Single crystal Ag nanoplate/Co3O4/Eu0.6Sr0.4FeO3 composite catalyst, preparation thereof and application thereof

A eu0.6sr0.4feo3, composite catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, incinerator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

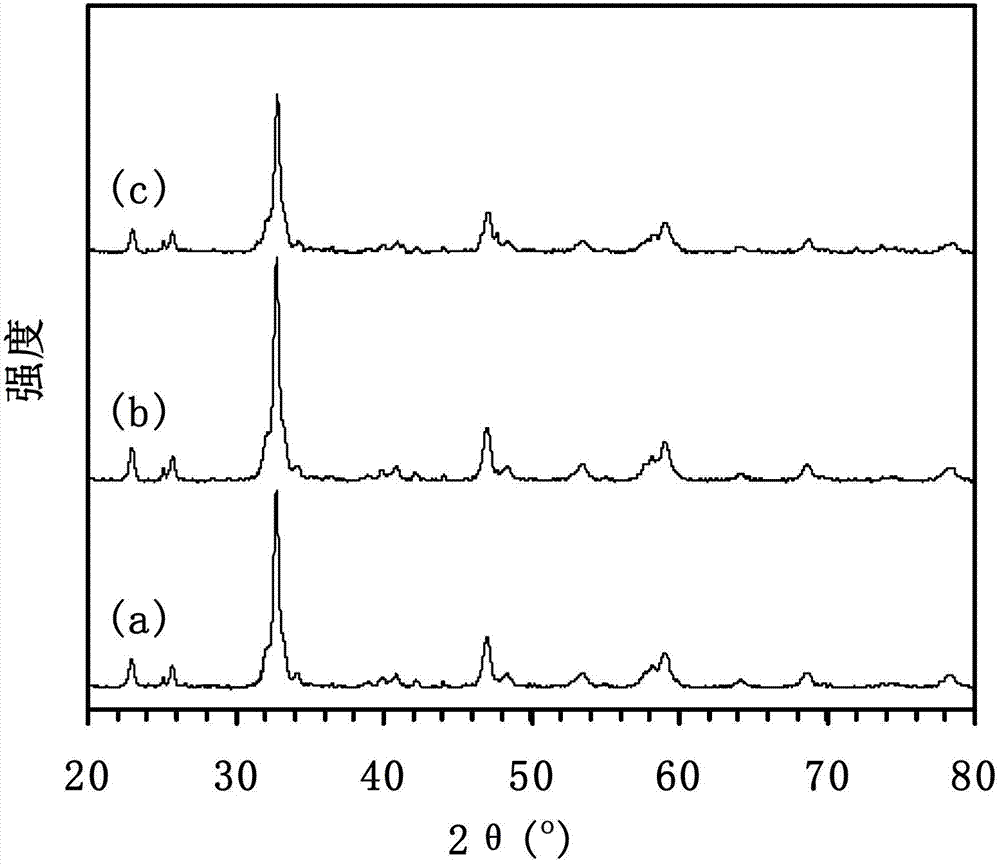

Embodiment 1

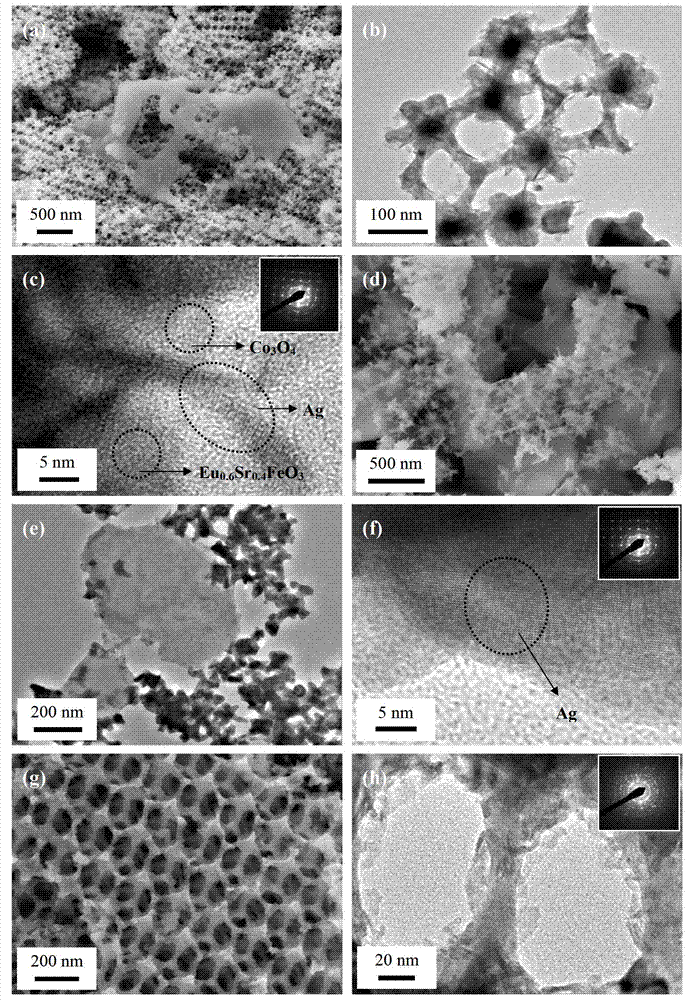

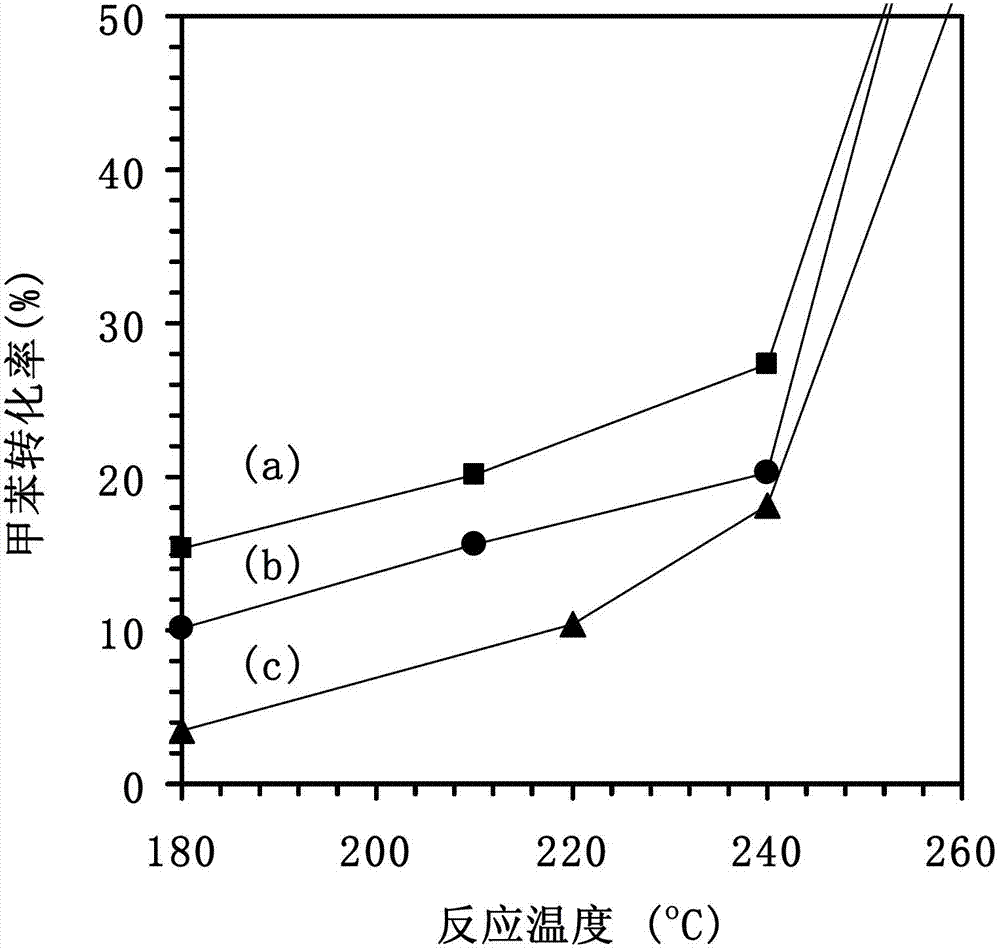

[0014] Embodiment 1: 1. 0.0068g silver nitrate (AgNO 3 ), 0.1261g citric acid and 0.8120g polyvinylpyrrolidone (PVP, calculated as 29000 molecular weight) were successively dissolved in 80mL deionized water, and after fully dissolved, the solution was fixed to 100mL; ② Weigh 0.0227g NaBH 4 Dissolve in 10mL deionized water; ③Take 25mL of the diluted silver nitrate solution prepared in ①, and add the prepared three-dimensional ordered macroporous structure supported catalyst Co 3 o 4 / Eu 0.6 Sr 0.4 FeO 3 0.20g, shake and disperse for 3min, then add 1.0mL NaBH prepared in ② 4 solution, and quickly transferred to a rotary evaporator and rotated and stirred for 60min. After the reaction was completed, it was slowly filtered, washed with 5.0ml deionized water, and dried at room temperature to obtain a composite catalyst Co 3 o 4 / Eu 0.6 Sr 0.4 FeO 3 . Among them, the shape and size of the single crystal Ag nanosheets are irregular, and the silver flakes with smaller diamet...

Embodiment 2

[0015] Example 2: Steps ① and ② are the same as in Example 2; ③ Take 25 mL of the diluted silver nitrate solution prepared in ①, add 0.25 mL of hydrogen peroxide with a mass fraction of 30%, mix well and add the prepared three-dimensional ordered macroporous structure The supported catalyst Co 3 o 4 / Eu 0.6 Sr 0.4 FeO 3 0.20g, continue to shake and disperse for 3min, then add 1.0mL of NaBH prepared in ② 4 solution, and quickly transferred to a rotary evaporator to rotate and stir for 30min. After the reaction was completed, it was slowly filtered, washed with 5.0ml deionized water, and dried at room temperature to obtain a composite catalyst Co 3 o 4 / Eu 0.6 Sr 0.4 FeO 3 . Among them, the single crystal Ag nanosheets are irregular in shape and non-uniform in size, and are mainly distributed between the carriers, showing an obvious diffraction pattern of Ag single crystal. When the toluene conversion is less than 20%, the catalyst increases the toluene conversion by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com