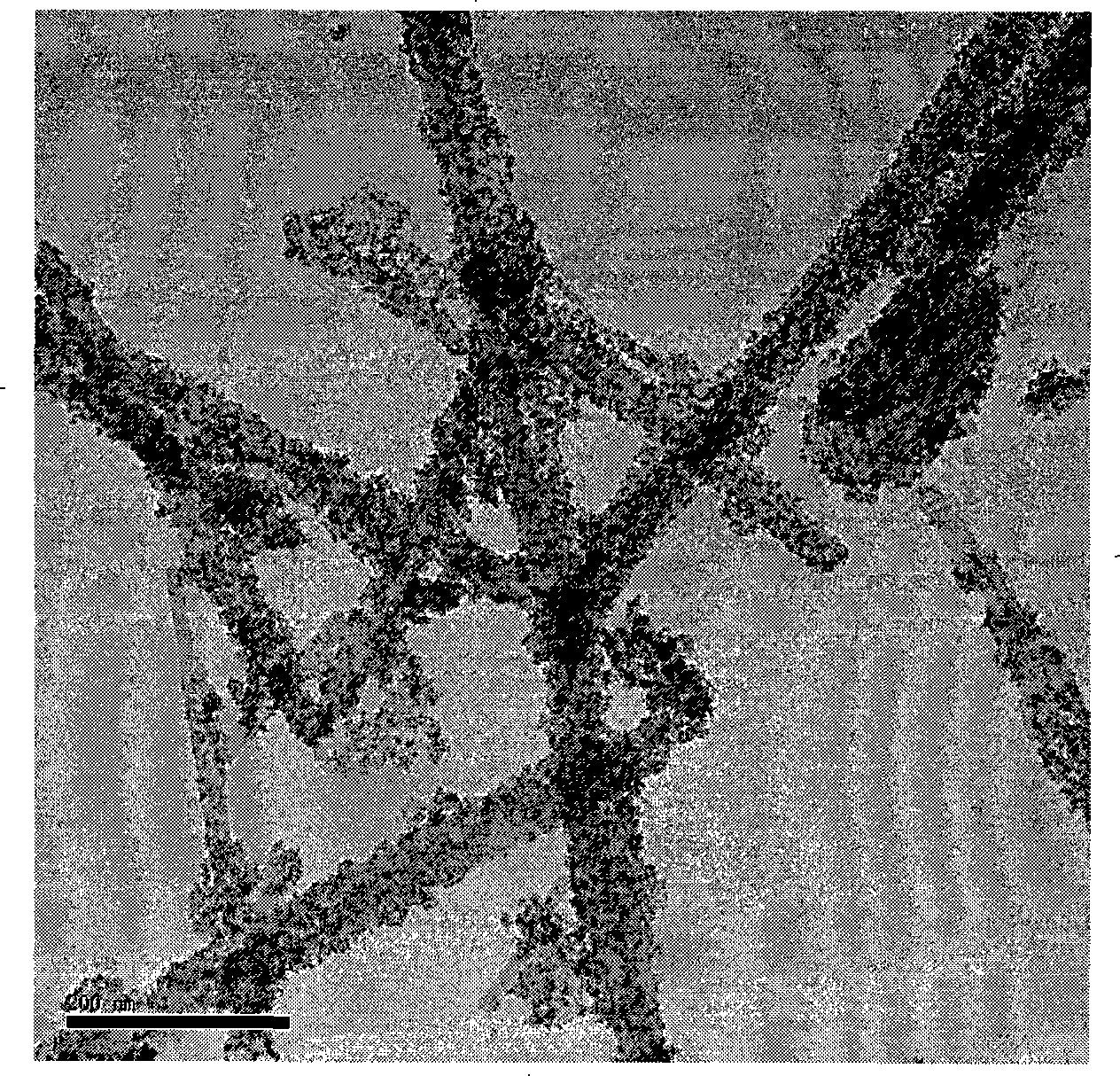

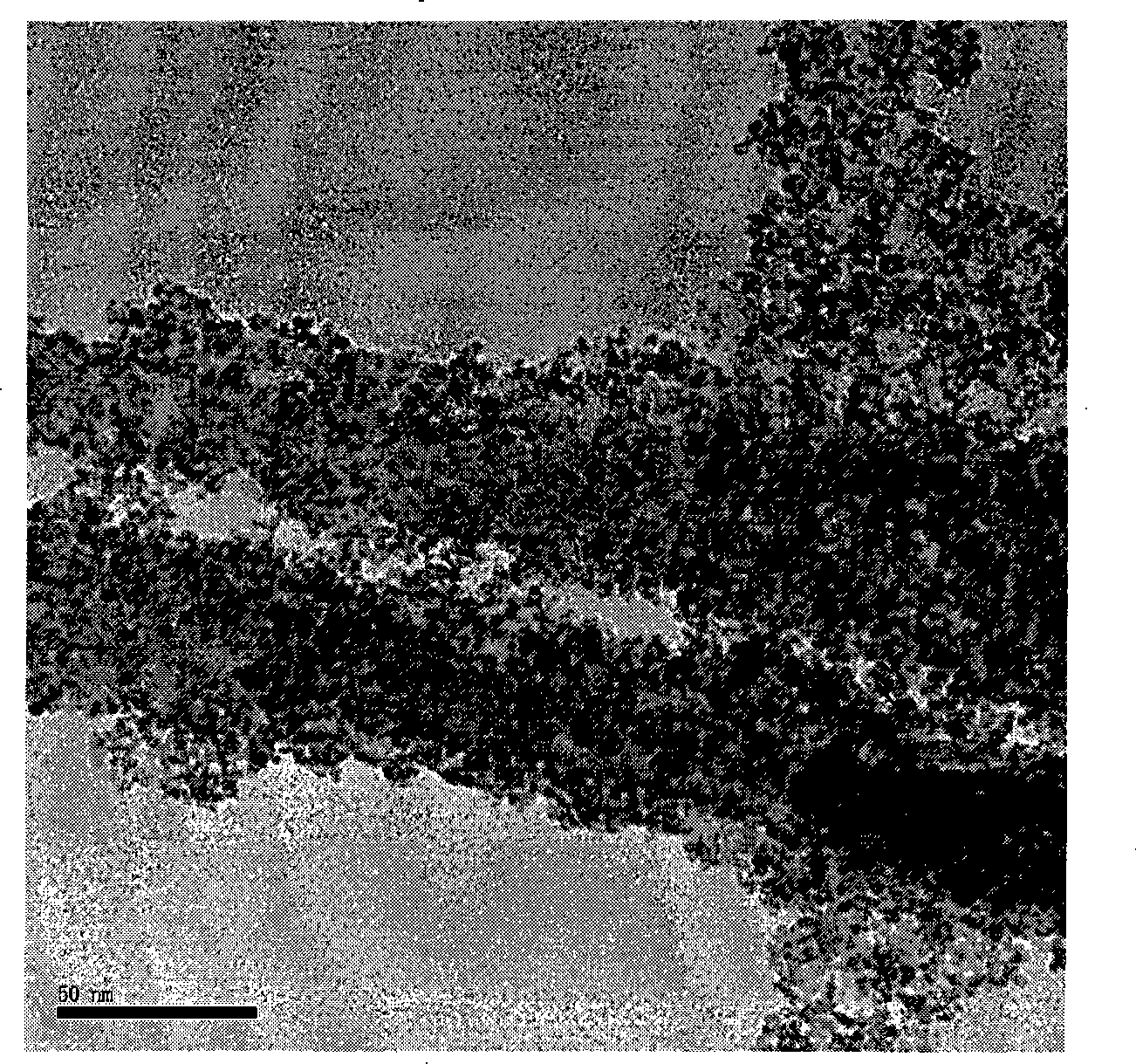

Method for preparing attapulgite loading with nano cerium oxide

ActiveCN101239308AAvoid uneven loadGood dispersionMetal/metal-oxides/metal-hydroxide catalystsWater bathsInorganic Chemical

The present invention provides a fine finishing of nonmetalic mineral resource and inorganic chemical industry field, characterized in that natural attapulgite clay is produced to sizing agent which solid content is about 10% after being pretreated by hydrochloric acid, a certain quality attapulgite clay and cerous salt are mixed to dissolve in the de-ionized water, the solution is evenly blended by electric mixer, wherein Ce3+ relative to the concentration range of solution is 0.001mol / l-0.5mol / l, the concentration range of the attapulgite clay is 2-50g / l; further adding a certain quality HMT, and mixing evenly, mol ratio of HMT and cerous salt is between 2:1-20:1; the blended solution is placed in the 70-100 Celsius water bath to react 1-5h under the mixing of the electric mixer, removing and cooling to the room temperature, calcining 1-5h under the temperature 200-700 Celsius after filtering, washing and drying, attapulgite powder loading nanometer cerium oxide is obtained. The attapulgite powder of the invention has a homogeneous load, better dispersivity, has no complex equipment, and less chemical material sorts, lower cost and better experiment repeatability.

Owner:溧阳常大技术转移中心有限公司

Nano-fiber membrane material capable of decomposing formaldehyde at normal temperature, and preparation method and application of same

ActiveCN109012164AImprove catalytic oxidation performanceLarge specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationPorosityFiber

The invention belongs to the technical field of removal of formaldehyde and discloses a nano-fiber membrane material capable of decomposing formaldehyde at normal temperature, and a preparation methodand an application of same. With carbonized MOFs being a formaldehyde catalyst, the material, compared with a conventional transition metal oxide, is large in specific surface area and high in porosity and has advantage of uniform dispersion of metal active components; compared with a conventional powdery formaldehyde catalyst, by using the nano-fiber membrane as a catalyst supporter, the productis uniform in catalyst particle distribution and is low in wind drag, so that the product is high in catalytic performance on the formaldehyde and also is long in service life. The room-temperature formaldehyde catalyst in the invention has excellent catalytic oxidization activity; compared with a formaldehyde catalyst in the prior art, at 25 DEG C, the product in the invention can reach more than 95% in catalytic conversion rate of the formaldehyde; after operation for 800 hours, the catalytic activity is not reduced, so that the product can satisfy present industrial demands better.

Owner:广州华园科技有限公司

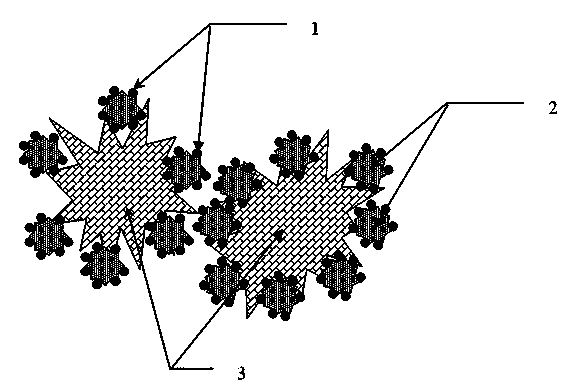

Catalyst for tail gas purification and preparation method thereof

InactiveCN103464152AGood dispersionImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCerium(IV) oxide

The invention provides a catalyst for tail gas purification and a preparation method of the catalyst for tail gas purification. The catalyst for tail gas purification comprises an alumina supporter, cerium dioxide borne on alumina and a precious metal active component borne on the surface of the cerium dioxide. The alumina supporter and the cerium dioxide are prepared according to the sediment hydrothermal method. The precious metal active component is borne according to the hydrothermal in-situ reduction sediment method. According to the catalyst for tail gas purification, the interaction between the cerium dioxide and a precious metal species is strong, the cerium dioxide supporter can generate more oxygen vacancies, oxygen molecules are activated and converted into a reactive oxygen species, and therefore the activity of catalytic oxidation is improved. Interspersion and mutual contact are conducted between the alumina and the cerium dioxide, the mutual insulation function is achieved, sintering with the single cerium oxide serving as a supporter can be avoided, and the thermal stability of the alumina at a high temperature is remarkably improved.

Owner:FUZHOU UNIV

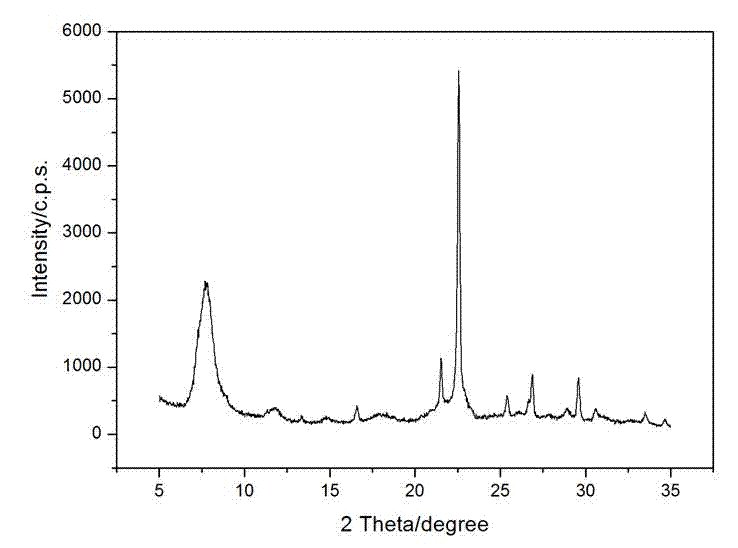

Modification method for titanium silicate molecular sieve

ActiveCN103539149AAdjust Ti distributionHigh catalytic oxidation activityOrganic chemistryMolecular sieve catalystsMolecular sieveAlcohol

The invention provides a modification method for a titanium silicate molecular sieve. The method comprises the steps of: evenly mixing an organic chelating agent-containing alkali solution and a titanium silicate molecular sieve according to a certain ratio, reacting in an airtight reaction kettle, filtering, washing, drying and calcinating the product to obtain the TS-1 molecular sieve which is modified with the organic chelating agent-containing alkali solution. By adopting the method, non-skeleton titanium can be reduced, even removed in the process of modifying the titanium silicate molecular sieve, so that the catalytic oxidation activity of the modified titanium silicate molecular sieve can be improved, especially, superior catalytic activity stability can be shown in reaction of olefin epoxidation, phenol hydroxylation, ketone ammoximation, alcohol oxidization and the like.

Owner:DALIAN UNIV OF TECH

Method for processing sulfur-containing waste lye

InactiveCN101143746ASimple preparation processHigh catalytic efficiencyMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationCatalytic oxidationPhthalocyanine

The invention relates to a processing method of sulfur containing waste alkali solution, which is in particular to a catalytic oxidation desulfurization method of the supported phthalocyanine cobalt. The sulfur containing waste alkali solution is processed by the method of the invention, which both avoids a second pollution caused by the direct discharging of the phthalocyanine cobalt into the water body, and improves the desulfurization effect of during the process of the sulfur containing waste alkali solution. The active carbon supported phthalocyanine cobalt has a higher catalytic oxidation activity, a simple process and a higher safety.

Owner:PETROCHINA CO LTD

Titanium silicon molecular sieve, synthetic method and applications thereof, and cyclic ketone oxidation method

ActiveCN107539998AImprove stabilityFacilitated DiffusionMaterial nanotechnologyMolecular sieve catalystsMolecular sieveSynthesis methods

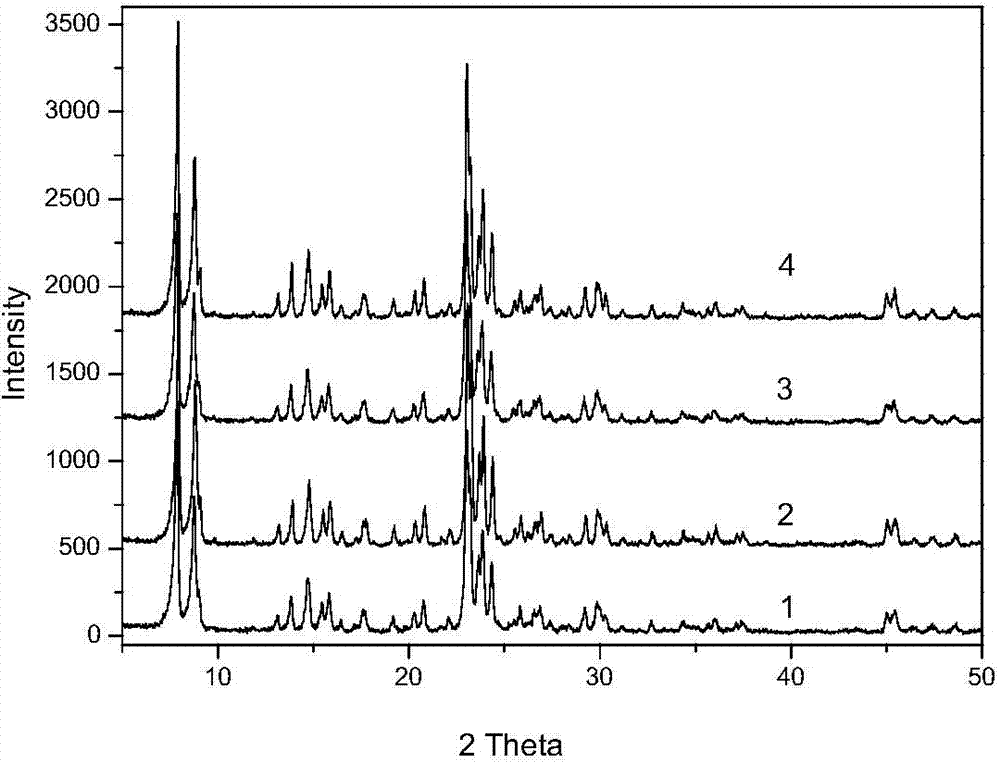

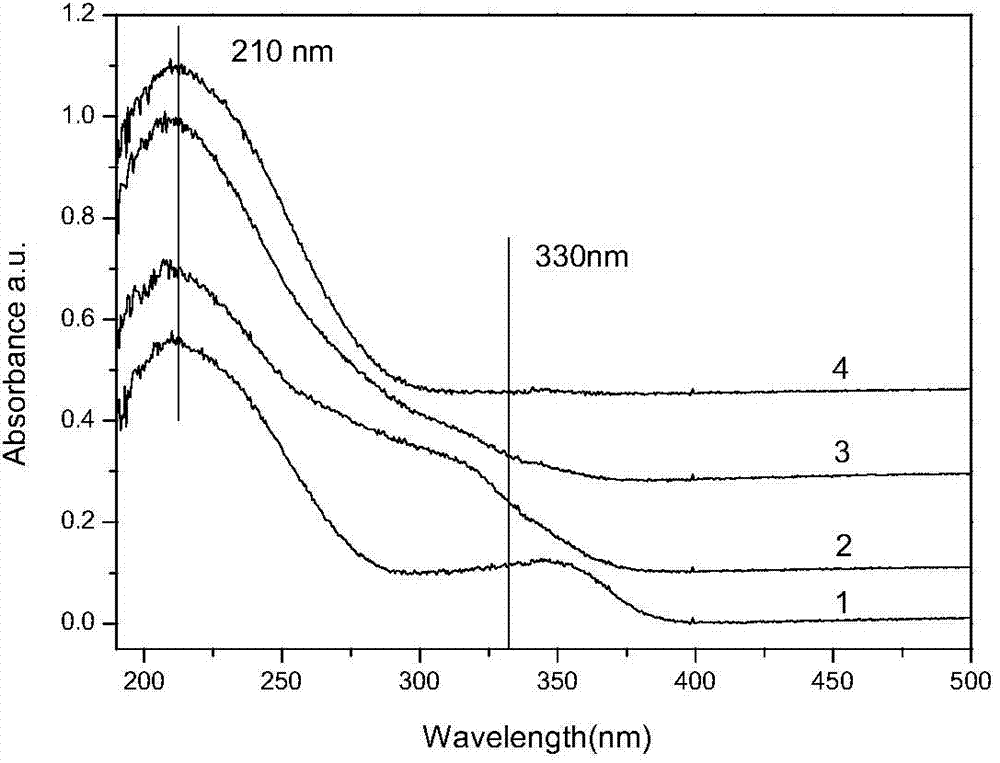

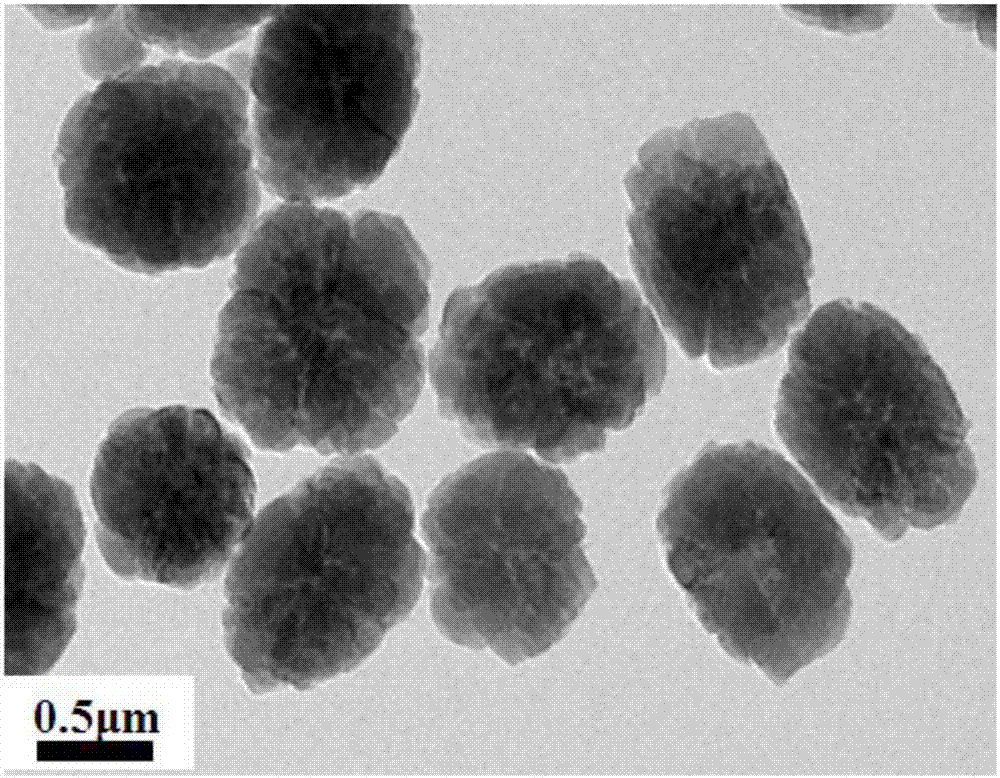

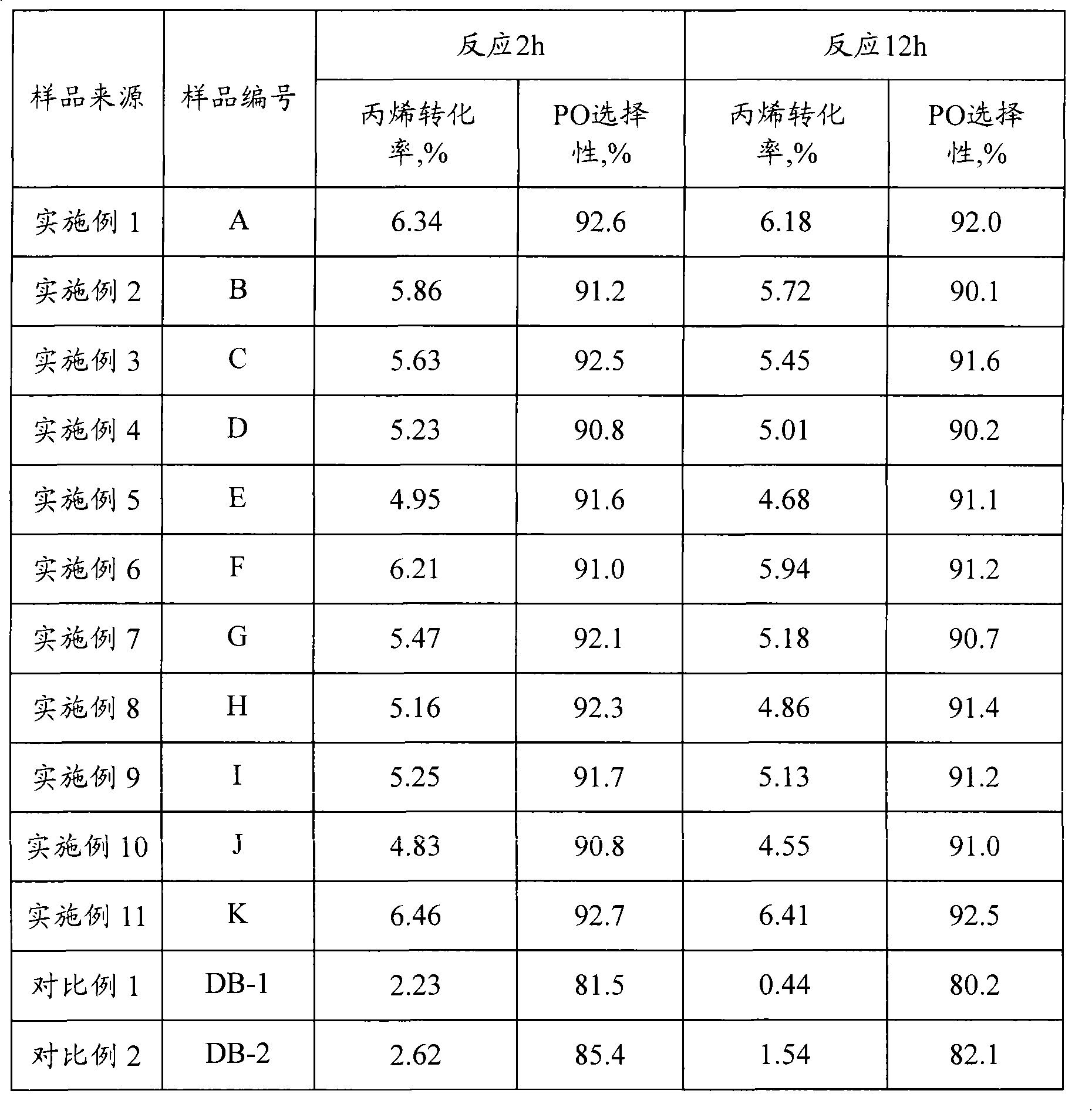

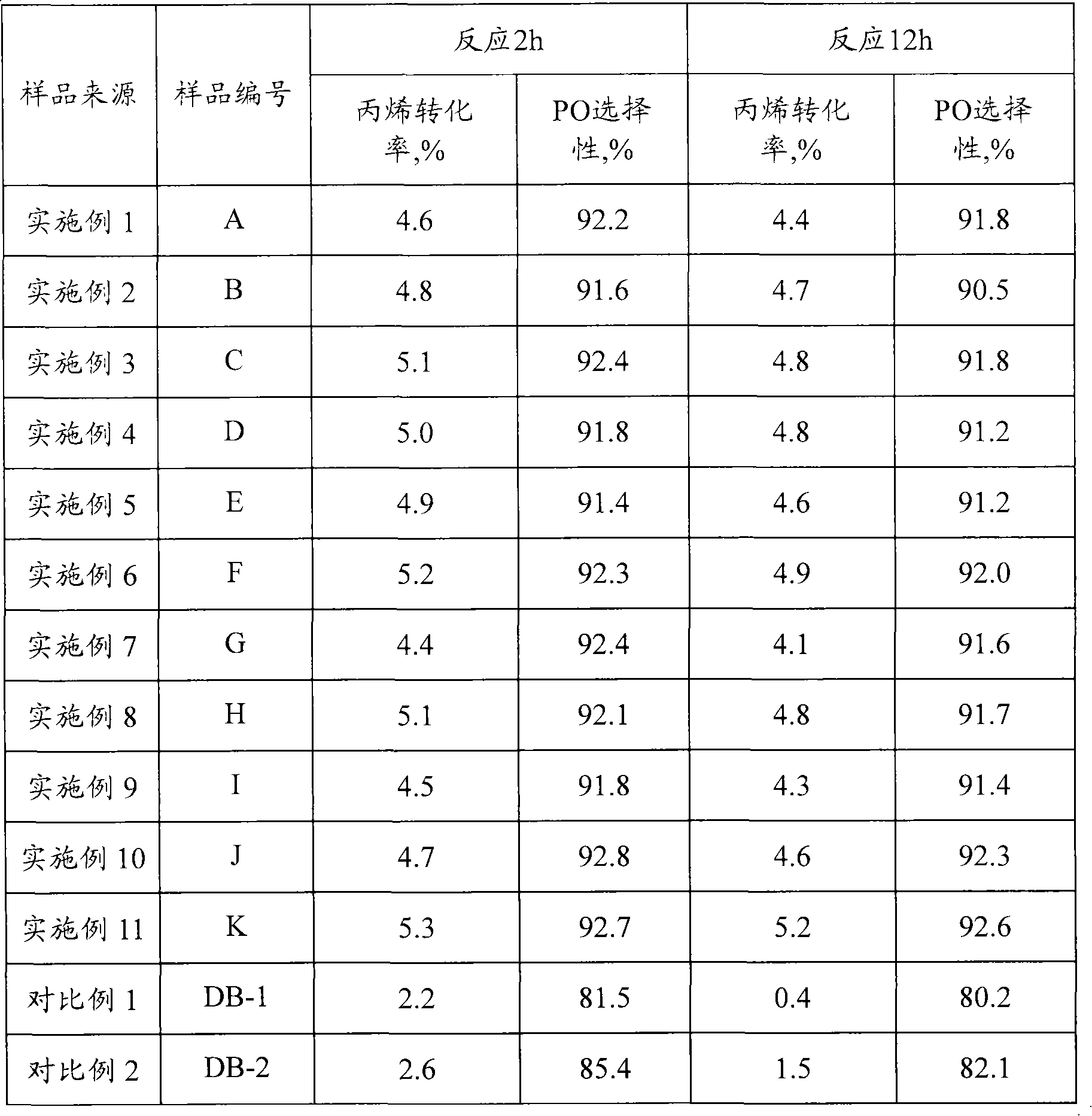

The invention belongs to the field of titanium silicon molecular sieve, and more specifically provides a titanium silicon molecular sieve, and a synthetic method and applications thereof. The titaniumsilicon molecular sieve is composed of crystal particles with a particle size ranging from 5 to 200nm via aggregation; the particle size of the titanium silicon molecular sieve ranges from 0.3 to 5<mu>m; the I960 / I550 value ranges from 0.7 to 0.85. The invention also provides a cyclic ketone oxidation method. The cyclic ketone oxidation method comprises a step of contact of cyclic ketone, and anoxidizing agent with a catalyst. The catalyst contains the titanium silicon molecular sieve. The crystal of the titanium silicon molecular sieve is high in I960 / I550 value, and is large in effective framework ti content. When the titanium silicon molecular sieve is used in oxidation reaction, the catalytic oxidation activity, and the reaction product selectivity are increased obviously, and excellent catalytic stability is achieved. The titanium silicon molecular sieve is capable of realizing aggregation of small crystal particles in crystallization growth process instead of simple physical aggregation of the small crystal particles, and micron order is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method for titanium-silicon molecular sieve

ActiveCN101537372ATotal Titanium IncreasedHigh catalytic oxidation activityMolecular sieve catalystsHydrazine compoundCyclodextrin

A modification method for a titanium-silicon molecular sieve comprises the following steps of mixing the titanium-silicon molecular sieve, a titanium source, a protective agent, an alkali source, a noble metal source, a reducing agent and water according to the proportion of 100:(0.001-1):(0.0001-5):(0.005-5):(0.005-10):(0.005-20):(500-10,000), and carrying out hydro-thermal treatment, wherein the protective agent is selected from one or more of polybenzimidazole, polypropylene, polyethyleneglycol, polystyrene, polyvinyl chloride, polyethylene and derivatives thereof, an anionic surfactant, a cationic surfactant, a non-ionic surfactant, glucose and cyclodextrin; and the reducing agent is selected from one or more of hydrazine, borohydride and sodium citrate. The titanium-silicon molecular sieve prepared by the method has high content of framework titanium and has high oxidation activity and selectivity as well as good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for modifying titanium-silicon molecular sieve

ActiveCN101618338AOvercome the disadvantages of aggregationHigh catalytic oxidation activityOrganic chemistryMolecular sieve catalystsMolecular sieveInorganic Chemical

The invention provides a method for modifying a titanium-silicon molecular sieve, and belongs to the technical field of inorganic chemicals and the synthesis of inorganic chemicals. The method comprises the following steps of: adding the titanium-silicon molecular sieve, a protective agent and a noble metal source in a solution containing organic amine, evenly mixing the mixture, adding a hydrating solution of silicon in the mixing solution and evenly mixing the mixed solution, putting the mixedsolution in a reaction kettle for hydro-thermal treatment, and recycling the sieve. The titanium-silicon molecular sieve modified by the method has obviously high catalytic oxidation activity, selectivity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for modifying titanium silicon molecular sieve

InactiveCN101591024AEasy to operateEasy to controlCrystalline aluminosilicate zeolitesMolecular sieveCatalytic oxidation

The invention discloses a method for modifying a titanium silicon molecular sieve, which comprises the following steps: evenly mixing the titanium silicon molecular sieve, fluorine-containing compounds, acid and water to form a reaction mixture, reacting the reaction mixture for 5 to 20 hours at the temperature of between 70 and 110 DEG C, and filtering, washing, drying and roasting the reaction product to obtain the modified titanium silicon molecular sieve. The method can effectively and selectively remove non-framework Ti species in the titanium silicon molecular sieve and change the hydrophilicity and hydrophobicity on the surface of the titanium silicon molecular sieve at the same time, and the catalytic oxidation activity of the obtained modified titanium silicon molecular sieve is greatly increased.

Owner:EAST CHINA NORMAL UNIV

Load type nano gold catalyst for preparing lactone by catalyzing air oxidation alpha, omega-diol and preparation method thereof

InactiveCN101683619AImprove conversion rateHigh selectivityOrganic chemistryChemical recyclingChemical industryGold particles

The invention belongs to the technical field of the chemical industry, which relates to a load type nano gold catalyst for preparing lactone by catalyzing air oxidation alpha, omega-diol. The invention adopts nano iron oxide as a carrier of a gold catalyst, the iron oxide is synthesized by a hydrothermal method, and nano iron oxide carriers with different crystal types and patterns can be preparedby calcination. The gold catalyst is prepared by a precipitation settling method, the prepared catalyst has small gold particles and good dispersivity, the interaction of gold and the carrier is strong, the gold catalyst represents an excellent activity in the preparation of gamma-butyrolactone by the direct oxidation of 1,4-butanediol through catalyzing air and the preparation of delta-valerolactone by oxidizing 1,5-pentanediol and conforms to the requirement of green chemistry, and the generation of lactone by oxidizing alpha, omega-diol in one step is realized. A magnetic iron oxide carrier can be obtained by selecting a proper preparation method, and the invention is convenient to separate and recover the catalyst and has better industrial application prospect.

Owner:FUDAN UNIV

Method for modifying titanium silicate molecular sieve material

ActiveCN101658798AImprove catalytic oxidation performanceHigh catalytic oxidation activityMolecular sieve catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMolecular sieveReducer

The invention discloses a method for modifying a titanium silicate molecular sieve material. In the method, titanium silicate molecular sieves, a reducer, a precious metal source and a protective agent are added into water, the mixture is mixed and stirred at 0 to 100 DEG C, and the product is recovered. The method is improved on the basis of the conventional loading process and is simple and easily implementable in operation, and the product obtained by the method is high in activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for producing propenal with direct oxidation of propylene and method of producing the same

InactiveCN101402044AProduce moreHigh selectivityOrganic compound preparationCarbonyl compound preparationPotassiumAcrolein

The invention relates to a catalyst for producing acrolein through direct oxidation of propylene, which is obtained by kneading, molding, drying and baking a cesium-containing catalyst (I) and a potassium-containing catalyst (II) which are mixed according to the mass percentages of between 10 and 50 percent of the catalyst (I) and to between 50 and 90 percent respectively. The catalysts (I) and (II) are as follows: the catalyst (I) comprises Moa, Wb, Bic, Fed, (Co and / or Ni)e, Sif, Csg, an Ox, while the catalyst (II) comprises Moa, Wb, Bic, Fed, (Co or / and Ni)e, Sif, Kg, and Ox, wherein the subscripts a, b, c, d, e, f, g, and x are atomic numbers of corresponding elements, and a is between 10 and 12, b is between 0 and 2, a plus b is equal to 12, c is between 0.5 and 2, d is between 0.5 and 2, e is between 3 and 6, f is between 1 and 3, g is between 0.01 and 0.3, and x is the summation of oxygen atomic numbers of oxides of the corresponding elements. The one-way conversion rate of the propylene for the catalyst for the propylene is more than or equal to 97 percent, and the one-way yield of the acrolein is more than or equal to 85 percent.

Owner:重庆紫光海力催化剂有限公司

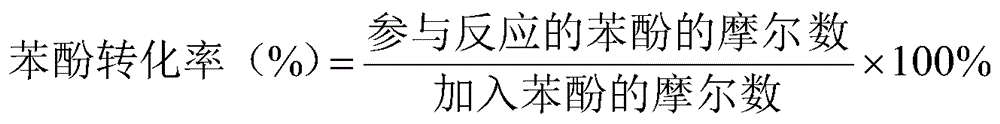

Method for oxidizing phenol

ActiveCN102757301AHigh selectivityLow costOxygen-containing compound preparationMolecular sieve catalystsCatalytic oxidationTitanium

The invention provides a method for oxidizing phenol. The method comprises the following steps of: making phenol and hydrogen peroxide contact with a catalyst under an oxidizing reaction condition, and is characterized in that: the catalyst contains titanium silicalite and a multi-metal oxygen-containing acid and / or multi-metal oxysalt. The method has the advantages of adoption of an environment-friendly synthesizing process, environment friendliness, low cost, no need of adding any inhibitor or initiator, no requirement on special production equipment, simple production process, easiness for controlling and contribution to industrial production and application. Moreover, the method has high catalytic oxidation activity and high benzoquinone selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

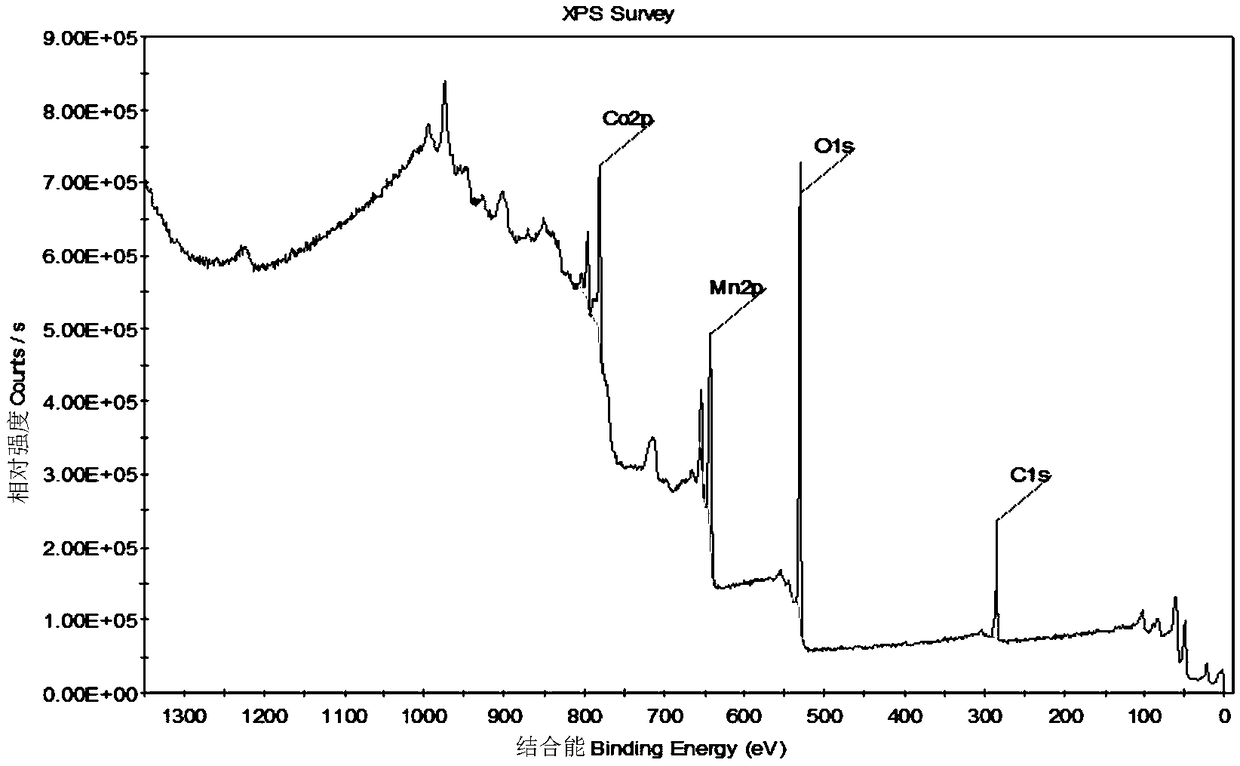

Mn/Co-based low-temperature SCO catalyst and preparation method thereof

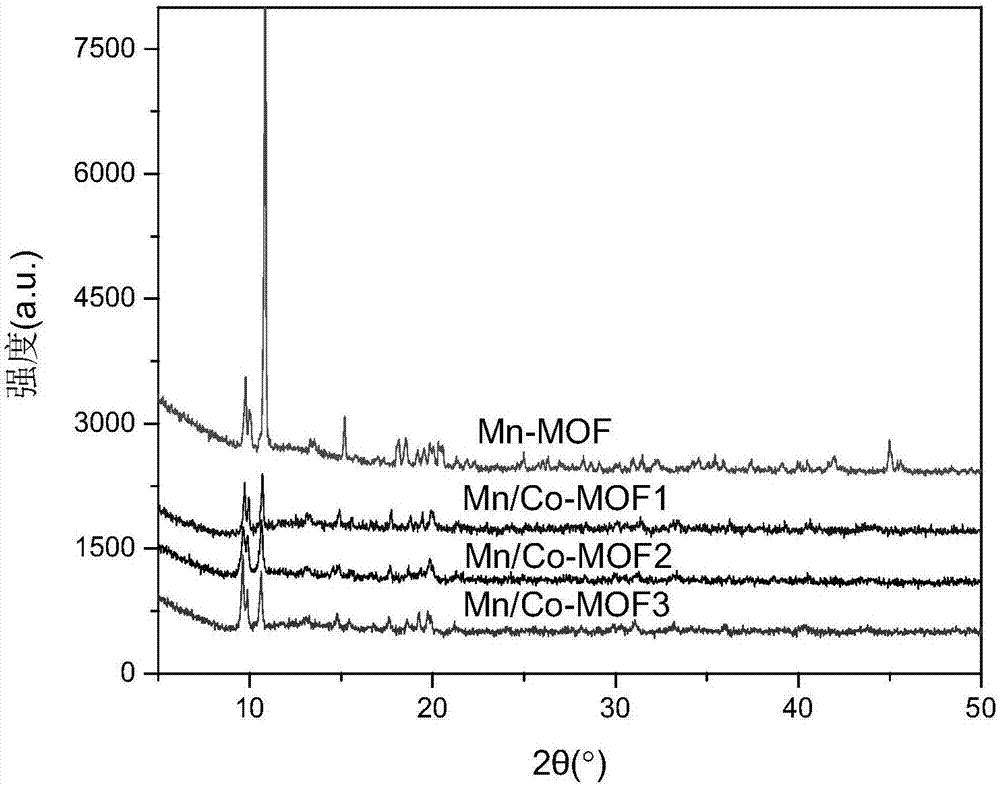

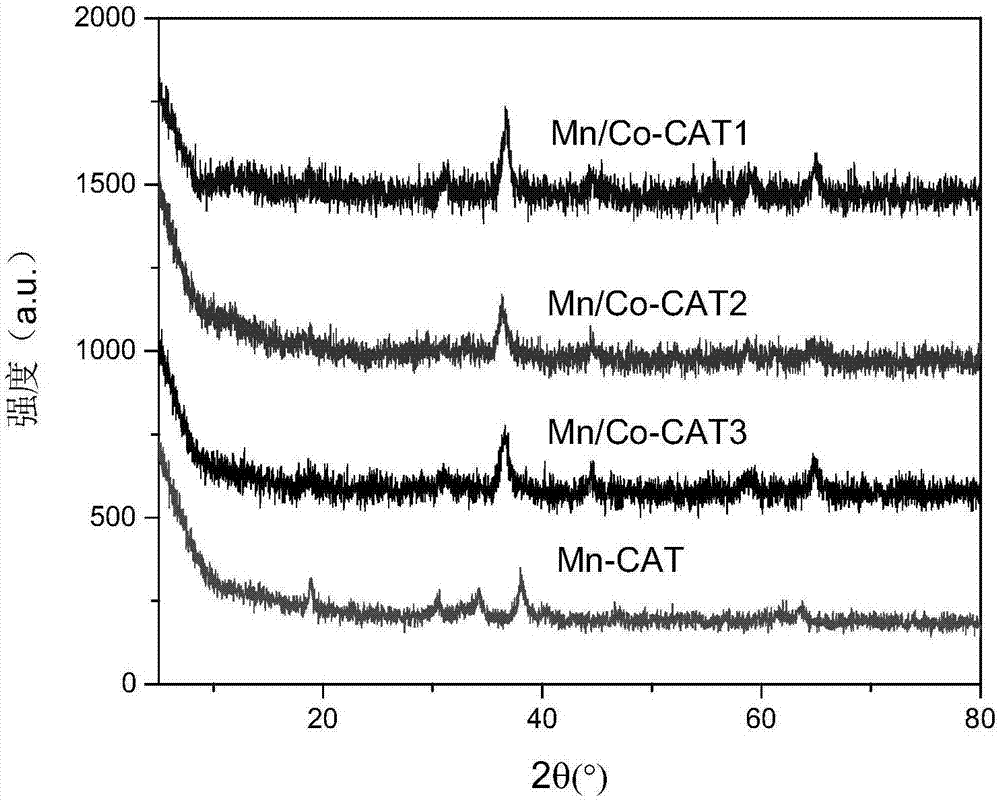

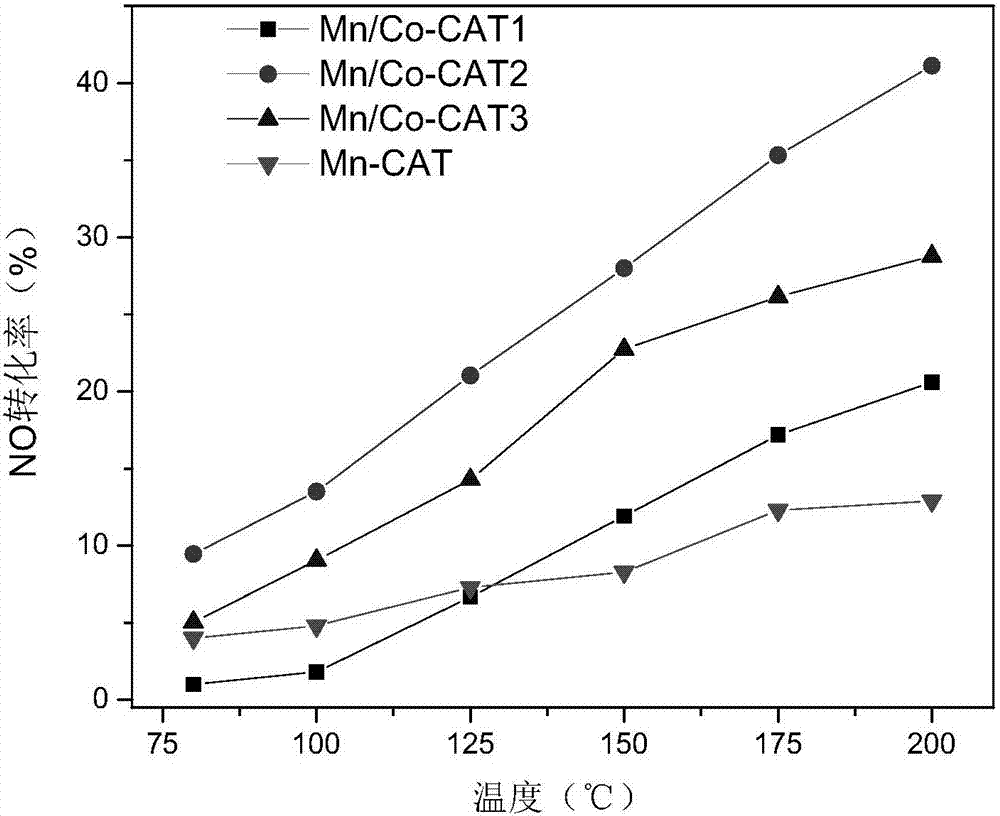

ActiveCN107362807AHigh porosityStable structureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseMetal-organic framework

The invention discloses a Mn / Co-based low-temperature SOC catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving manganese-containing metal salt and cobalt-containing metal salt in dimethylformamide, adding an organic ligand and water, and magnetically stirring and uniformly mixing the components to obtain a mixed solution; and (2) carrying out hydrothermal reaction on the obtained mixed solution in a reactor, reacting to obtain Mn / Co double-metal organic framework crystal, soaking the Mn / Co double-metal organic framework crystal in the dimethylformamide and activating the Mn / Co double-metal organic framework crystal, and then purifying, filtering and roasting the activated crystal to obtain the Mn / Co-based low-temperature SCO catalyst. The Mn / Co-based low-temperature SCO catalyst has good low-temperature denitration activity. Compared with an existing low-temperature denitration catalyst, the Mn / Co-based low-temperature SOC catalyst has the advantages that the conversion rate of catalyzed NO is greatly increased, at the low temperature of 150-200 DEG C, the catalyzed conversion rate of NO can reach 50% or above, and existing industrial requirements can be met.

Owner:SOUTH CHINA UNIV OF TECH

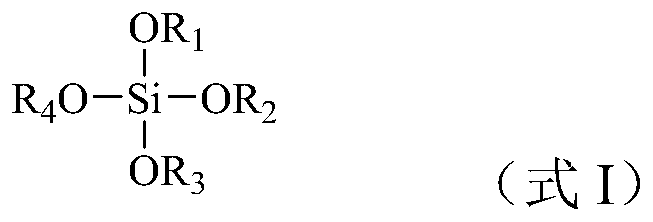

Stepped-type crystallization preparation method of titanium-containing molecular sieve

ActiveCN103864093AReduce dosageShort hydrothermal crystallization timeOrganic chemistryMolecular sieve catalystsMolecular sieveTitanium

The invention relates to a synthesis method of a titanium-containing molecular sieve, and particularly relates to a method for preparing a titanium-containing molecular sieve by adopting a stepped crystallization also called as a lattice vacancy filling method. The invention provides a method for fast preparing a TS-1 molecular sieve, which is simple and feasible and relatively low in cost. According to the technical scheme, the stepped crystallization preparation method of the titanium-containing molecular sieve comprises the following steps: 1, sufficiently hydrolyzing a tetrapropylammonium hydroxide solution added with an inorganic silicon source to prepare gel; 2, transferring the gel to a sealed reaction kettle, carrying out pre-crystallization to prepare a pure silicon molecular sieve guiding agent, then slowly dropwise adding a titanium source to the pure silicon molecular sieve guiding agent, and continuously pre-crystallizing for 1-6 hours to obtain a mixture to be crystallized; 3, crystallizing the mixture to be crystallized, controlling the temperature to rise to 160-200 DEG C, and carrying out hydrothermal crystallization for 6-48 hours to obtain the titanium-containing molecular sieve.

Owner:TAIYUAN DACHENG ENVIRONMENTAL ENERGY CHEM TECH

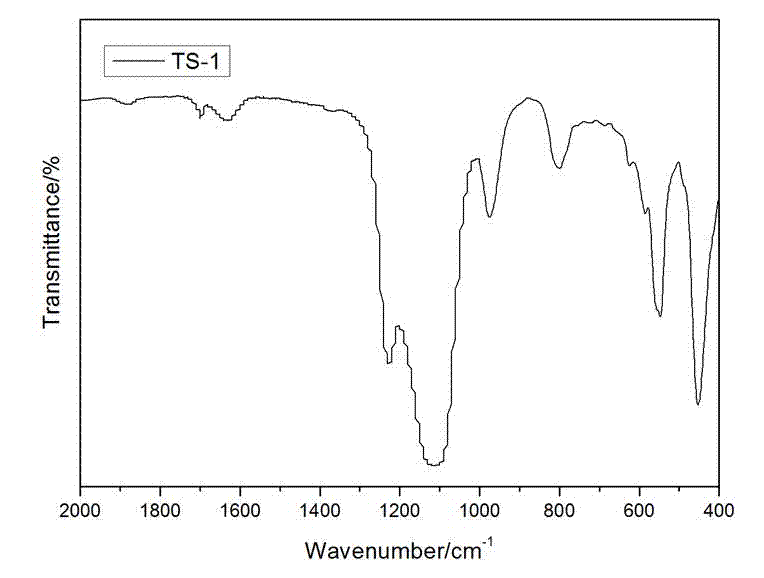

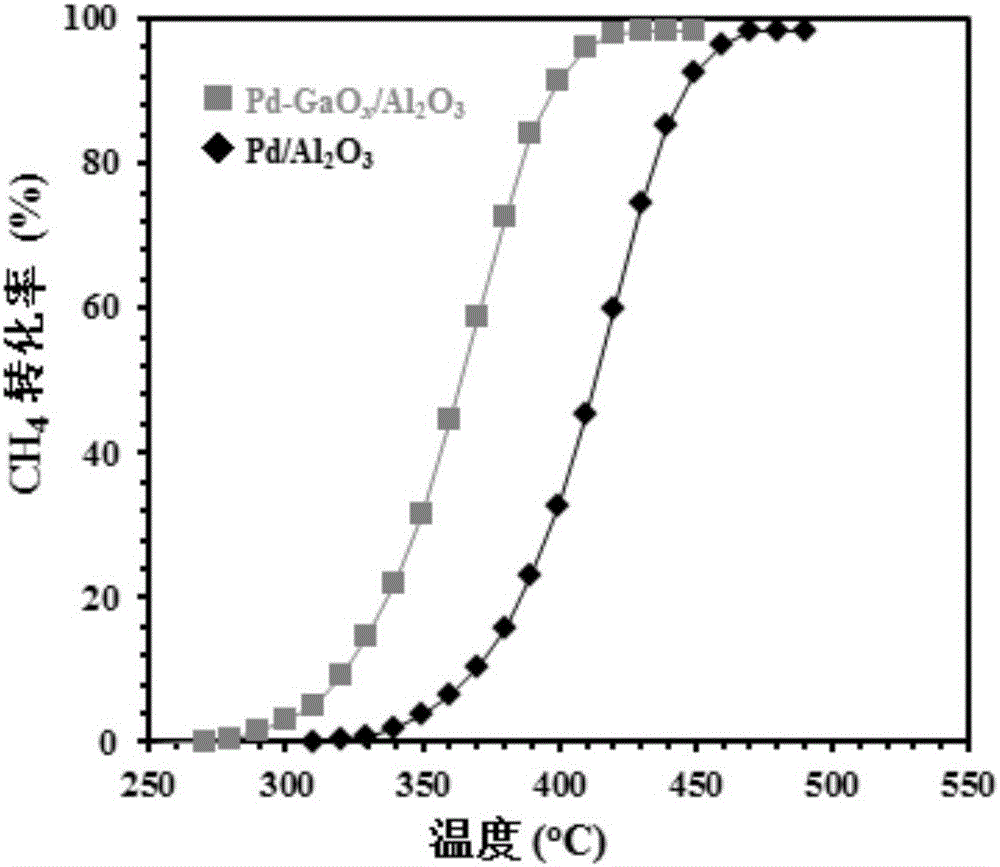

Palladium gallium oxide double-metal nano-catalyst capable of efficiently catalyzing methane to combust and preparation

InactiveCN106693987AUniform particle sizeGood size controlHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsNano catalystMetal particle

The invention provides a palladium gallium oxide double-metal nano-catalyst capable of efficiently catalyzing methane to combust and preparation and belongs to the technical field of functional materials. PdGa double-metal nano-particles are loaded on a gamma-Al2O3 carrier, and then the carrier is fired to form a Pd-GaOx / Al2O3 catalyst. The loading amount of metal palladium is 1.0wt%. A preparation method comprises the following steps: simultaneously reducing palladium acetylacetonate and gallium chloride in an oleylamine system by adopting a liquid-phase co-reduction method, so as to form PdGa double-metal particles with a uniform size; loading the metal particles on an Al2O3 carrier by adopting an immersion method, wherein the Pd loading amount is 1.0wt%; and firing a load type catalyst at 450 DEG C to form the Pd-GaOx / Al2O3 nano-catalyst. The Pd-GaOx / Al2O3 nano-catalyst prepared by the invention has the advantages that a preparation process is simple, the size of the nano-particles is uniform, and the nano-catalyst has a good application prospect in the field of catalysis.

Owner:BEIJING UNIV OF TECH

Method for synthesizing titanium silicon zeolite material

ActiveCN101935052ALow cost of preparationGood reproducibilityCrystalline aluminosilicate zeolitesTitaniumAqueous solution

The invention relates to a method for synthesizing a titanium silicon zeolite material, which comprises the following steps of: adding all silicone zeolite and / or boron silicon zeolite in an alkaline aqueous solution, mixing uniformly, adding a titanium source, mixing uniformly, treating under hydro-thermal treatment conditions, and recovering the products to obtain the titanium silicon zeolite material. The method has the characteristics of low cost and good repeatability. Compared with the prior art, the obtained zeolite material has high oxidative activity in an oxidizing reaction and good selectivity of the target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Smoke denitration catalyst by catalytic oxidation, and preparation method thereof

ActiveCN102188979AHigh catalytic oxidation activityGood tolerance to sulfuric waterDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationCopper nitrate

The invention discloses a smoke denitration NO (Nitric Oxide) oxidation catalyst by catalytic oxidation, and a preparation method thereof. The NO oxidation catalyst is prepared from titanium crosslinking clay as a carrier and copper oxide and vanadium oxide as active ingredients, wherein the titanium crosslinking clay carrier is prepared by taking acetone as a dispersing agent and crosslinking and aging titanic acid butyl acetate and sodium base montmorillonite turbid liquid under an acid condition. Copper nitrate and ammonium metavanadate solutions are used as the precursors of the active ingredients, are fixed on the carrier by an immersion method, and are dried and calcined by program heating to obtain the smoke denitration catalyst by catalytic oxidation. In the catalyst, the copper capacity is 2-10%, and the vanadium capacity is 0.5-5%. The smoke denitration catalyst by catalytic oxidation has the advantages of good sulfur and water tolerance, good reproducibility and good denitration effect.

Owner:BEIJING UNIV OF CHEM TECH

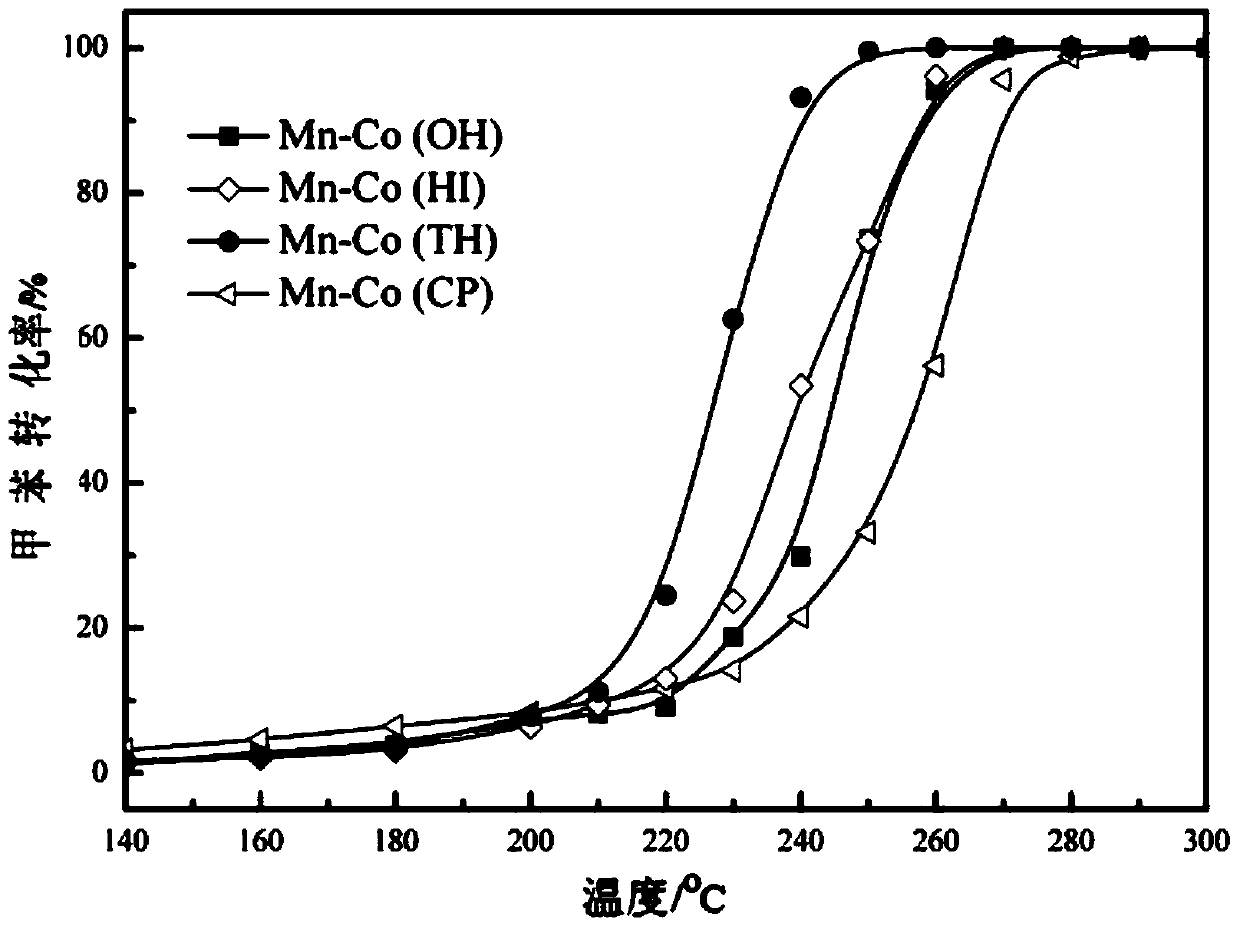

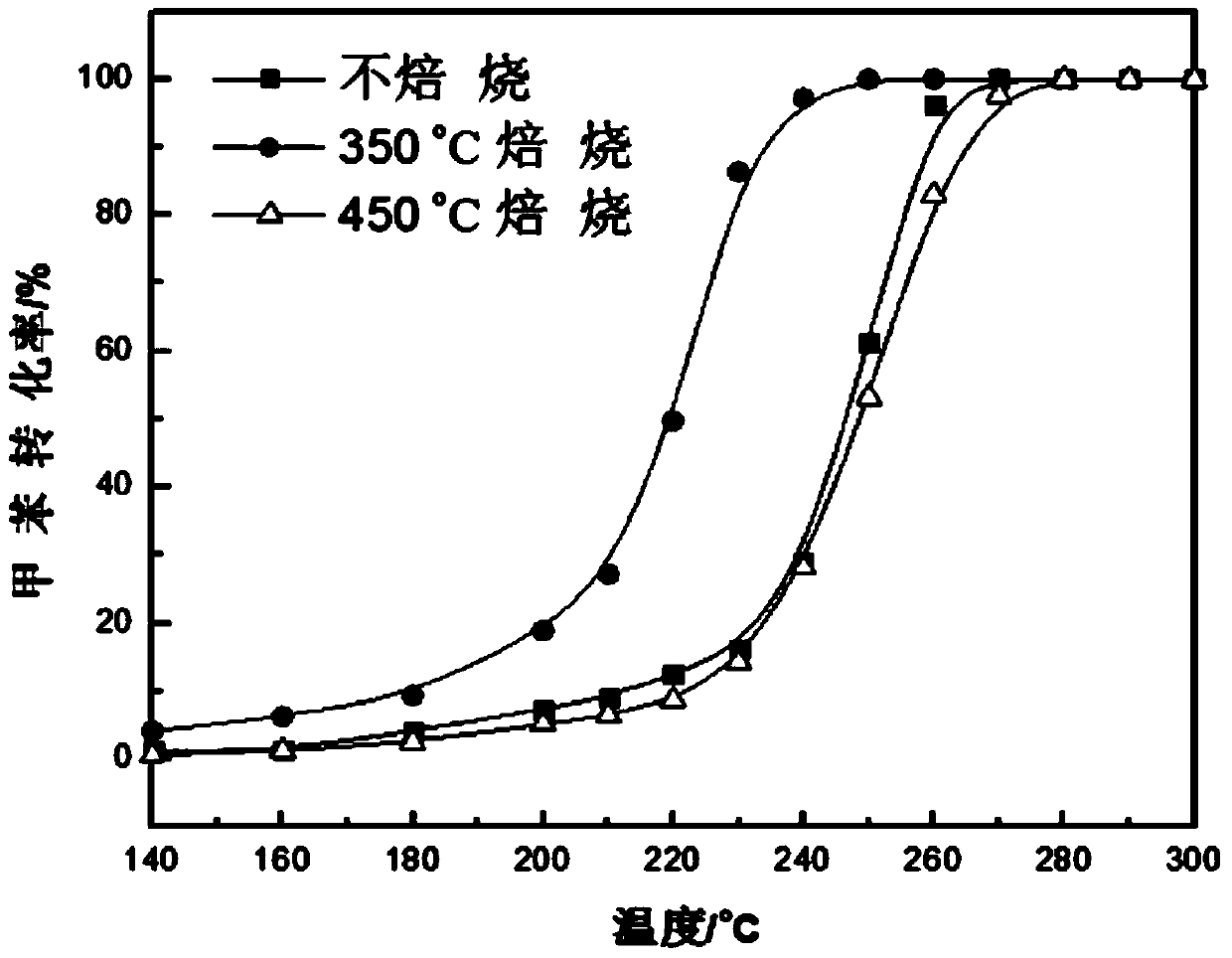

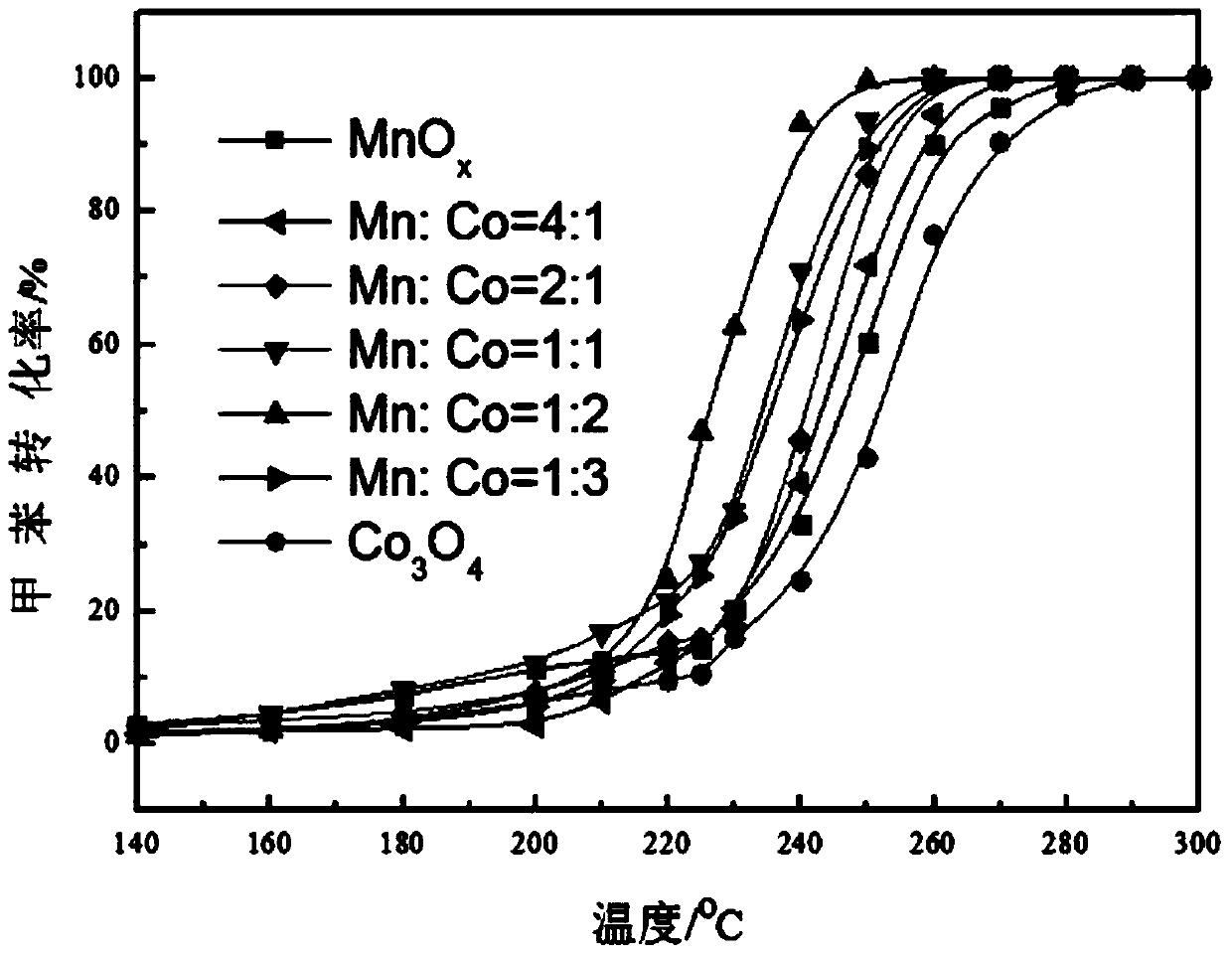

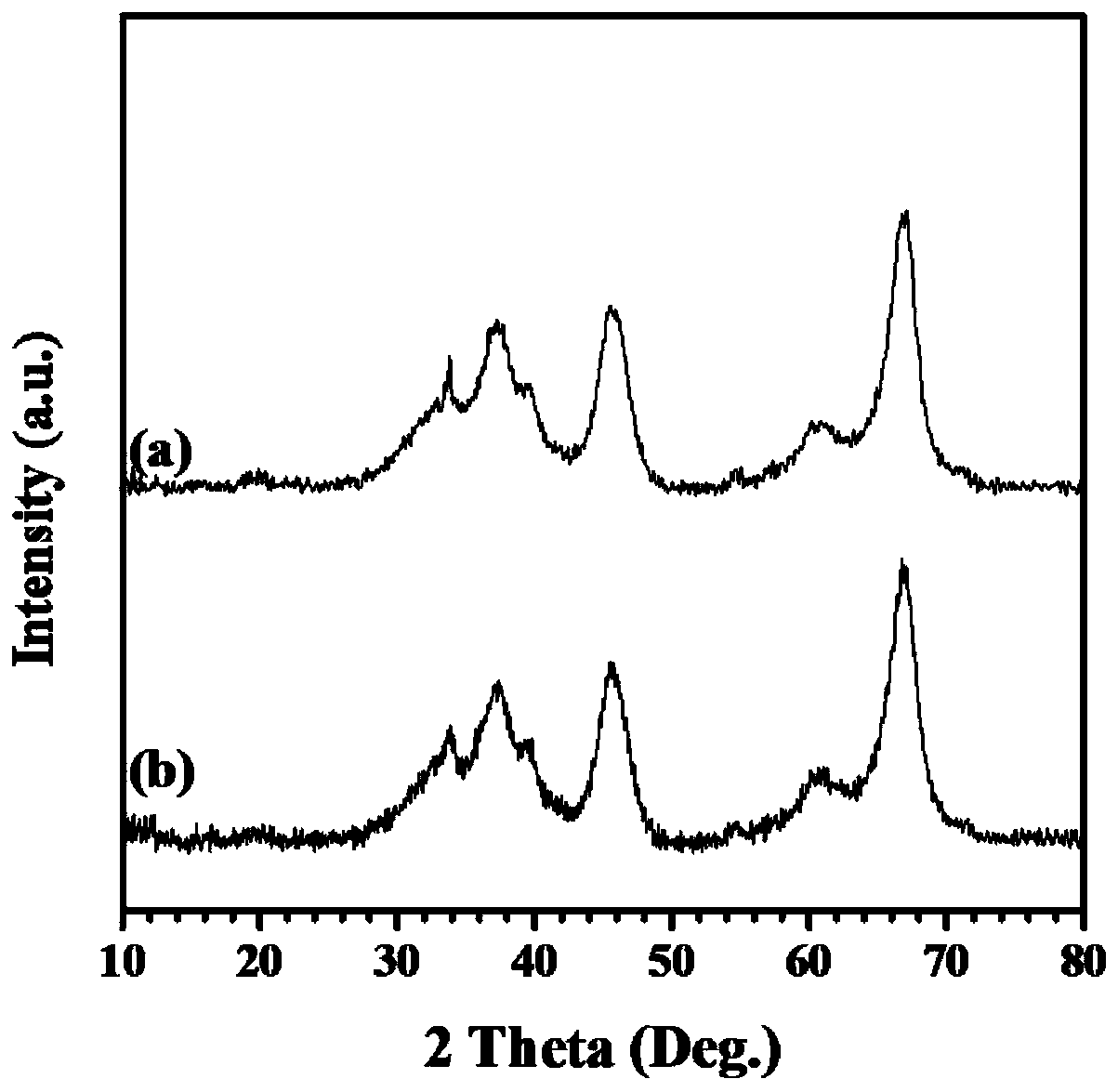

Manganese-cobalt nanocrystalline catalyst for catalytic oxidation of methylbenzene as well as preparation method and application thereof

InactiveCN104190435AImprove stabilitySimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPorosityCatalytic oxidation

The invention belongs to the field of inorganic nano catalytic materials and relates to a manganese-cobalt nanocrystalline catalyst for catalytic oxidation of methylbenzene as well as a preparation method and application thereof. The manganese-cobalt nanocrystalline catalyst comprises Mn3O4, Co3O4 and a Mn-Co solid solution, wherein the molar ratio of Mn to Co in the active ingredients is (4:1)-(1:4) and Mn-Co oxide is presented in a highly sparse and porous cotton-shaped big grain form. The preparation method is a two-step hydrothermal synthesis method which comprises preparation of nanocrystalline Mn3O4 and preparation of a manganese-cobalt nanocrystalline catalyst. According to the invention, the prepared manganese-cobalt nanocrystalline catalyst is presented in a cotton-shaped big grain structure of high sparseness and porosity, is uniform and regular in nanocrystalline form and has a high specific surface area and wide application prospect as a methylbenzene removal catalyst with high activity and stability.

Owner:DALIAN UNIV OF TECH

Method for synthesizing crotonic acid by oxidizing croton aldehyde selectively

InactiveCN101003472AEasy to manufactureLow costPhysical/chemical process catalystsOrganic compound preparationPhosphomolybdic acidCrotonaldehyde

This invention relates to a method for synthesizing crotonic acid by selective oxidation of crotonaldehyde. The method adopts crotonaldehyde as the raw material, acetone, acetic acid, benzene or toluene as the solvent, phosphomolybdic acid as the main catalyst, and V2O5 as the cocatalyst, and reacts at 30-100 deg.C and 0.3-0.9 MPa in the presence of O2 to obtain crotonic acid. Phosphomolybdic acid can be supported by such carriers as active carbon, SiO2, gamma-Al2O3 or molecular sieve. Therefore, the catalyst can be separated from the reaction solution by filtration, and dried in air at 120 deg.C for recycling. The supported catalyst has such advantages as simple preparation, high catalytic activity, high selectivity, and high stability, and can be used repeatedly.

Owner:SINOPEC YANGZI PETROCHEM

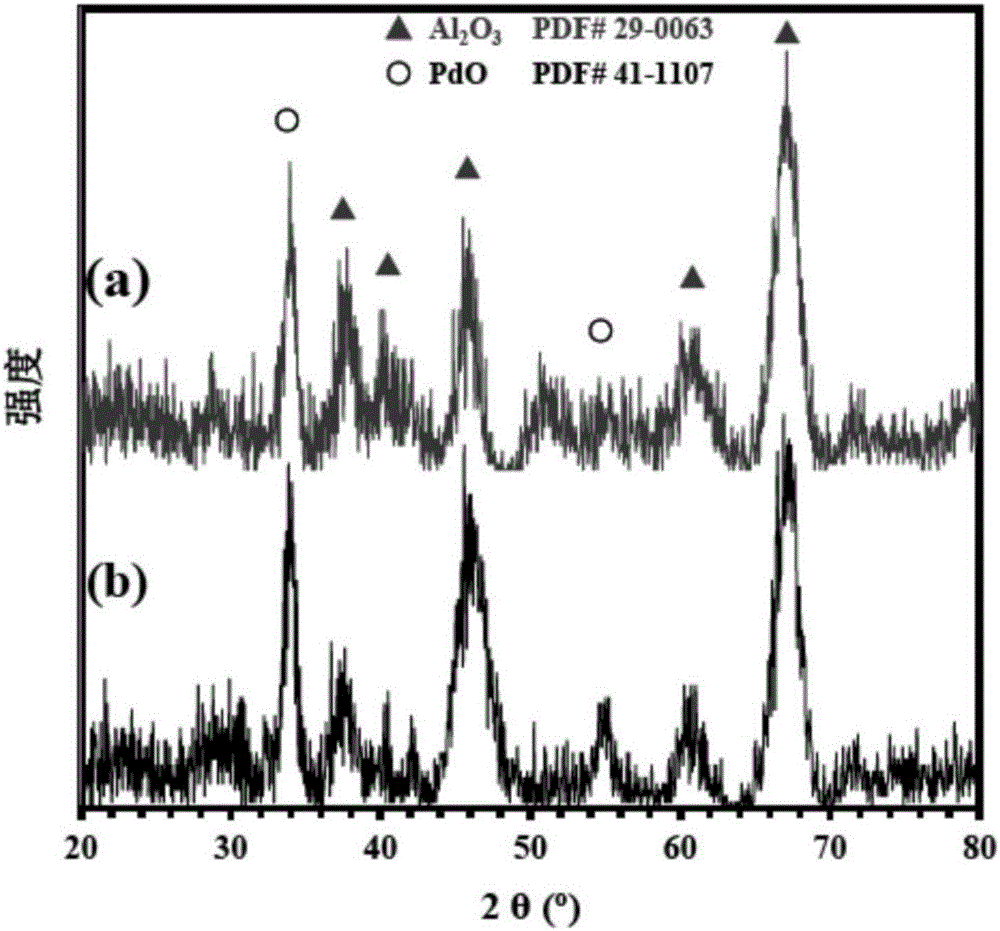

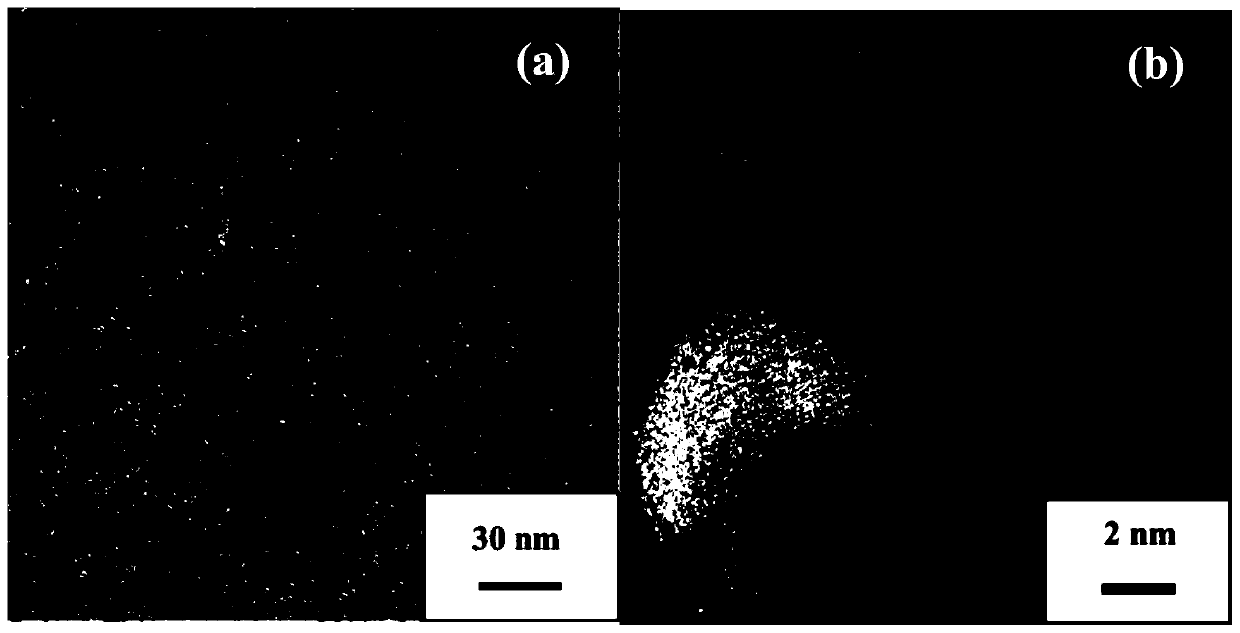

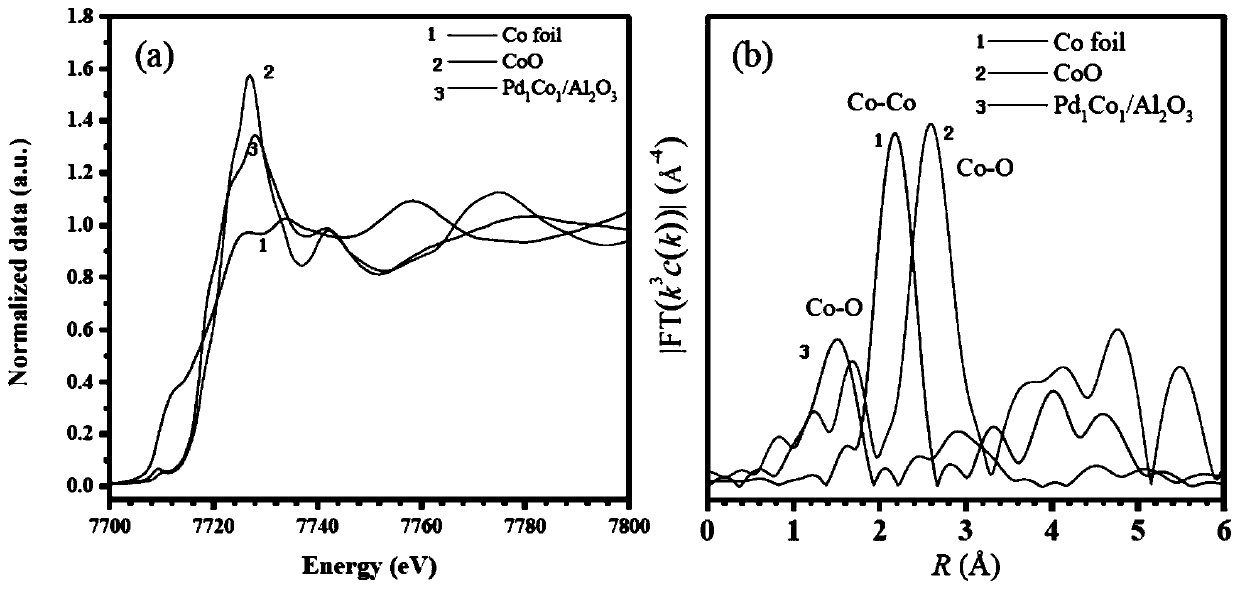

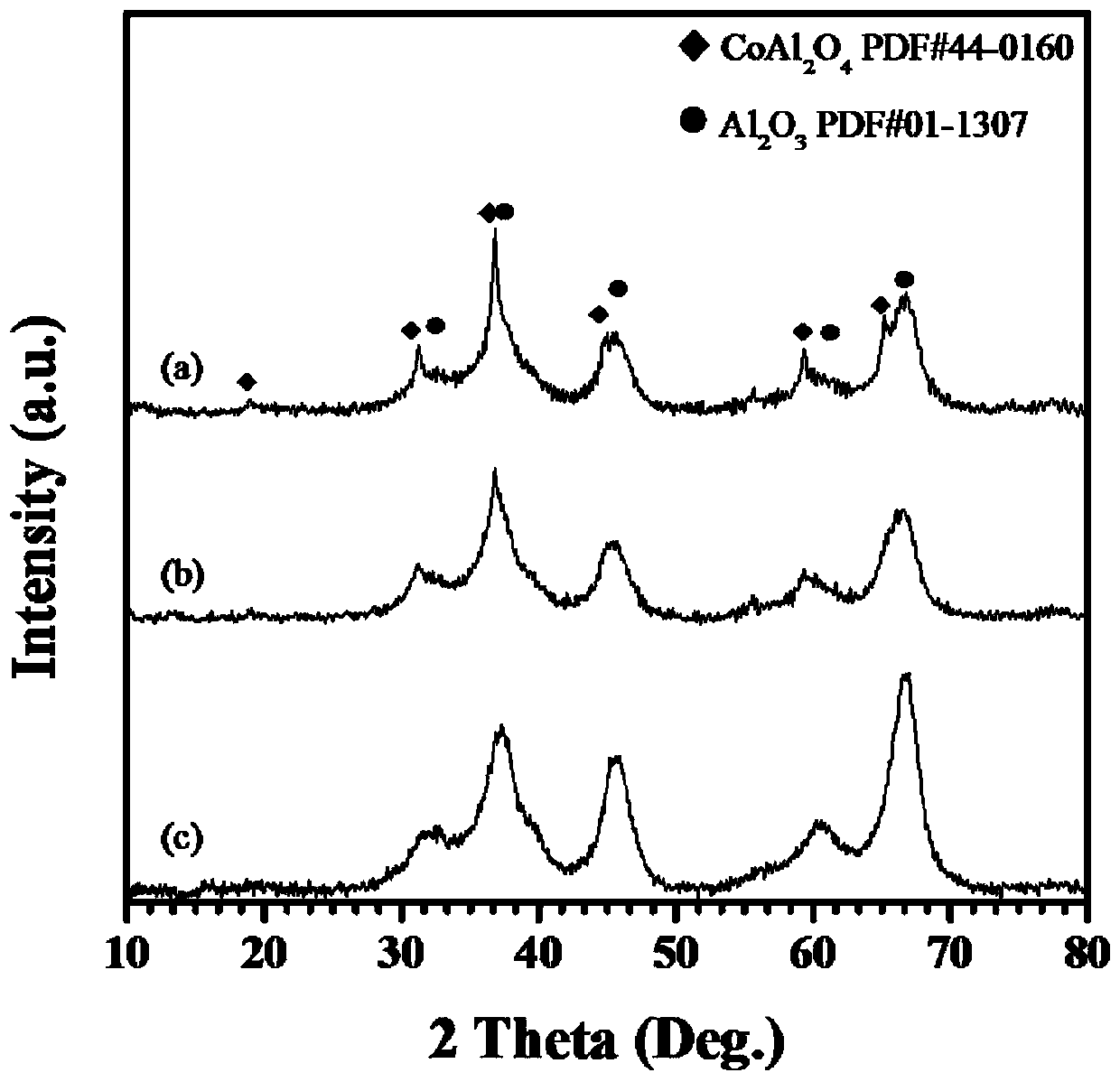

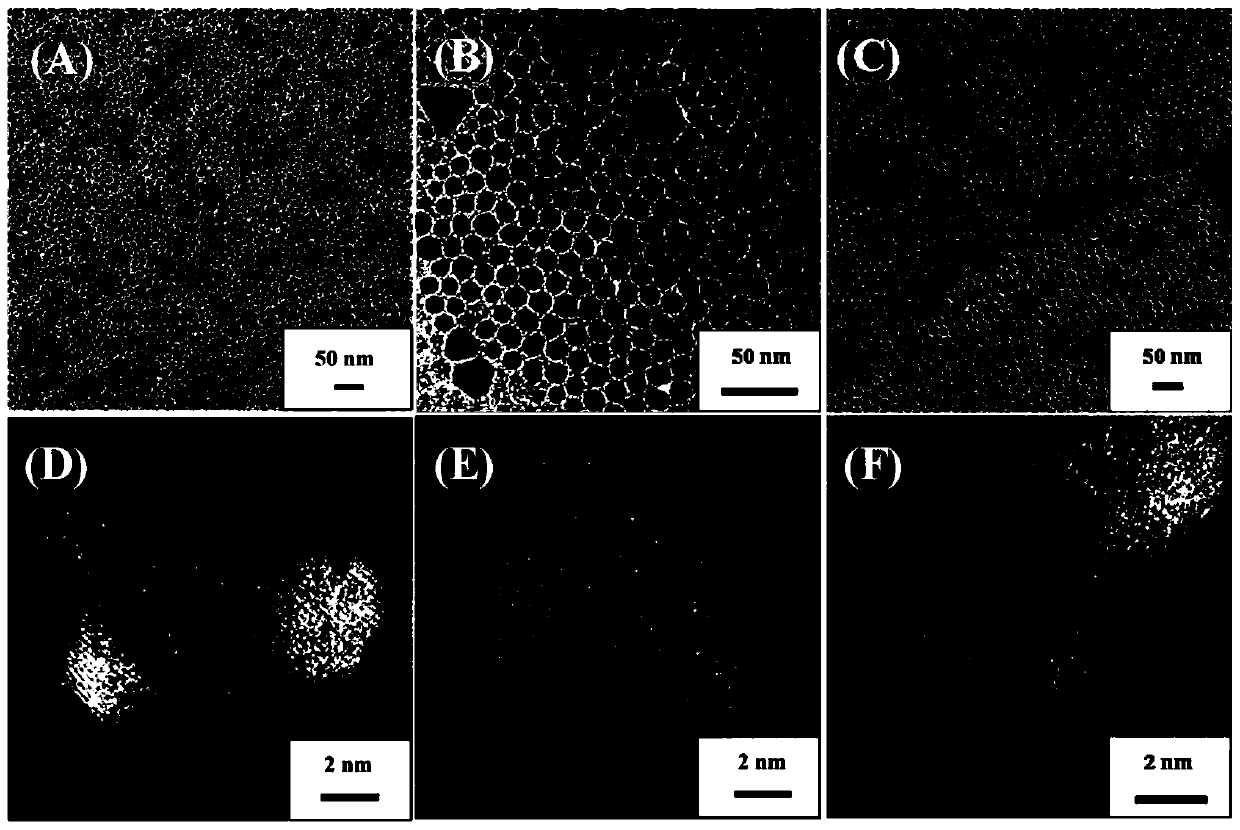

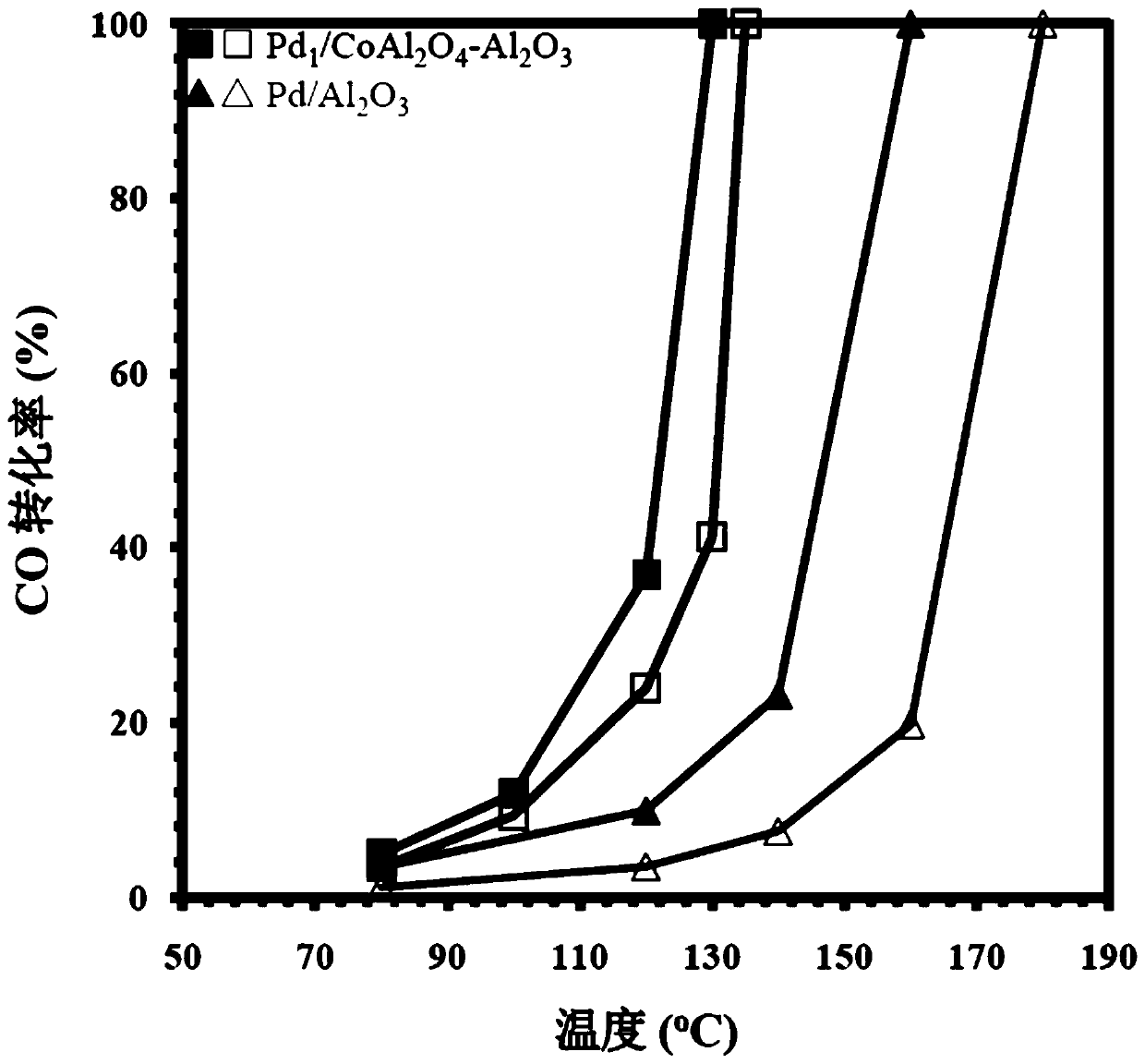

Monatomic palladium-cobalt bimetallic nano-catalyst for efficiently catalyzing benzene oxidation

ActiveCN110639548AUniform particle sizeGood size controlCarbon compoundsWaterNano catalystPtru catalyst

The invention discloses a monatomic palladium-cobalt bimetallic nano-catalyst for efficiently catalyzing benzene oxidation, and belongs to the technical field of functional materials, wherein PdCo bimetallic nanoparticles are loaded onto a gamma-Al2O3 carrier, firing is performed to form a Pd1Co1 / Al2O3 catalyst, and the loading capacity of the metal palladium is 0.4 wt%. The preparation method comprises: in a dichlorobenzene system, simultaneously pyrolyzing and reducing palladium acetylacetonate and octacarbonyldicobalt by adopting an oil-phase one-step pyrolysis method to form PdCo bimetallic particles with uniform size, and loading the metal particles onto an Al2O3 carrier by adopting an impregnation method, wherein the Pd loading capacity is 0.4 wt%; and carrying out hydrothermal roasting on the supported catalyst at a temperature of 800 DEG C to form the Pd1Co1 / Al2O3 nano-catalyst. The Pd1Co1 / Al2O3 nano-catalyst prepared by the method is simple in preparation process, the double metals are in monatomic dispersion, and the Pd1Co1 / Al2O3 nano-catalyst has good application prospect in the field of catalysis.

Owner:BEIJING UNIV OF TECH

Formaldehyde degradation catalyst and preparation method thereof

InactiveCN105749974APromote degradationHigh catalytic oxidation activityGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsPrecious metalPt element

The invention provides a formaldehyde degradation catalyst and a preparation method thereof. The catalyst is formed by compounding 0.1 to 0.5 percent by mass of nanogold and 0.1 to 0.5 percent by mass of nano platinum which are loaded into a porous matrix, wherein the porous matrix is a covalent organic porous polymer COP-4. By taking the covalent organic polymer as a carrier and taking precious metal, namely the nanogold and the nano platinum as active components, the active components are highly dispersed on a porous carrier to efficiently catalyze the degradation of formaldehyde while adsorbing the formaldehyde at room temperature, and therefore the air detergency to the formaldehyde is effectively improved.

Owner:NINGBO XIAYUAN TECH

Mesoporous titanium-silicon material preparation method

ActiveCN104512904AHigh selectivityHigh crystallinityCrystalline aluminosilicate zeolitesMaterials preparationTitanium

The present invention provides a mesoporous titanium-silicon material preparation method, which is characterized by comprising: adding an organic silicon source and a surfactant to a titanium source-containing alkali source aqueous solution to obtain a mixture A, transferring the mixture A into a sealed reaction kettle after the organic silicon source is hydrolyzed, carrying out hydrothermal crystallization for 1-12 h at a temperature of 100-180 DEG C, contacting a silica gel or silica sol after the crystallization, uniformly mixing to obtain a mixture B, carrying out hydrothermal crystallization on the mixture B in the sealed reaction kettle for 6-36 h at a temperature of 120-200 DEG C, and recovering to obtain the mesoporous titanium-silicon material, wherein the molar ratio of the organic silicon source to the titanium source to the alkali source (calculated as OH<-> or N) to the surfactant to the water is 1:0.001-0.5:0.05-0.8:0.01-0.5:5-250, the molar ratio of the silica gel or silica sol in the mixture B to the organic silicon source in the mixture A is 1:0.05-0.5, the organic silicon source is calculated as SiO2, the titanium source is calculated as TiO2, and the alkali source templating agent is calculated as OH<-> or N. The mesoporous titanium-silicon material prepared by the preparation method of the present invention has characteristics of yield increasing, relative crystallinity increasing, and excellent catalysis performance on macromolecule oxidation reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for catalytic preparation of delta-valerolactone by using supported nano-gold catalyst

InactiveCN101157677AHigh catalytic oxidation activityImprove conversion rateOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsChemical industryChemistry

The invention pertains to the technical field of chemical industry, in particular to a preparation method of delta-valerolactone by using the load-type nano-gold catalyst. The using catalyst of the invention adopts a deposition precipitation method for preparation, in particular to the Au / TiO2 catalyst with the nano size after the calcination synthesis at certain temperature and the deposition of gold on the titanium dioxide. The catalyst is characterized by good dispersion of activity, small particles of gold and good stability, and can be used for catalytic air direct oxidation of 1, 5-pentanediol for the preparation of delta-valerolactone, so as to realize the one-step oxidation of 1, 5-pentanediol, further to generate the delta-valerolactone. The air is used as the oxidant during the oxidation process of 1, 5-pentanediol to replace the strong oxidants in the traditional methods, such as peracid, halogen oxides, nitrogen oxides and so on, thus avoiding the violent reaction conditions and the pollution substances generated by oxidants, which is in line with the requirements of green chemistry. The catalyst has the advantages of easy recovery and regeneration, can maintain a higher activity after a plurality of repeated uses and has higher industrial application value.

Owner:FUDAN UNIV

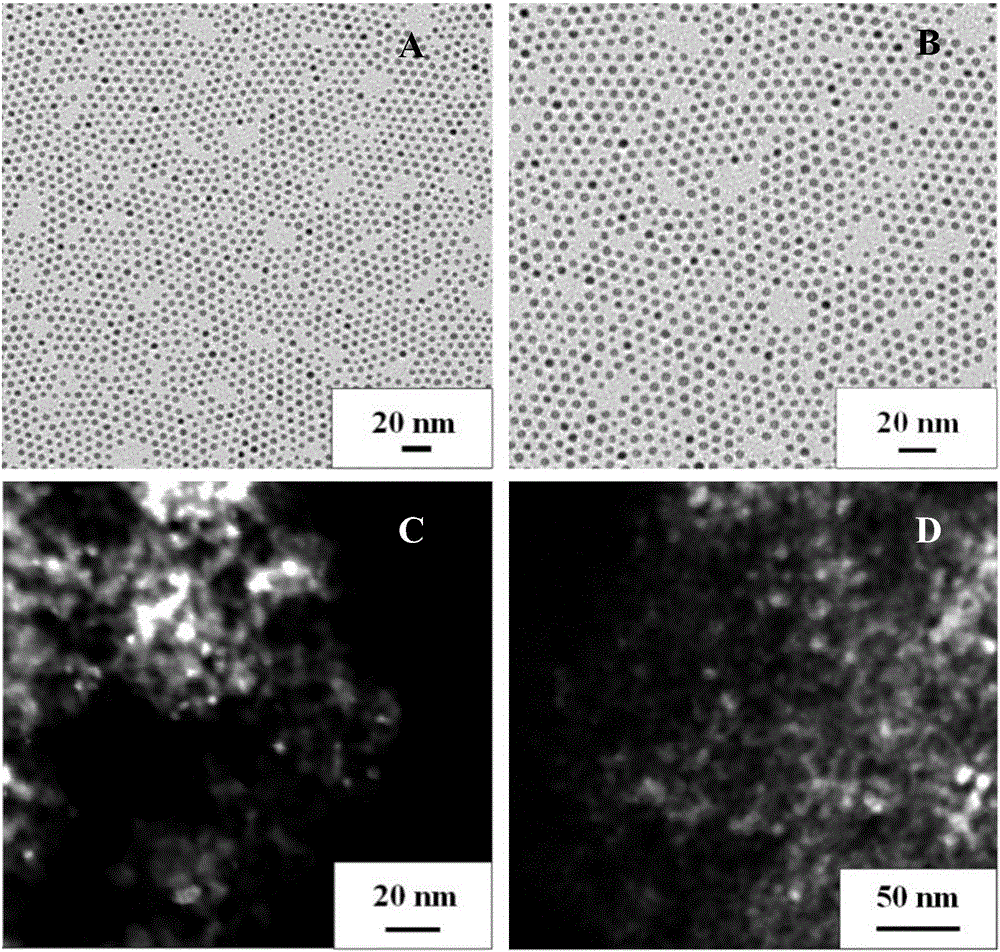

Universal method for preparing high-stability noble metal monatomic catalyst

PendingCN110639549AImprove stabilityHigh crystallinityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetallurgy

The invention discloses a universal method for preparing a high-stability noble metal monatomic catalyst, and belongs to the technical field of functional materials, wherein a MCo (M is Pd, Pt, Au andthe like) bimetal nano-crystal is loaded on a commercial gamma-Al2O3 carrier, and then shock heating roasting is performed to form the noble metal monatomic catalyst. The preparation method comprises: in a dichlorobenzene system, simultaneously pyrolyzing and reducing a noble metal precursor and octacarbonyldicobalt by adopting an oil-phase one-step pyrolysis method to form MCo bimetallic particles with uniform size, and loading the metal particles onto a commercial gamma-Al2O3 carrier by adopting an impregnation method; and pushing the loaded catalyst into a tubular furnace heated to about 800 DEG C in advance, and roasting for 3 h to form the noble metal monatomic catalyst. According to the invention, the preparation process of the monatomic catalyst is simple, noble metals are in monatomic dispersion, the method has universality and is suitable for preparing various noble metal monatomic catalysts, and the obtained catalyst has good application prospects in the field of catalysis.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com