Three dimensional ordered macroporous structure Ag micrometer beam/Eu0.6Sr0.4FeO3 composite catalyst, its preparation and its application

A eu0.6sr0.4feo3, composite catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, incinerators, etc., can solve the problems of no literature and patent reports, and achieve enhanced The dispersion effect and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: 1. prepare the silver nitrate solution of 5mmol / L: weigh 0.3398g AgNO 3 Dissolve in 50mL deionized water, stir well to dissolve, add 0.3330g polyvinylpyrrolidone (PVP), adjust the volume of the solution to about 80mL, and finally adjust the pH value of the solution system with NaOH solution with a concentration of 0.1mol / L 8~9, and dilute to 400mL with deionized water; ②Prepare 20mmol / L NaBH 4 Reduction solution: 0.1515g NaBH 4 Fully dissolved in 200mL deionized water; ③Ultrasonic-assisted membrane reduction method (UAMR method) to prepare the three-dimensional ordered macroporous structure Eu loaded with bundled Ag 0.6 Sr 0.4 FeO 3 : Take the AgNO prepared in ① 3 Dilute 4.64mL of dilute solution to 200mL, weigh 0.25g Eu 0.6 Sr 0.4 FeO 3 The catalyst is impregnated in it, take the NaBH prepared in ② 4 2.32mL of the dilute solution was diluted to 200mL, and then the beakers containing the two solutions were respectively placed in the corresponding p...

Embodiment 2

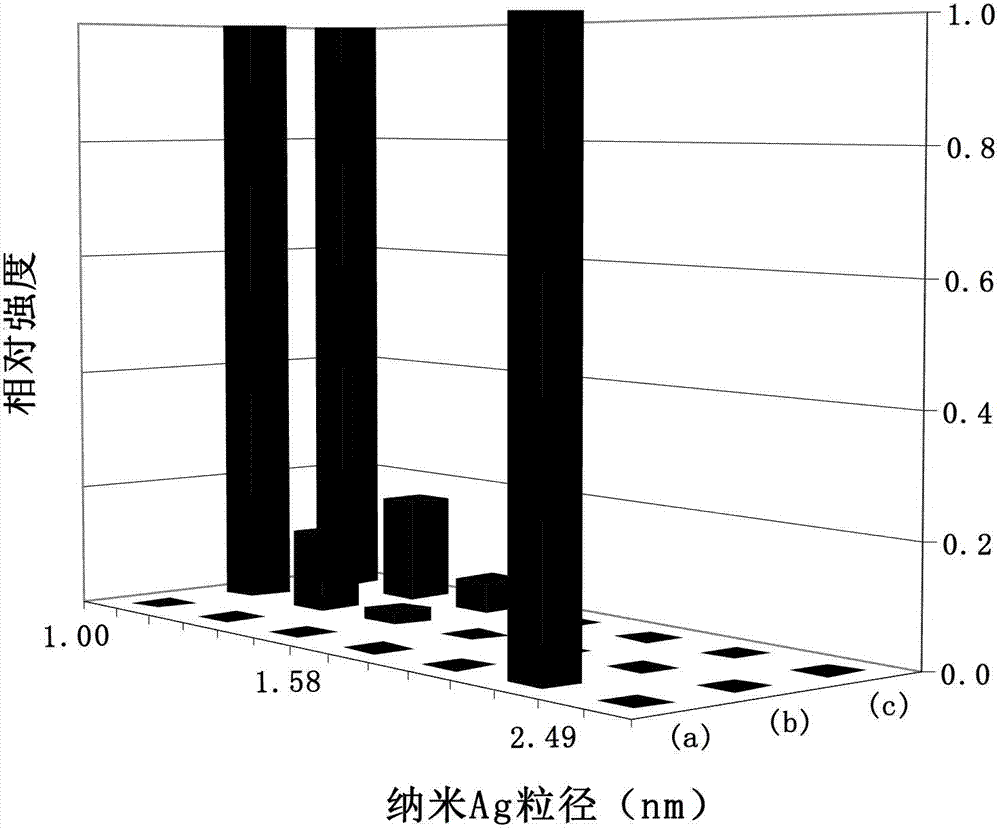

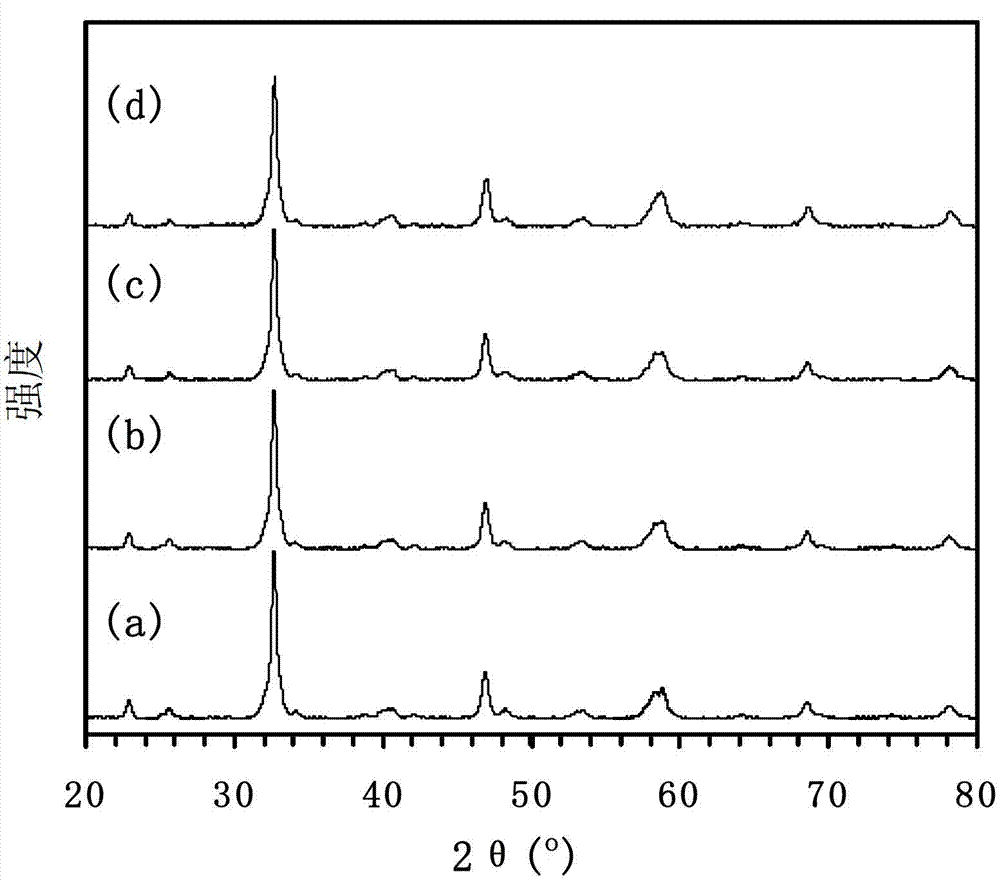

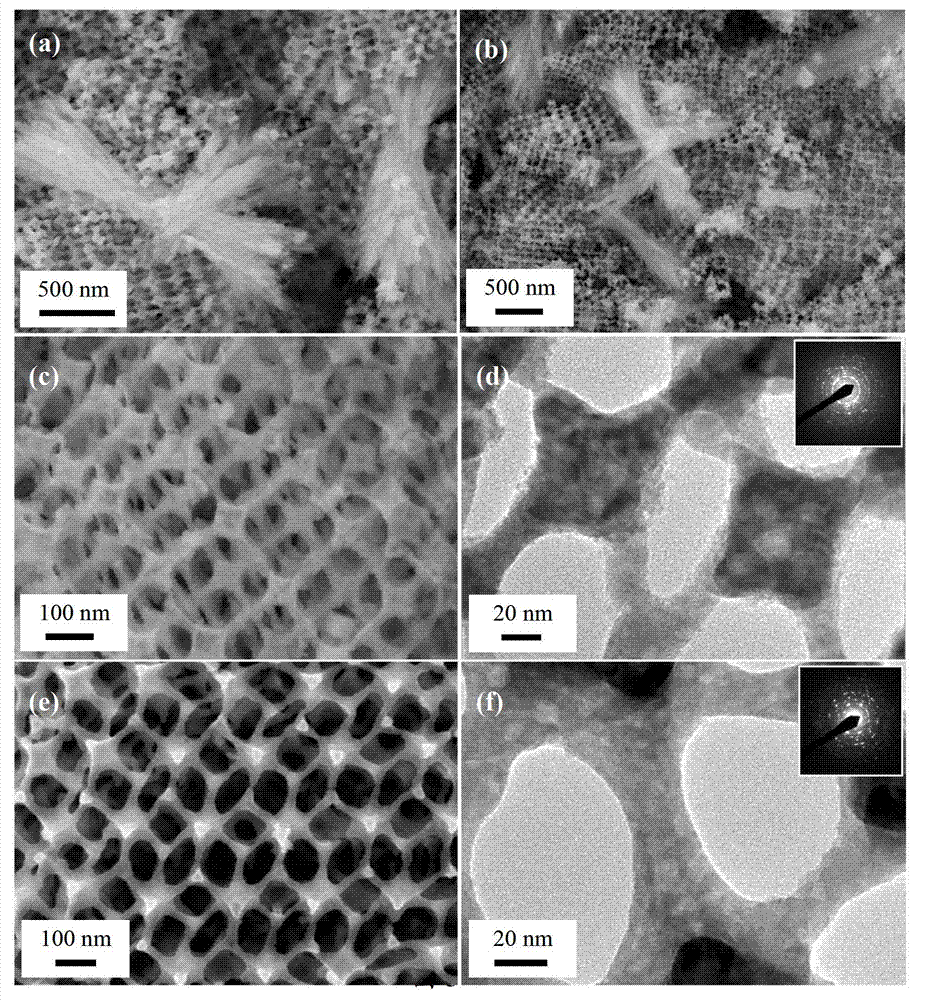

[0020] Embodiment 2: other steps and implementation method are the same as embodiment 1, only in step 3.: get AgNO 3 Dilute 27.81mL of dilute solution to 200mL, weigh 0.50g Eu 0.6 Sr 0.4 FeO 3 The catalyst is impregnated in it, and the prepared NaBH 4 13.91mL of dilute solution was diluted to 200mL. At this point, Ag microbeams / Eu with a theoretical loading of 3wt% 0.6 Sr 0.4 FeO 3 supported catalyst. The particle size of Ag particles prepared in this example is about 1nm, and the supported catalyst exhibits a pure perovskite crystal structure, and Ag nanoparticles are aggregated into bundles and distributed on the surface of the carrier. The diameter of each bundle is about 100nm, and the length is about 500~1500nm, the obtained three-dimensional ordered macroporous structure 3wt%Ag micro beam / Eu 0.6 Sr 0.4 FeO 3 The catalytic activity test result of catalyst to toluene shows that its T 50% and T 90% are about 254°C and 296°C respectively, while Eu 0.6 Sr 0.4 Fe...

Embodiment 3

[0021] Embodiment 3: other steps and implementation method are the same as embodiment 1, only in step 3.: get AgNO 3 Dilute 23.18mL of dilute solution to 200mL, weigh 0.25g Eu 0.6 Sr 0.4 FeO 3 The catalyst is impregnated in it, and the prepared NaBH 4 11.59mL of dilute solution was diluted to 200mL. At this point, Ag microbeams / Eu with a loading of 5wt% were obtained 0.6 Sr 0.4 FeO 3 supported catalyst. The particle size of Ag particles prepared in this example is about 1nm, and the supported catalyst exhibits a pure perovskite crystal structure. 0.6 Sr 0.4 FeO 3 The comparison of the electron microscope photos shows that the Ag material may be loaded on the surface of the procatalyst pore channel, because the prepared Ag particles are very small, and the distribution state of a single Ag particle cannot be determined. 0.6 Sr 0.4 FeO 3 The catalyst is still polycrystalline, and the catalytic activity test result to toluene shows that its T 50% and T 90% are about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com