Patents

Literature

107 results about "Toluene oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chemical reactions and pathways resulting in the loss of electrons from one or more atoms in toluene. [GOC:mah]

Method for preparing benzaldehyde by toluene oxidation

InactiveCN104693002AHigh yieldReduce spawn ratePreparation by oxidation reactionsOrganic compound preparationToluene oxidationBenzaldehyde

The invention discloses a preparation method of benzaldehyde. According to the method disclosed by the invention, by taking toluene as a raw material, a metal as well as a metal oxide loaded on a carrier as a catalyst, peroxide as a co-catalyst, oxygen as an oxygen source and methanol as a reaction solvent, the reaction time is 1-80 hours, the reaction temperature is 25-120 DEG C, the pressure is 0.1-6.0MPa, the conversion rate can reach 10-50% and the selectivity can reach 60-90%. The method disclosed by the invention has the advantages of simple process, low cost, environmental friendliness, low energy consumption, high authenticity of benzaldehyde, easily separable and reusable catalyst and the like.

Owner:NANJING TECH UNIV

Toluene oxidation method

ActiveCN103288592AHigh selectivityImprove effective utilizationPreparation by ozonolysisOxygen compounds preparation by hydrocarbon oxidationBenzoic acidToluene oxidation

The invention discloses a toluene oxidation method. The method comprises a step of letting toluene make contact with an oxidizing agent under an oxidation reaction condition, and the method is characterized in that the oxidizing agent is a gas containing ozone. According to the invention, the total selectivity of benzaldehyde and benzoic acid is high, and the selectivity of benzaldehyde is improved in the presence of a catalyst containing titanium.

Owner:CHINA PETROLEUM & CHEM CORP +1

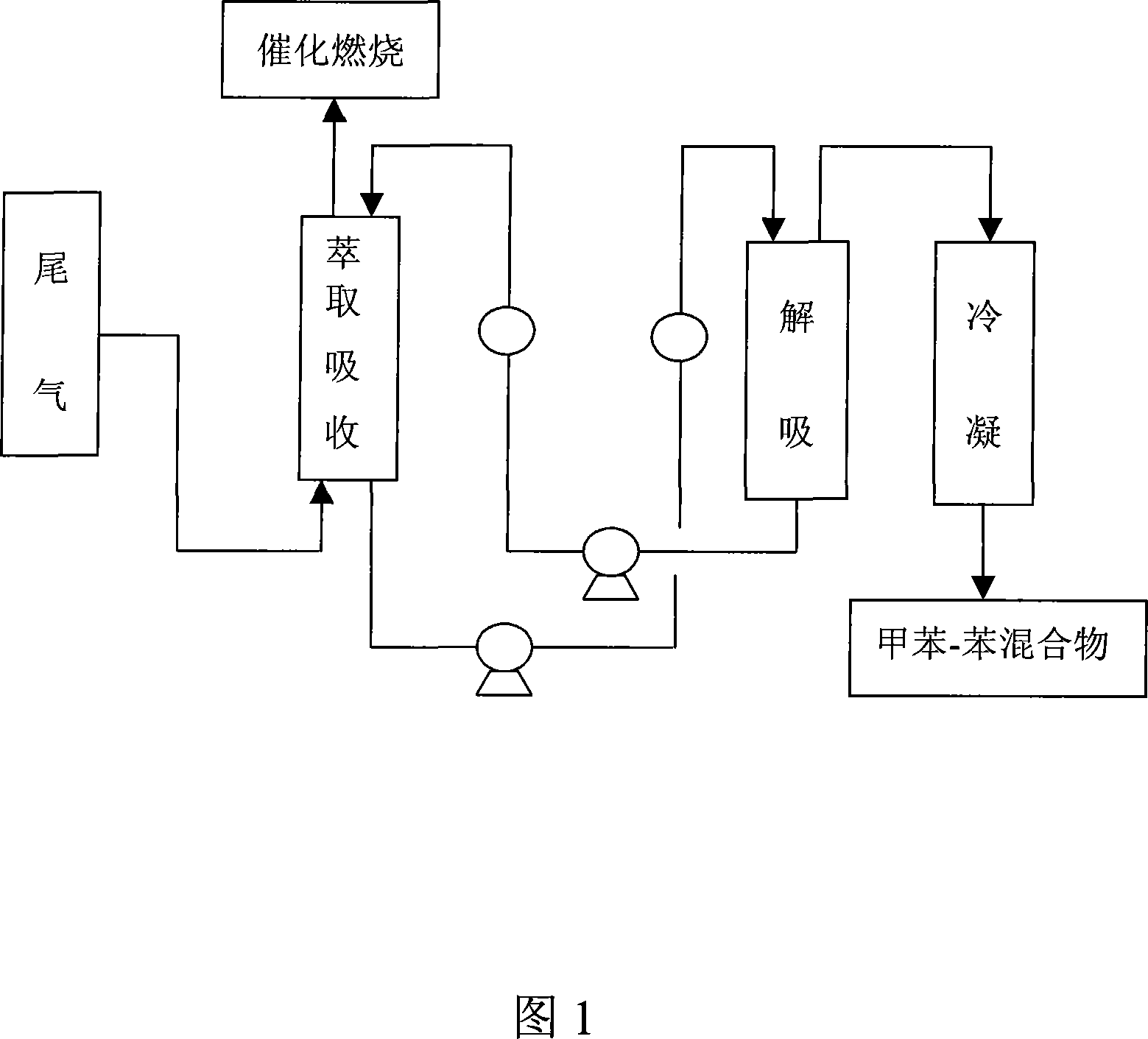

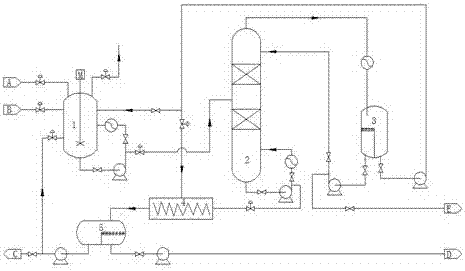

Toluol-benzene solvent recovery technology from vent gas

InactiveCN101229471AEffective absorptionImprove absorption rateDispersed particle separationAbsorption purification/separationBenzeneSocial benefits

The invention discloses a toluene-benzene vent gas recovery process during hexanolactam production by adopting toluene oxidation method, which comprises the following steps: toluene-benzene vent gas discharged from a toluene oxidation device is introduced into an adsorption tower to carry out gas-liquid countercurrent contact with absorbent that is injected form the tower top under the temperature of 20-50 DEG C and pressure of 0.5-1.0MPa; when the adsorption rate of the toluene-benzene vent gas is up to 90-98 percent, the solution absorbed with toluene-benzene is introduced to a desorption tower and desorption is carried out under temperature of 90-108 DEG C and pressure of 0.1-0.12MPa; when the adsorption rate is higher than 95 percent, desorbed toluene-benzene mixture air is cooled to 20-40 DEG C, the adsorbent after desorption is cooled to 20-50 DEG C and recycled. The recovery rate of toluene and benzene of the process of the invention can be more than 90 percent, and the gross content of toluene and benzene after the recovery process can reach more than 95 percent; therefore, not only the toluene and benzene can be effectively recovered, but also the discharged gas can be up to national and industry emission standards; in addition, economic and social benefits of enterprises are improved.

Owner:河北美邦工程科技股份有限公司

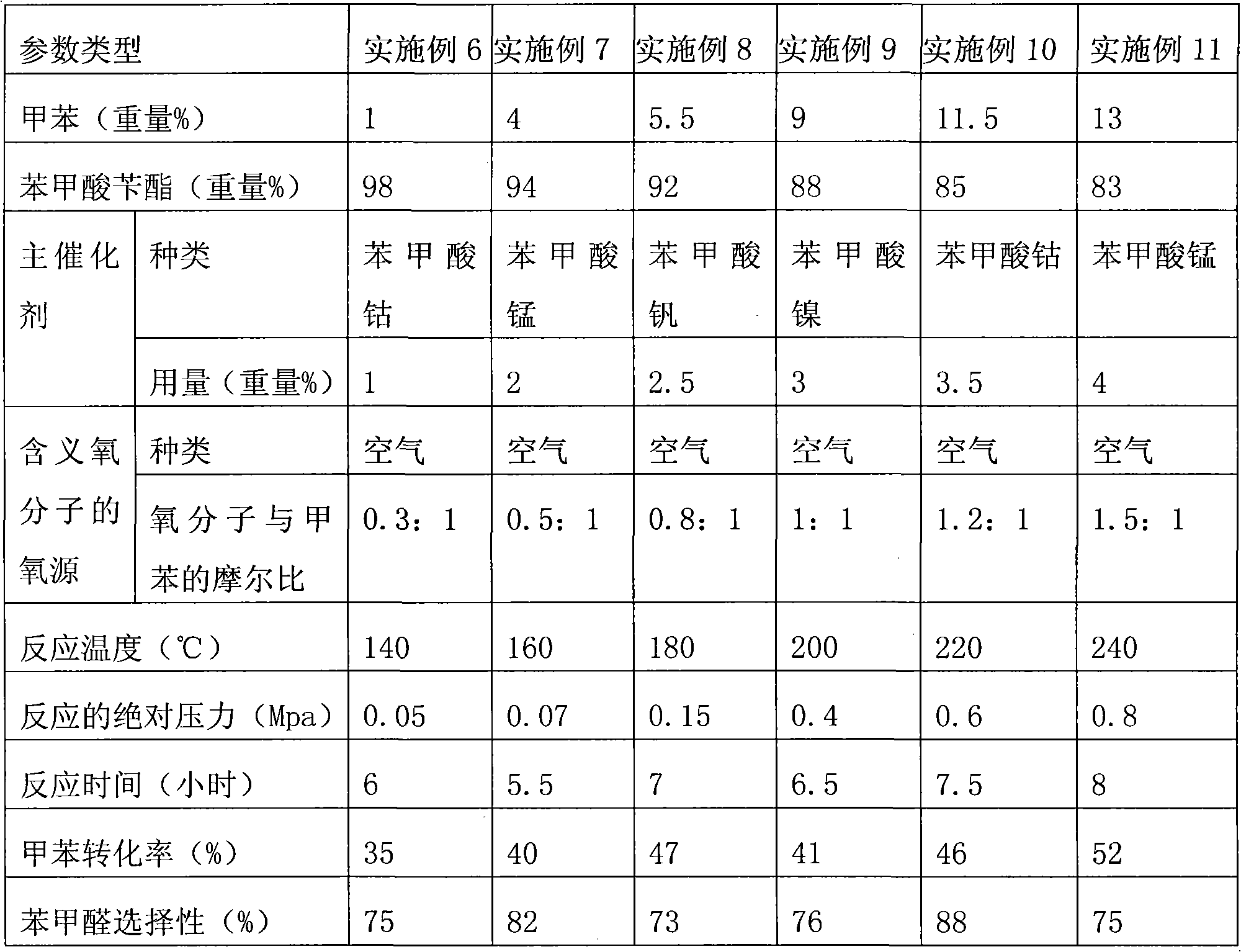

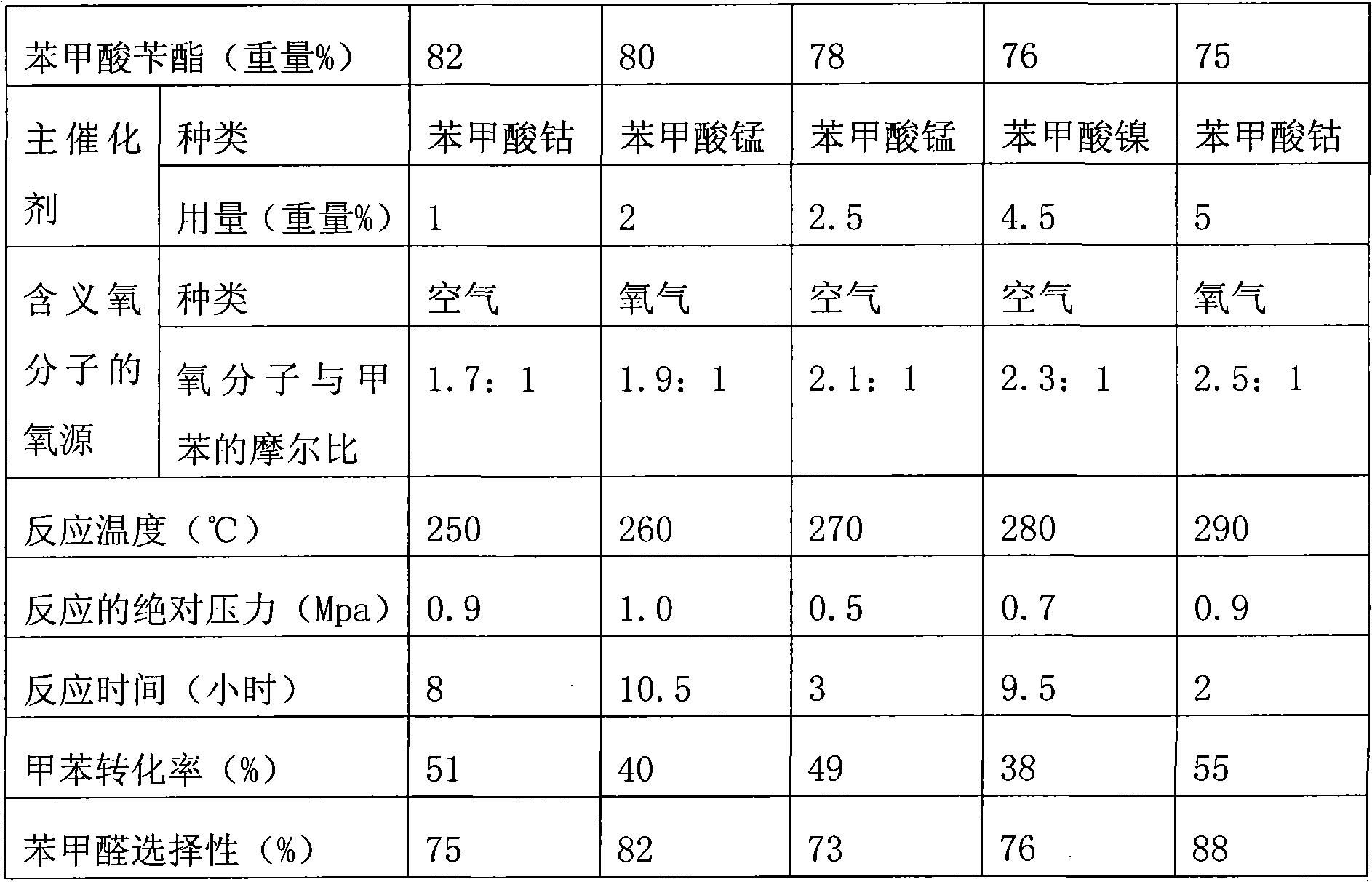

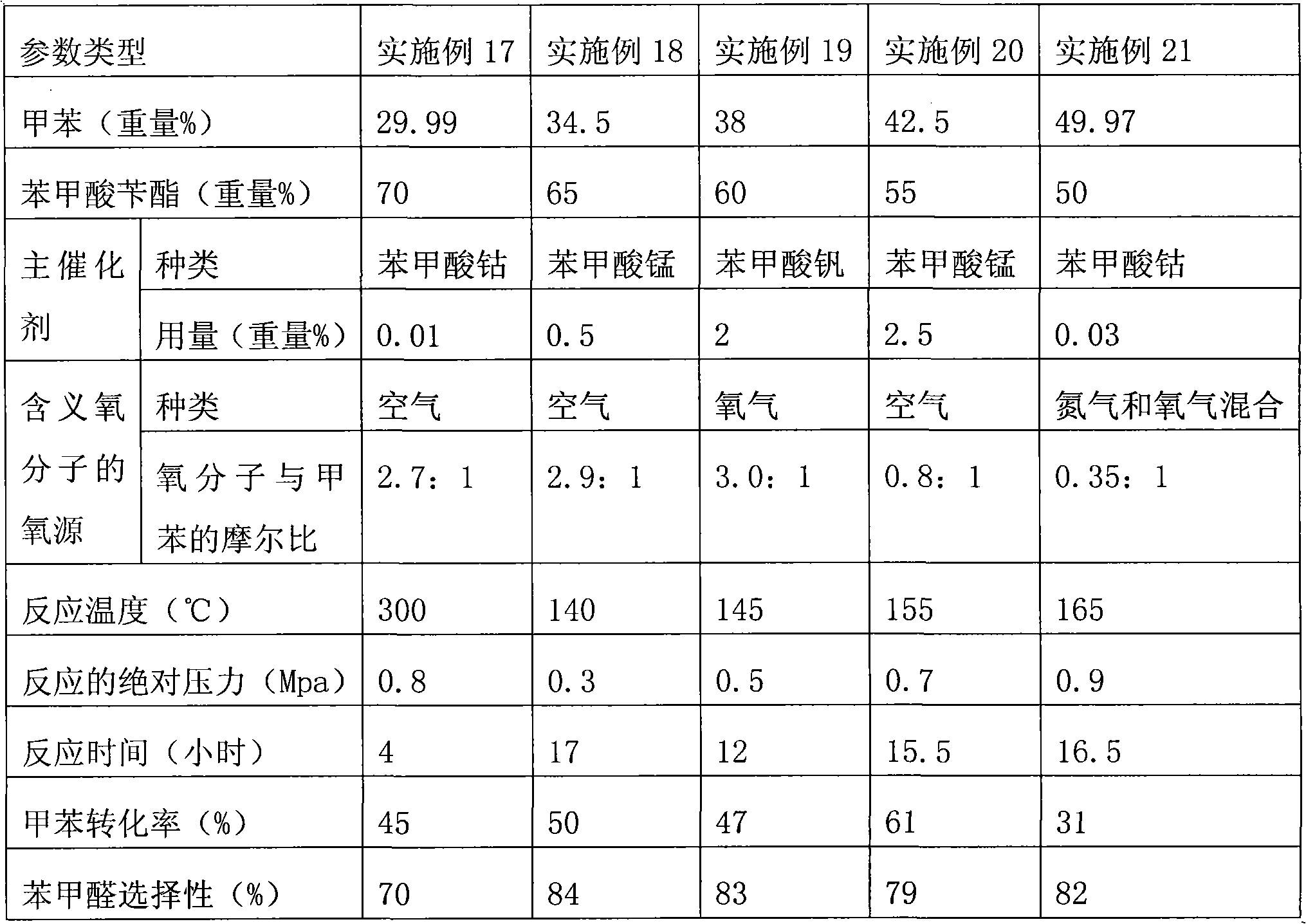

Method for preparing benzaldehyde by oxidizing toluene

InactiveCN101786947AHigh selectivityEasy to separateOrganic compound preparationCarbonyl compound preparationBenzaldehydeToluene oxidation

The invention relates to a method for preparing benzaldehyde by oxidizing toluene. Currently, no method for producing the benzaldehyde has simple reactions as well as high toluene percent conversion and benzaldehyde selectivity. The raw materials comprise 1-59% of toluene, 0.005-5% of master catalyst, oxygen source and 40-98% of benzyl benzoate, wherein the mol ratio of oxygen molecules in the oxygen source to toluene is (0.3-3):1, and the master catalyst is one or more than two of cobalt ions, manganese ions, vanadium ions and nickel ions. The method comprises the following steps: mixing the toluene, master catalyst and benzyl benzoate in a reactor; at the temperature of 140-300 DEG C and under the absolute pressure of 0.05-1.0 MPa, introducing the oxygen source into the mixed liquor to react for more than 2 hours; and refining the mixed liquor to obtain the benzaldehyde. The toluene percent conversion is higher than 30%, and the benzaldehyde selectivity is higher than 70%. The invention has the advantages of simple reaction, energy conservation, environmental protection, easy separation of products and solvent, and high toluene percent conversion and benzaldehyde selectivity.

Owner:申广照

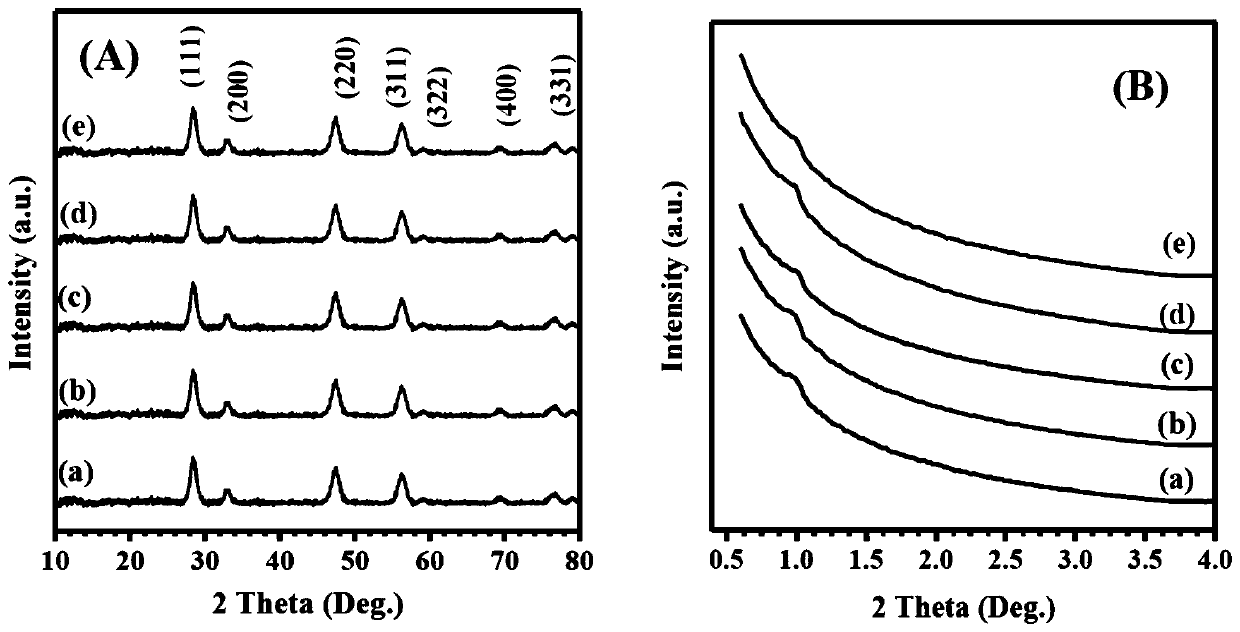

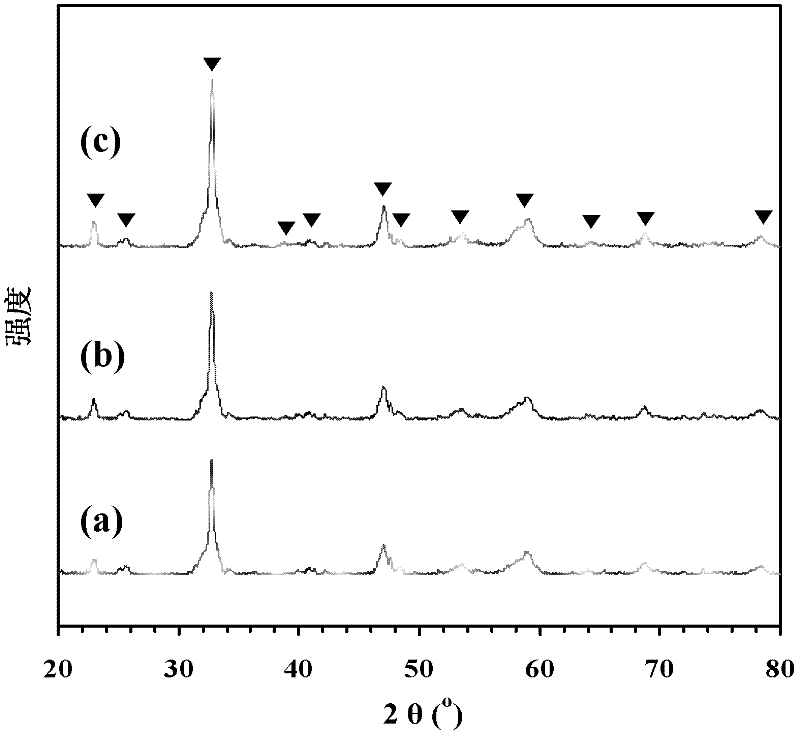

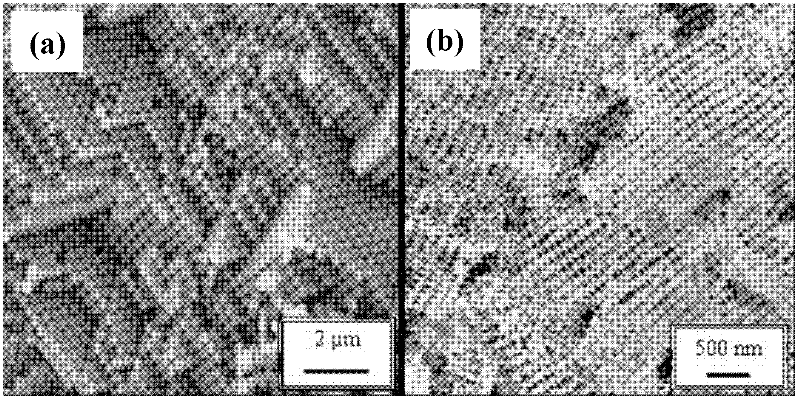

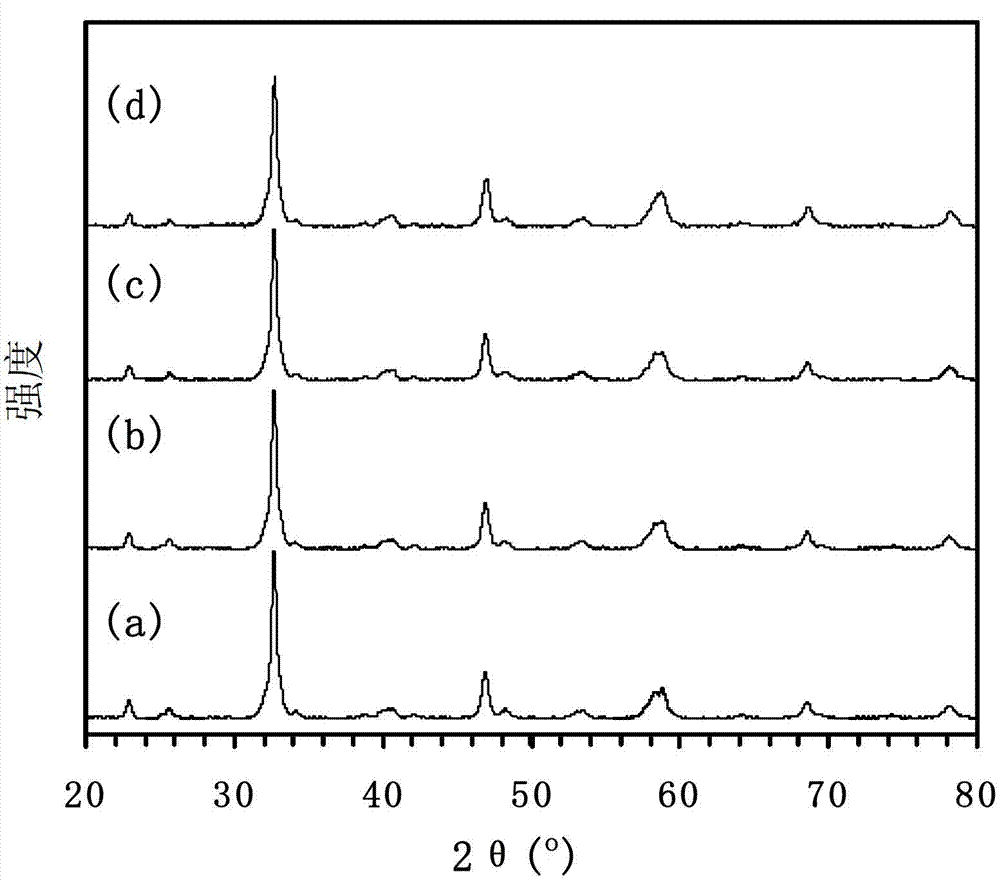

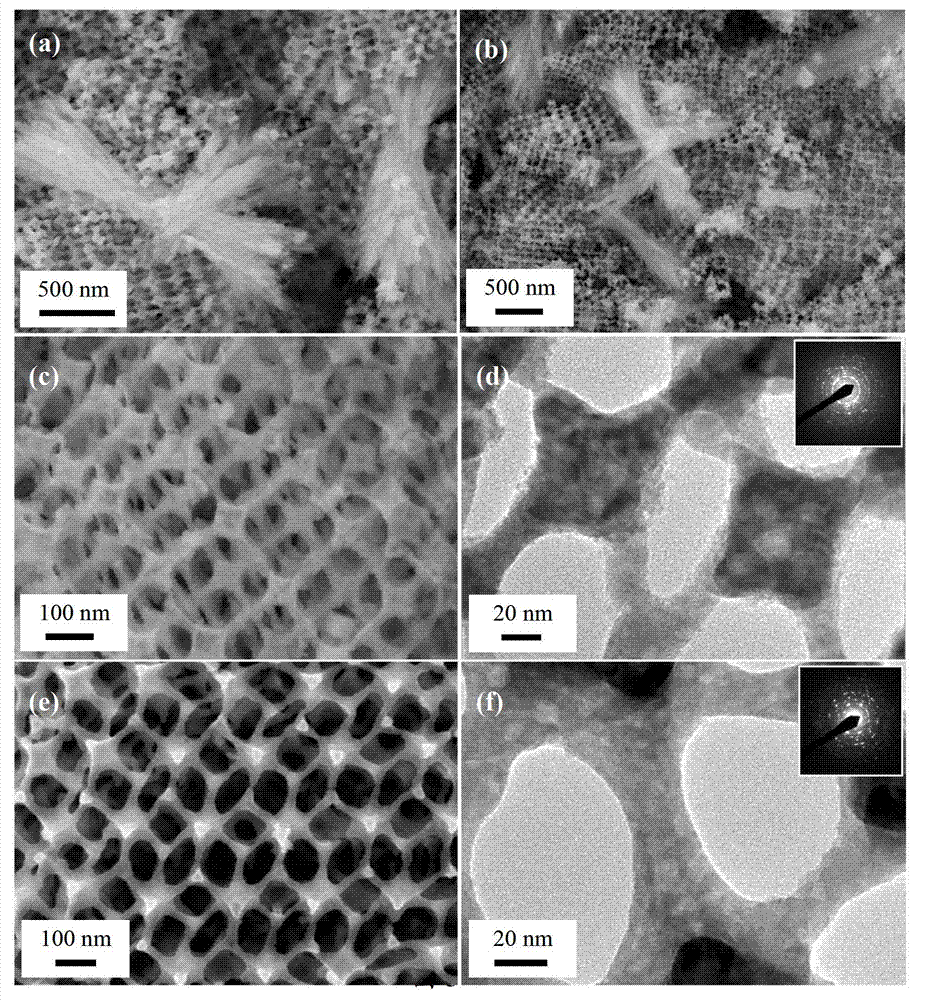

Three-dimensional ordered mesoporous cerium dioxide supported Pt-MnO<x> catalyst for efficient catalytic oxidation of toluene

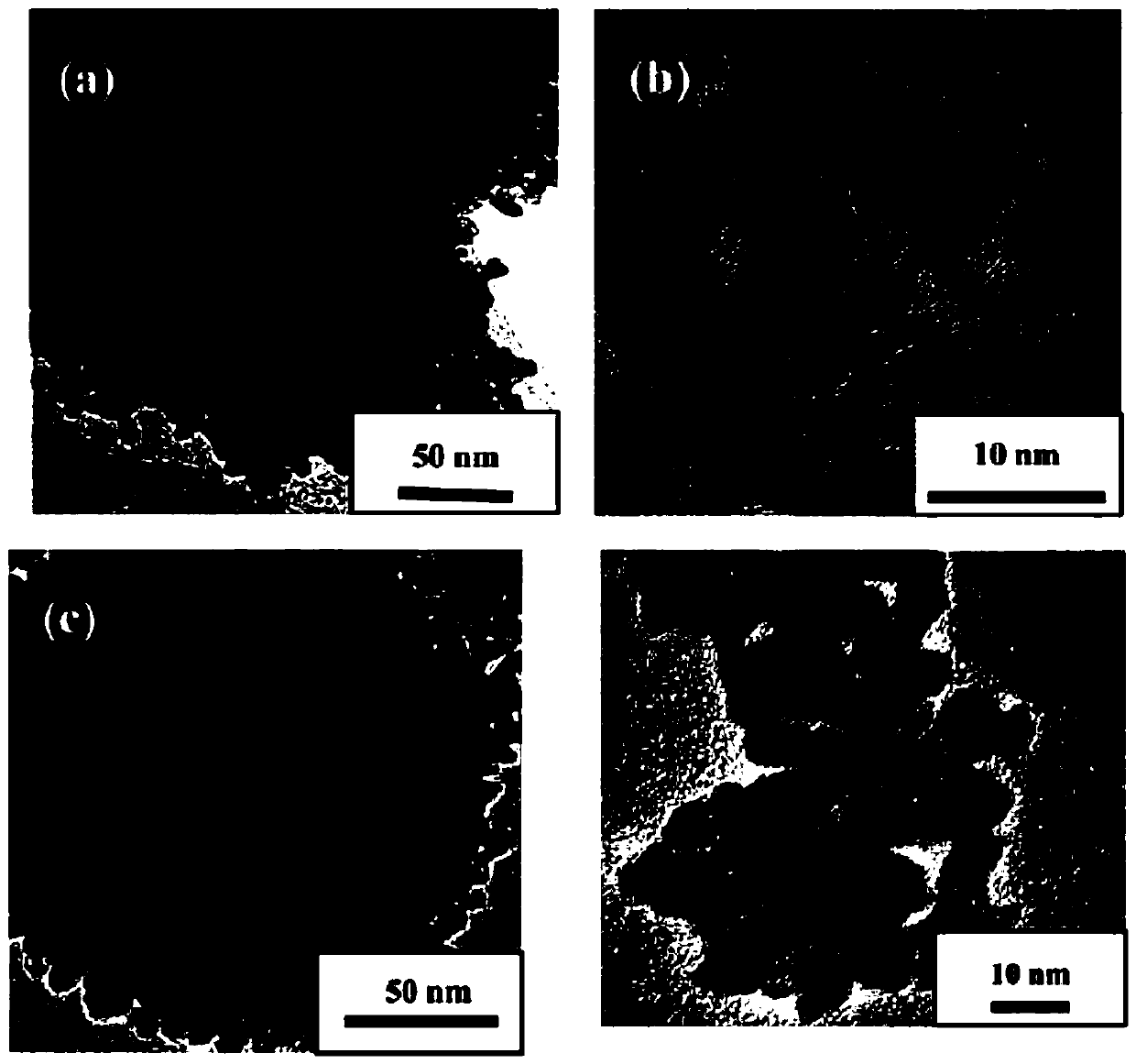

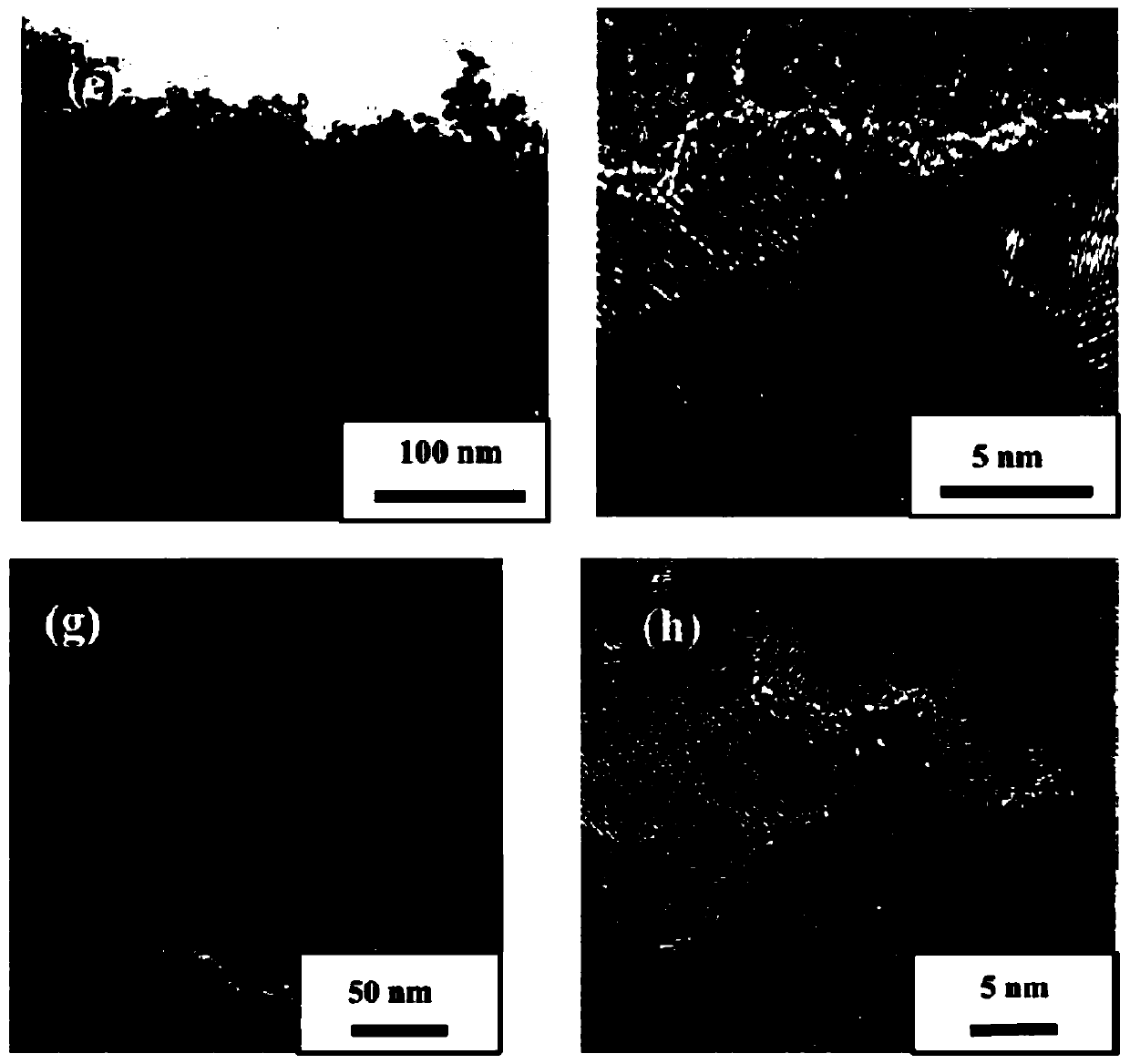

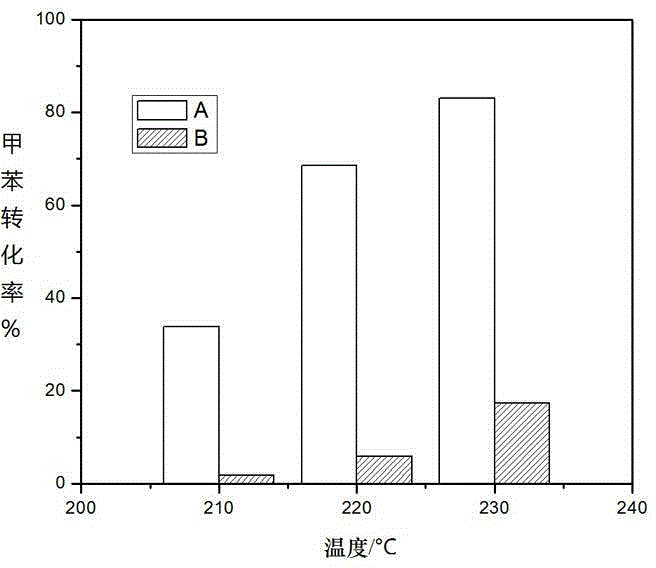

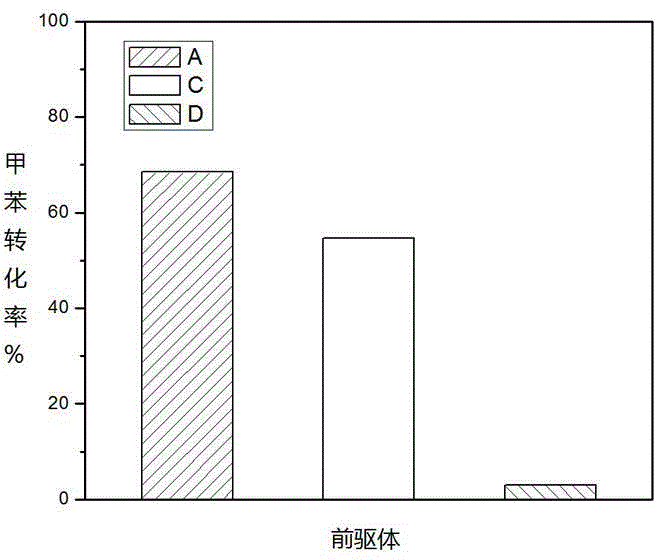

The invention discloses a three-dimensional ordered mesoporous cerium dioxide supported Pt-MnO<x> catalyst for efficient catalytic oxidation of toluene, and belongs to the fields of catalytic chemistry and nano-science. Firstly, a three-dimensional ordered mesoporous cerium oxide carrier is prepared by a KIT-6 template method, wherein Ce(NO3)3.6H2O is used as a precursor solution, and ethanol is used as a solvent; then Pt-Mn nanoparticles are prepared by an ethylene glycol reduction method, wherein chloroplatinic acid and manganese acetate are used as metal precursors, and an ethylene glycol solution containing sodium borohydride is used as a reducing agent; and finally, a meso-CeO2 supported Pt-Mn bimetal catalyst is obtained by using an adsorption method by mixing and stirring the meso-CeO2 carrier and the Pt-Mn nanoparticles, and the mPt-nMnO<x> / meso-CeO2 catalyst is obtained by roasting in air. The material is novel, the preparation process is simple, the morphology of product particles is regular and controllable, and the obtained catalyst shows good catalytic activity, thermal stability and water resistance for toluene oxidation.

Owner:BEIJING UNIV OF TECH

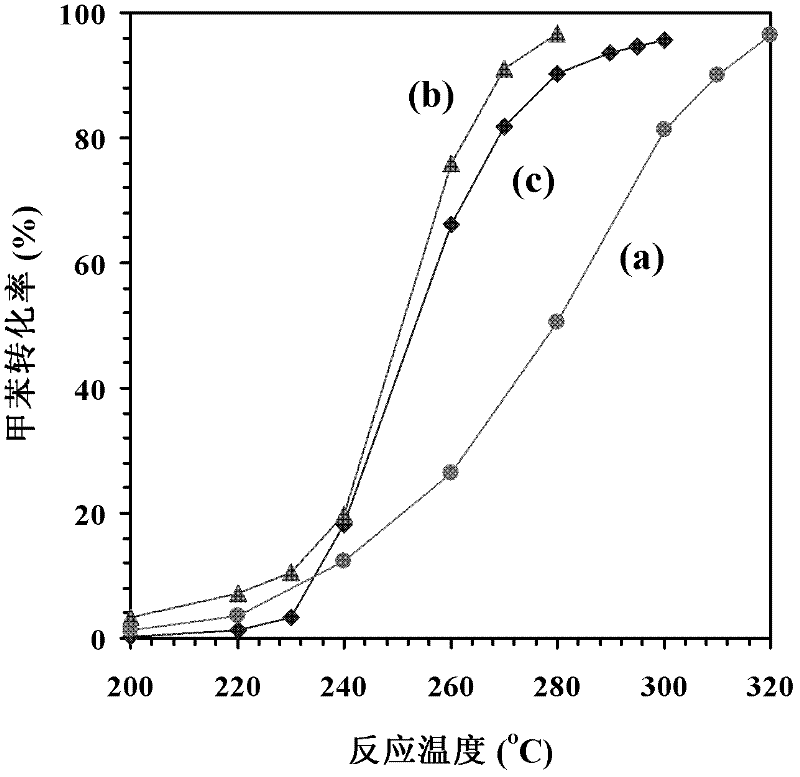

Method for removing toluene by catalytic oxidation

InactiveCN104676610AGood removal effectHigh catalytic activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystToluene oxidation

The invention relates to the technical field of treatment of a volatile substance toluene, in particular to a method for removing toluene by oxidation under the catalysis of rod-like nanometer cerium dioxide-loaded palladium. According to the method for removing toluene by catalytic oxidation, cerium dioxide-loaded palladium is taken as a catalyst, and toluene is removed by oxidative combustion. According to the method, cerium dioxide-loaded palladium is taken as the catalyst, toluene is treated by an oxidation combustion method, and no related reports about the treatment of toluene in the presence of the catalyst in the prior art are made, and by the method, toluene is oxidized into carbon dioxide, so that obvious removal effects are achieved. Rod-like nanometer cerium dioxide is selected as a carrier, and compared with common nanoparticles cerium dioxide-loaded palladium, rod-like nanometer cerium dioxide-loaded palladium has the advantages that the catalytic activity is high, and better catalytic treatment effects can be achieved.

Owner:NANJING UNIV

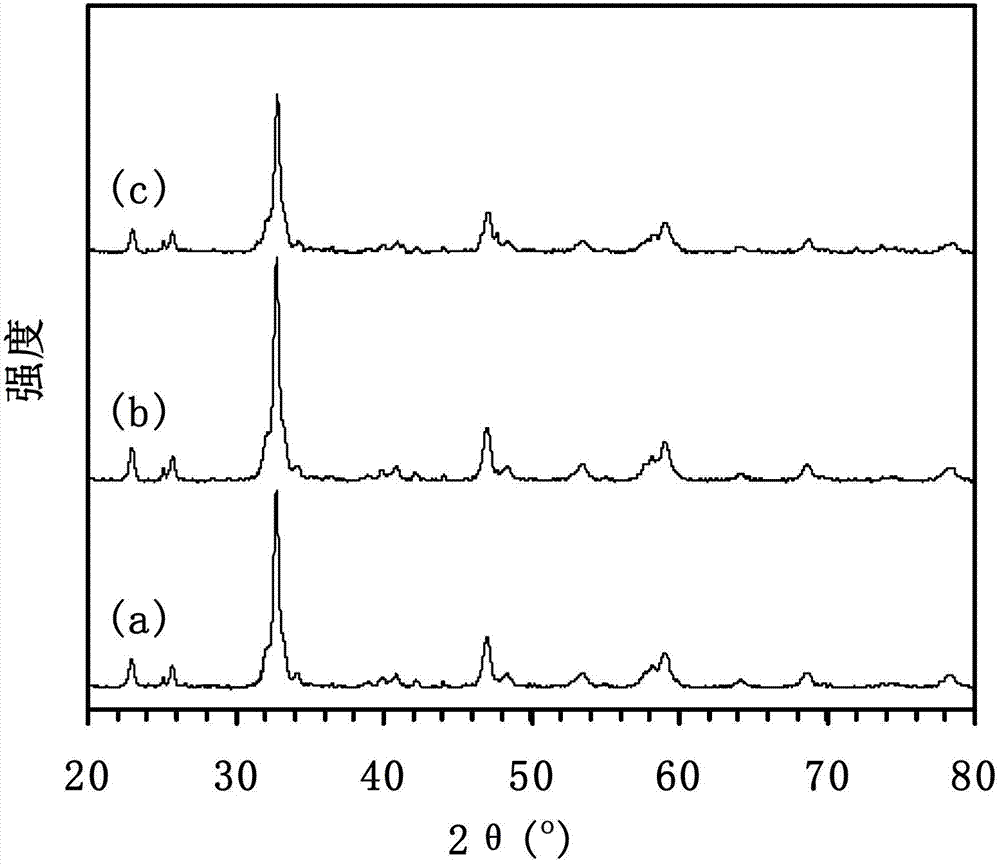

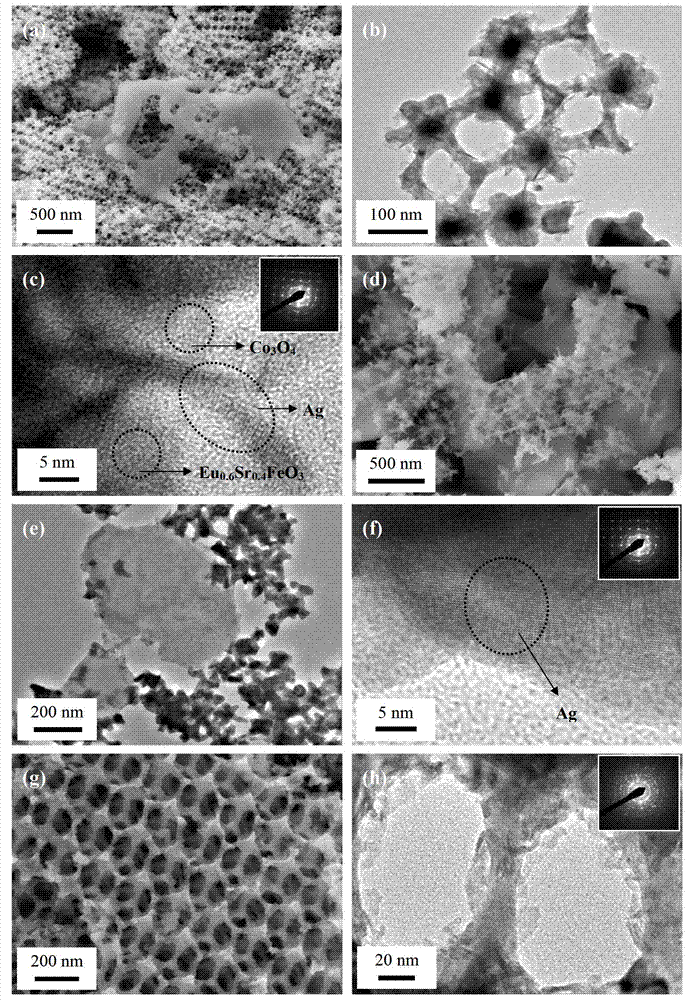

Three-dimensional order macroporous structural CoOx/Eu0.6 Sr0.4 FeO3 catalyst, preparation method and application thereof

InactiveCN102380395AHigh crystallinityRaw materials are cheap and easy to getDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMaterial synthesisCOBALTOUS NITRATE

A three-dimensional order macroporous structural CoOx / Eu0.6 Sr0.4 FeO3 catalyst, a preparation method and application thereof belong to the field of porous functional material synthesis and heterogeneous catalysis. The preparation method includes steps of preparing Eu0.6 Sr0.4 FeO3 in three-dimensional order macroporous structure at first, and then preparing a CoOx / Eu0.6 Sr0.4 FeO3 catalyst with high-dispersed cobalt oxide by the isometric impregnation process while utilizing the Eu0.6 Sr0.4 FeO3 catalyst in the three-dimensional order macroporous structure as a carrier and utilizing cobaltous nitrate as a cobalt source. The Eu0.6 Sr0.4 FeO3 and the CoOx / Eu0.6 Sr0.4 FeO3 prepared by the preparation method have excellent catalytic property to p-xylene oxidation reaction, and the CoOx / Eu0.6Sr0.4 FeO3 catalyst in the three-dimensional order macroporous structure has good application prospect in terms of removing volatile organic compounds by means of oxidation.

Owner:BEIJING UNIV OF TECH

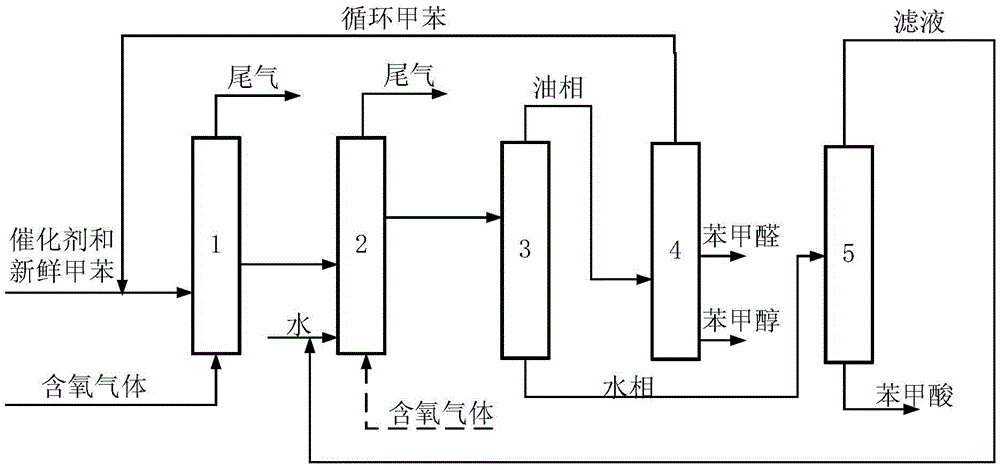

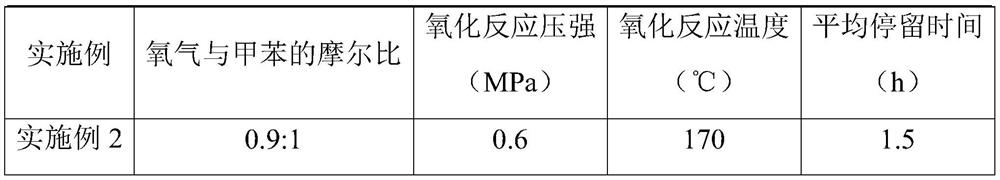

Method for combined production of benzyl alcohol, benzaldehyde and benzoic acid through oxidizing toluene

ActiveCN105601473AAvoid the major pitfalls of rectification separationsIncrease profitPreparation by oxidation reactionsOrganic compound preparationBenzoic acidToluene oxidation

The invention discloses a method for combined production of benzyl alcohol, benzaldehyde and benzoic acid through oxidizing toluene. The method comprises the following steps: 1, oxidizing: continuously introducing toluene, a catalyst and an oxygen-containing gas to an oxidation reactor, and reacting to obtain an oxidation reaction solution; 2, hydrolyzing: continuously introducing the oxidation reaction solution to a hydrolysis reactor, continuously adding water to the hydrolysis reactor, and reacting to obtain a hydrolysis reaction mixture; 3, carrying out liquid-liquid layering: continuously adding the hydrolysis reaction mixture to a liquid-liquid layering device to obtain an upper layer oil phase containing toluene, benzyl alcohol and benzaldehyde and a lower layer water phase containing benzyl alcohol, benzaldehyde and benzoic acid; and 4, carrying out product separation: rectifying the upper layer oil phase to obtain incompletely reacted toluene, benzyl alcohol and benzaldehyde products, and cooling and crystallizing the lower layer water phase, and filtering the cooled and crystallized lower layer water phase to obtain a filtrate and a benzoic acid product. The method has the advantages of high raw material conversion rate, few byproducts, good selectivity of target products, and environmental protection.

Owner:山东友道化学有限公司

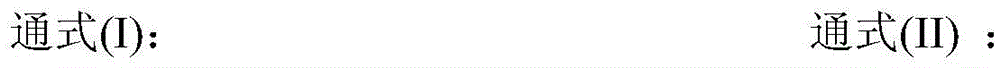

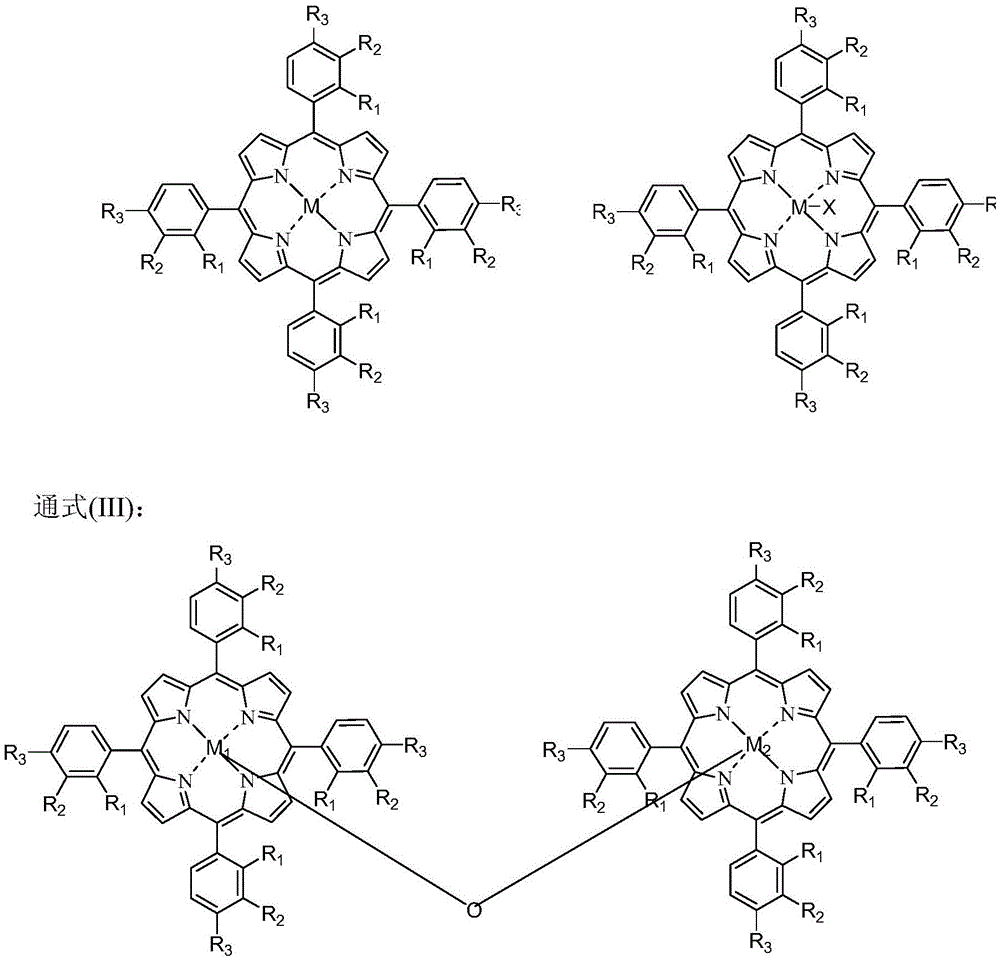

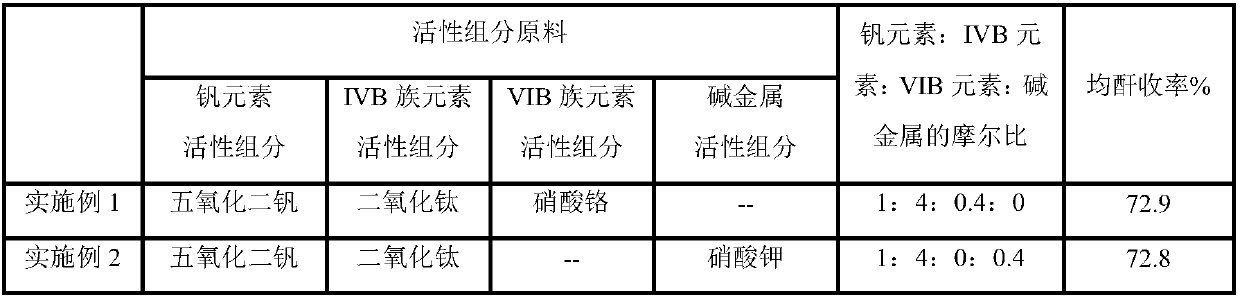

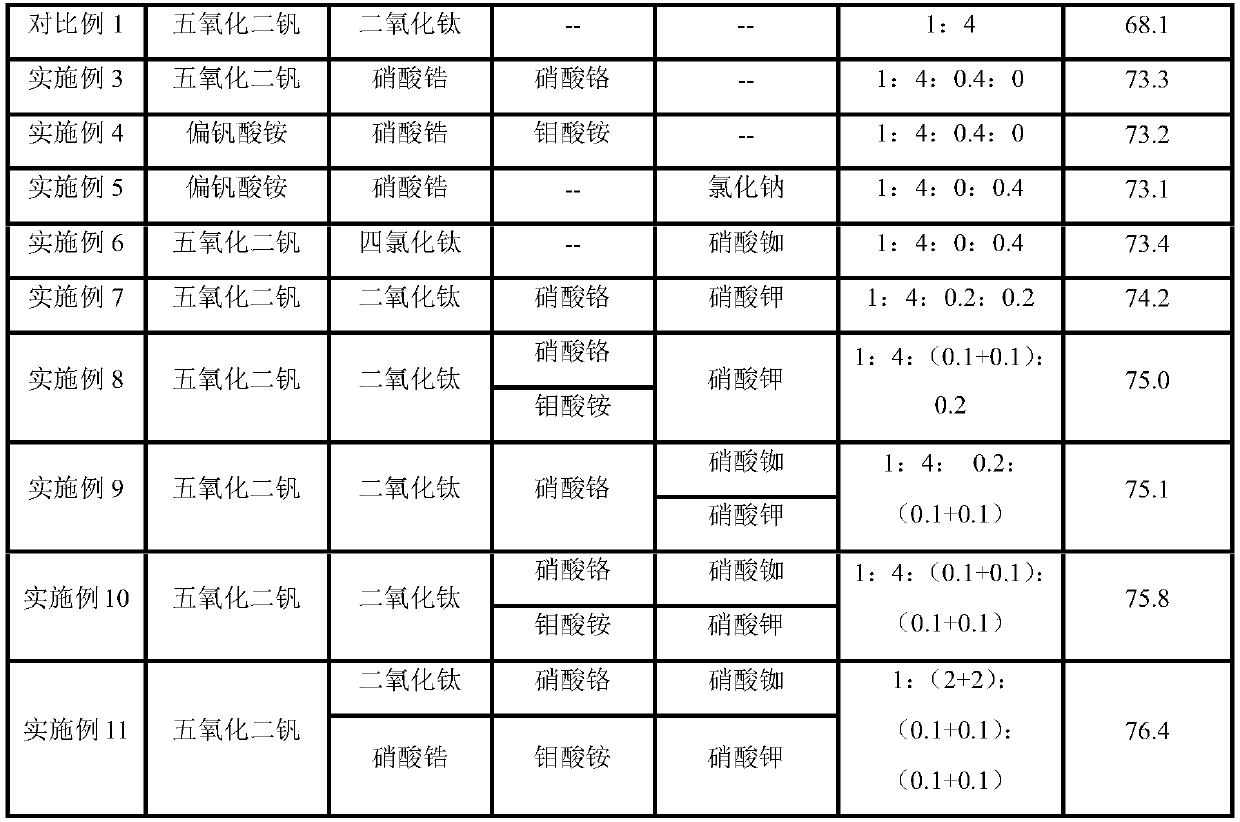

Catalyst for synthesizing pyromellitic dianhydride from durene

ActiveCN107866215AHigh activityImprove stabilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActive componentPyromellitic dianhydride

The invention relates to a catalyst for synthesizing pyromellitic dianhydride from durene. The catalyst mainly overcomes the problem of low yield of the target product pyromellitic dianhydride due toa great number of side reactions in oxidation of durene in the prior art. According to the invention, an oxide catalyst is employed; the catalyst adopts alpha-Al2O3, silicon carbide, a ceramic ring ora mixture thereof as a carrier; and the active component of the catalyst is at least one selected from a group consisting of elemental vanadium, group-IVB elements, group-VIB elements and alkali metal elements. With such a technical scheme, the above technical problem is overcome, side reactions in oxidation of durene are reduced, and the yield of pyromellitic dianhydride is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

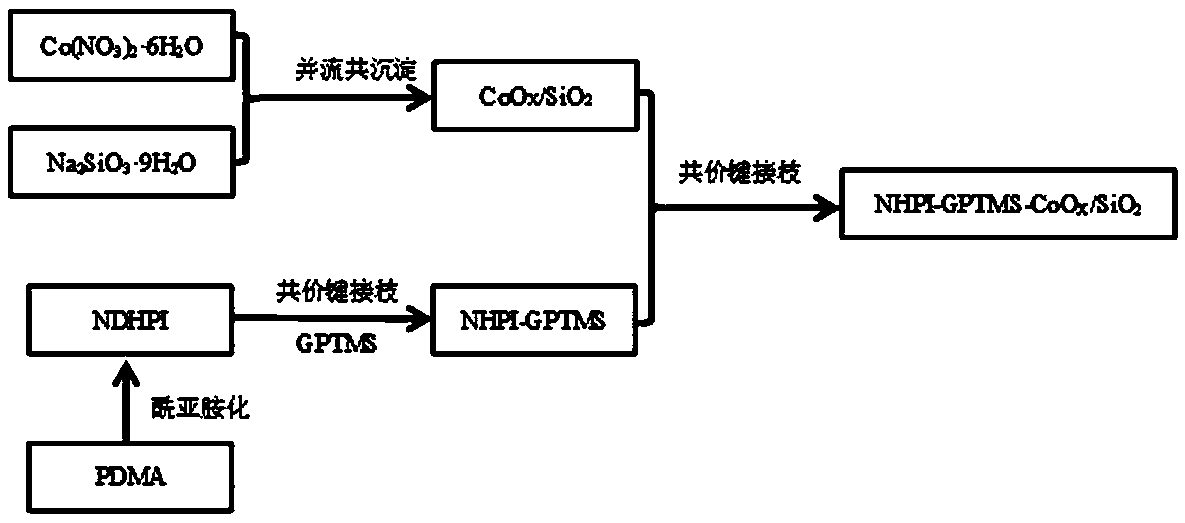

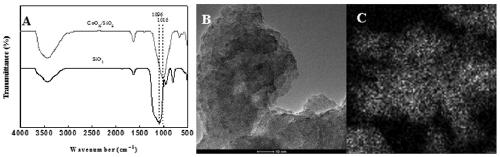

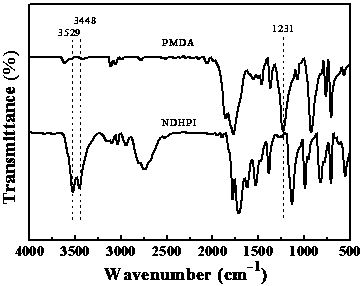

NHPI-GPTMS-CoOX/SiO2 heterogeneous catalyst, applications and recovery method thereof

InactiveCN110193381AReduce consumptionRealize repeated recyclingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRecovery methodToluene oxidation

The invention relates to a NHPI-GPTMS-CoOX / SiO2 heterogeneous catalyst, applications and a recovery method thereof, and belongs to the technical field of heterogeneous catalysts, wherein Co<2+>-containing CoOX / SiO2 is prepared by using a co-precipitation method, and then NHPI is immobilized on the CoOX / SiO2 through a covalent bond grafting method to prepare the NHPI-GPTMS-CoOX / SiO2 catalyst. According to the present invention, the cobalt in the NHPI-GPTMS-CoOX / SiO2 has good dispersibility, and forms the Si-O-Co bond with the carrier SiO2, the cobalt content is basically unchanged during the catalyst preparation and the catalytic toluene oxidation reaction, and the leaching phenomenon is not observed; the NHPI is grafted with the silane coupling agent KH-560 (GPTMS) through the C-O-N bond,and the GPTMS is bonded to the carrier through the Si-O-Si bond; when the catalyst is recycled, the graft bond of the NHPI does not break, such that the significant loss of the NHPI cannot be generated; and in the selective oxidation of toluene with hexafluoroisopropanol as solvent, the catalyst has good catalytic activity, good selectivity and good stability.

Owner:YANGZHOU UNIV

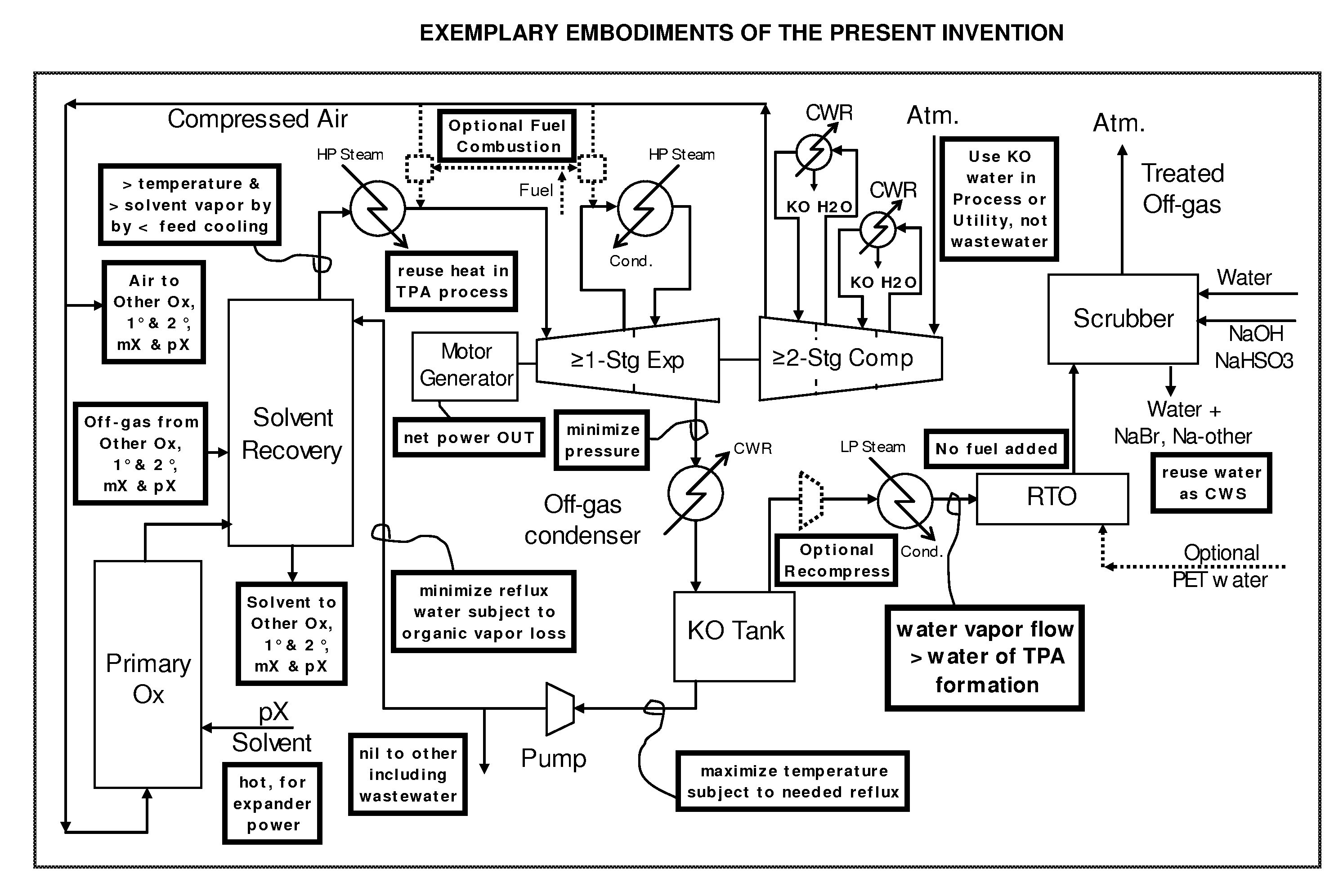

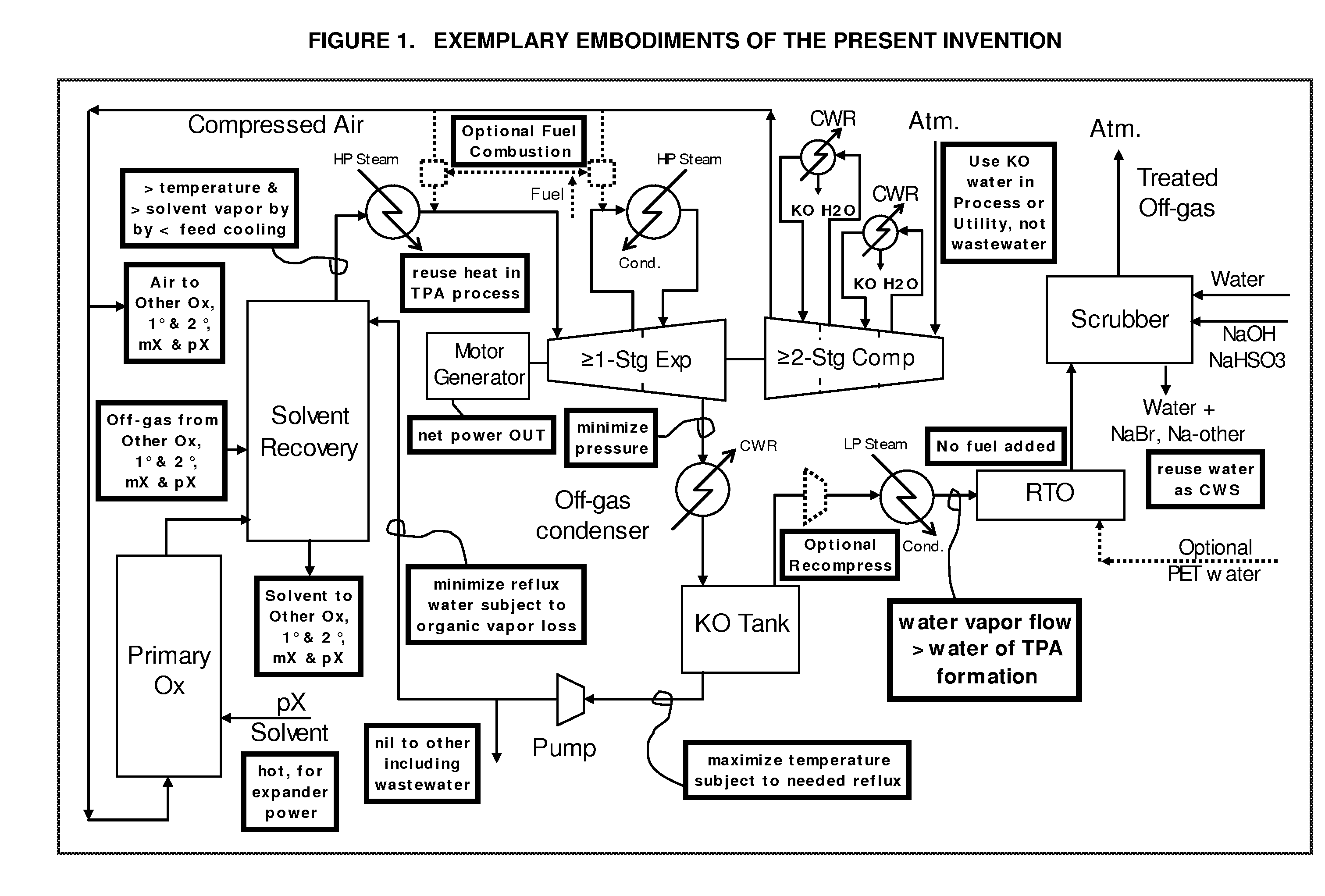

Dicarboxylic Acid Production with Enhanced Energy Recovery

ActiveUS20100113826A1Effectively no liquid wastewaterConvenient amountOrganic compound preparationCrystallization separationGas phaseEnergy recovery

The invention provides improved energy content in and shaft power recovery from off-gas from xylene oxidation reactions while at the same time minimizing wastewater treatment cost. More shaft power is produced using off-gas than is required to drive the main air compressor, even with preferred, relatively low oxidation temperatures. Simultaneously, an amount of wastewater greater than byproduct water from oxidation of xylene is kept in vapor form and treated along with off-gas pollutants in a self-sustaining (self-fueling) gas-phase thermal oxidative destruction unit. Optionally, off-gas is combined from multiple xylene oxidation reactors, comprising primary and / or secondary oxidation reactors and forming TPA and / or IPA. Optionally, air compressor condensate and caustic scrubber blowdown are used in a TPA process or as utility water, effectively eliminating normal flow of liquid wastewater effluent from a TPA plant. Optionally, PET off-gas containing the water of PET formation is treated in a shared thermal oxidative destruction unit, effectively eliminating normal flow of liquid wastewater effluent from a combined pX-to-TPA-to-PET plant.

Owner:ALPEK POLYESTER SA DE CV

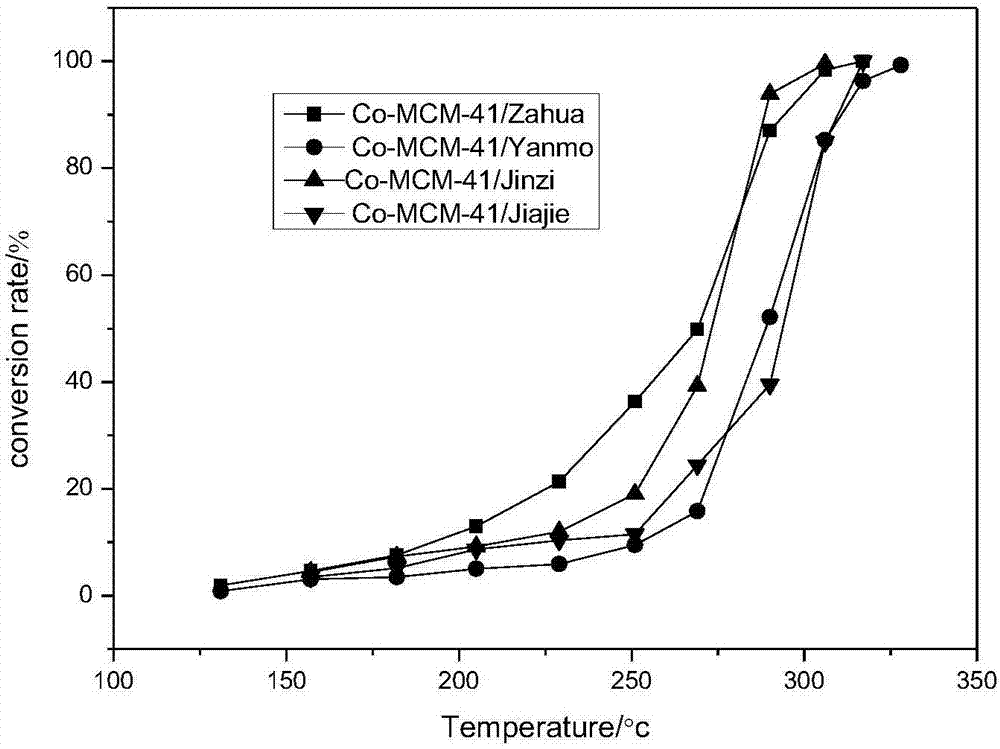

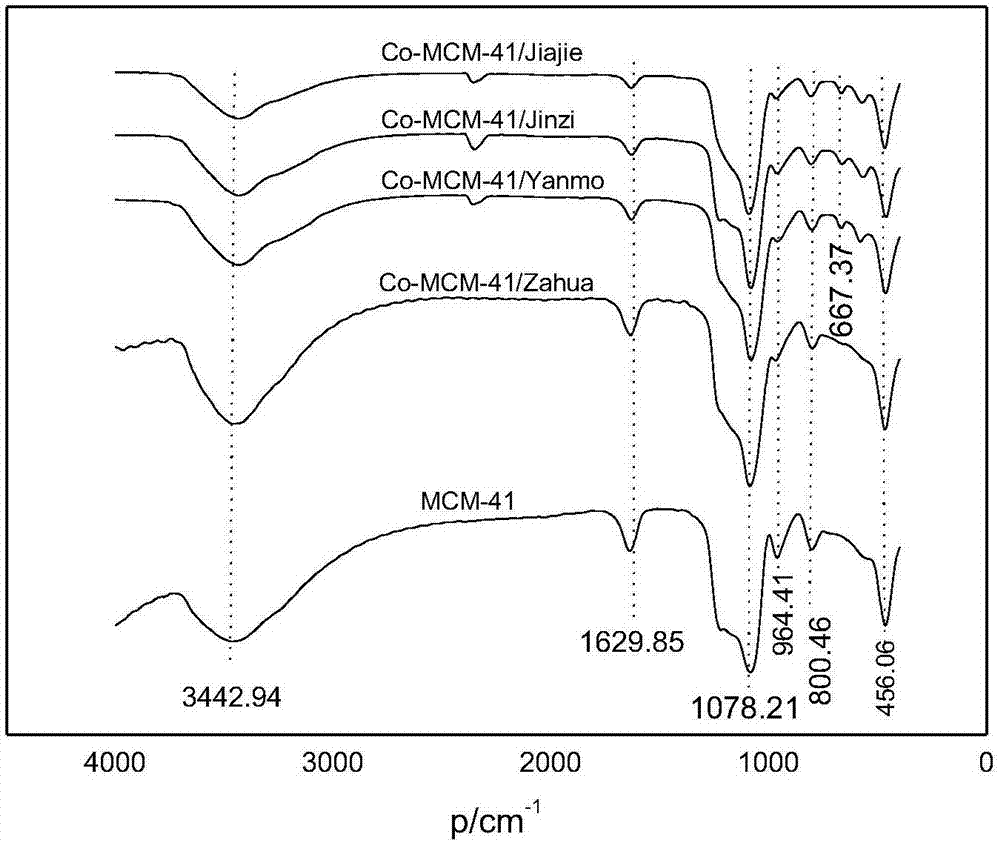

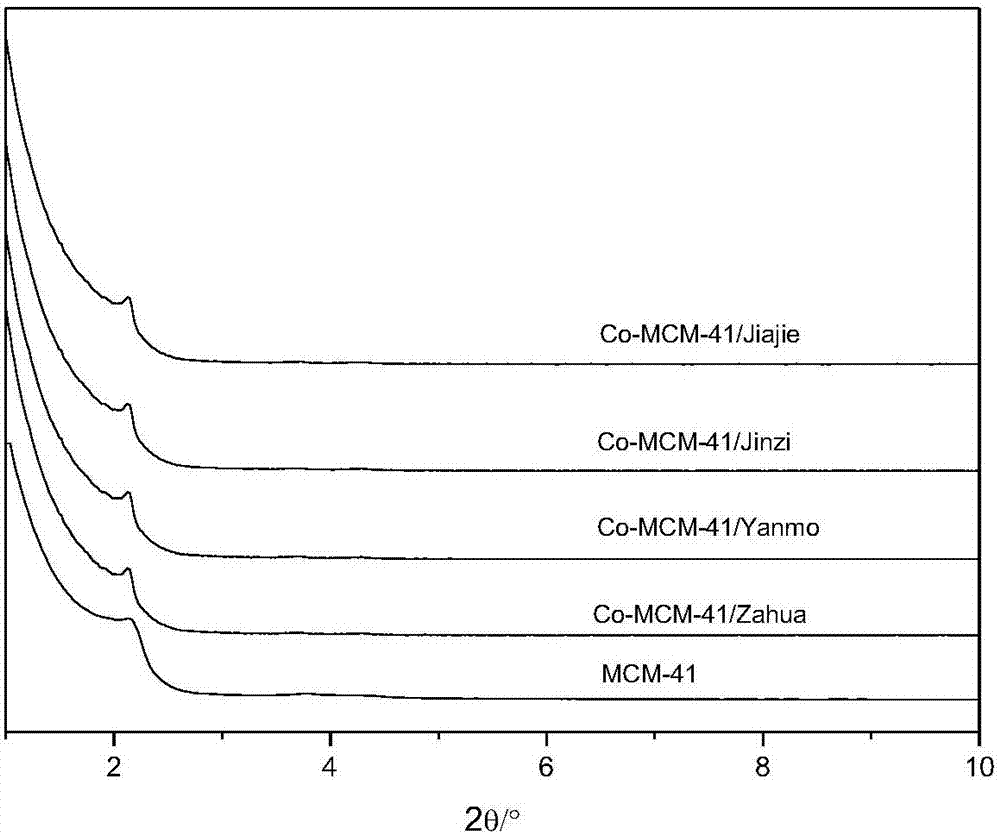

Co/MCM-41 catalyst and preparation method thereof

The invention relates to a toluene oxidation catalyst, and especially relates to a Co / MCM-41 catalyst and a preparation method thereof. The method comprises the following steps: mixing solid cetyl trimethyl ammonium bromide (CTAB) powder and a proper amount of water, and performing stirring until the above powder is dissolved fully; adjusting the system pH value to be 11-12 by using ammonia waterunder intense stirring, and performing stirring continuously for 30-40min; adding tetraethoxysilane (TEOS) to the system dropwise, pouring an aqueous solution containing cobalt ions once, and performing intense stirring for 24-26h; transferring an obtained mixed liquid to a crystallization kettle with a polytetrafluoroethylene inner liner, and allowing the obtained liquid to stand for 24-26h for crystallization under constant-temperature and dry conditions, wherein the temperature is 110+ / -5 DEG C; performing cooling on the crystallization kettle, performing vacuum filtration, and putting an obtained material into a calorstat with a temperature of 60+ / -5 DEG C, and performing drying for 12-24h; and after the obtained material is dried fully, transferring the dried material to a crucible, putting the crucible to a muffle furnace, and performing roasting to obtain the Co / MCM-41 catalyst.

Owner:刘义林

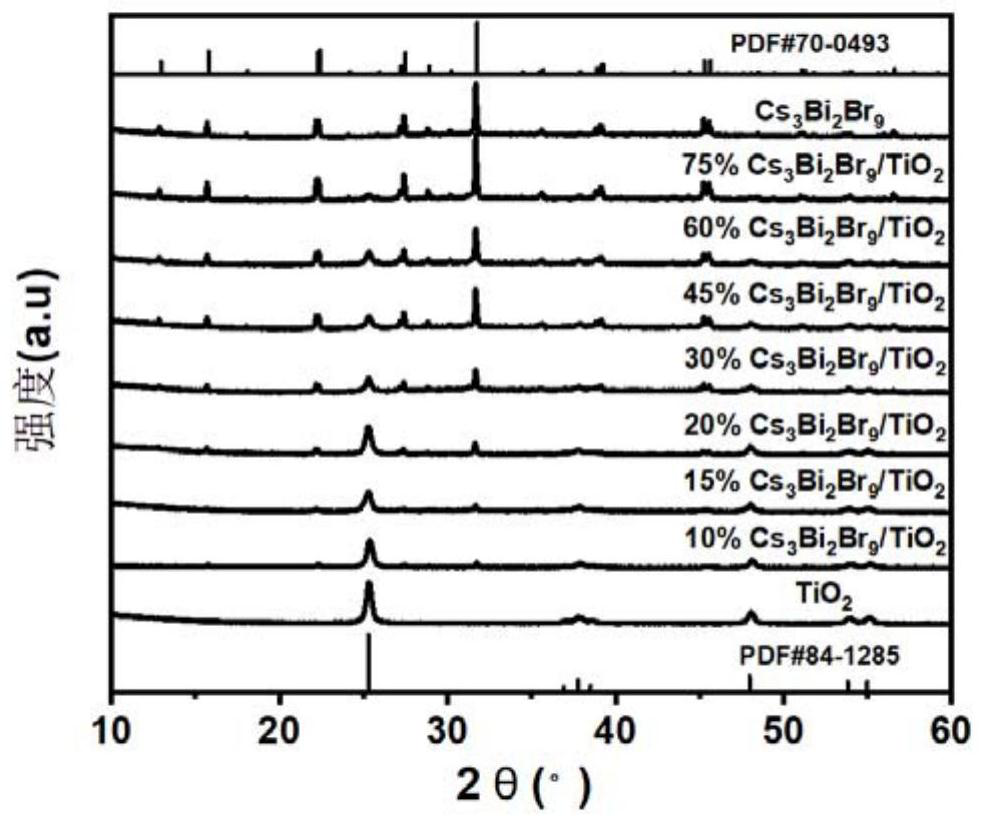

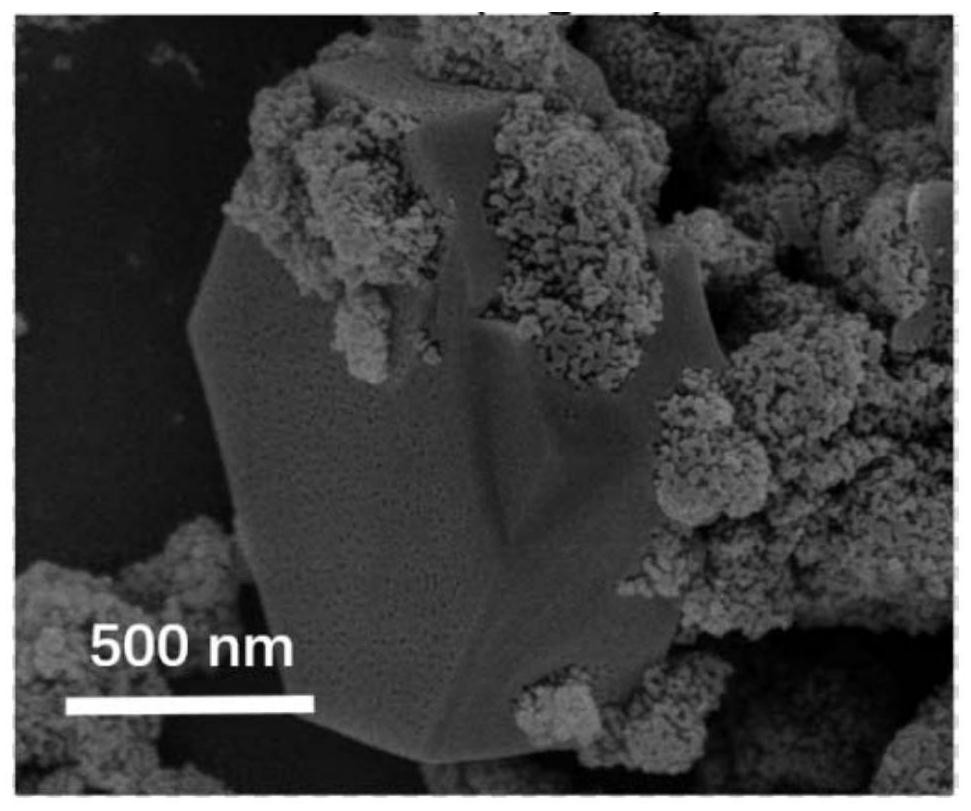

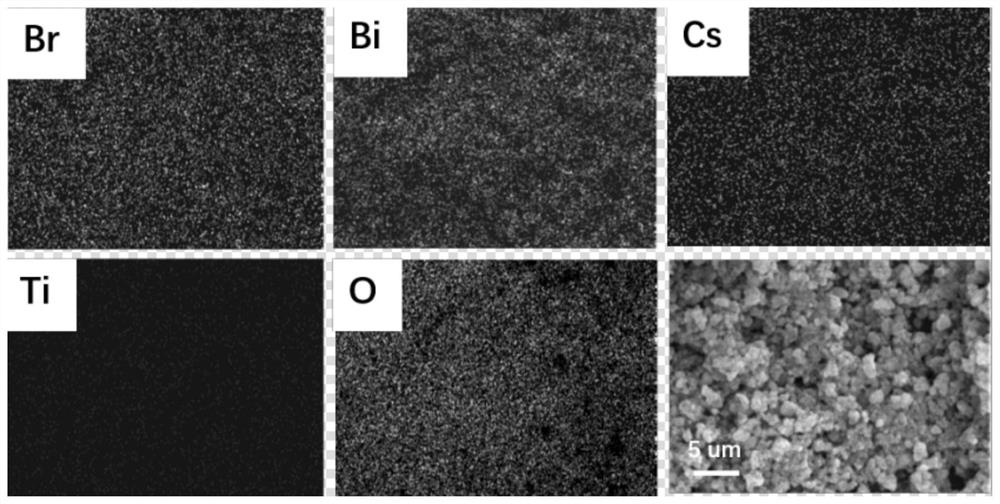

Cs3Bi2Br9/TiO2 perovskite heterojunction and preparation method thereof, and application of Cs3Bi2Br9/TiO2 perovskite heterojunction in photocatalytic toluene oxidation

PendingCN112295576AEasy to prepareEasy to operatePreparation by oxidation reactionsPhysical/chemical process catalystsHeterojunctionToluene oxidation

The invention discloses a Cs3Bi2Br9 / TiO2 perovskite heterojunction and a preparation method thereof, and an application of the Cs3Bi2Br9 / TiO2 perovskite heterojunction in photocatalytic toluene oxidation. The preparation method comprises the following steps: dropwise adding CsBr and BiBr3 solutions into a TiO2 dispersion liquid under stirring, then carrying out ultracentrifugation, and then dryinga solid to obtain the Cs3Bi2Br9 / TiO2 perovskite heterojunction. According to the invention, the Cs3Bi2Br9 / TiO2 perovskite heterojunction is added into toluene, illumination is carried out in the presence of oxygen, and benzyl alcohol is prepared, wherein the conversion rate exceeds 70%, and the selectivity is close to 100%.

Owner:SUZHOU UNIV

Synthetic method of benzoic acid in presence of 9-thienone compound

InactiveCN107814695AReduce energy consumptionAvoid heavy pollutionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidToluene oxidation

The invention belongs to the technical field of chemical engineering and in particular relates to a synthetic method of benzoic acid in presence of a 9-thienone compound. The synthetic method providedby the invention takes toluene as a raw material and the 9-thienone compound as a catalyst and does not need to adopt a solvent, and reaction is carried out for 40-48 hours under the irradiation of visible lights and room temperature and air conditions, so that toluene oxidation can be efficiently realized and the benzoic acid is generated. The synthetic method provided by the invention has the advantages that the benzoic acid can be prepared by adopting a toluene photooxidation method under room temperature and solvent-free conditions, so that optimization and transformation on an existing production technology for preparing the benzoic acid by adopting the toluene oxidation method are realized; and a visible light photosensitizer is adopted as the catalyst, and cost is reduced. The synthetic method provided by the invention can greatly reduce energy consumption, and the problem that the environment is polluted by waste produced by heavy metals and an acetic acid solvent and the problem of heavy metal residues in a product are thoroughly solved, thereby achieving energy-saving and environment-friendly effects. Compared with the traditional production technology, the synthetic method provided by the invention is greatly reduced in the whole power consumption, equipment investment and overall operation cost.

Owner:FUDAN UNIV

Integrated process for the production of benzoate plasticizers

InactiveUS20160068655A1Reduced impurity profileOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidAlcohol

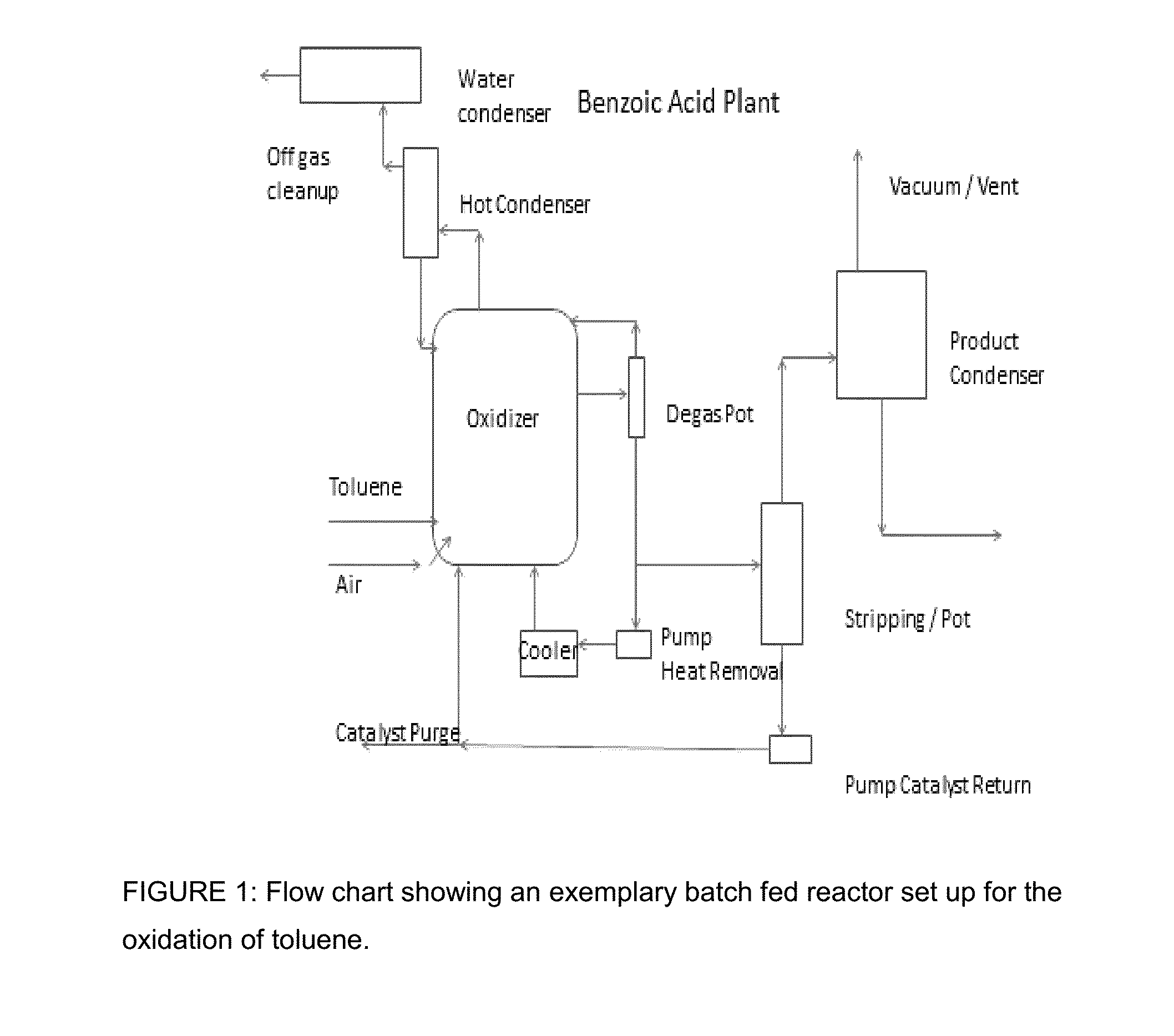

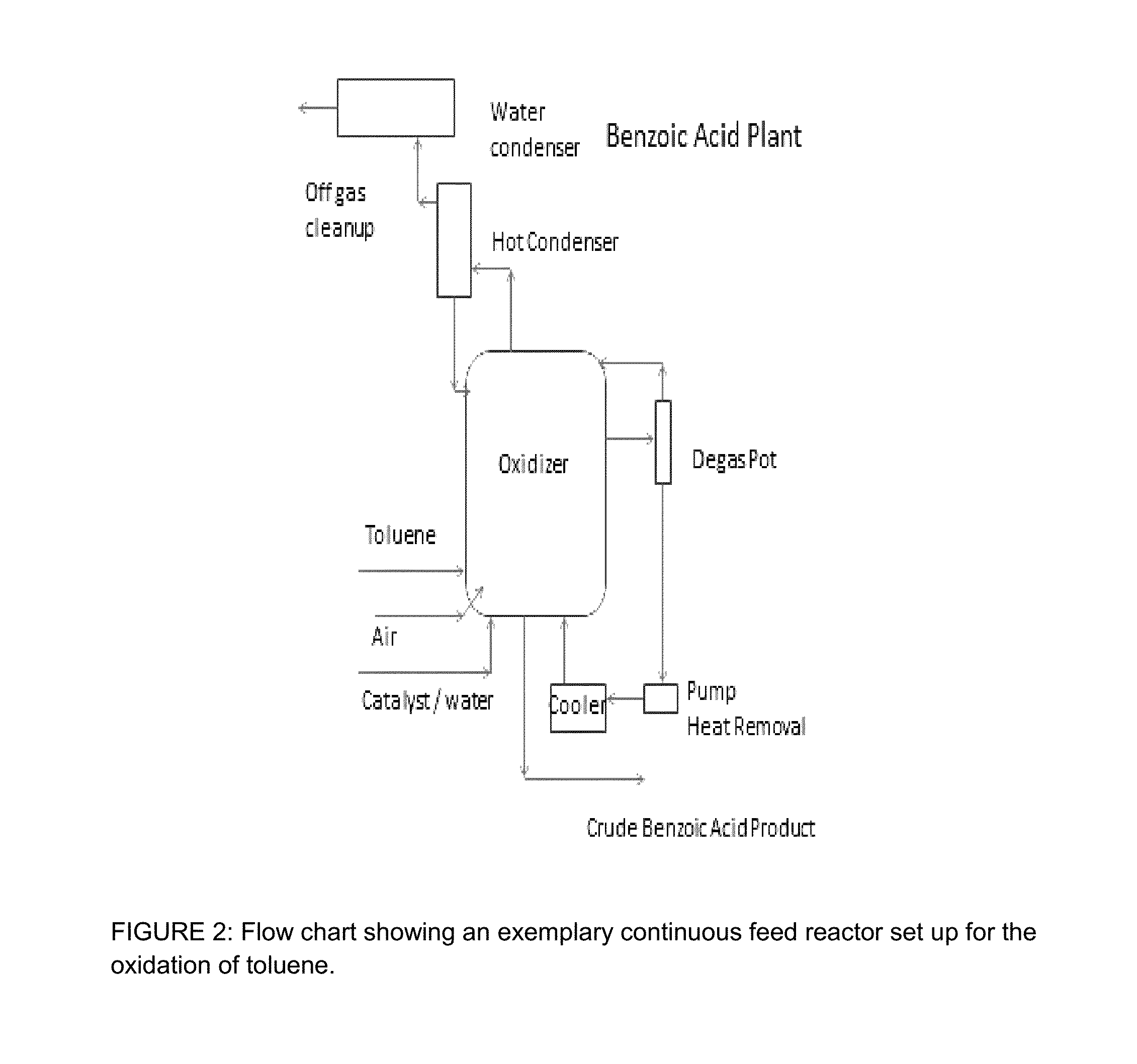

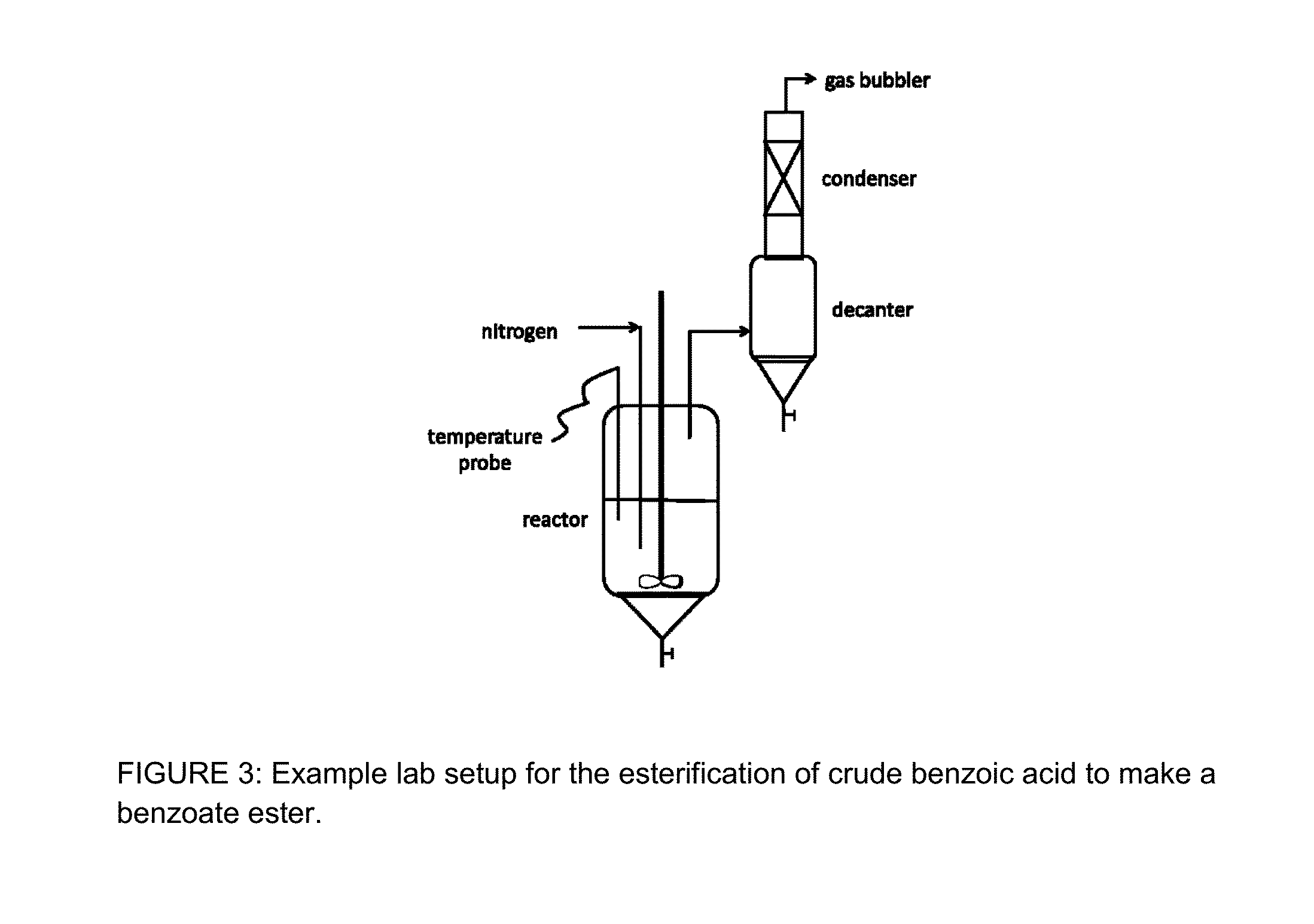

The invention relates to a process that integrates the oxidation of toluene to benzoic acid with the production of benzoate plasticizers. Toluene is fed to an oxidation vessel in the presence of oxygen and an oxidation catalyst wherein benzoic acid serves as the solvent for the oxidation. The crude benzoic acid produced is not purified and is then reacted with an alcohol in the presence of an esterification catalyst to produce the crude benzoate ester. The oxidation catalyst, esterification catalyst, and other impurities can be mostly removed from the crude benzoate ester in subsequent washing and filtering steps. The benzoate esters produced through this method can be made in fewer steps with both yields and purities above 80%.

Owner:EASTMAN CHEM CO

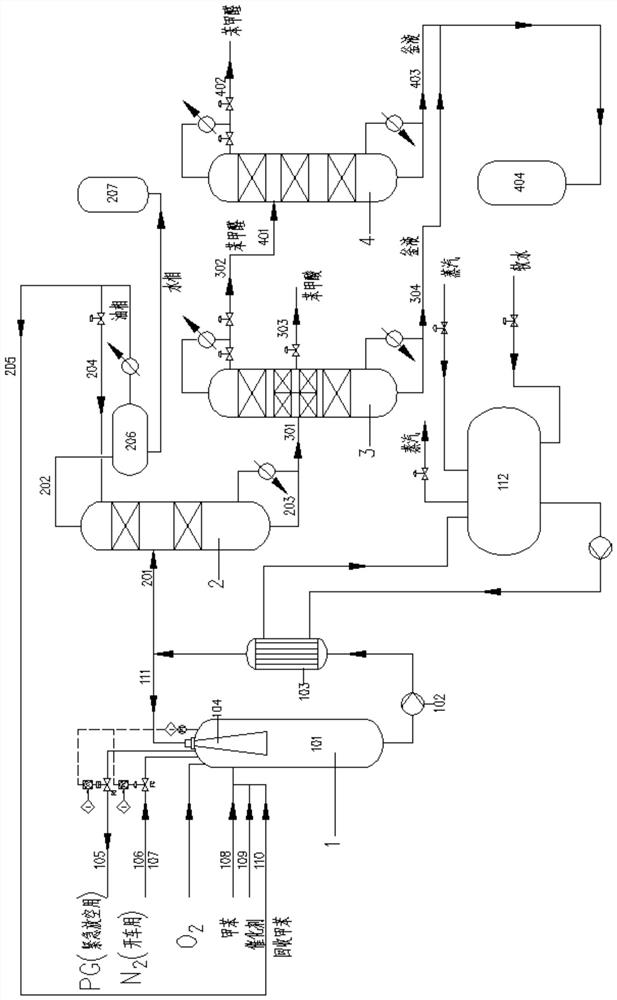

Preparation method of propylene oxide

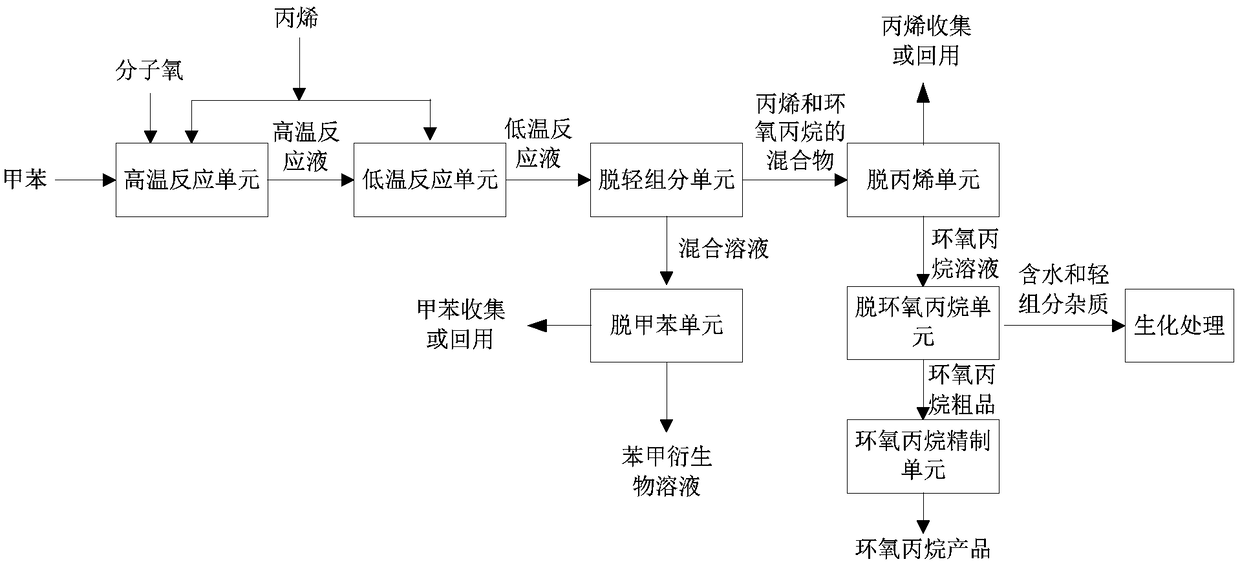

ActiveCN108912071ALess side effectsHigh selectivityOrganic chemistryBulk chemical productionPolymer scienceToluene oxidation

The invention discloses a preparation method of propylene oxide. Toluene, molecular oxygen and propylene are taken as raw materials, and the propylene oxide is prepared through a high-temperature reaction unit, a low-temperature reaction unit, a light component removal unit, a propylene removal unit, a propylene oxide removal unit, a propylene oxide refining unit and a toluene removal unit. The preparation method is an improvement on the basis of a method for preparing propylene oxide through a toluene oxidation reaction and a propylene epoxidation reaction. Compared with the existing processfor preparing propylene oxide, the preparation method provided by the invention has the advantages of high one-way toluene conversion rate, high reaction selectivity, high conversion rate, low energyconsumption, short technological process, and low operation cost.

Owner:河北美邦工程科技股份有限公司

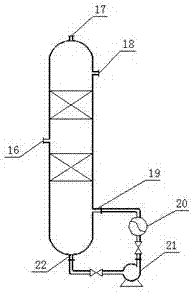

Method of two-column separation of benzoic acid, benzaldehyde and methylbenzene

InactiveCN104974034AHigh purityImplement extractionDistillation purification/separationCarbonyl compound separation/purificationBenzoic acidReflux

The invention discloses a method of extracting benzoic acid, benzaldehyde and methylbenzene from a toluene oxidation reaction liquid and belongs to a separation method of the toluene oxidation reaction liquid. The method includes following steps: 1) feeding the toluene liquid-phase oxidation reaction liquid into the bottom of a first rectifying column, and heating the reaction liquid when the liquid level reaches 1 / 3-1 / 2 of the bottom of the first rectifying column; (2) when the apparatus reaches total reflux, feeding vapor for controlling the temperature of the bottom of the first rectifying column to be 250-260 DEG C and the temperature of the bottom of the first rectifying column to be 185 DEG C; (3) feeding the top discharged material from the first rectifying column into the middle-lower part of a second rectifying column, and controlling the temperature of the bottom of the second rectifying column to be 177-180 DEG C and the temperature of the bottom of the second rectifying column to be 110-112 DEG C; and (4) through a continuous middle material feeding method, withdrawing a material flow from the bottom of the first rectifying column to obtain the benzoic acid, withdrawing a top distilled substance from the top of the second rectifying column to obtain the methylbenzene, and withdrawing a material flow from the bottom of the second rectifying column to obtain the benzaldehyde. The method is short in separation period, is simple in operation, is low in energy consumption and is high in yield. The obtained benzoic acid is high in purity. The method can achieve industrialization of extraction of the benzoic acid, the benzaldehyde and the methylbenzene from the toluene oxidation reaction liquid.

Owner:SINOPEC YANGZI PETROCHEM +1

Method for rectification and separation of benzoic acid, benzaldehyde, and toluene by single tower sidestream

ActiveCN103130639AHigh purityImplement extractionDistillation purification/separationCarbonyl compound separation/purificationBenzoic acidReflux

A method for rectification and separation of benzoic acid, benzaldehyde, and toluene by a single tower sidestream comprises the following steps: firstly adding a toluene liquid phase catalytic oxidation reaction solution into a tower kettle of a sidestream rectifying tower, heating when the liquid level reaches1 / 3-1 / 2 of the tower kettle height; when the device reaches total reflux, adjusting the temperature at the sidestream D-1 to 110-112 DEG C, the temperature at the sidestream D-2 to 177-180 DEG C, and the temperature at the sidestream D-3 to 249-255 DEG C from up to down; adding a reaction solution after toluene oxidation into the rectifying tower in a continuous intermediate charging mode, adjusting a reflux ratio to 3-5, wherein the sidestream D-1 distillate is toluene, the sidestream D-2 distillate is benzaldehyde, and the sidestream D-3 distillate is benzoic acid. The tower plate number of the rectifying tower is 96 or more than 96, but less than 110, and the raw material of the toluene oxidation reaction solution is preferably charged at the 25th-30th plate; the sidestream D-1 discharging port is the first tower plate, and the sidestream D-2 discharging port is the 40th-45th tower plate; the sidestream D-3 is the tower bottom.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing pyromellitic dianhydride by oxidizing durene and preparation method thereof

ActiveCN111068644AImprove responseHigh reactivityOrganic chemistryHeterogenous catalyst chemical elementsPtru catalystToluene oxidation

The invention provides a catalyst for preparing pyromellitic dianhydride by oxidizing durene and a preparation method thereof. The active component of the catalyst is composed of an active component,an auxiliary agent and a composite oxide carrier, and the composition is V-Ma-Ox / Ti-Mb-Ox, wherein V is the active component, the content of V in the active component is 10-30 wt%, Ma is the auxiliaryagent and is selected from one or more of Mo, W, P, Sb and Nb, and the molar ratio of the auxiliary agent Ma to the active component V is 0.01-0.5, the composite oxide carrier is Ti-Mb-Ox, Mb is oneor more of Ce, Zr and Sn, and the molar ratio of Mb to Ti is 0.1-0.8. A solid solution composite oxide with relatively high activation and oxygen species transmission capabilities is prepared througha coprecipitation or sol-gel method and then mixed with an active component solution to obtain active component slurry and then sprayed onto a spherical or annular catalyst carrier, dried and roastedto obtain the catalyst.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

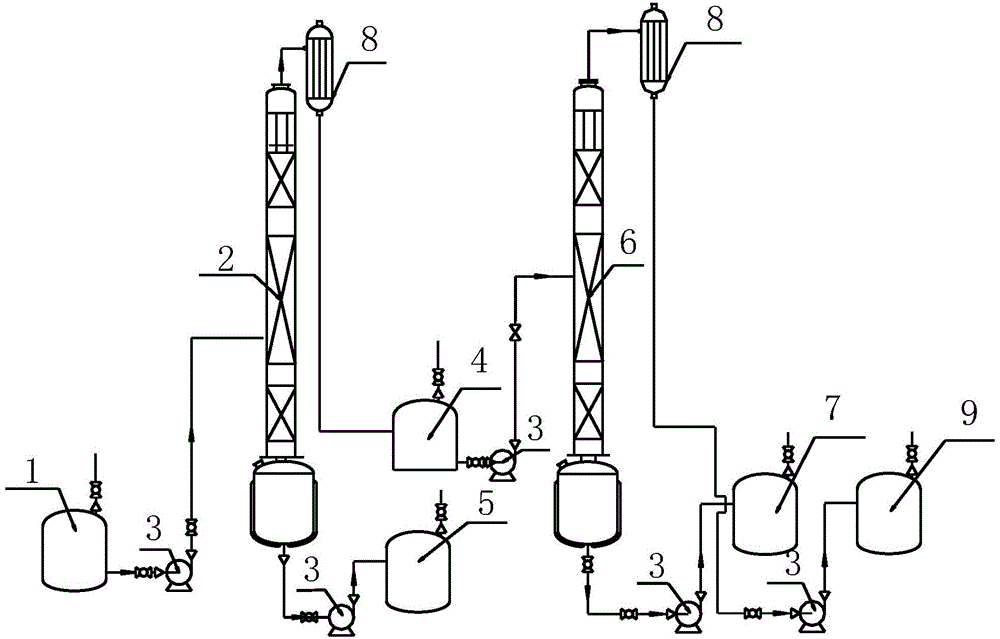

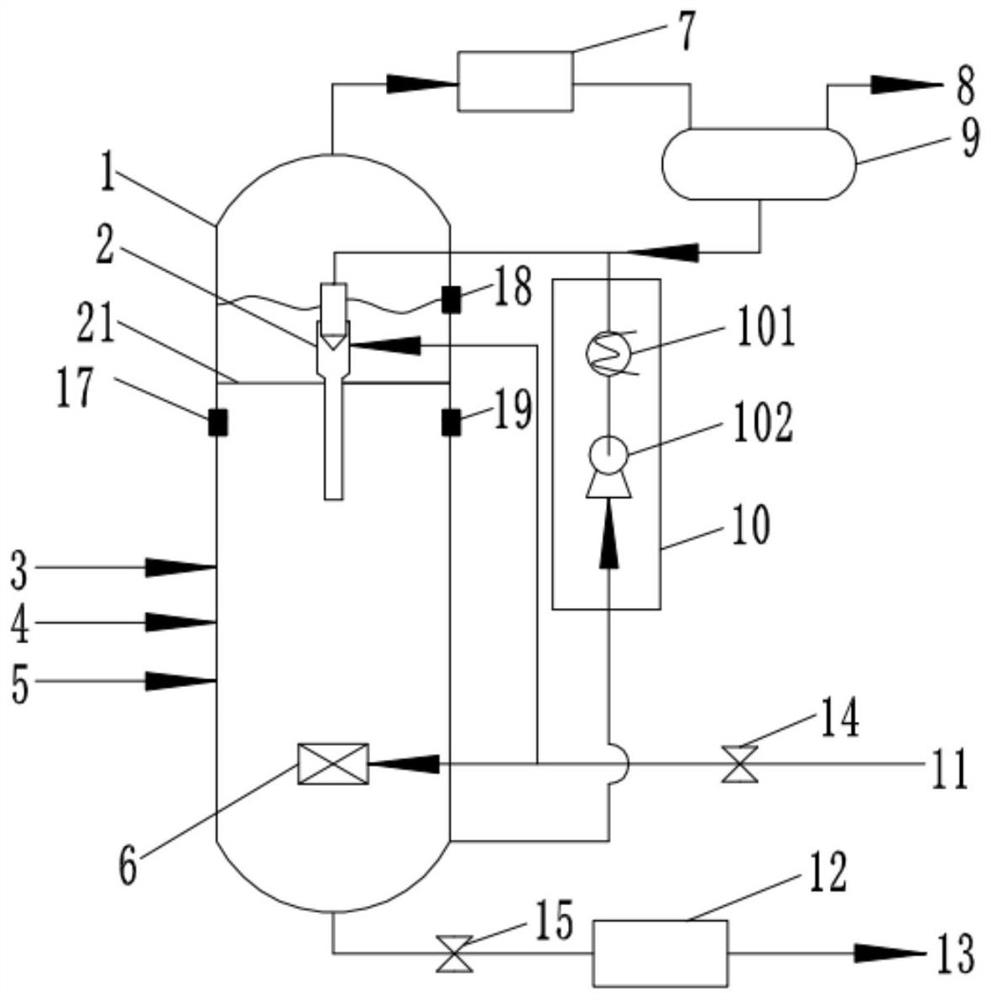

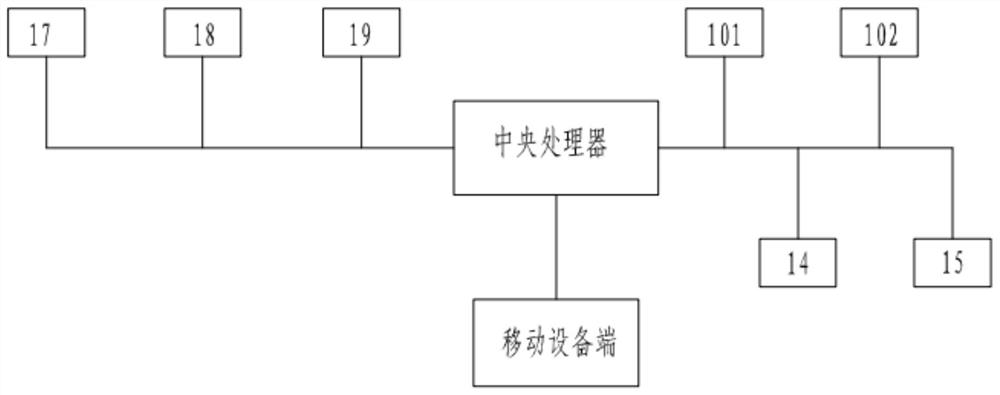

System and method for continuously producing high-quality and high-selectivity benzaldehyde and benzoic acid by using jet loop reactor

ActiveCN111606790AIncrease profitRealize continuous productionOrganic compound preparationDistillation separationBenzoic acidPtru catalyst

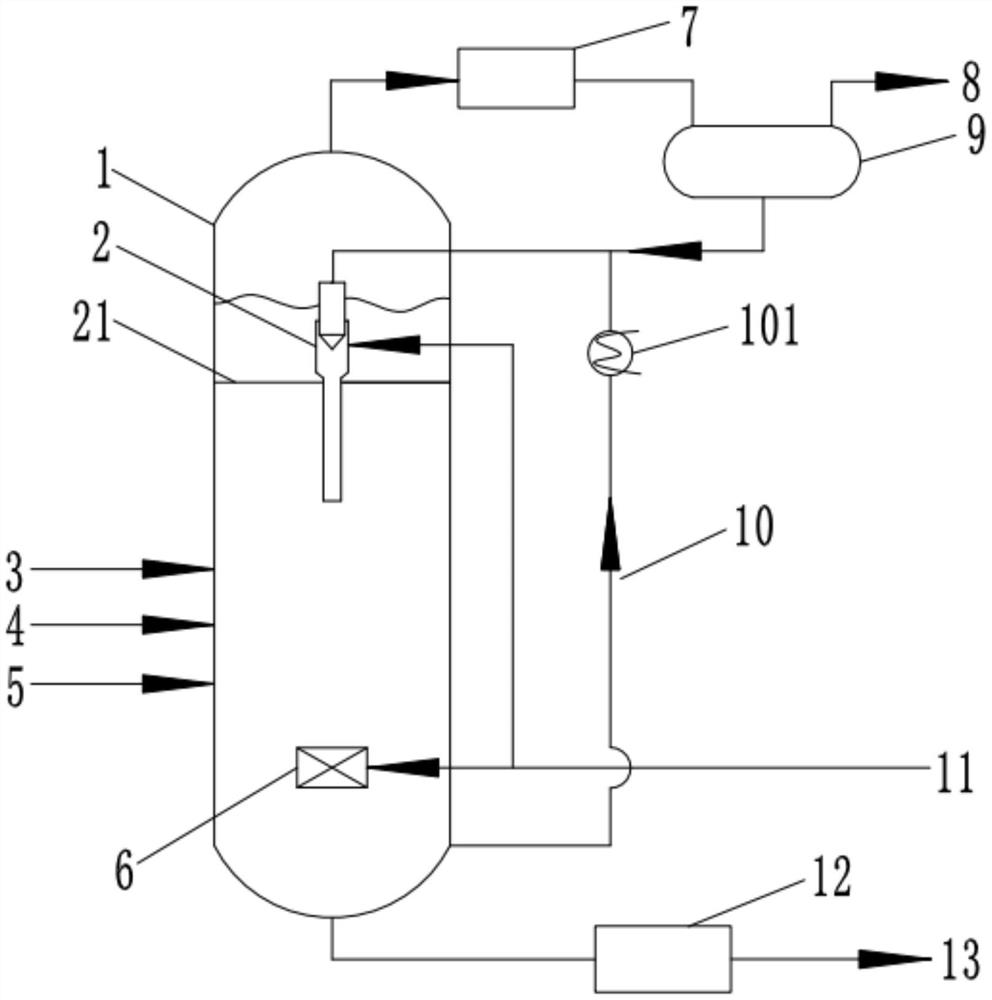

The invention discloses a system and a method for continuously producing high-quality and high-selectivity benzaldehyde and benzoic acid by using a jet loop reactor. The system comprises a jet loop reactor, a toluene removal tower, a dividing wall tower and a benzaldehyde rectifying tower. Based on the system, toluene oxidation reaction is performed in the jet loop reactor by taking toluene as a raw material, oxygen as an oxidizing agent and organic salt as a catalyst, and oxidation liquid after reaction is subjected to product purification through the toluene removal tower, the dividing walltower and the benzaldehyde rectifying tower, so that continuous production of high-quality and high-selectivity benzaldehyde and benzoic acid is realized. By means of the mode, the selectivity of benzaldehyde can be effectively improved, and high-quality benzoic acid and benzaldehyde with high purity can be produced. The production system is simple in structure and low in equipment investment, theproduction method is simple in operation, easy to control, short in reaction time and high in raw material utilization rate, and the whole reaction process is safe, stable, green and environment-friendly.

Owner:WUHAN YOUJI IND

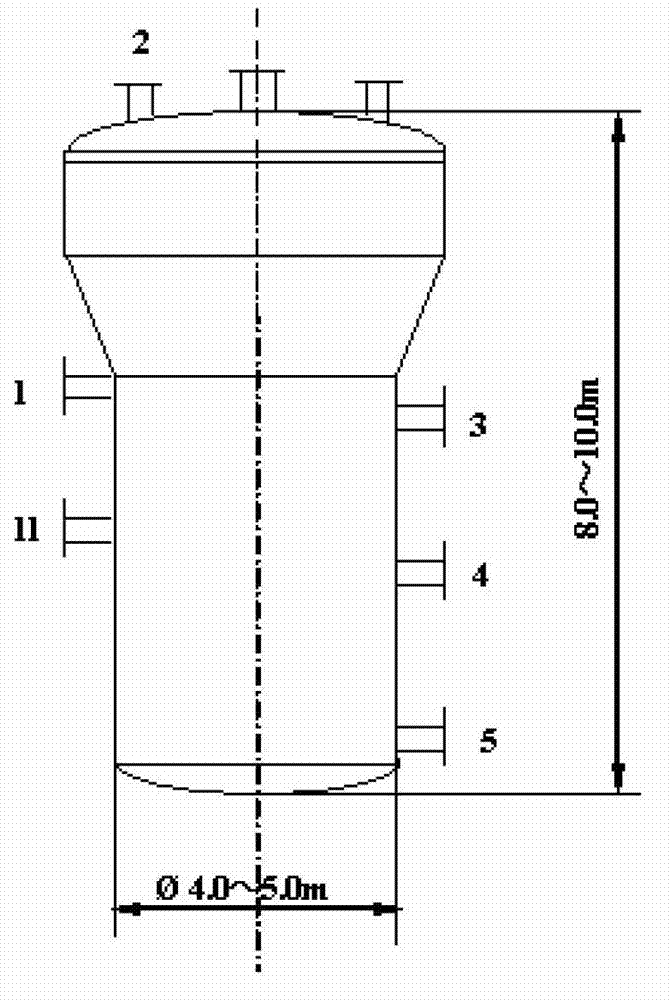

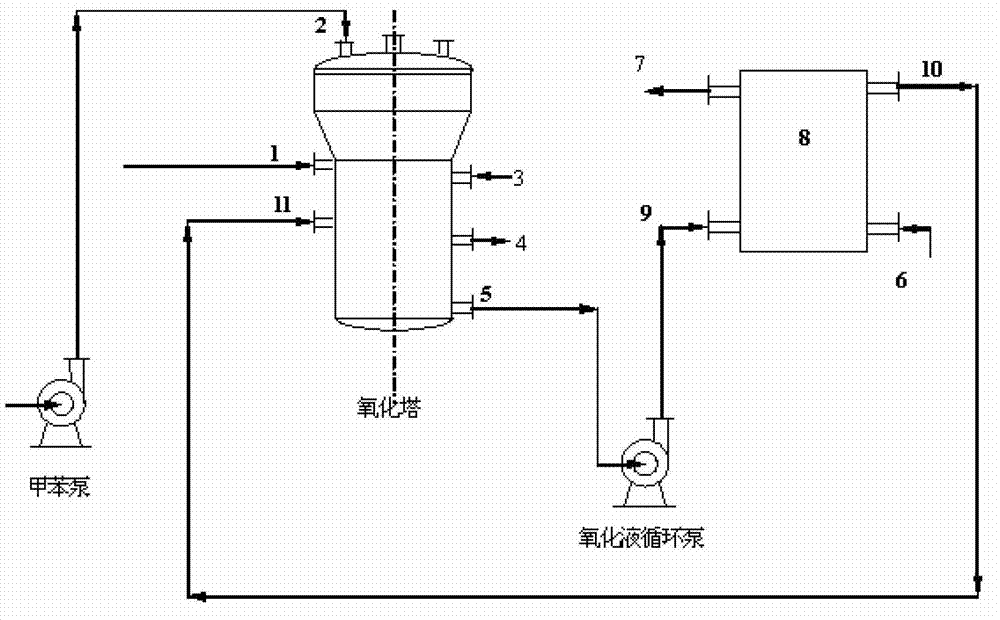

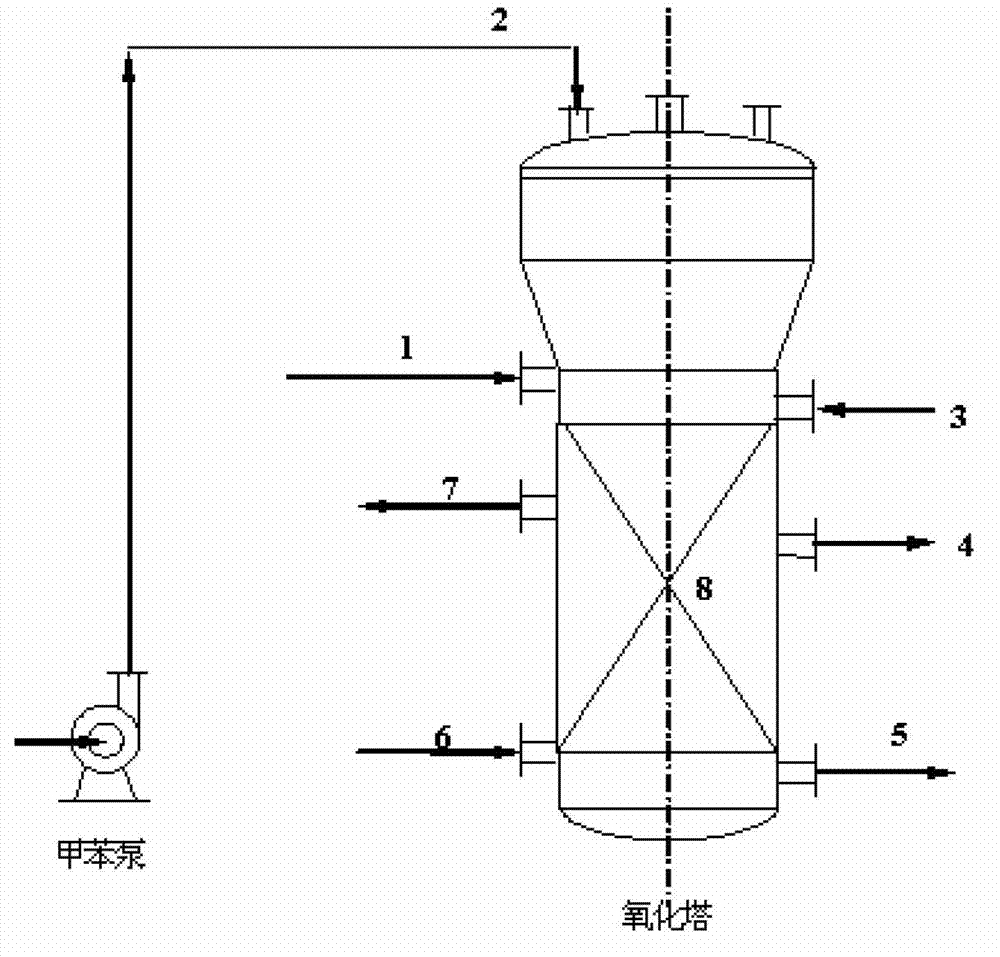

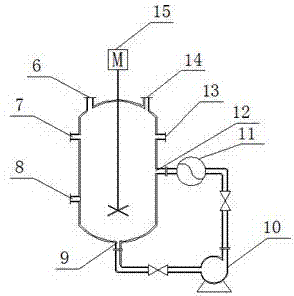

Methylbenzene oxidation tower in 10000-tone level benzoic acid production

The invention relates to a methylbenzene oxidation tower in 10000-tone level benzoic acid production. The oxidation tower has a height of between 8 and 10m, and a diameter of between 4 and 5m, wherein an air inlet, a methylbenzene inlet, a vapor inlet, a vapor outlet, an oxidation liquid outlet and an oxidation cooling liquid incoming oxidation tower port are arranged on the oxidation tower body; the distance from the air inlet to the bottom of the tower is between 6 and 8m, the distance from the vapor inlet to the bottom of the tower is between 4 and 6m, the distance from the vapor outlet to the tower bottom is between 3.5 and 5.5m, the distance from the oxidation liquid inlet to the bottom of the tower is between 0.3 and 0.5m, and the distance from the oxidation cooling liquid incoming oxidation tower port is between 5 and 7m; and the methylbenzene inlet is formed on the tower top. After the independently researched and developed oxidation tower is adopted, the methylbenzene oxidation reaction is an exothermic reaction, the heat exchange operation process is performed outside the tower, so that the construction investment of a methylbenzene oxidation workshop in benzoic acid production can be saved by 50 percent, and a previously adopted water-circulating pump of 55kw / h is replaced by a water-circulating pump of 22kw / h by virtue of a technology of circulating cooling outside the tower, and electric energy is saved by 40 percent by the methylbenzene oxidation tower. The methylbenzene oxidation tower is convenient to maintain and operate.

Owner:TIANJIN DONGDA CHEM GRP

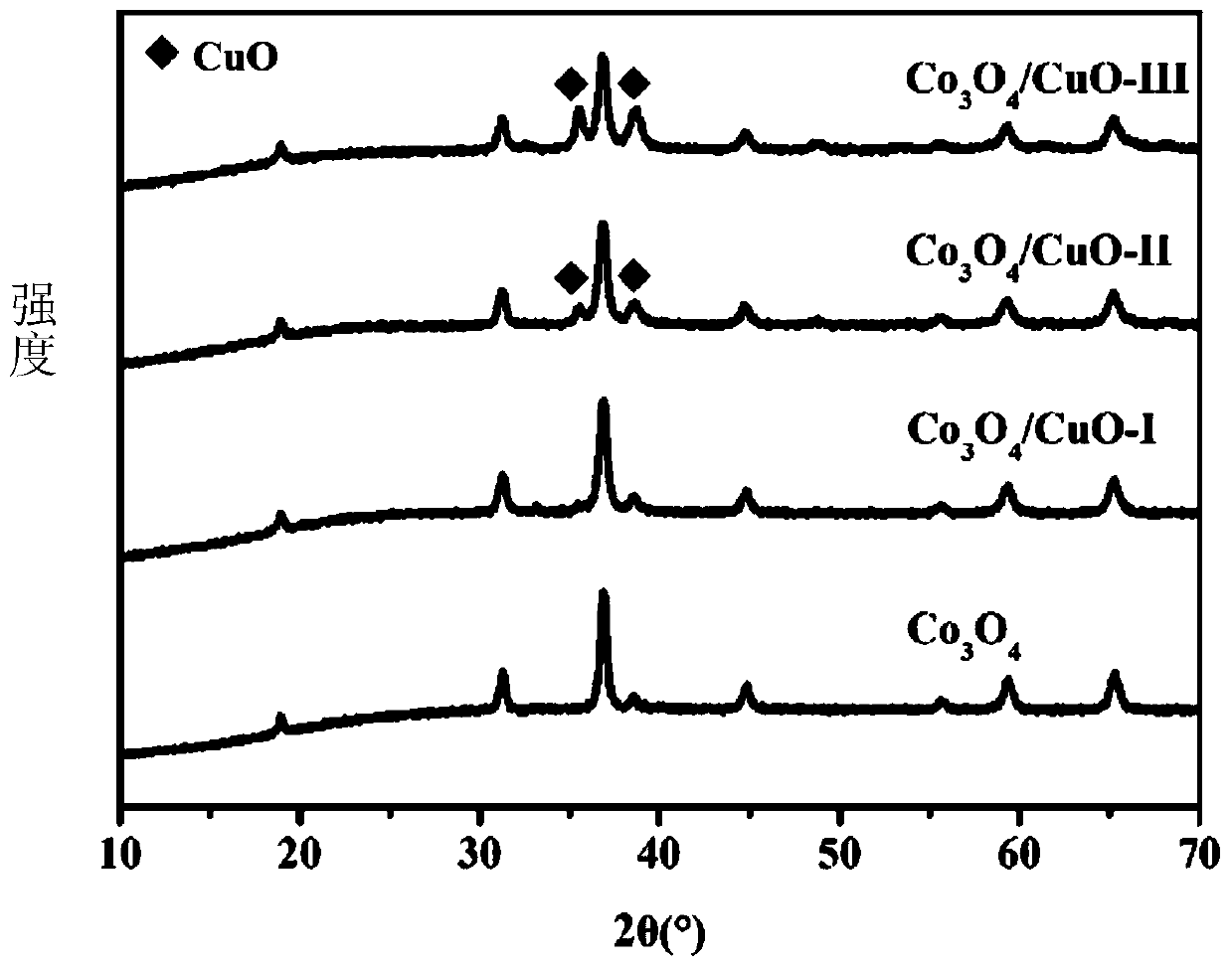

Co3O4/CuO high-efficiency photo-thermal catalyst, and preparation method and applications thereof

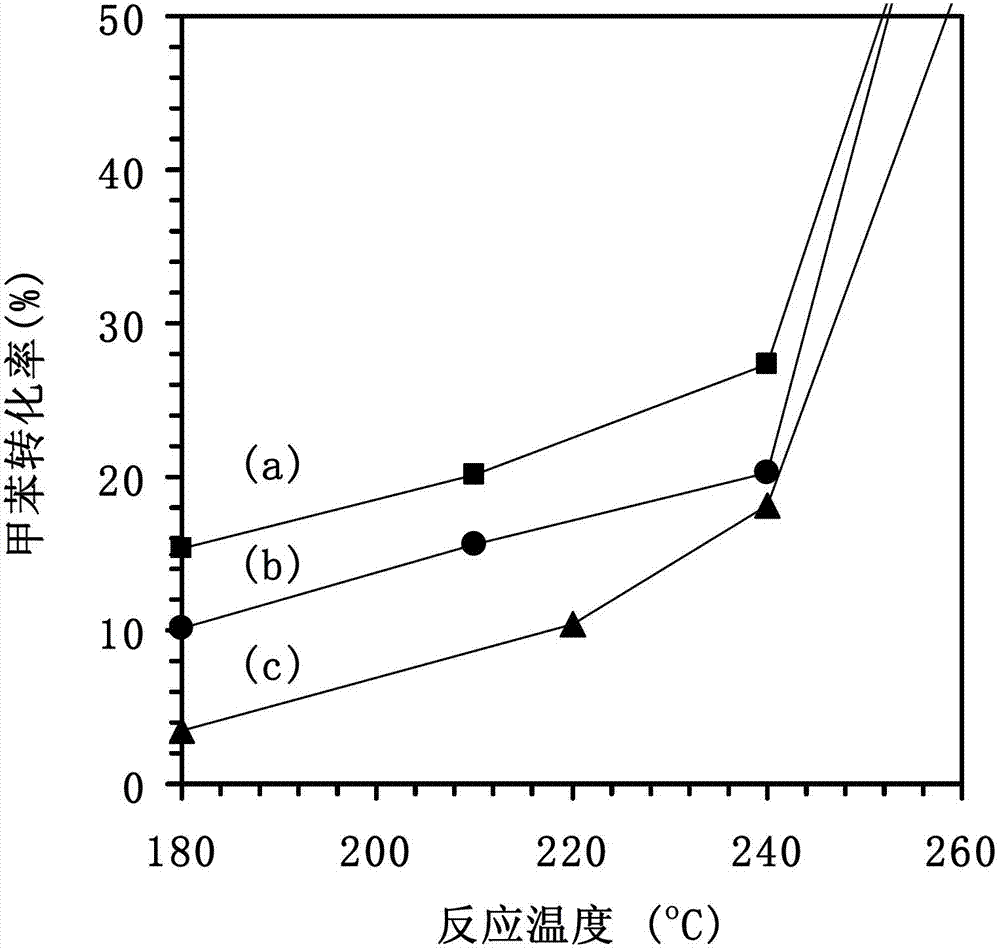

ActiveCN110152670AUniform shapeGood repeatabilityDispersed particle separationCatalyst activation/preparationToluene oxidationCobalt

The invention discloses a Co3O4 / CuO high-efficiency photo-thermal catalyst, and a preparation method and applications thereof. The preparation method comprises following steps: cobalt nitrate, cupricnitrate, and urea are taken as reaction raw materials, dissolving is carried out, coprecipitation hydro-thermal reaction is carried out, and washing and vacuum drying are carried out so as to obtain aprecursor; and 2, the precursor is subjected to roasting so as to obtain the Co3O4 / CuO high-efficiency photo-thermal catalyst. The technology is simple; cost is relatively low; the obtained product is uniform in morphology; the repeatability is high; high photo-thermal conversion performance is achieved; the Co3O4 / CuO interface effect is capable of reducing molecular oxygen activation energy obviously; compared with pure Co3O4, the advantages of Co3O4 / CuO are that more active substances are generated, so that toluene oxidation process sis more easy; toluene initial concentration is 360ppm, weight hourly space velocity is 90000 ml g<-1>h<-1>, when the temperature is increased to 125 DEG C through illumination heating, toluene degradation rate is as high as 91% or higher, inactivation resistance is improved greatly; and effective stable degradation of toluene at a low temperature is realized.

Owner:SOUTH CHINA UNIV OF TECH

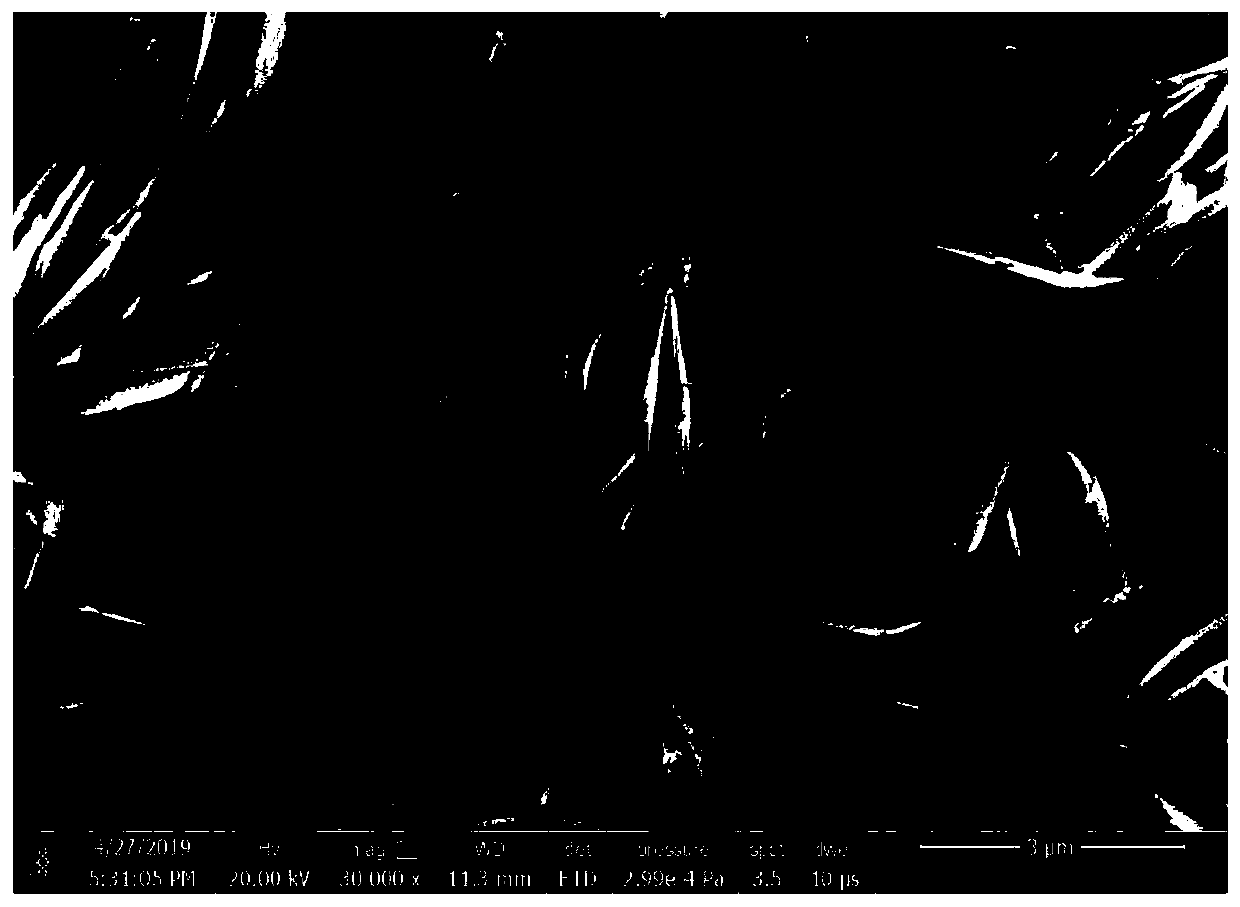

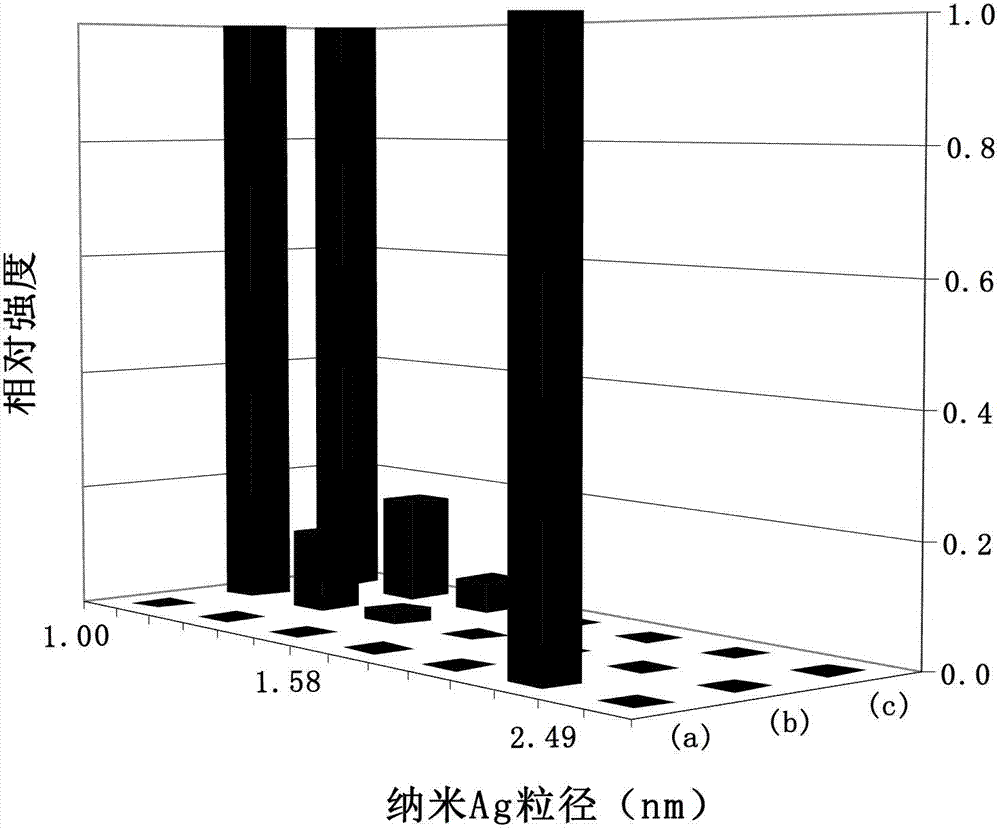

Single crystal Ag nanoplate/Co3O4/Eu0.6Sr0.4FeO3 composite catalyst, preparation thereof and application thereof

InactiveCN102728388AIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsRotary evaporatorToluene oxidation

The invention relates to a single crystal Ag nanoplate / Co3O4 / Eu0.6Sr0.4FeO3 composite catalyst, a preparation thereof and an application thereof, which belongs to the composite catalyst technical field. The single crystal Ag nanoplate / Co3O4 / Eu0.6Sr0.4FeO3 composite catalyst is loaded on the pore channel and the surface of Co3O4 / Eu0.6Sr0.4FeO3; 4mmol / L of AgNO3 solution and 6.0mmol / L NaBH4 solution are prepared according to the mol ratio of 1: 15: 0.7 of AgNO3, citric acid to PVP; 3DOM Co3O4 / Eu0.6S r0.4FeO3 is dipped in the AgNO3 solution, a NaBH4 solution is added according the mol ratio of 1: 6 of AgNO3 to NaBH4, and then the mixture is rapidly transferred to a rotary evaporation instrument when the concussion is carried out, and rotated and stirred at the room temperature for 60 minutes, filtered, washed, and dried at the room temperature to obtain the catalyst. The loaded sample presents more excellent catalytic performance on a toluene oxidation reaction at a low conversion rate phase.

Owner:BEIJING UNIV OF TECH

C12-to-C18 alkyl phosphonic acid protection magnetic ferroferric oxide nanocrystalline as well as preparation method and application thereof

InactiveCN102380421AHigh selectivityHigh activityCatalyst protectionOrganic compound preparationPtru catalystToluene oxidation

The invention provides a C12-to-C18 alkyl phosphonic acid protection magnetic ferroferric oxide nanocrystalline. The diameter of the magnetic ferroferric oxide nanocrystalline is 10 to 100nm, and the surface of the magnetic ferroferric oxide nanocrystalline is covered with C12 to C18 alkyl phosphonic acid. The invention also provides a preparation method of the nanocrystalline and an application of the nanocrystalline as catalysts to the preparation of benzaldehyde through toluene oxidation. The whole process is simple, the nanocrystalline is applicable to large-scale production, in addition, economy is realized, and no pollution is caused. The nanocrystalline provided by the invention has higher conversion rate and selectivity when being used as the catalyst under the certain reaction condition, the simple and full separation can be realized by magnetism after the reaction completion, the repeated use is realized, and in addition, the conversion rate and the selectivity maintain unchanged.

Owner:NANJING UNIV

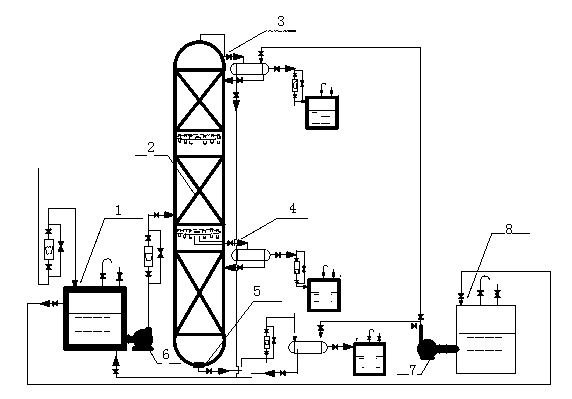

Process and apparatus for processing heavy byproducts in toluene oxidation process

ActiveCN106966861AReduce economic lossLiquid carbonaceous fuelsCarbonyl compound preparation by hydrolysisSaline waterBenzoic acid

The invention discloses a process and apparatus for processing heavy byproducts in toluene oxidation process; the heavy byproducts in the toluene oxidation process are hydrolyzed under alkaline conditions, the hydrolysate is separated by a separation column into a light component and a heavy component, the light component is separated again into water, benzyl alcohol and benzaldehyde, the benzyl alcohol and benzaldehyde are returned to the original production process, part of the water is reused as process water for hydrolysis, the other part of the water is used as process water to desalt the heavy component by washing, saline water is recycled after the heavy component is desalted, and the desalted heavy oil is used as a heat source. By using the process and apparatus, it is possible to convert toluene-oxidized heavy byproducts into high-added-value products, benzyl alcohol and benzaldehyde, the produced saline water is recyclable for the production of a high-added-value product, sodium benzoate or benzoic acid, part of the heavy byproducts are converted into little heavy oil used as a fuel, and economic loss is lowered.

Owner:湖北科林博伦新材料有限公司

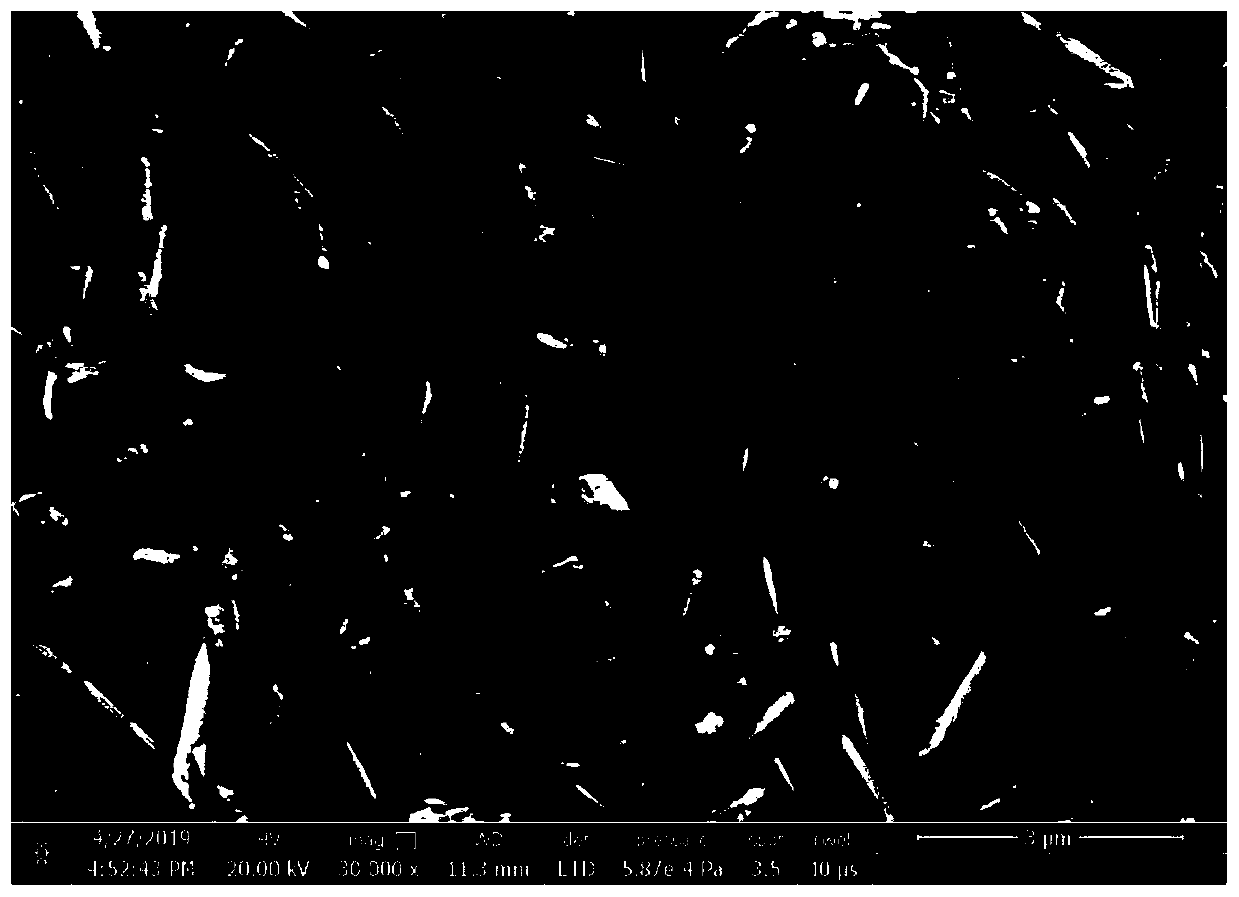

Three dimensional ordered macroporous structure Ag micrometer beam/Eu0.6Sr0.4FeO3 composite catalyst, its preparation and its application

InactiveCN102728387AThe load is easy to controlEnhance mass transfer movementIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsUltrasonic assistedToluene oxidation

The invention relates to a three dimensional ordered macroporous structure Ag micrometer beam / Eu0.6Sr0.4FeO3 composite catalyst, its preparation and its application, which belongs to the composite catalyst technical field. Ag nanoparticles is aggregated to a micrometer bundles and loaded on a carrier Eu0.6Sr0.4FeO3 surface, the composite catalyst presents a pure perovskite phase. A 1mmol / L-5mmol / L AgNO3 solution is prepared according to mol ratio of 2:3 of AgNO3 to PVP constitutional unit, the pH value can be regulated to 8-9; a NaBH4 solution is prepared, wherein the AgNO3 concentration accounts for 1 / 2 of NaBH4 concentration; 3DOM Eu0.6Sr0.4FeO3 is immersed in the AgNO3 solution, AgNO3 and NaBH4 is added in the NaBH4 solution according to mol ratio of 1:2; a super ultrasonic wave auxiliary membrane reduction method is employed for connecting two solutions in a tubular type membrane reactor with nanometer Ag sol generated by reaction, and filtered and dried under the room temperature after the reaction is completed to obtain the catalyst. The loaded sample presents more excellent catalysis performance on the toluene oxidation reaction.

Owner:BEIJING UNIV OF TECH

Control system and process for producing terephthalic acid by m-xylene oxidation

InactiveCN112552160AImprove mass transfer efficiencyShort reaction timeOrganic compound preparationChemical/physical/physico-chemical microreactorsXylyleneTemperature control

The invention discloses an intelligent control system and process for producing terephthalic acid by m-xylene oxidation. The intelligent control system comprises a slurry bed reactor, a first micro-interface generator, a second micro-interface generator, a condensation unit, a separation unit, a temperature control circulation unit and a crystallization filter, wherein the slurry bed reactor is used as a reaction place of xylene oxidation and is filled with liquid-phase phthalic acid; at least one first micro-interface generator is arranged on a fixed plate positioned in the slurry bed reactor; and at least one second micro-interface generator is arranged in the slurry bed reactor and is positioned below the first micro-interface generator. The system is further provided with the temperature control circulation unit which is used for pumping liquid at the bottom of the slurry bed reactor into a liquid phase inlet of the second micro-interface generator so as to achieve the effect of circulating a solvent in the reactor. The micro-interface generator and other devices are arranged in the reactor, so that the mass transfer efficiency of the gas phase and the liquid phase is improved,the reaction time is shortened, and the material consumption and energy consumption are reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Clean recovery method of toluene oxidation catalyst

InactiveCN103240104AHigh yieldThe method of recovering the catalyst is simplePhysical/chemical process catalystsCarbonyl compound separation/purificationRecovery methodBenzoic acid

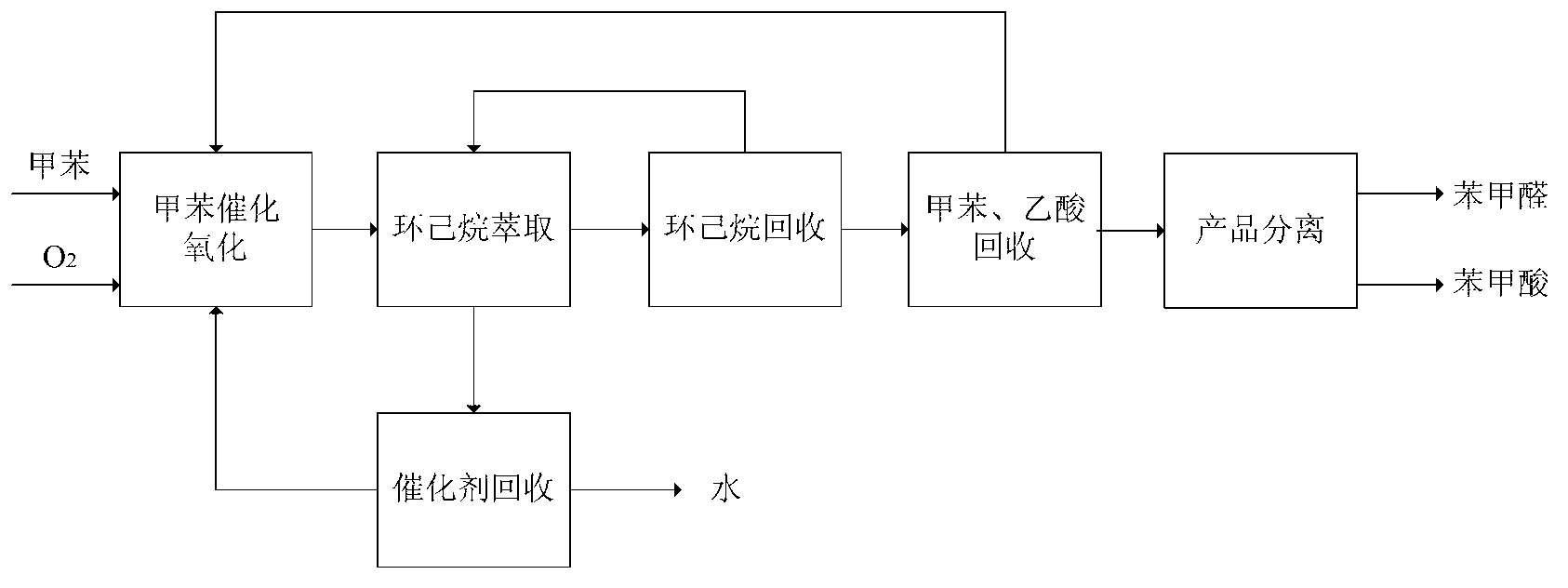

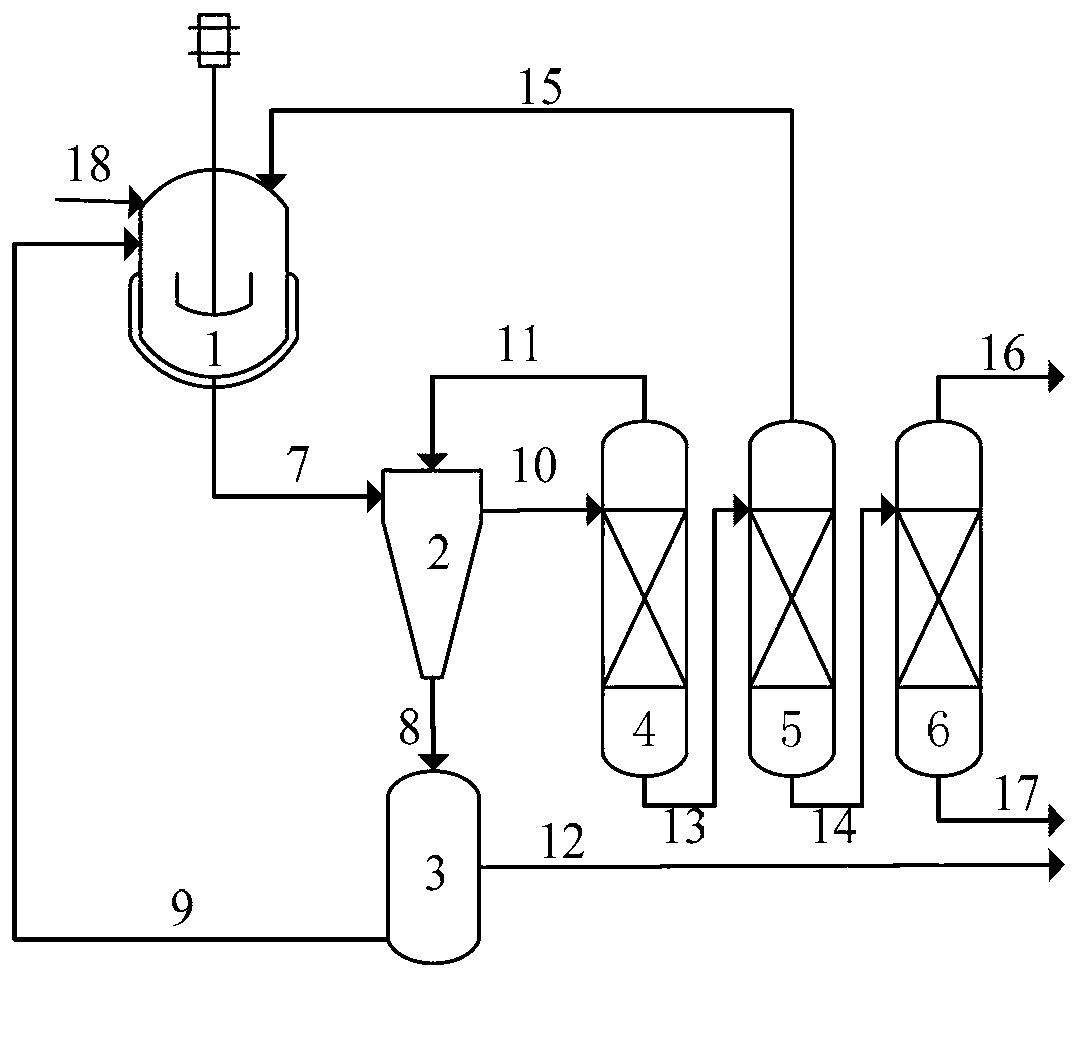

The invention discloses a recovery method for toluene oxidation production of benzaldehyde or a benzoic acid catalyst. The method is mainly characterized by comprising the following steps of: oxidizing toluene to produce benzaldehyde, benzyl alcohol and benzoic acid, and generating water in toluene oxidation reaction of taking cobalt, manganese and bromine as a catalytic system; firstly, extracting reactant toluene, and products benzaldehyde, benzoic acid and benzyl alcohol into cyclohexane by cyclohexane after the reaction is finished; separating an organic phase from a water phase containing the catalyst; separating the organic phase by rectification; firstly, separating all cyclohexane to feed to an extraction system; then separating acetic acid and toluene to feed to a reaction system; finally separating the product benzaldehyde and benzyl alcohol from benzoic acid; and feeding the catalyst containing a little of benzoic acid to the reaction system for directly carrying out next batch of toluene oxidation reaction after carrying out simple distillation to remove moisture by a water phase. The result shows that the recovered catalyst still has a good catalytic effect on toluene oxidation; and main product benzaldehyde is less in loss and high in yield in the separating process.

Owner:NANJING UNIV

System and process for producing phthalic acid by strengthening xylene oxidation

PendingCN112546973AImprove mass transfer efficiencyShort reaction timeOrganic compound preparationChemical/physical/physico-chemical microreactorsXylyleneFluid phase

The invention provides a system and process for producing phthalic acid by strengthening xylene oxidation. The system comprises a slurry bed reactor, micro-interface generators, a circulating pipeline, a gas inlet pipeline and a separation unit, wherein the upper part of the slurry bed reactor is communicated with the condensation unit, and the lower part is communicated with the crystallization filter; the micro-interface generators are arranged in the slurry bed reactor and used for crushing gas into micron-sized micro bubbles, so that the mass transfer efficiency of gas and liquid is improved, and the reaction pressure is reduced; the circulating pipeline is used for pumping a liquid-phase material at the bottom of the slurry bed reactor into the second micro-interface generator; and afeed port of the separation unit is connected with the condensation unit, and a liquid-phase material outlet of the separation unit is communicated with a liquid-phase material inlet of the first micro-interface generator.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Method of preparing dihalogen nitrobenzoate using dihalogen methyl nitrobenzene oxidation

InactiveCN100999457AReduce manufacturing costOperational securityOrganic compound preparationCarboxylic compound preparationSocial benefitsToluene oxidation

This invention provides a method of using dipl-halogena nitrotoluene to prepare dipl-halogena nitrobenzoic acid. Mix dipl-halogena nitrotoluene with nitric acid under normal temperature, and then take reaction at 110 to 300 deg C and 0 to 10MPa, to gain dipl-halogena nitrobenzoic acid. The mixture ratio (mol / mol) of nitric acid and dipl-halogena nitrotoluene is 1:21 to 100; the nitric acid concentration of 4% to 70%. Since the invention at room temperature and atmospheric pressure directly mix the materials, so operating temperature is low than the start temperature many, thus making operation simple and safe, the low production costs and high-yield, the reaction residue can be reused, little pollution, and good economic and social benefits.

Owner:YANCHENG SHIHONG CHEM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com