Process and apparatus for processing heavy byproducts in toluene oxidation process

A technology of oxidation process and treatment process, which can be used in hydrolysis to prepare carbonyl compounds, organic chemistry, petroleum industry, etc., can solve problems such as economic loss and low added value, and achieve the effect of reducing economic loss and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

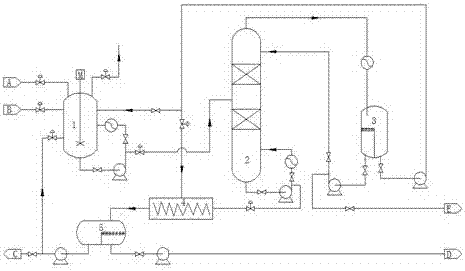

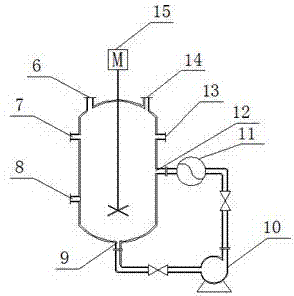

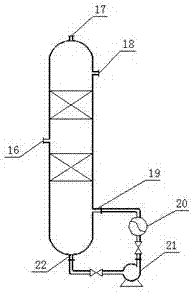

[0038] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Given the schematic diagram of the technological process of the present invention and the installation schematic diagram of each key equipment, the technological process of the present invention comprises the following steps:

[0039] (1) Hydrolysis reaction

[0040]The heavy by-product A produced in the toluene oxidation process, the concentration of 35% sodium hydroxide solution B, process water (part of the process water from the light component tank) are added to the hydrolysis reactor 1, under the action of the agitator 15 , at a temperature of 200°C, a pressure of 1.8 MPa(G), and an oil-water mass ratio of 6:1, the hydrolyzable heavy by-products undergo hydrolysis under alkaline conditions. After a residence time of 95 min, the hydrolyzed solution and non- Condensed gas and non-condensable gas are discharged through the non-condensable gas control valve at the top of the hydrolysis react...

Embodiment 2

[0052] The difference between Example 2 and Example 1 is that the sodium hydroxide solution with a concentration of 35% (wt) in step (1) is changed to a potassium hydroxide solution with a mass concentration of 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com