Co/MCM-41 catalyst and preparation method thereof

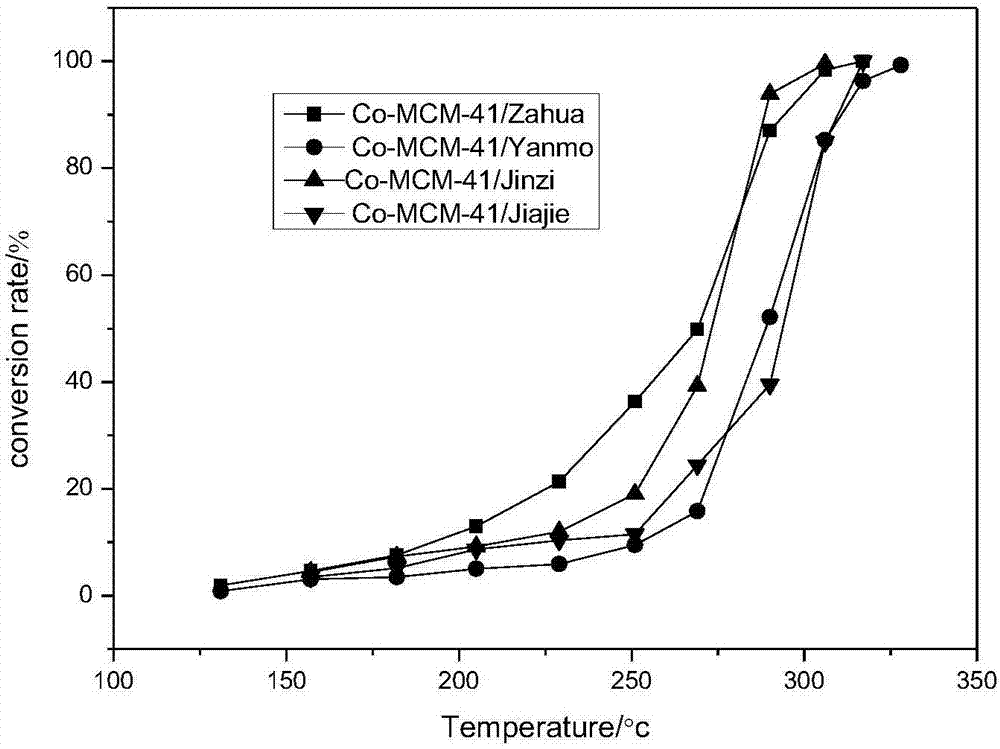

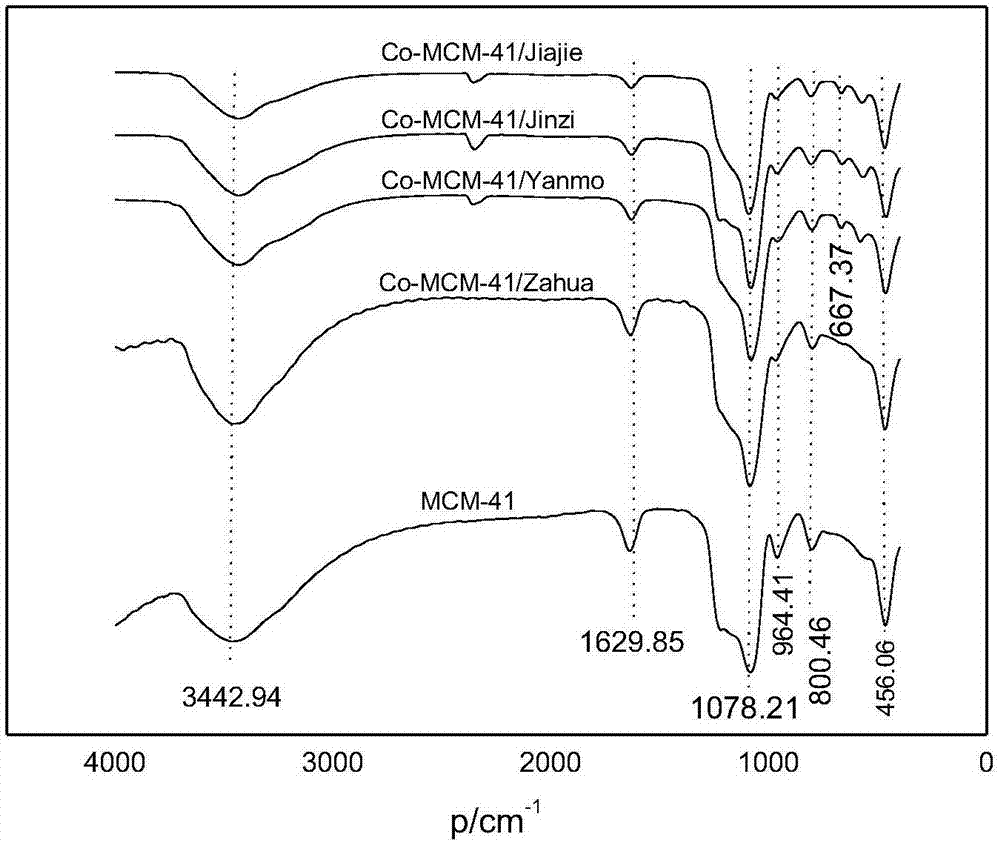

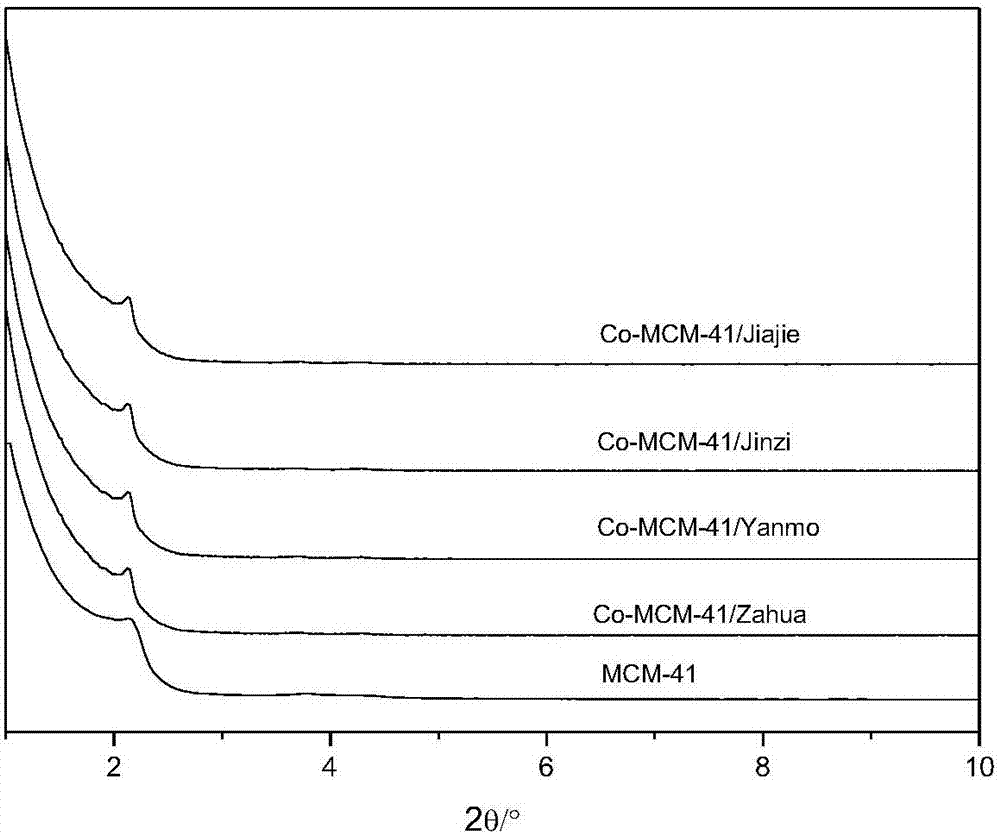

A technology of MCM-41 and catalyst, applied in the field of Co/MCM-41 catalyst and its preparation, can solve the problems of poor hydrothermal stability, no stable structure of pore walls, etc., and achieve the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] 1. Preparation of pure MCM-41 mesoporous molecular sieve

[0035] At room temperature, put 2.77 g of solid cetyltrimethylammonium bromide (CTAB) powder into a beaker containing 120 g of deionized water, and stir with a glass rod until completely dissolved. Then the solution was transferred to a three-necked flask, and 9.52 g of ammonia water was added at one time under vigorous stirring, and the stirring was continued for 30 minutes. Add 10.42 g of tetraethyl orthosilicate (TEOS) dropwise with a constant pressure dropping funnel, and continue stirring for 6 hours after the dropwise addition until the reaction is complete. The mixed solution was transferred to a crystallization kettle lined with polytetrafluoroethylene, placed in a constant temperature drying oven at 110°C, and left to stand for crystallization for 24 hours. After the crystallization kettle cools down, suction filter and rinse with deionized water until neutral, and then put it in a 60°C constant temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com