Toluene oxidation method

A toluene and oxidant technology, which is applied in the fields of ozone oxidation to prepare carboxylic acid, hydrocarbon oxidation to prepare oxygenated compounds, organic chemistry, etc., can solve the problems of equipment corrosion, environmental pollution, harsh operating conditions, etc. Improve the effect of simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

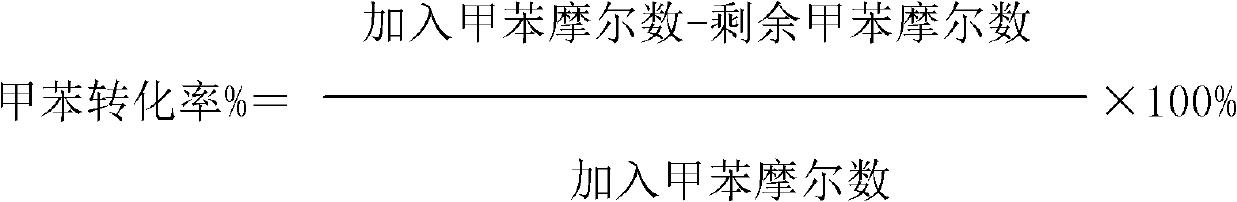

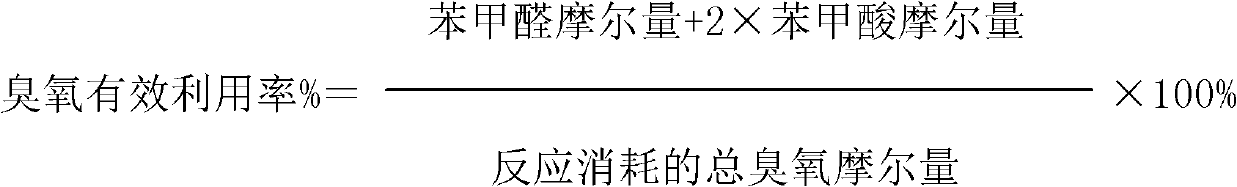

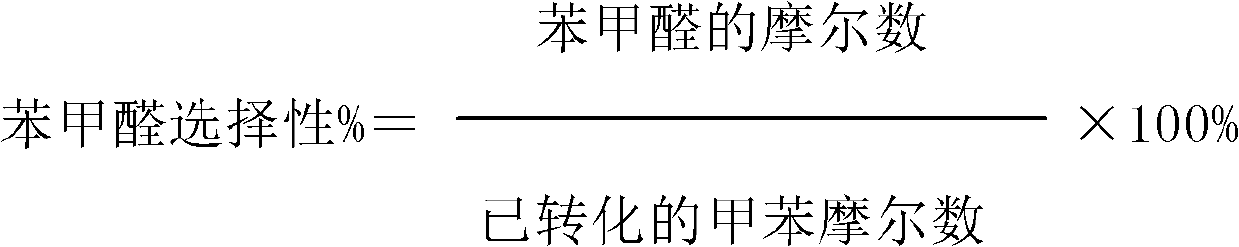

[0039] At a temperature of 60° C. and a pressure of 0.5 MPa, with ozone (15% by volume, the rest being oxygen) as an oxidant, toluene, ozone and solvent acetone were reacted in a molar ratio of 1:1:1. The results of the reaction for 2 hours are as follows: the conversion rate of toluene is 21%; the effective utilization rate of ozone is 36%; the selectivity of benzaldehyde is 44%; the selectivity of benzoic acid is 23%.

Embodiment 2

[0040] Embodiment 2 (no solvent)

[0041] At a temperature of 20° C. and a pressure of 1.5 MPa, with ozone (30% by volume, the rest being air) as an oxidant, toluene and ozone were reacted at a molar ratio of 1:5. The results of the reaction for 5 hours are as follows: the conversion rate of toluene is 12%; the effective utilization rate of ozone is 38%; the selectivity of benzaldehyde is 39%; the selectivity of benzoic acid is 20%.

Embodiment 3

[0043] At a temperature of 80° C. and a pressure of 0.2 MPa, with ozone (5% by volume, the rest being oxygen) as an oxidant, toluene, ozone and solvent butanone were reacted in a molar ratio of 1:2:10. The results of the reaction for 2 hours are as follows: the conversion rate of toluene is 42%; the effective utilization rate of ozone is 33%; the selectivity of benzaldehyde is 40%; the selectivity of benzoic acid is 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com