Toluol-benzene solvent recovery technology from vent gas

A tail gas recovery and toluene technology, applied in the direction of absorption purification/separation, organic chemistry, dispersed particle separation, etc., to achieve the effect of improving the economic and social benefits of enterprises and solving the problem of atmospheric environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

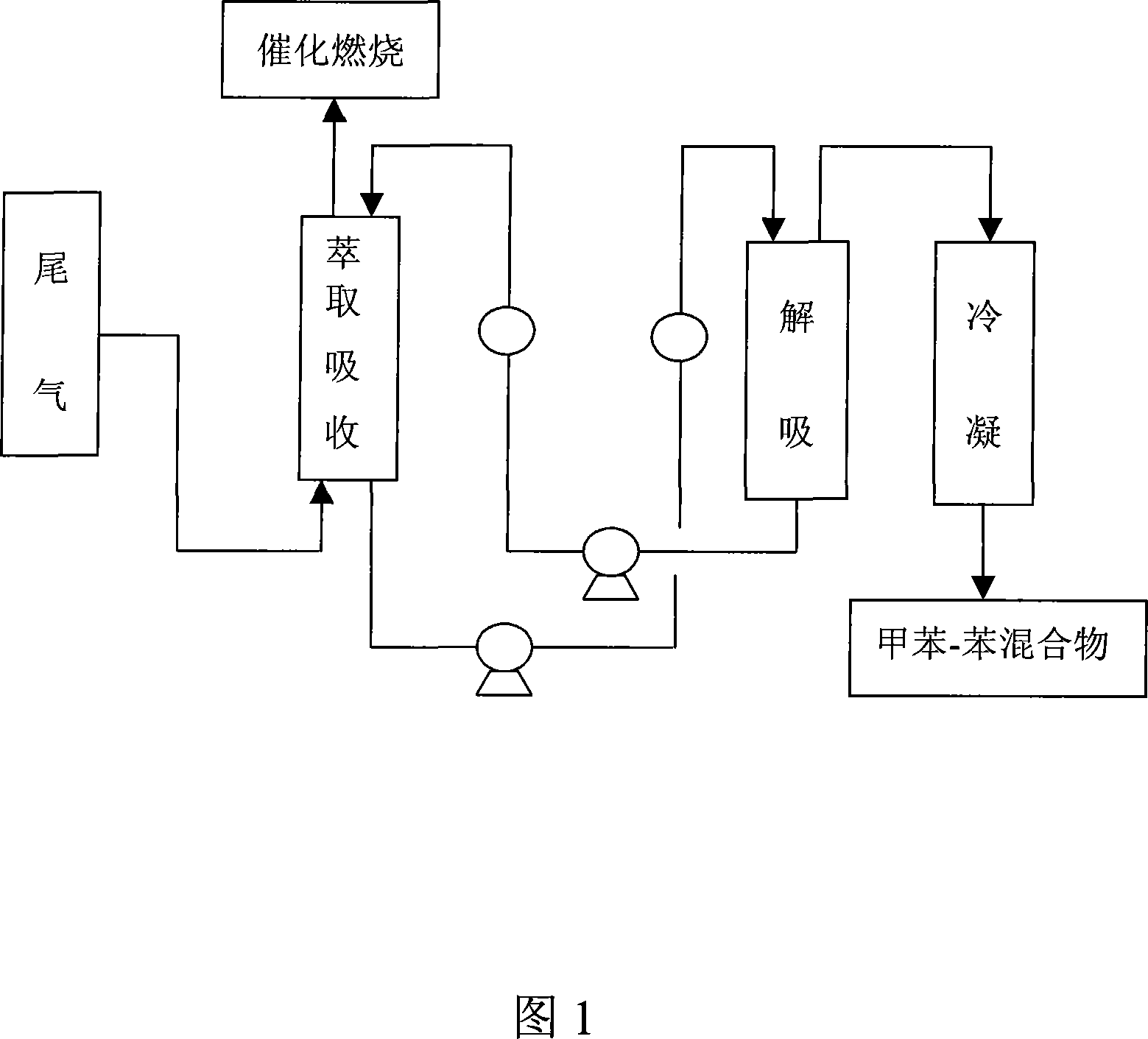

[0016] Embodiment 1: As shown in Figure 1, the toluene-benzene-containing tail gas discharged from the toluene oxidation device is sent into the extraction and absorption tower from the bottom through the pipeline using the pressure of the tail gas itself, and the fresh toluene-benzene special liquid sprayed from the top of the extraction and absorption tower The absorbent is in gas-liquid countercurrent contact with the above-mentioned tail gas at 30°C and 0.8Mpa to absorb toluene and benzene. The above-mentioned absorbent is a special liquid absorbent for toluene and benzene produced by Hebei Ruitong Meibang Company with the model number RTMB102. The boiling point is higher than 200°C. When the absorption rate of toluene-benzene tail gas reaches 95%, the gas after absorbing toluene and benzene is discharged from the top of the tower, and then sent to the subsequent catalytic combustion treatment system for further power generation, catalytic combustion, and then discharged int...

Embodiment 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the toluene-benzene-containing tail gas discharged from the toluene oxidation device is sent into the extraction and absorption tower from the bottom through the pipeline using the pressure of the tail gas itself, and the fresh fresh water injected from the top of the extraction and absorption tower The special liquid absorbent for toluene-benzene carries out gas-liquid countercurrent contact with the above-mentioned tail gas at 20°C and 0.5Mpa to absorb toluene and benzene. When the absorption rate of toluene-benzene tail gas reaches 90%, the gas after absorbing toluene and benzene is discharged It is discharged from the top, and then sent to the subsequent catalytic combustion treatment system for further power generation and catalytic combustion, and then discharged into the atmosphere. The content of toluene and benzene in the gas discharged into the atmosphere reaches the emission standard;...

Embodiment 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the toluene-benzene-containing tail gas discharged from the toluene oxidation device is sent into the extraction and absorption tower from the bottom through the pipeline using the pressure of the tail gas itself, and the fresh fresh gas injected from the top of the extraction and absorption tower The special liquid absorbent for toluene-benzene carries out gas-liquid countercurrent contact with the above-mentioned tail gas at 50°C and 1.0Mpa to absorb toluene and benzene. When the absorption rate of toluene-benzene tail gas reaches 98%, the gas after absorbing toluene and benzene is discharged It is discharged from the top, and then sent to the subsequent catalytic combustion treatment system for further power generation and catalytic combustion, and then discharged into the atmosphere. The content of toluene and benzene in the gas discharged into the atmosphere reaches the emission standard; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com