C12-to-C18 alkyl phosphonic acid protection magnetic ferroferric oxide nanocrystalline as well as preparation method and application thereof

A technology of triiron tetroxide and alkyl phosphonic acid, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

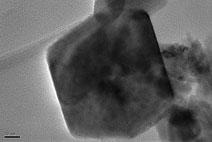

[0039] Prepare 10 mL of 1.5 mol / L ferrous chloride aqueous solution, and then prepare 0.015 mol / L hexadecylphosphonic acid solution with a mixed solution of 15 mL of distilled water and 5 mL of ethanol. The hexadecylphosphonic acid solution was slowly added to the ferrous chloride solution and stirred for 60 min, and the pH value of the mixed solution was adjusted to 5.0 with concentrated ammonia water. The above prepared mixed solution was transferred to a 50mL stainless steel autoclave, treated at 180°C for 24h, and cooled naturally. Separation of magnetic Fe using a magnet 3 o 4 product, such as Figure 13 shown. Vacuum dried at 40°C. The obtained product was identified as Fe by X-ray powder diffraction 3 o 4 ,Such as Figure 8 shown. The alkylphosphonic acid coated on its surface was characterized by thermogravimetric analysis and infrared spectroscopy, such as Figure 9 and Figure 12 shown. Using transmission electron microscopy to characterize its morphology,...

Embodiment 2

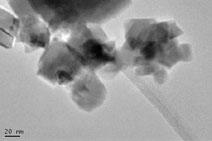

[0041] Prepare 10 mL of 1.5 mol / L ferrous chloride aqueous solution, and then prepare 0.015 mol / L dodecylphosphonic acid solution with a mixed solution of 15 mL of distilled water and 5 mL of ethanol. The dodecylphosphonic acid solution was slowly added to the ferrous chloride solution and stirred for 60 min, and the pH value of the mixed solution was adjusted to 5.0 with concentrated ammonia water. The above prepared mixed solution was transferred to a 50mL stainless steel autoclave, treated at 180°C for 24h, and cooled naturally. Separation of magnetic Fe using a magnet 3 o 4 The product was dried under vacuum at 40°C. The obtained product was identified as Fe by X-ray powder diffraction 3 o 4 , characterized by thermogravimetric analysis and infrared spectroscopy of the alkyl phosphonic acid coated on its surface, and its morphology was characterized by transmission electron microscopy, such as figure 2 shown. 0.1 g of the prepared alkylphosphonic acid protected Fe ...

Embodiment 3

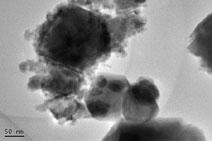

[0043] Prepare 10 mL of 1.5 mol / L ferrous sulfate aqueous solution, and then prepare 0.015 mol / L octadecylphosphonic acid solution with a mixed solution of 15 mL of distilled water and 5 mL of ethanol. The octadecylphosphonic acid solution was slowly added to the ferrous sulfate solution and stirred for 60 min, and the pH value of the mixed solution was adjusted to 5.0 with concentrated ammonia water. The above prepared mixed solution was transferred to a 50mL stainless steel autoclave, treated at 180°C for 24h, and cooled naturally. Separation of magnetic Fe using a magnet 3 o 4 The product was dried under vacuum at 40°C. The obtained product was identified as Fe by X-ray powder diffraction 3 o 4 , characterized by thermogravimetric analysis and infrared spectroscopy of the alkyl phosphonic acid coated on its surface, and its morphology was characterized by transmission electron microscopy, such as image 3 shown. 0.1 g of the prepared alkylphosphonic acid protected Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com