Method for rectification and separation of benzoic acid, benzaldehyde, and toluene by single tower sidestream

A technology of benzaldehyde and benzoic acid, applied in the field of benzaldehyde, benzoic acid, and toluene extraction, can solve the problems of high production cost, low yield, high energy consumption, etc., and achieve short reaction cycle, simple operation, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

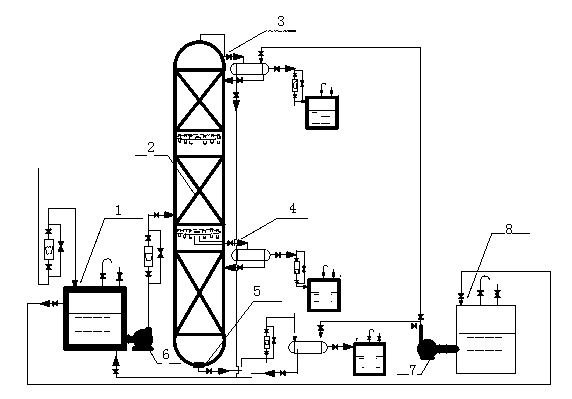

Image

Examples

Embodiment 1

[0020] The toluene oxidation reaction solution in this experiment was from Sinopec Shijiazhuang Refining and Chemical Company, and the feed temperature of the reaction solution was 25°C. The number of trays in the rectification column is 96, the toluene reaction solution is fed in the 25th tray of the rectification column, the outlet of the side line D-1 is the first tray, and the outlet of the side line D-2 is the 40th tray. Add the reaction liquid after oxidation of toluene to the rectification tower, and start heating when the liquid level reaches 1 / 3 of the tower tank; The temperature at -2 is 175-178°C, and the temperature at side line D-3 is 240-245°C; adopt the continuous intermediate feeding method, continuously add toluene reaction liquid to the rectification tower, and adjust the reflux ratio at side line D-1 to 5 , the reflux ratio at the side line D-2 is 2 to 4, the reflux ratio at the side line D-3 is 1 to 3, the side line D-1 distillate is toluene with a mass con...

Embodiment 2

[0022] The toluene oxidation reaction solution in this experiment was from Sinopec Shijiazhuang Refining and Chemical Company, and the feed temperature of the reaction solution was 25°C. The number of trays in the rectification column is 96, the toluene reaction liquid is fed on the 30th tray of the rectification column, the outlet of the side line D-1 is the first tray, and the outlet of the side line D-2 is the 45th tray. Add the reaction liquid after oxidation of toluene to the rectification tower, and start heating when the liquid level reaches 1 / 3 of the tower tank; The temperature at -2 is 177-180°C, the temperature at side line D-3 is 249-255°C; adopt continuous intermediate feeding method, continuously add toluene reaction liquid to the rectification tower, and adjust the reflux ratio at side line D-1 to 5 , the reflux ratio at the side line D-2 is 2 to 4, the reflux ratio at the side line D-3 is 1 to 3, the side line D-1 distillate is toluene with a mass content of 96...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com