System and process for producing phthalic acid by strengthening xylene oxidation

A technology for producing phthalic acid and xylene, which is applied in the field of preparation of phthalic acid, can solve the problems of increasing reaction cost, increasing the risk of reaction device, and high reaction pressure, so as to achieve improved utilization rate, long residence time, and reduced reaction the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

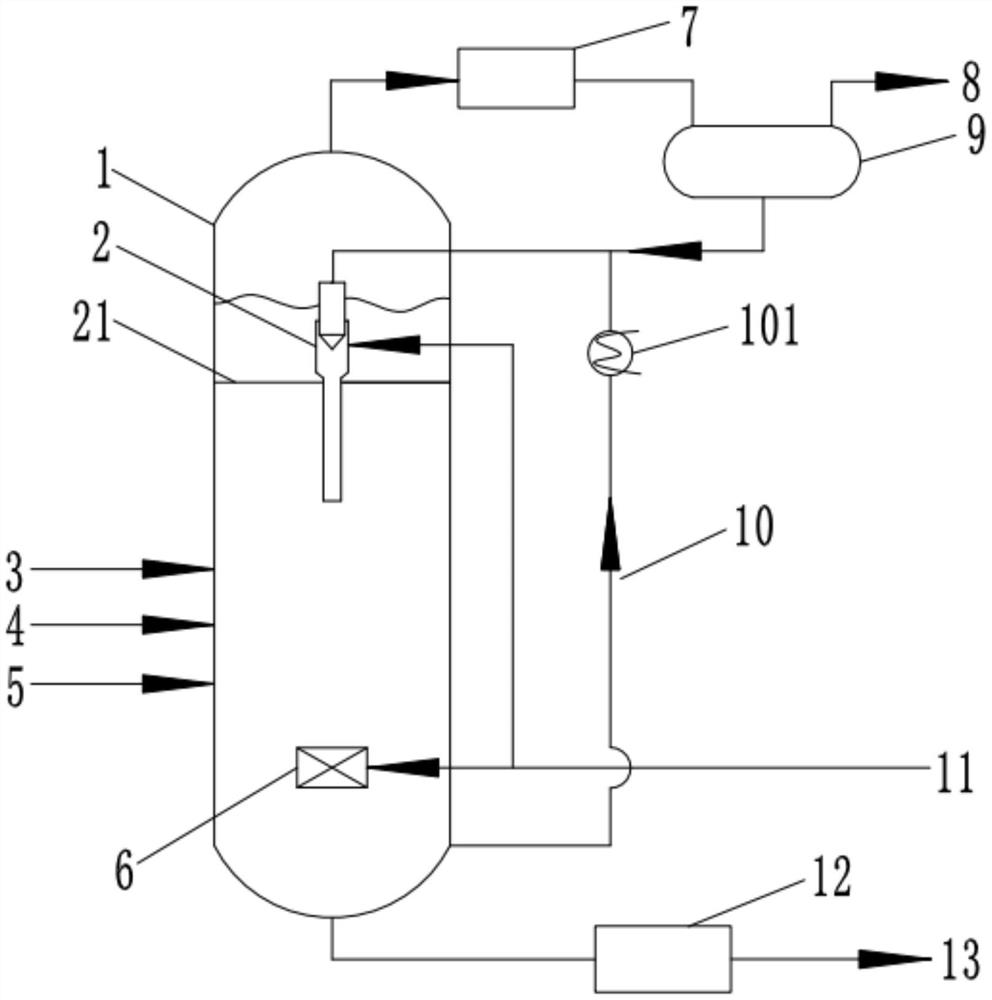

[0043] The use of o-xylene with a purity of 98% is the oxidation of phthalic acid as a raw material. When starting the reaction, valve 14 and valve 15 were in a closed state earlier, and the acetic acid solvent and o-xylene entered the slurry bed reactor to form a mixed solution. Oxygen enters the second micro-interface generator and is broken into micron-sized bubbles, forming a gas-liquid emulsion with the surrounding mixed solution; at the same time, the catalyst enters the slurry bed reaction from the catalyst dosing pipeline above the second micro-interface generator device, and is suspended in the slurry bed reactor by the action of the micron-sized bubbles broken up by the second micro-interface generator floating upward; after 47 minutes of reaction, the valve 14 and the valve 15 are opened, and the temperature control circulation unit starts to work, and the The liquid phase material at the bottom of the slurry bed reactor is drawn out, and after being cooled by the he...

Embodiment 2

[0046] Using m-xylene with a purity of 99.5% as raw material to oxidize isophthalic acid, the reaction pressure is 1.5MPa, the weight ratio of solvent to m-xylene in the slurry bed reactor is 4:1, when the reaction starts, the valve 14 And the valve 15 is in the closed state first, the acetic acid solvent and m-xylene enter the slurry bed reactor to form a mixed solution, and the oxygen enters the second micro-interface generator and is broken into micron-scale bubbles, forming a gas mixture with the surrounding mixed solution. liquid emulsion; at the same time, the catalyst enters the slurry bed reactor from the catalyst dosing pipeline above the second micro-interface generator, and is suspended in the slurry state by the micron-sized bubbles broken by the second micro-interface generator. In the bed reactor; after 47 minutes of reaction, the valve 14 and the valve 15 are opened, and the temperature control circulation unit starts to work, which extracts the liquid phase mate...

Embodiment 3

[0049] Using p-xylene as raw material to oxidize terephthalic acid, the reaction pressure is 1.45MPa, and the mass ratio of p-xylene, acetic acid solvent and catalyst is 1:3:0.001; when starting the reaction, acetic acid solvent and p-xylene enter A mixed solution is formed in the slurry bed reactor, oxygen enters the second micro-interface generator and is broken into micron-sized bubbles, forming a gas-liquid emulsion with the surrounding mixed solution; at the same time, the catalyst is released from above the second micro-interface generator The catalyst dosing pipeline enters the slurry bed reactor, and is suspended in the slurry bed reactor by the action of the micron-sized bubbles broken by the second micro-interface generator floating upward; the temperature control circulation unit The liquid phase material at the bottom is drawn out, and after being heated or cooled to 150°C by a heat exchanger, it is sent together with the liquid phase material separated from the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com