Method for oxidizing phenol

A technology of phenol and hydrogen peroxide, applied in chemical instruments and methods, preparation of quinone oxide, preparation of oxygenated compounds, etc., can solve problems such as poor selectivity of benzoquinone, and achieve low cost, environmental friendliness, and industrial production and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

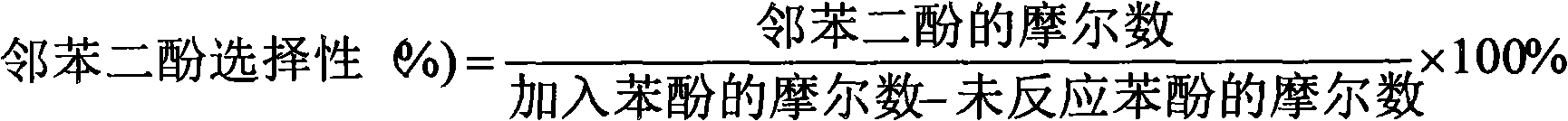

[0037] With phenol, hydrogen peroxide (hydrogen peroxide is provided with the form of the hydrogen peroxide aqueous solution of 30% by weight in this embodiment, the following examples are the same), solvent methanol and catalyst (TS-1 and dodecaphosphotungstic heteropoly acid The weight ratio is 100:1, and the phosphotungstic heteropolyacid is H 3 PW 12 o 40 ) According to the molar ratio of phenol to hydrogen peroxide is 1:2, the weight ratio of solvent methanol to catalyst is 20:1, the weight ratio of phenol to catalyst is 20:1, at a temperature of 30°C and a pressure of 1.5MPa react.

[0038] The results of the 2-hour reaction were as follows: the conversion rate of phenol was 76%; the selectivity of benzoquinone was 23%, the selectivity of catechol was 42%, and the selectivity of hydroquinone was 35%.

Embodiment 2

[0044] The weight ratio of phenol, hydrogen peroxide, solvent methanol and catalyst (TS-1 to phosphotungstopoly blue is 0.1:1, phosphotungstopoly blue is H 5 PW 12 o 40 ) According to the molar ratio of phenol and hydrogen peroxide is 1:2, the weight ratio of solvent methanol and catalyst is 120:1, the weight ratio of phenol and catalyst is 40:1, the temperature is 30 ℃, the pressure is the condition of 1.5MPa react below.

[0045] The results of the 2-hour reaction were as follows: the conversion rate of phenol was 53%; the selectivity of benzoquinone was 26%, the selectivity of catechol was 41%, and the selectivity of hydroquinone was 39%.

Embodiment 3

[0047] The weight ratio of phenol, hydrogen peroxide, solvent acetone and catalyst (TS-1 and isovanadium polyacid is 50:1, isovanadium polyacid is H 6 V 10 o 28 ) According to the molar ratio of phenol and hydrogen peroxide is 1:5, the weight ratio of solvent acetone and catalyst is 200:1, the weight ratio of phenol and catalyst is 80:1, the temperature is 60 ℃, the condition of pressure is 1.0MPa react below.

[0048] The results of the 2-hour reaction were as follows: the conversion rate of phenol was 74%; the selectivity of benzoquinone was 29%, the selectivity of catechol was 36%, and the selectivity of hydroquinone was 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com