System and method for continuously producing high-quality and high-selectivity benzaldehyde and benzoic acid by using jet loop reactor

A loop reactor, high-selectivity technology, applied in chemical instruments and methods, separation methods, preparation of organic compounds, etc., can solve problems such as application methods to be studied, and achieve short reaction residence time, high raw material utilization, and gas. The effect of sufficient liquid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

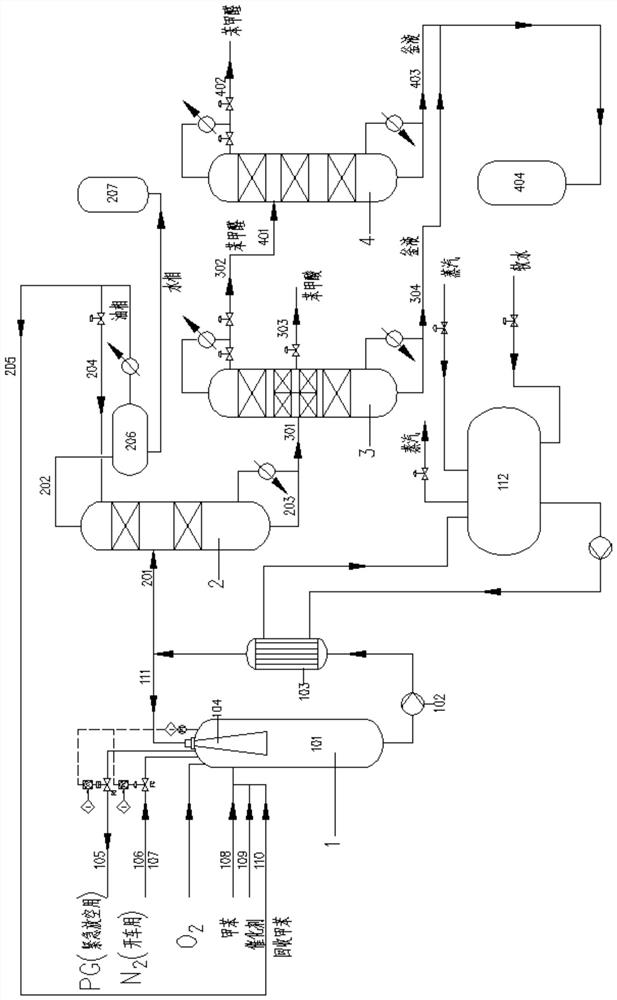

[0048] see figure 1 , the embodiment of the present invention provides a system for continuously producing high-quality high-selectivity benzaldehyde and benzoic acid using a jet loop reactor, including a jet loop reactor 1, a toluene removal tower 2, a dividing wall tower 3 and a benzaldehyde rectification tower 4.

[0049] The jet loop reactor 1 includes a feed inlet, a high-pressure reactor 101, a loop circulation pump 102, a shell-and-tube heat exchanger 103, a Venturi ejector 104, an emergency vent valve 105, and a reaction liquid outlet 111; The tube-and-tube heat exchanger 103 is connected with the steam drum 112 for heat exchange and temperature control, removing the reaction heat in time, and promoting the reaction; the emergency vent valve 105 is located at the top of the high-pressure reactor for To ensure the safety of the reaction in the high-pressure reactor 101 ; the feed ports include a nitrogen feed port 106 , an oxygen feed port 107 , a toluene feed port 108...

Embodiment 2

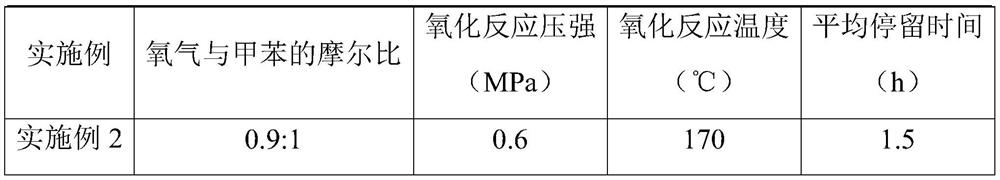

[0065] Embodiment 2 provides a kind of method utilizing jet loop reactor to continuously produce high-quality high-selectivity benzaldehyde and benzoic acid, compared with embodiment 1, difference is to change the catalyst type, relative flow rate and The parameters related to the oxidation reaction are the same as the rest of the steps, and will not be repeated here.

[0066] The catalyst used in embodiment 2 is the mixture that 150g cobalt isooctanoate and 150g manganese isooctanoate form, and the mixed solution that this catalyst forms with 1000L toluene injects in the jet loop reactor with the flow velocity of 70L / h, and its jet flow velocity is 70m / s The relevant parameters of the oxidation reaction in embodiment 2 are as shown in table 1.

[0067] Oxidation reaction related parameters in the step S1 of the embodiment 2 of table 1

[0068]

[0069] The product obtained in Example 2 is analyzed, and the toluene conversion rate, product selectivity and product purity in...

Embodiment 3

[0074] Embodiment 3 provides a kind of method utilizing jet loop reactor to continuously produce high-quality high-selectivity benzaldehyde and benzoic acid. Compared with embodiment 1, the difference is that the catalyst type and oxidation reaction in step S1 are changed. parameter. Wherein, the catalyst used in step S1 of Example 3 is cobalt isooctanoate, and the oxidation reaction is carried out under the action of pure oxygen. The oxidation reaction temperature is 165° C., and the oxidation reaction time is 1 h. The remaining parameters are consistent with those in Example 1. This will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com