Method for designing rock breaking cutterhead combined by flexible expanding excavation hobbing cutters and water jets

A design method, water jet technology, used in mining equipment, earthmoving, tunnels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

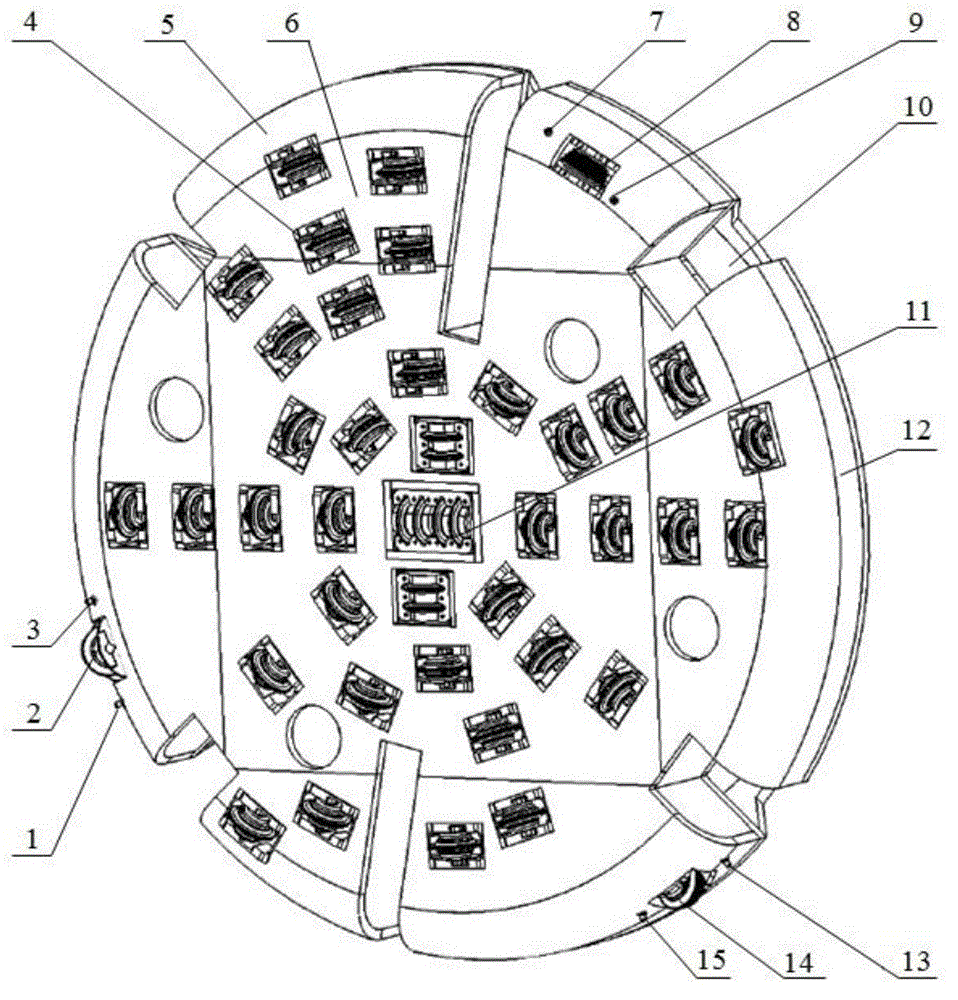

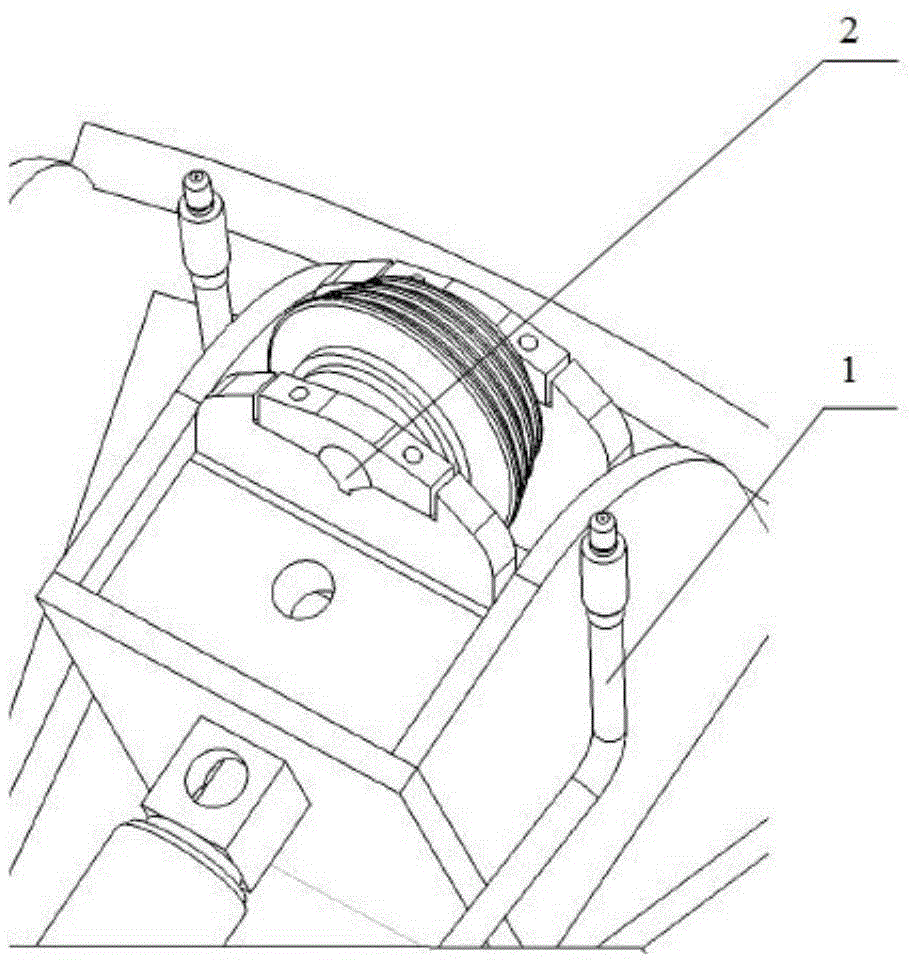

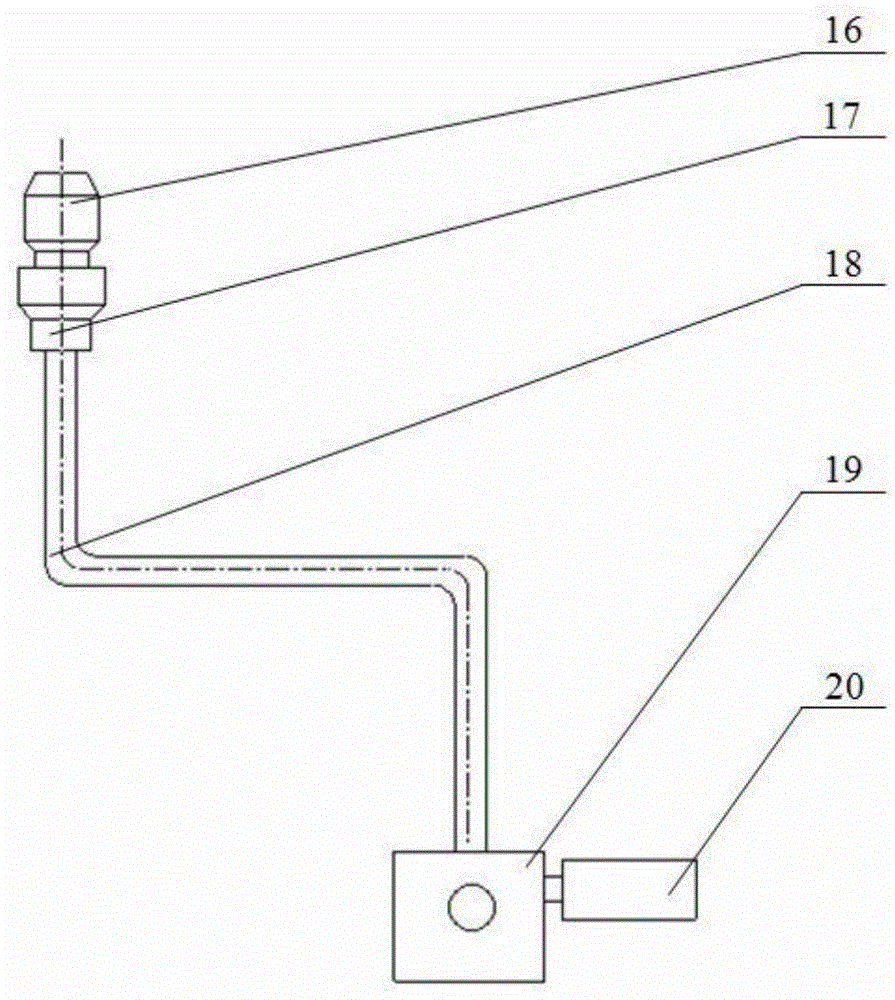

[0056] The specific implementation process of the design method of the telescopic expanding excavation hob and the water jet combined rock-breaking cutter head of the present invention will be described in detail in conjunction with the accompanying drawings and the technical scheme. As one of the most important components of the full-face rock boring machine, the cutter head is the installation carrier for all rock breaking tools. In actual engineering, the full-face rock boring machine is mostly caused by the side force caused by the lateral force of the side hob cutting rock. If the cutter head vibrates too much, it will not only affect its service life, but also affect its performance.

[0057] Therefore, the present invention aims at defects such as relatively large vibrations caused by the lateral force that the edge hob is subjected to when cutting rocks when the cutter head is in operation. Considering the overall technical performance requirements and construction req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com