Method for preparing SBA-15 loaded metal or metallic oxide composite material

A composite material, metal-loaded technology, applied in the directions of silicon oxide, silicon dioxide, nanotechnology, etc., can solve the problems of difficult control of loading, waste of precursors, poor dispersion, etc., and achieves low equipment requirements, controllable structure, and reaction. mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

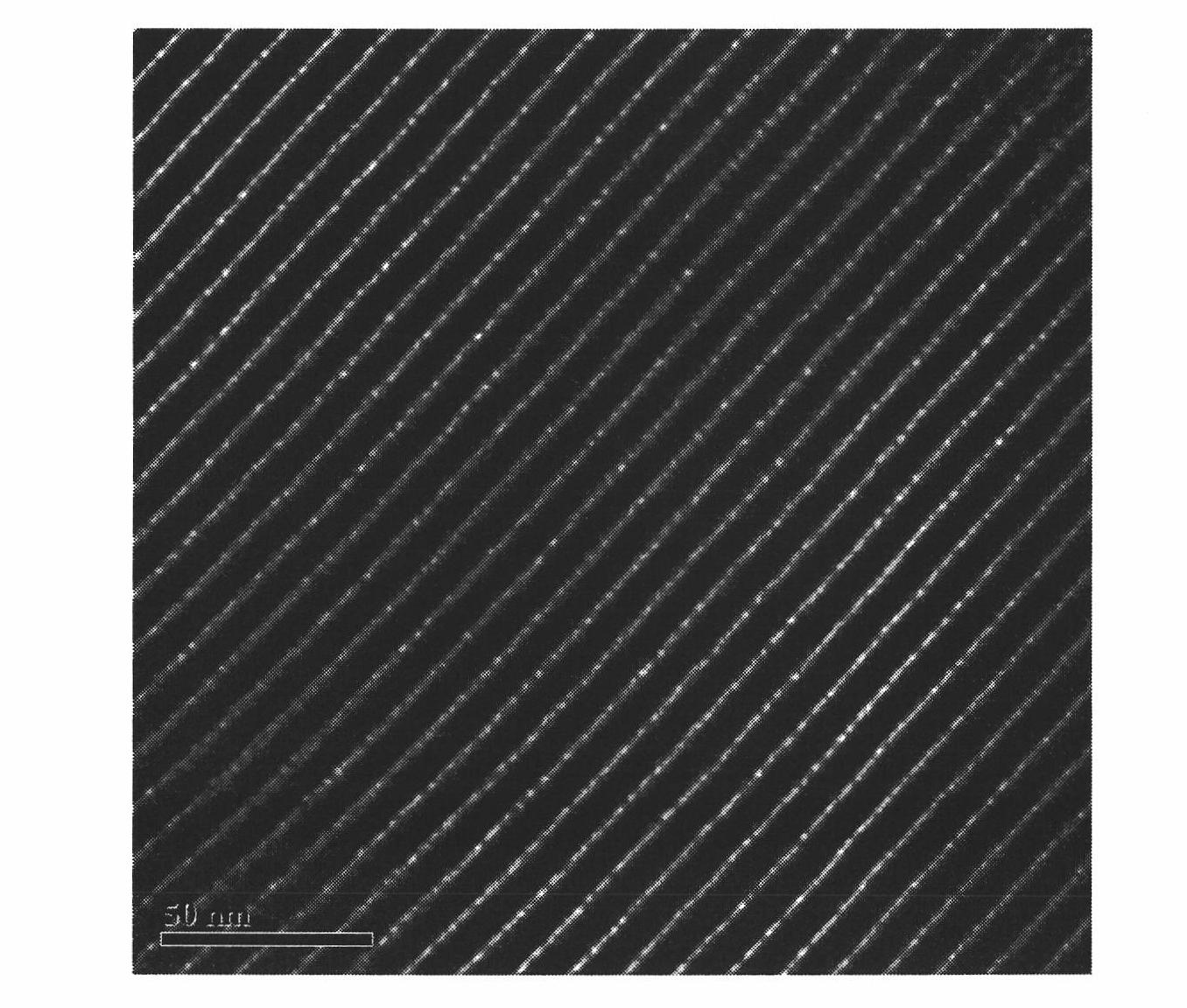

[0019] figure 1 It is the HRTEM picture of SBA-15 in Example 1 of the present invention, with SBA-15 as the carrier and manganese nitrate as the precursor, SBA-15 is loaded with Mn 2 o 3 nanowire composites.

[0020] Take 0.4g of SBA-15 mesoporous silica and vacuumize at 120°C to remove water, then add 6mL of n-hexane into the mesoporous silica, stir magnetically, and add 0.5mL of 1.5mol / L Mn( NO 3 ) 2 The solution was stirred at room temperature for 4 hours, n-hexane was removed, and then dried at 80°C for 4 hours; heated to 600°C at a rate of 1°C / min under an oxygen atmosphere, kept at 600°C for 4 hours, and cooled to room temperature. The molar ratio of raw materials is as follows: SBA-15: n-hexane: Mn 2+ :H 2 O=1.0:6.9:0.11:4.2. Detected as Mn by XRD 2 o 3 / SBA-15 composite.

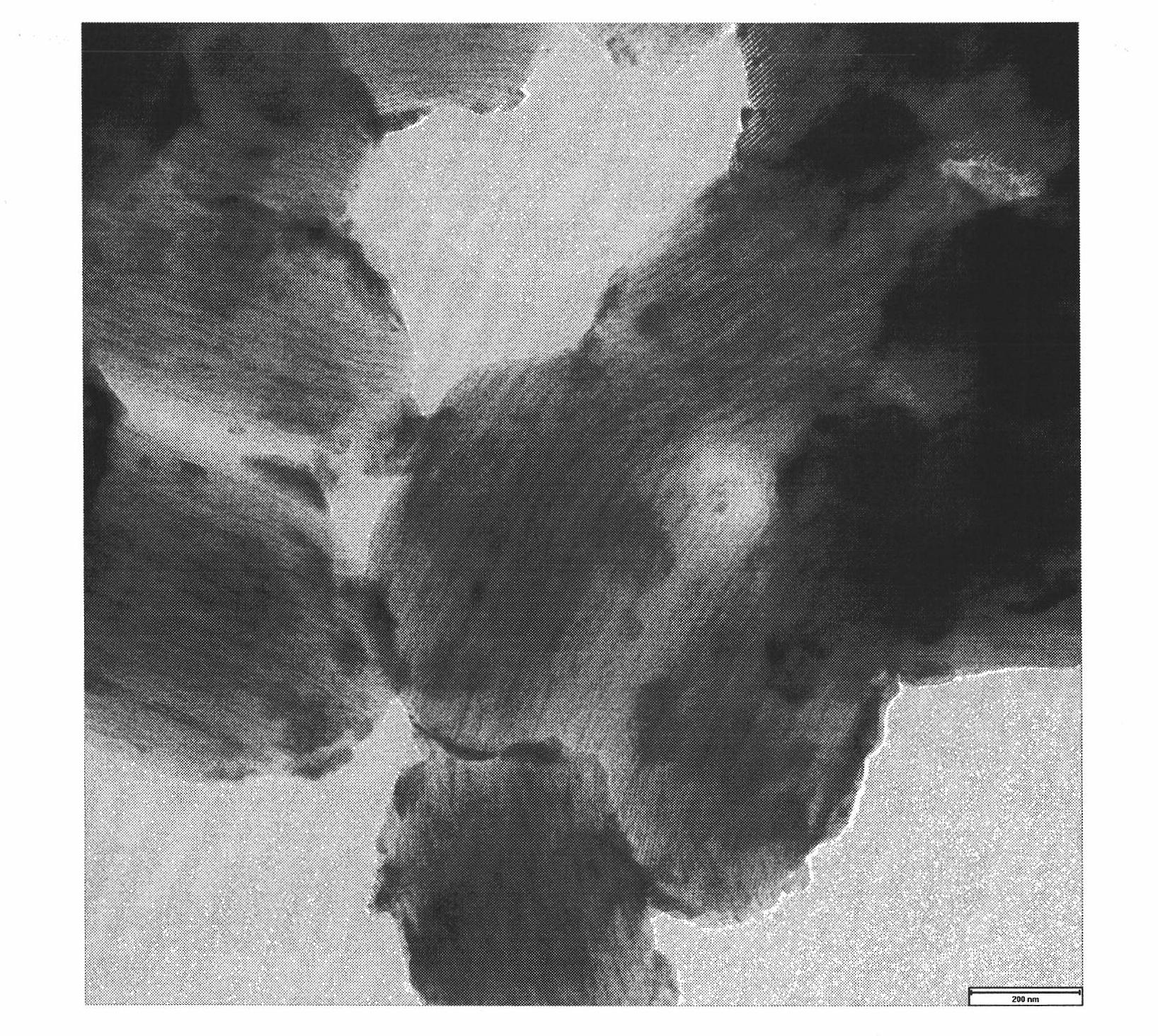

[0021] Prepared Mn 2 o 3 / SBA-15 composite materials such as figure 2 As shown, Mn 2 o 3 The nanowires are evenly distributed in the pores of SBA-15, with a pore diameter of 7.8nm and...

Embodiment 2

[0023] Using SBA-15 as the carrier and nickel nitrate as the precursor, the SBA-15 loaded NiO nanoparticle composite was obtained.

[0024] Take 0.4g of SBA-15 mesoporous silica and vacuumize at 120°C to remove water, then add 6mL of cyclohexane into the mesoporous silica, stir magnetically, and add 0.5mL of 2.5mol / L Ni under stirring (NO 3 ) 2 The solution was stirred at room temperature for 4 hours to remove cyclohexane, then dried at 80°C for 4 hours; heated to 450°C at a rate of 1°C / min under an oxygen atmosphere, kept at 450°C for 4 hours, and cooled to room temperature. The molar ratio of raw materials is as follows: SBA-15: cyclohexane: Ni 2+ :H 2 O=1.0:8.3:0.19:4.2. It is NiO / SBA-15 composite material detected by XRD.

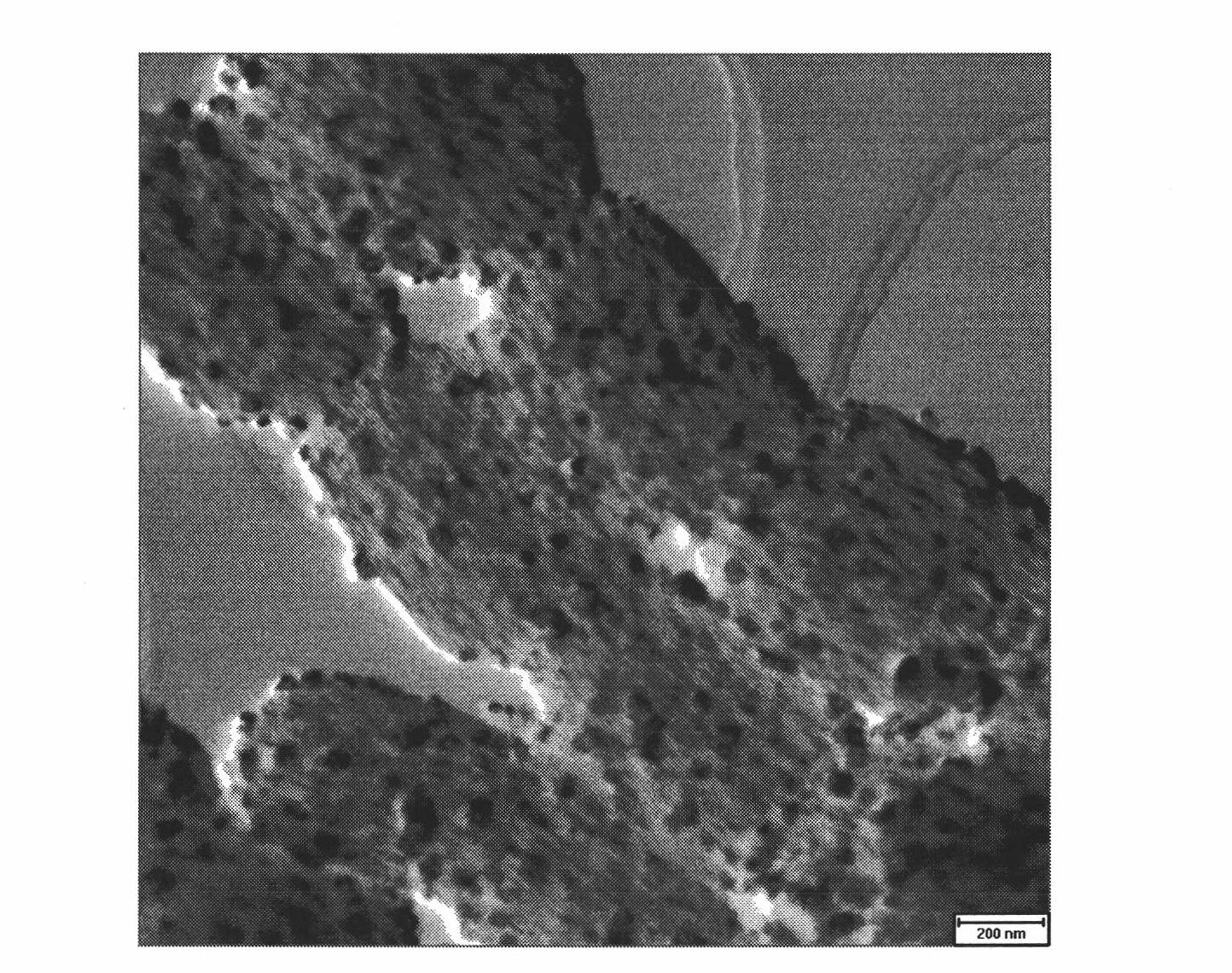

[0025] Prepared NiO / SBA-15 composites such as image 3 As shown, the nanoparticles of NiO are uniformly distributed in the pores of SBA-15, the pore diameter is 7.7nm, and the specific surface area is 341.4m 2 / g, the pore volume is 0.69cm 3 / g....

Embodiment 3

[0027] Using SBA-15 as a carrier and silver nitrate as a precursor, the SBA-15 loaded Ag nanowire composite material was obtained.

[0028] Take 0.2g of SBA-15 mesoporous silica and heat at 120°C to remove water, then add 20mL of n-hexane into the mesoporous silica, stir magnetically, and add 0.3mL of 1.0mol / L AgNO under stirring 3 The solution was stirred at room temperature for 4 hours, n-hexane was removed, and then dried at 80°C for 4 hours; heated to 350°C at a rate of 2°C / min under an oxygen atmosphere, kept at 350°C for 2 hours, and cooled to room temperature. The molar ratio of raw materials is as follows: SBA-15: n-hexane: Ag + :H 2 O=1.0:46:0.09:5.0. It is Ag / SBA-15 composite material detected by XRD.

[0029] Prepared Ag / SBA-15 composites such as Figure 4 As shown, Ag nanowires are evenly distributed in the pores of SBA-15, with a pore diameter of 7.7nm and a specific surface area of 541.8m 2 / g, the pore volume is 0.91cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com