Co3O4/CuO high-efficiency photo-thermal catalyst, and preparation method and applications thereof

A catalyst and photothermal technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of high cost, unfavorable sustainable development, high energy consumption, etc. , to achieve the effects of low cost, high light-to-heat conversion performance, and uniform product morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Only difference with comparative example is in step (1), add copper nitrate trihydrate and cobalt nitrate hexahydrate, urea mix and dissolve in water, and copper nitrate trihydrate add-on is 0.1057g, other process is identical with comparative example, not here Let me tell you more. Wherein the mol ratio of cobalt nitrate and copper nitrate is 8:1, and the catalyst that this embodiment prepares is marked as Co 3 o 4 / CuO-I.

Embodiment 2

[0035] Only difference with embodiment 1 is that copper nitrate trihydrate add-on is 0.2114g, and other processes are identical with embodiment 1, repeat no more here. Wherein the mol ratio of cobalt nitrate and copper nitrate is 4:1, and the catalyst that this embodiment prepares is marked as Co 3 o 4 / CuO-II.

Embodiment 3

[0037] Only difference with embodiment 1 is that copper nitrate trihydrate add-on is 0.4227g, and other processes are identical with embodiment 1, repeat no more here. Wherein the mol ratio of cobalt nitrate and copper nitrate is 2:1, and the catalyst that this embodiment prepares is marked as Co 3 o 4 / CuO-III.

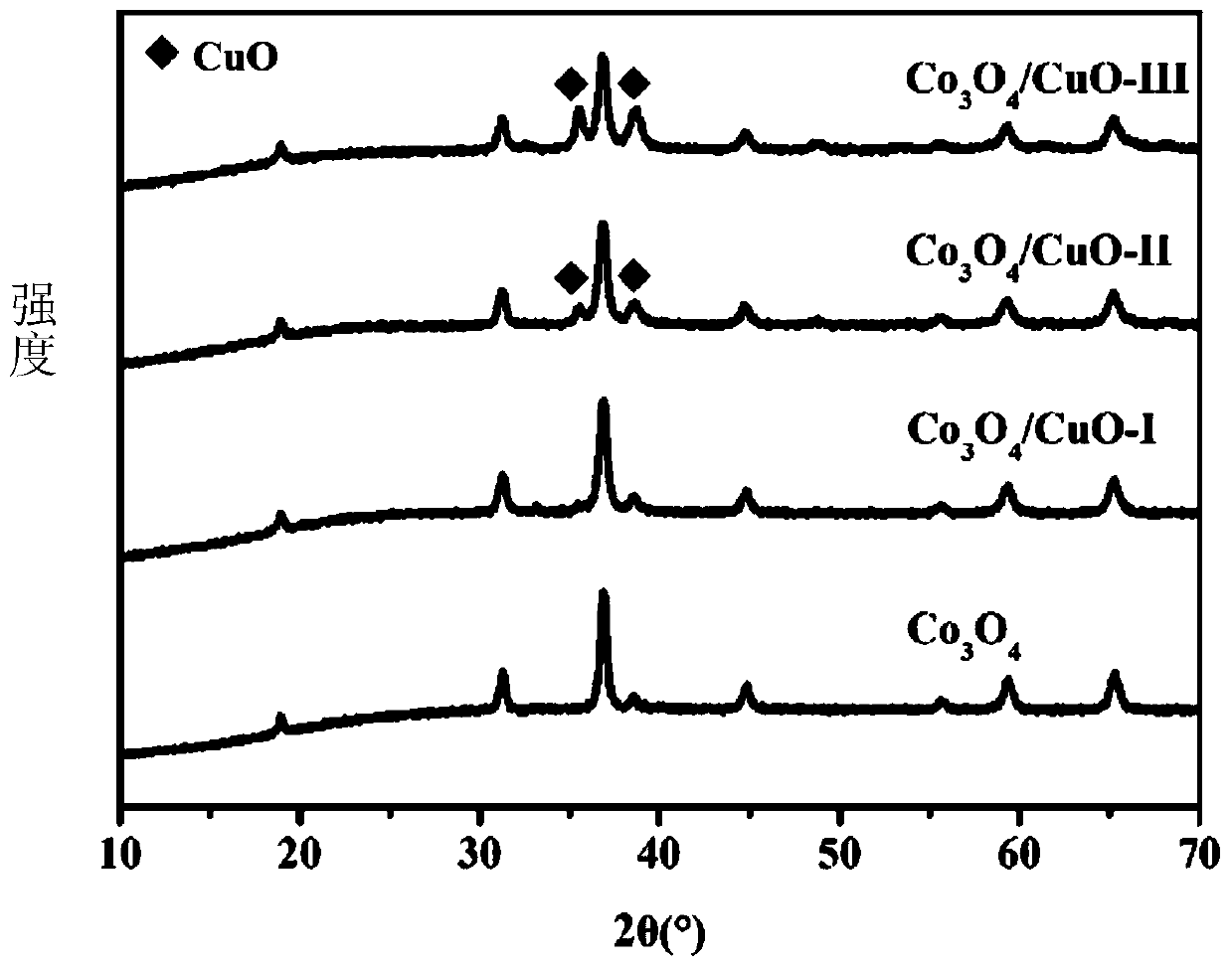

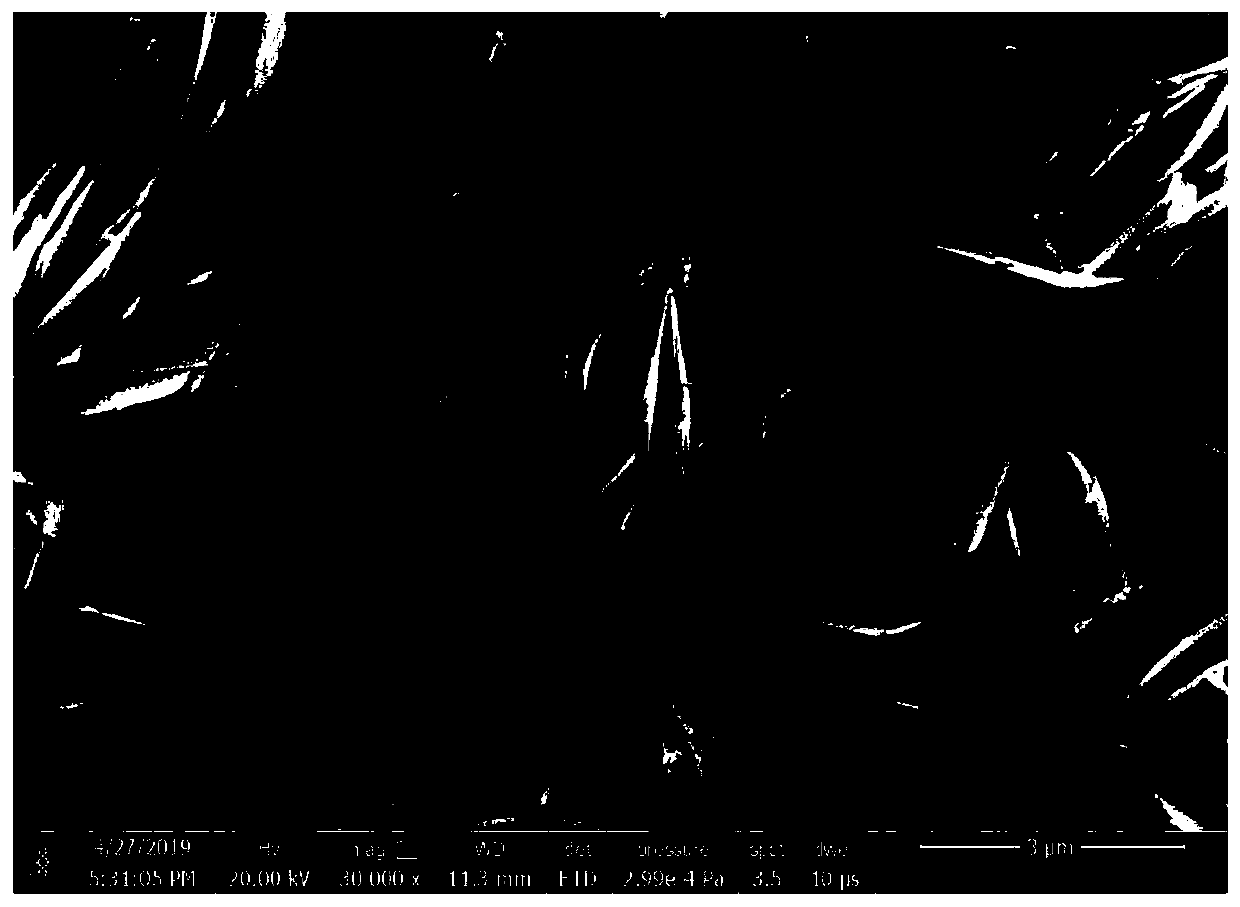

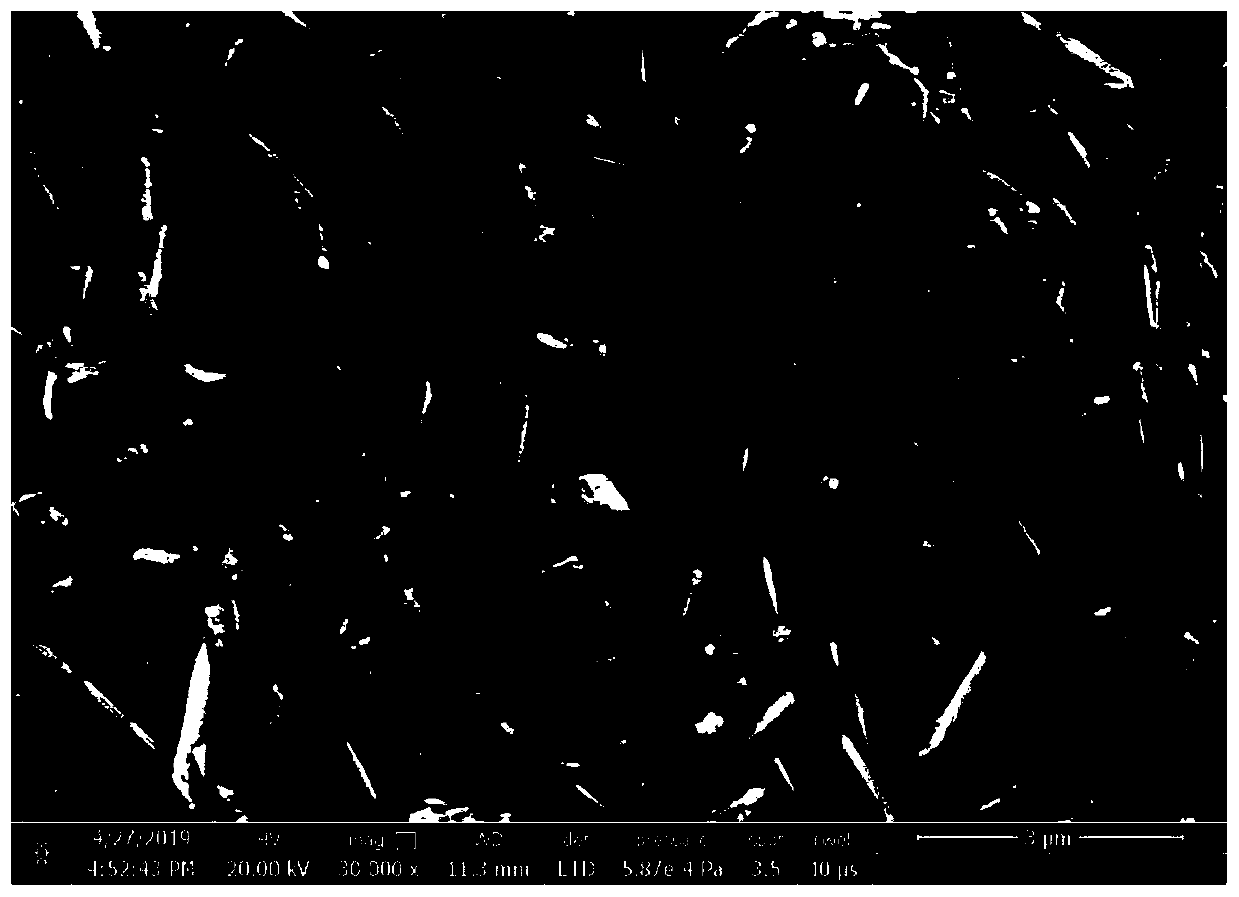

[0038] The catalyst XRD spectrum that comparative example and embodiment 1~3 prepare are as figure 1 As shown, as can be seen from the figure, along with the increase of copper nitrate consumption, the peak of copper oxide in the XRD pattern is more obvious, shows that the product that embodiment 1-3 finally prepares is Co 3 o 4 / CuO. The SEM images of the catalysts prepared in Comparative Examples and Examples 1 to 3 are as follows: Figure 2-5 As shown, it can be seen that pure Co 3 o 4 It is a sheet structure, with the addition of copper nitrate, Co 3 o 4 / CuO still maintains a flaky structure, and pure Co 3 o 4 The morphology differs in the Co 3 o 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com