Preparation method of monoatomic catalyst for indoor air purification

An indoor air and catalyst technology, applied in the field of single-atom catalyst preparation, can solve the problems of secondary pollution, incomplete decomposition and removal of pollutants, etc., and achieve the effects of low price, abundant reserves and various types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

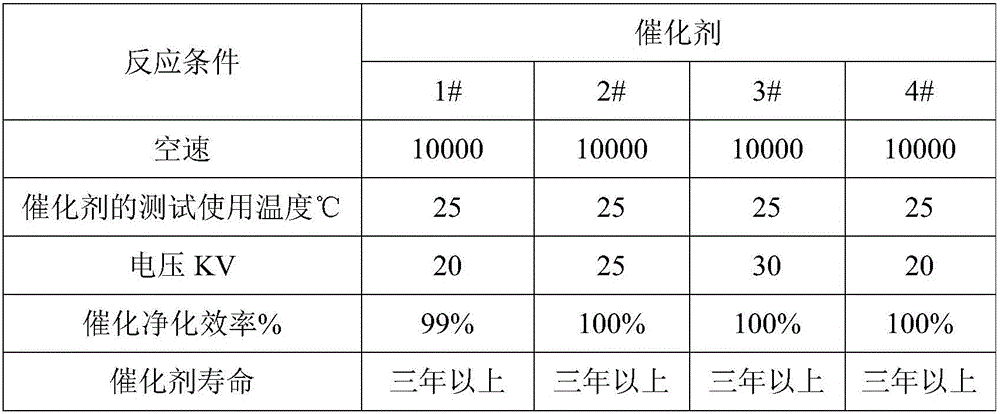

Examples

preparation example Construction

[0021] A kind of preparation method of the single-atom catalyst of indoor air purification of the present invention comprises the following steps:

[0022] (a) Prepare the carrier:

[0023] (1) Ce(NO 3 ) 3 ·6H 2 O is dissolved in deionized water to make its concentration 0.3-0.6mol / L, and then ethylene glycol or glycerin is added to the solution as a dispersant, and the dispersant in the solution and Ce 3+ The molar ratio is (2-3):1;

[0024] (2) Add ammonia water dropwise to the solution to pH=8-10, stir, then let stand for 8-12h, and filter to obtain the precipitate;

[0025] (3) Wash the filtered precipitate with distilled water, then wash with ethanol to remove ethylene glycol or glycerol;

[0026] (4) Dry the washed precipitate in an oven at 100-120° C. for 4-6 hours;

[0027] (5) Grind the dried precipitate so that the particle diameter is 20-40 mesh, or directly put it into a mortar, then put it into a muffle furnace, and roast it at 300-500°C to obtain a yellow s...

Embodiment 1

[0032] (a) Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to make its concentration 0.3mol / L, and an appropriate amount of ethylene glycol was added as a dispersant (dispersant and Ce 3+ The molar ratio is 2). Aqueous ammonia was added dropwise to pH=10. Continue to stir, and after standing for 8 hours, filter, wash with distilled water for 3 times, and wash with ethanol for 3 times, and then place it in an oven at 110° C. for 4 hours to dry. Grind the dried precipitate so that the particle diameter is 20-40 mesh, then put it into a muffle furnace, and bake it at 300°C to obtain a yellow solid powder—CeO 2 carrier.

[0033] (b) RuCl 3 ·3H 2 O is dissolved in deionized water to prepare an impregnating solution, and the mass concentration of ruthenium in the impregnating solution is 5 mg Ru / mL;

[0034] (c) Using an equal volume impregnation method, the CeO prepared in step (a) 2 Add the carrier to the impregnating solution prepared in step (b), then add iodoform ...

Embodiment 2

[0037] (a) Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to make its concentration 0.6mol / L, and an appropriate amount of glycerin was added as a dispersant (dispersant and Ce 3+The molar ratio is 3). Aqueous ammonia was added dropwise to pH=8. Continue to stir, and after standing for 12 hours, filter, wash with distilled water for 3 times, and wash with ethanol for 3 times, and then dry in an oven at 100° C. for 6 hours. The dried precipitate is directly put into a mortar, put into a muffle furnace, and calcined at 500°C to obtain a yellow solid powder—CeO 2 carrier.

[0038] (b) RuCl 3 ·3H 2 O is dissolved in deionized water to prepare an impregnating solution, and the mass concentration of ruthenium in the impregnating solution is 50 mg Ru / mL;

[0039] (c) CeO prepared by step (a) 2 Add the carrier to the impregnating solution prepared in step (b), then add iodoform solution dissolved in ethylene glycol, mix well, and impregnate at 30°C for 18 hours, then dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com