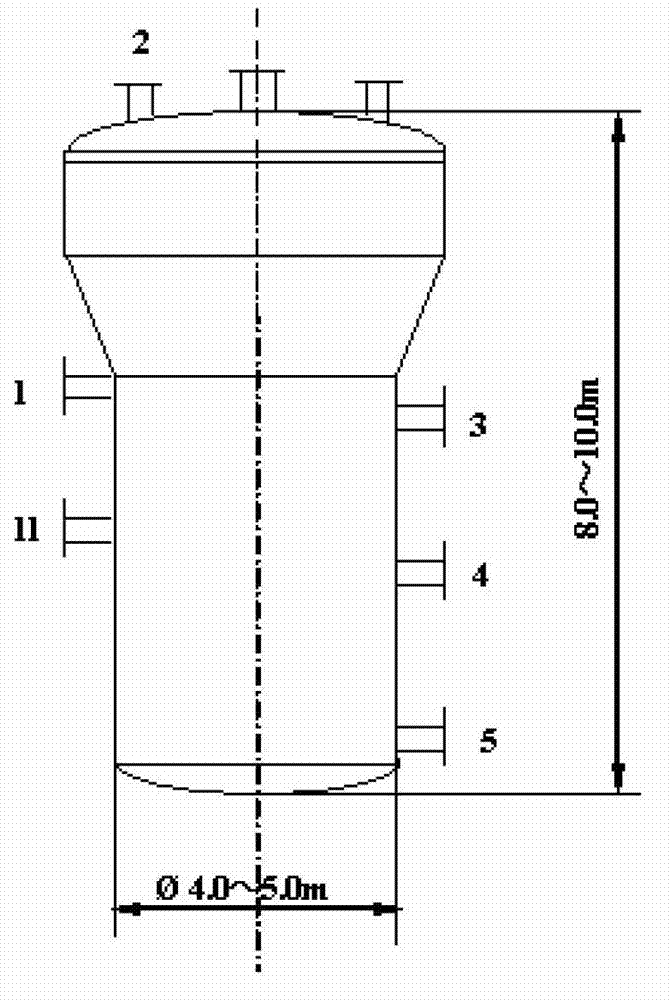

Methylbenzene oxidation tower in 10000-tone level benzoic acid production

A technology of oxidation tower and benzoic acid, which is applied in the chemical method of making liquid react with liquid, chemical industry, organic chemistry, etc. It can solve problems such as safety accidents, hidden dangers, and inconvenient maintenance in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

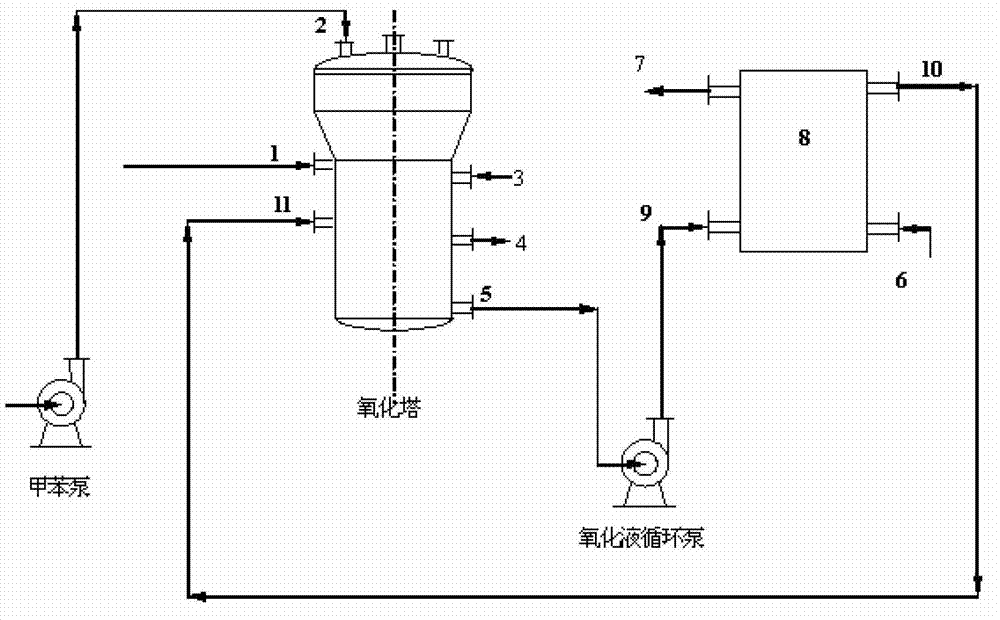

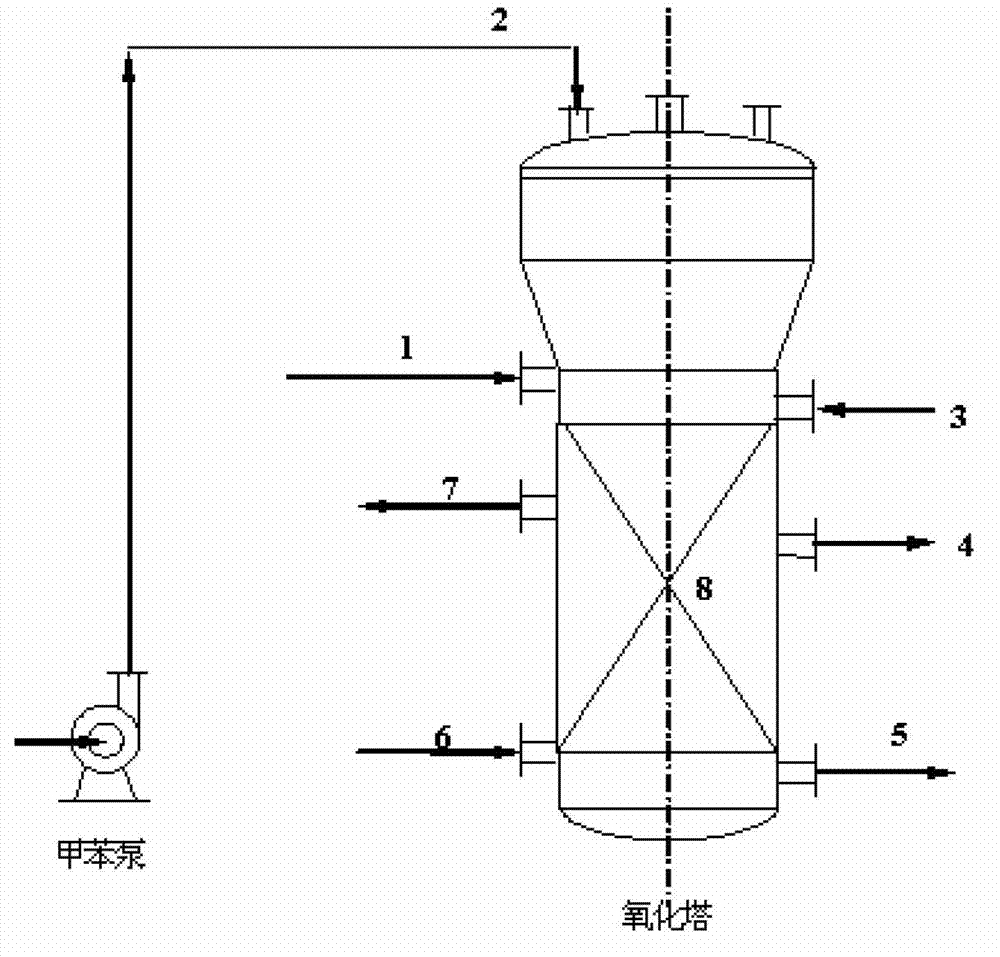

[0022] The toluene pump passes the toluene liquid through the toluene inlet 2 of the oxidation tower, and after entering the oxidation tower, steam is introduced to heat the toluene liquid. When the temperature of the toluene liquid reaches 115°C-125°C, the air starts to pass through while continuing to heat up to 155°C-160°C, and then close the steam valve. The toluene liquid undergoes oxidation exothermic reaction in the oxidation tower. After 6-7 hours of oxidation, open the oxidation tower oxidation cooling liquid inlet 11, open the oxidation liquid cooling device outlet 10, open the oxidation liquid cooling device inlet 9, (the heat exchanger has been fed with cooling medium, and will not be described in detail here) Open the outlet 5 of the oxidizing liquid of the oxidation tower; start the circulating pump of the oxidizing liquid to circulate and cool the oxidizing liquid outside the tower.

Embodiment 2

[0024] The toluene pump passes the toluene liquid through the toluene inlet 2 of the oxidation tower, and after entering the oxidation tower, steam is introduced to heat the toluene liquid. When the temperature of the toluene liquid reaches 120°C-125°C, start to pass air while continuing to heat up to 160°C-165°C, and then close the steam valve. The toluene liquid undergoes oxidation exothermic reaction in the oxidation tower. After oxidizing for 6.5-7.5 hours, open the oxidation cooling liquid inlet 11 of the oxidation tower, open the outlet 10 of the cooling device for the oxidation liquid, and open the inlet 9 of the cooling device for the oxidation liquid, (the heat exchanger has been fed with the cooling medium, and will not be described in detail here) Open the outlet 5 of the oxidizing liquid in the oxidation tower; start the oxidizing liquid circulation pump to circulate and cool the oxidizing liquid outside the tower, and there is already oxidizing liquid at 163°C-166...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com