Manganese-cobalt nanocrystalline catalyst for catalytic oxidation of methylbenzene as well as preparation method and application thereof

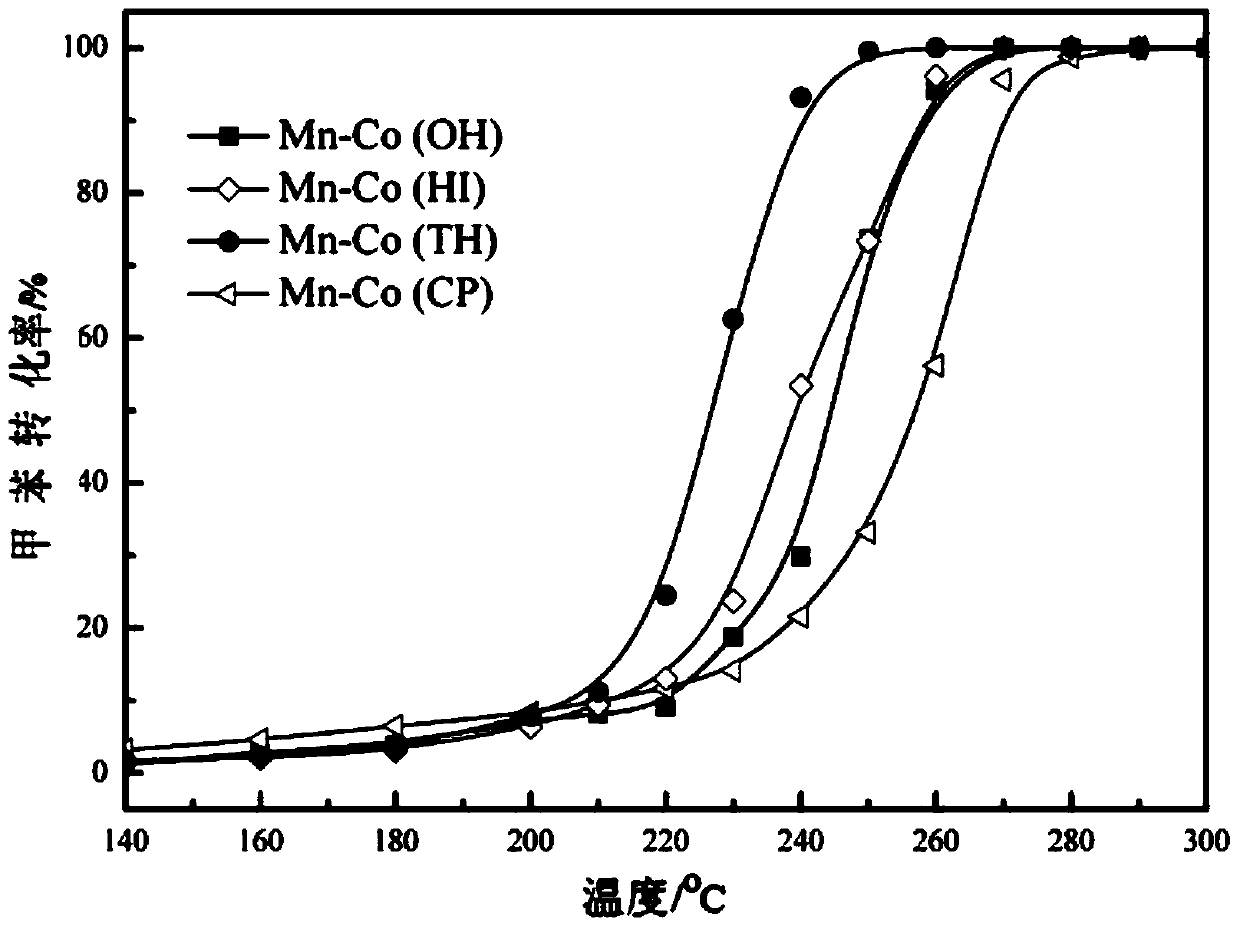

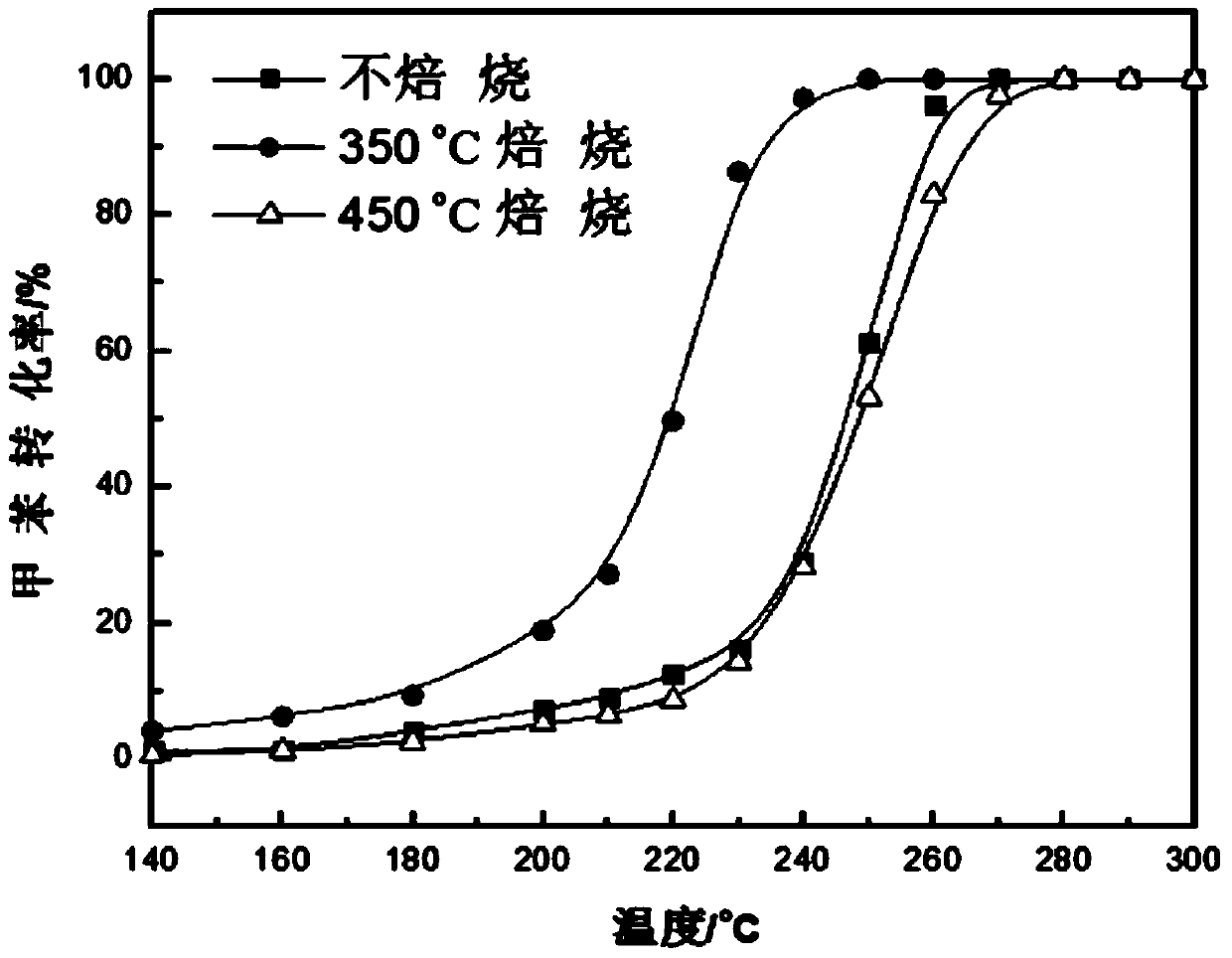

A catalytic oxidation, cobalt nanotechnology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve low crystallinity or amorphous form, toluene oxidation reaction High temperature, unfavorable practical application and other problems, achieve the effect of low cost, high concentration of reducible oxygen species, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Nanocrystalline MnO x The preparation of: first 0.65g Mn(NO 3 ) 2 and 0.65g NaOH were dissolved in 18.75mL deionized water, respectively. Subsequently, the NaOH solution was added dropwise to the Mn(NO 3 ) 2 The solution was stirred vigorously for 10 minutes, then placed in a reaction kettle, and kept at a constant temperature of 180°C for 4 hours. The obtained material was centrifugally washed and dried in an oven at 100°C for 10 hours, and finally the dried sample was baked in a muffle furnace at 350°C for 4 hours. Nanocrystalline Mn 3 o 4 .

[0028] Preparation of nanocrystalline Mn-Co oxides: a two-step hydrothermal method, above which Mn 3 o 4 The preparation is the first step. Subsequently, a certain proportion of Co(NO 3 ) 2 Dissolved in 18.75mL water, then the prepared Mn 3 o 4 The powder was ultrasonically dispersed in Co(NO 3 ) 2in solution. Then, with vigorous stirring, the above mixture was added dropwise into the NaOH solution, stirred for ...

Embodiment 2

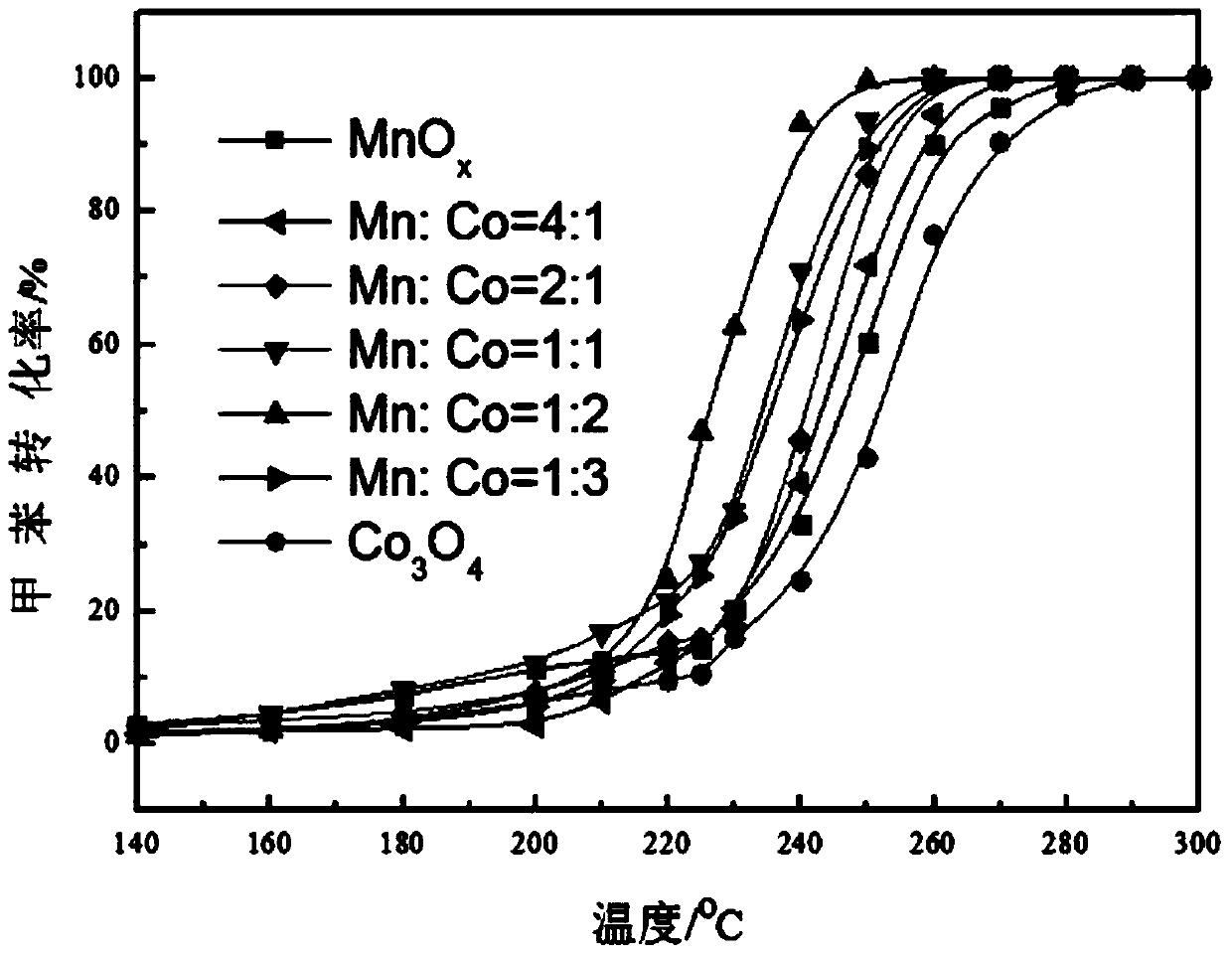

[0038] According to the preparation method of the present invention in Example 1, Mn 3 o 4 According to the Mn / Co molar ratio of 1:1 ultrasonic dispersion in Co(NO 3 ) 2 in solution. The evaluation method of the catalyst is the same as in Example 1. The activity test showed that the reaction rate of the Mn-Co(1:1) sample was 11.2×10 -4 mol / (g·s), 4.0×10 -4 mol / (m 2 s), T 50 The temperature was 235°C.

Embodiment 3

[0040] According to the preparation method of the present invention in Example 1, Mn 3 o 4 According to the Mn / Co molar ratio of 2:1 ultrasonic dispersion in Co(NO 3 ) 2 in solution. The evaluation method of the catalyst is the same as in Example 1. The activity test showed that the reaction rate of the Mn-Co(2:1) sample was 7.0×10 -4 mol / (g·s), 3.0×10 -4 mol / (m 2 s), T 50 The temperature is 240°C.

[0041] The toluene oxidation activity of manganese-cobalt oxide catalysts with different molar ratios is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com