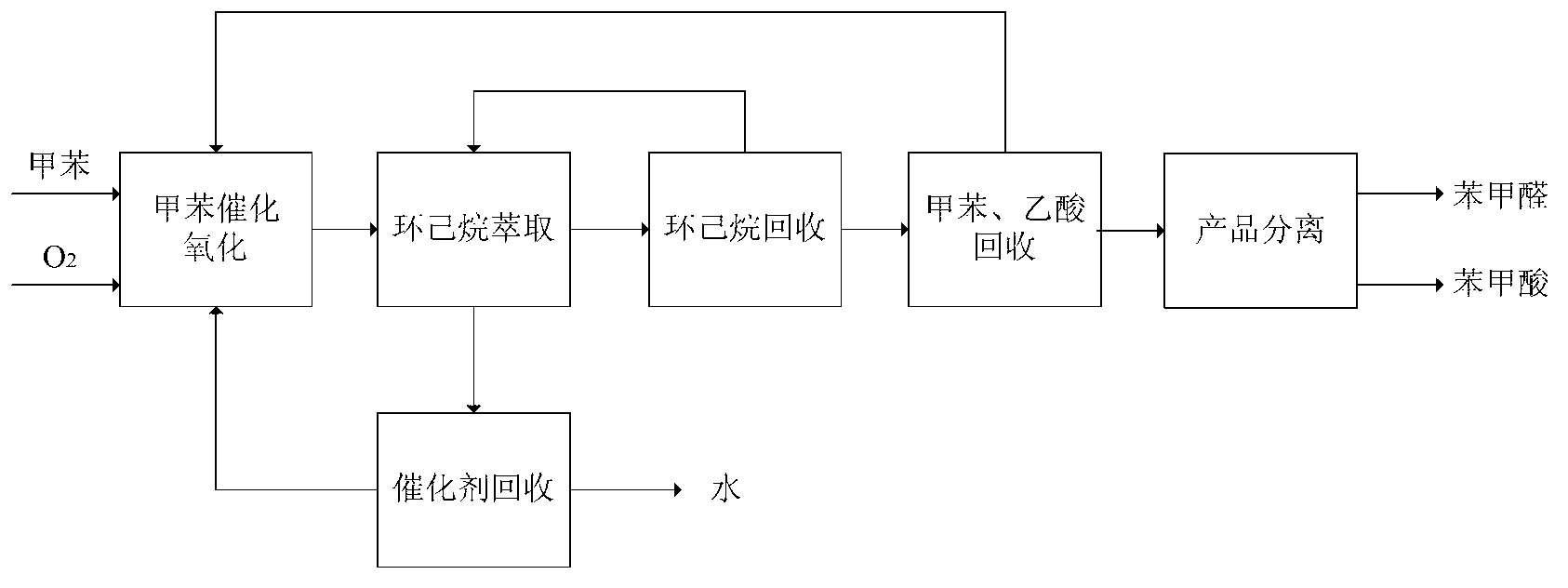

Clean recovery method of toluene oxidation catalyst

An oxidation process and recovery method technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing the steps of catalyst recovery, easy to be oxidized, etc., to achieve good recycling effect, Less by-products and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

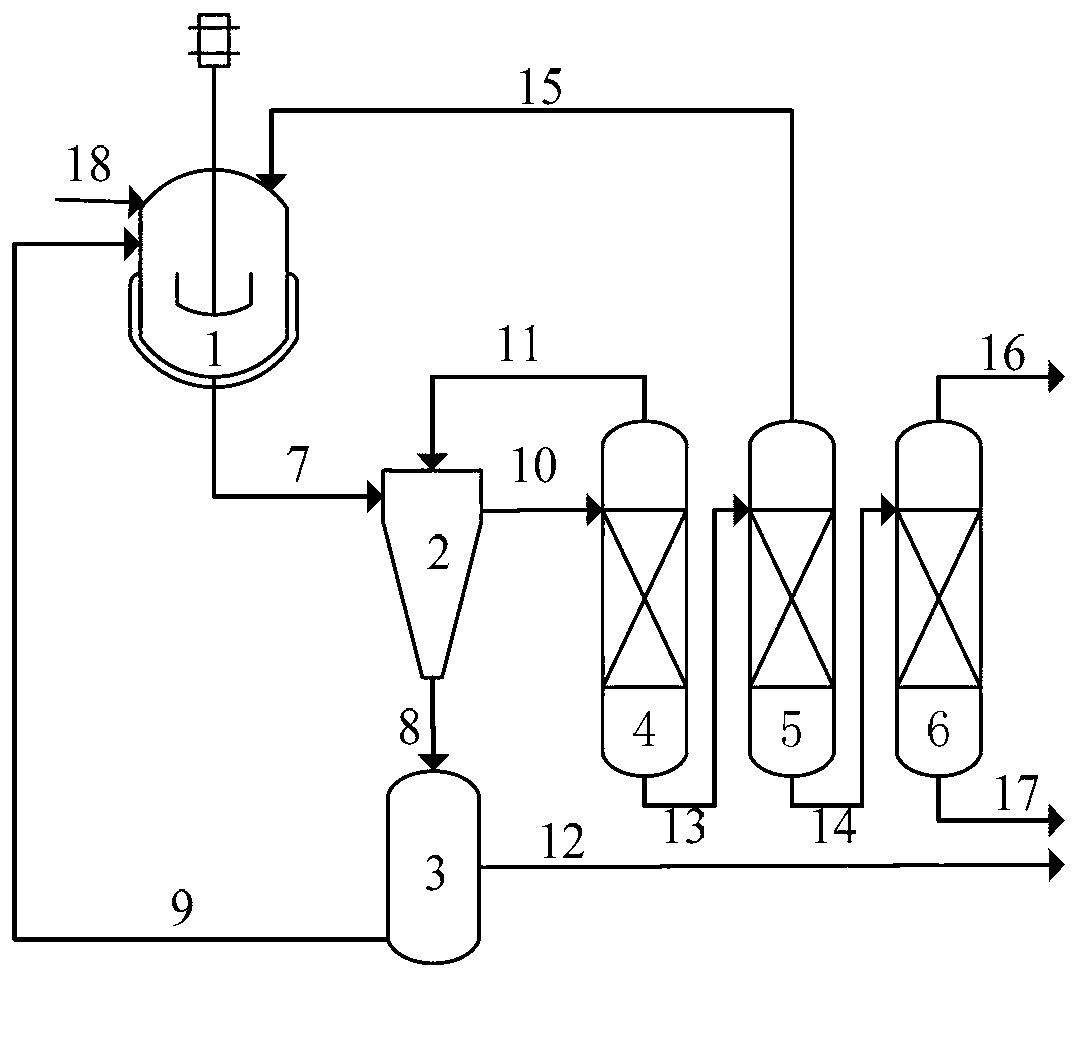

[0016] Embodiment 1: After the toluene oxidation reaction is completed in reactor 1, enter extraction separator 2 through material delivery pipeline 7, add the hexanaphthene of 3-20 times initial toluene volume in extraction separator 2, hexanaphthene as The extractant extracts the reactant toluene and the products benzaldehyde, benzoic acid and benzyl alcohol, acetic acid will also be brought into it, and the organic phase is separated from the water phase through the separator 2, and the organic phase enters the rectification tower 4 through the pipeline 10 for separation , the water phase enters the distillation tower 3 through the pipeline 8, the water is distilled out under normal pressure, and the water is discharged through the pipeline 12. The catalyst that contains a small amount of benzoic acid can be added in the reactor through pipeline 9 and be recycled. In the rectifying tower 4, cyclohexane can be distilled out as the top product, and then input into the separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com