Catalyst for tail gas purification and preparation method thereof

A technology for exhaust gas purification and catalyst, which is applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. The effect of burning temperature, improving thermal stability, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

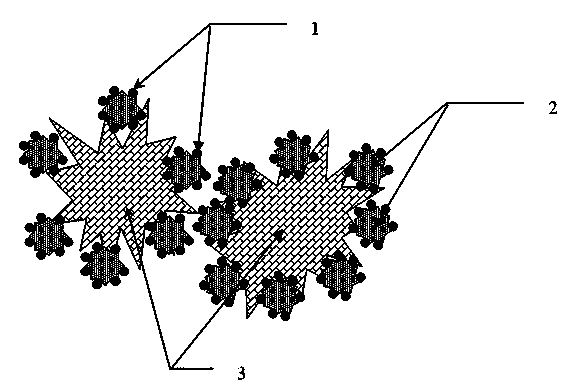

Image

Examples

Embodiment 1

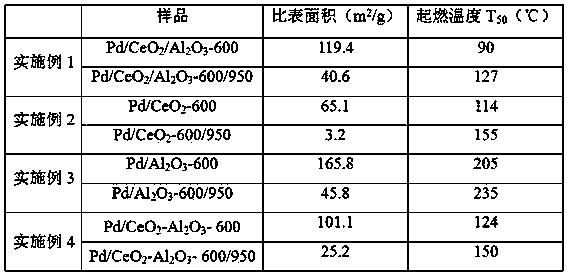

[0027] The inventive method prepares a Pd / CeO 2 / Al 2 o 3 - Catalyst for 600 / 950.

[0028] (1) Take 55.2g of Al(NO 3 ) 3 9H 2 O, use deionized water to make 350mL A solution; take 1.2 times the theoretical precipitation amount of ammonia solution and dilute it to make 350mL B solution; slowly add A solution to B solution under stirring, and control the pH value at about 8.5 after adding. After aging for 12 hours, after centrifugal washing, alumina precursor C was obtained;

[0029] (2) Take 23.9g (NH 4 ) 2 Ce(NO 3 ) 6And 6.3 g urea, add deionized water to make 700mL solution D, add D solution in the hydrothermal reaction kettle, take it out after hydrothermal reaction for 3 hours, after centrifugal washing, obtain the precursor E of cerium oxide;

[0030] (3) Take Pd(NO 3 ) 2 Solution, ammonium citrate 0.15g, polyvinylpyrrolidone (PVP) 0.15g, add deionized water to make solution F, add precursor E to F solution to make 700mL solution, stir well and move to the hydr...

Embodiment 2

[0034] The inventive method prepares a Pd / CeO 2 - Catalyst for 600 / 950.

[0035] Precursor G was dried for 12h and calcined at 600°C for 2h to obtain a fresh sample of Pd / CeO 2 -600 catalyst, the fresh sample was calcined at 950℃ for 3h to obtain the aged sample Pd / CeO 2 -600 / 950 catalyst. Pd / CeO 2 The specific surface area of -600 catalyst is 65.1 m 2 / g,T 50 It is 114°C. Pd / CeO 2 The specific surface area of -600 / 950 catalyst is 3.2 m 2 / g,T 50 is 155°C. See Table 1.

Embodiment 3

[0037] The inventive method prepares a Pd / Al 2 o 3 - Catalyst for 600 / 950.

[0038] Add precursor C to F to form a 700mL solution, stir evenly and move it to a hydrothermal reaction kettle, take it out after 3 hours of hydrothermal reaction, wash by centrifugation, dry for 12 hours, and roast at 600°C for 2 hours to obtain a fresh sample of Pd / Al 2 o 3 -600 catalyst, the fresh sample was calcined at 950℃ for 3h to obtain the aged sample Pd / Al 2 o 3 -600 / 950 catalyst. Pd / Al 2 o 3 -600 catalyst specific surface area is 165.8m 2 / g,T 50 It is 205°C. Pd / Al 2 o 3 -600 / 950 catalyst specific surface area is 45.8m 2 / g,T 50 is 235°C. See Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com