Preparation method of propylene oxide

A technology for propylene oxide and epoxidation reaction, which is applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of affecting the production of propylene oxide, a large amount of chlorine-containing wastewater, inconvenient transportation, etc., and achieves low production cost and process flow. Short, low running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

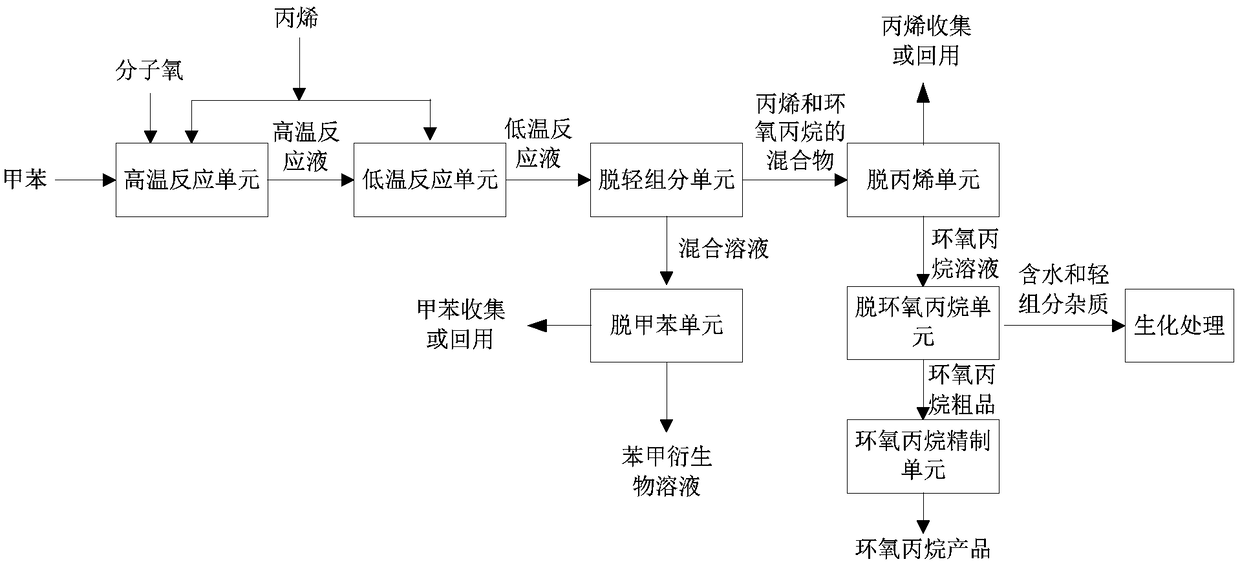

Image

Examples

Embodiment 1

[0043] Embodiment 1 A kind of preparation method of propylene oxide comprises the following steps:

[0044] (1) High temperature reaction unit

[0045] Toluene, air, and propylene were pretreated to a pressure of 1.4 MPa and a temperature of 110 ºC before being added to the high-temperature reactor;

[0046]Add the pretreated toluene, air, and propylene into a high-temperature reactor equipped with an oxidation catalyst and an epoxidation catalyst. The mol ratio of oxygen, propylene, and toluene in the air is 2:0.1:1, and the temperature is 110 ºC. Under the condition of a pressure of 1.3 MPa, under the action of an oxidation catalyst, toluene undergoes an oxidation reaction with oxygen in the air to generate benzyl hydroperoxide, and the generated benzyl hydroperoxide reacts with propylene under the action of an epoxidation catalyst. Oxidation reaction produces propylene oxide and benzyl alcohol, and the reaction residence time is 45 min, obtains the high-temperature reactio...

Embodiment 2

[0068] Embodiment 2 A kind of preparation method of propylene oxide comprises the following steps:

[0069] (1) High temperature reaction unit

[0070] Toluene, air, and propylene were pretreated to a pressure of 1.5 MPa and a temperature of 120 ºC before being added to the high-temperature reactor;

[0071] Add the pretreated toluene, air, and propylene into a high-temperature reactor equipped with an oxidation catalyst and an epoxidation catalyst. The mol ratio of oxygen, propylene, and toluene in the air is 3:0.2:1, and the temperature is 120 ºC. Under the condition of a pressure of 1.5 MPa, under the action of an oxidation catalyst, toluene undergoes an oxidation reaction with oxygen in the air to form benzyl hydroperoxide, and the formed benzyl hydroperoxide reacts with propylene under the action of an epoxidation catalyst. Oxidation reaction produces propylene oxide and benzyl alcohol, and the reaction residence time is 50 min, obtains the high-temperature reaction liqu...

Embodiment 3

[0093] Embodiment 3 A kind of preparation method of propylene oxide comprises the following steps:

[0094] (1) High temperature reaction unit

[0095] Toluene, air, and propylene were pretreated to a pressure of 1.6MPa and a temperature of 180 ºC before being added to the high-temperature reactor;

[0096] Add pretreated toluene, air, and propylene into a high-temperature reactor equipped with an oxidation catalyst and an epoxidation catalyst. The mol ratio of oxygen, propylene, and toluene in the air is 4:0.3:1, and the temperature is 180 ºC. Under the condition of a pressure of 1.5 MPa, under the action of an oxidation catalyst, toluene undergoes an oxidation reaction with oxygen in the air to form benzyl hydroperoxide, and the formed benzyl hydroperoxide reacts with propylene under the action of an epoxidation catalyst. Oxidation reaction produces propylene oxide and benzyl alcohol, and the reaction residence time is 60 min, obtains the high-temperature reaction liquid co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com