Flat-plate wide-temperature sulfur-resistant alkali-metal-resistant SCR denitrification catalyst and production method thereof

A denitration catalyst, flat-plate technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problems of easy sulfur poisoning, narrow active temperature range, alkali metal poisoning, etc. , to avoid deactivation, increase specific surface area, and achieve the effect of excellent wide temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

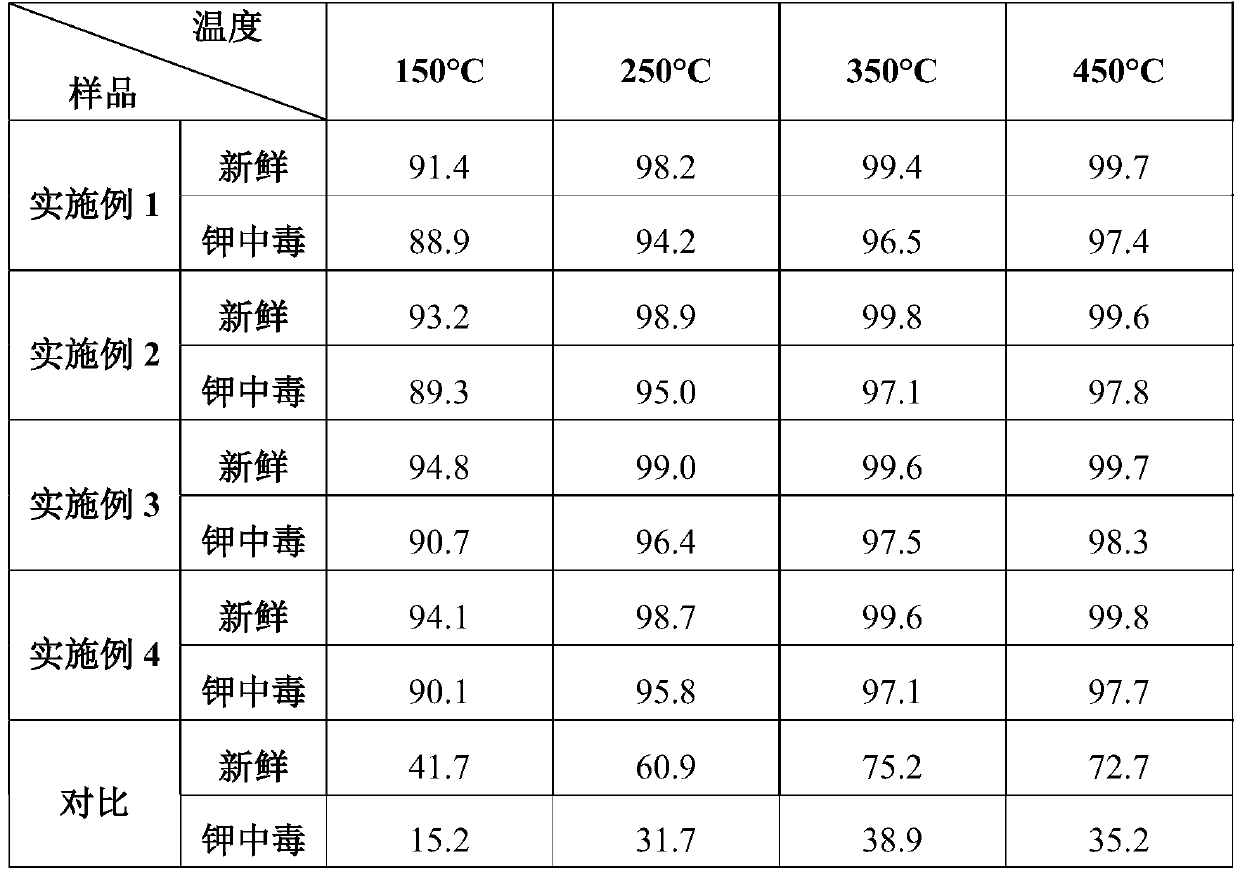

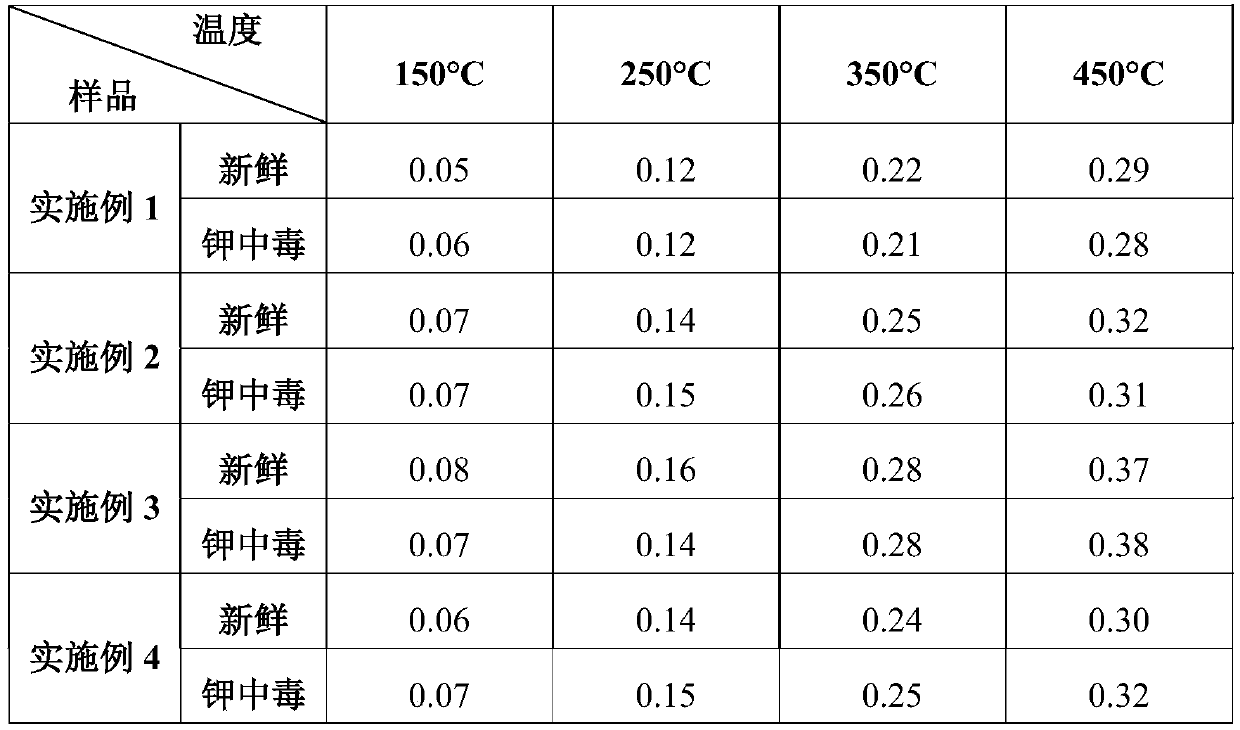

Examples

preparation example Construction

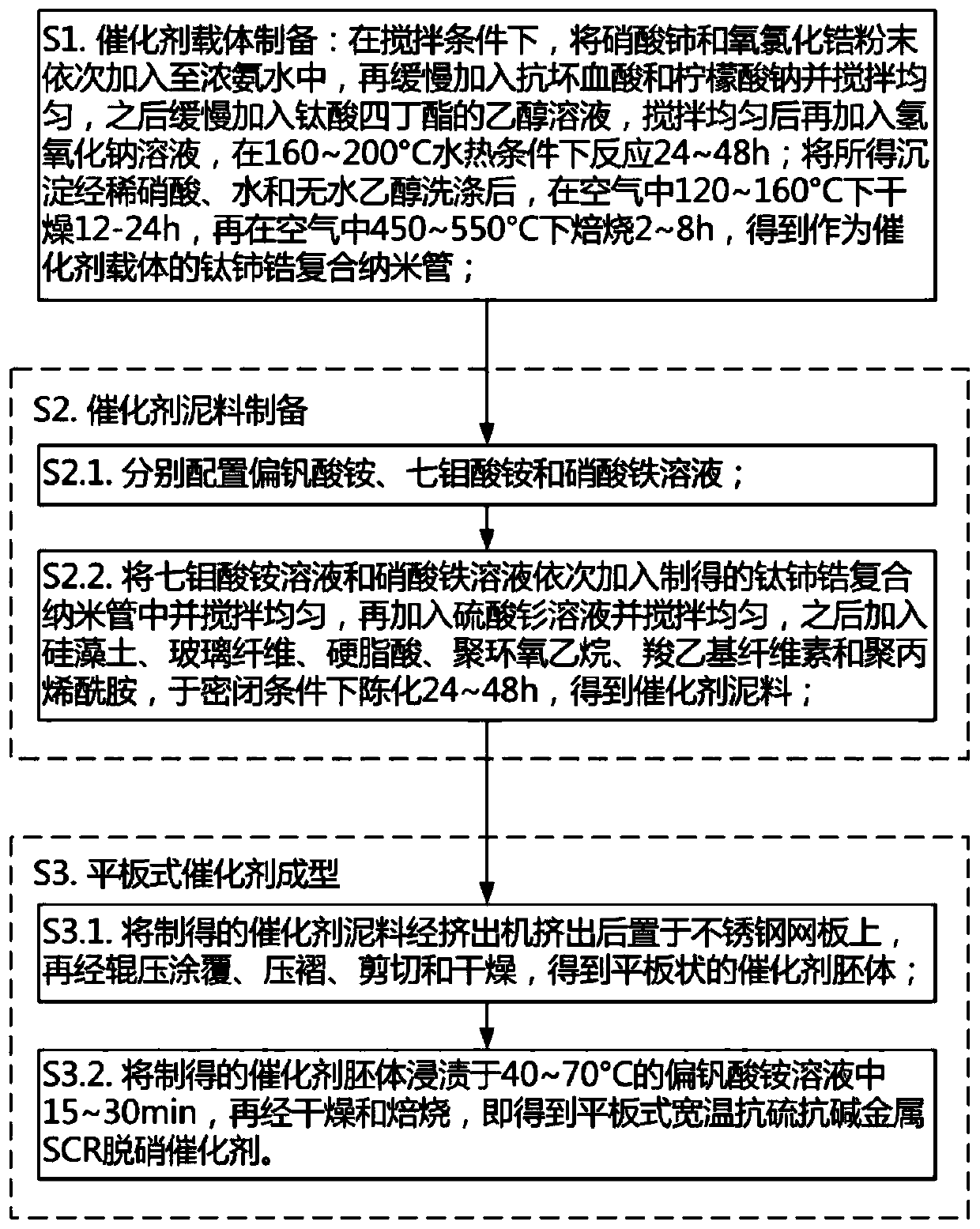

[0035] The preparation method of the flat-plate wide-temperature anti-sulfur and anti-alkali metal SCR denitrification catalyst provided by the invention, such as figure 1 shown, including the following steps:

[0036] S1. Catalyst carrier preparation:

[0037] Under stirring conditions, add cerium nitrate and zirconium oxychloride powder into concentrated ammonia water in turn, then slowly add ascorbic acid and sodium citrate and stir well, then slowly add tetrabutyl titanate ethanol solution, stir well and then add Sodium hydroxide solution, react under hydrothermal conditions at 160-200°C for 24-48 hours; wash the obtained precipitate with dilute nitric acid, water and absolute ethanol, dry it in the air at 120-160°C for 12-24 hours, and then dry it in the air Calcination at 450-550°C for 2-8 hours to obtain titanium-cerium-zirconium composite nanotubes as catalyst supports;

[0038] S2. Catalyst sludge preparation:

[0039] S2.1. respectively configure ammonium heptamol...

Embodiment 1

[0050] In this example, the preparation process of the flat-plate wide-temperature anti-sulfur and anti-alkali metal SCR denitration catalyst is as follows:

[0051] (1) Under stirring conditions, add 1181g of cerium nitrate and 869g of zirconium oxychloride powder into 20L of concentrated ammonia water in sequence, then slowly add 2040g of ascorbic acid and 4080g of sodium citrate and stir evenly, then slowly add 40L containing 1852g of tetrabutyl titanate After stirring the ethanol solution of the ester, add 150L 5mol / L sodium hydroxide solution, and react for 48h under the hydrothermal condition of 160°C; ℃ drying for 24 hours, and finally calcination in air at 450 ℃ for 8 hours to obtain titanium cerium zirconium composite nanotubes.

[0052] (2) Dissolve 183g ammonium heptamolybdate, 76g ferric nitrate and 8g samarium sulfate in 500ml, 300ml and 400ml water respectively, then add ammonium heptamolybdate solution and ferric nitrate solution to the prepared titanium cerium ...

Embodiment 2

[0057] In this example, the preparation process of the flat-plate wide-temperature anti-sulfur and anti-alkali metal SCR denitration catalyst is as follows:

[0058] (1) Under stirring conditions, add 1181g of cerium nitrate and 869g of zirconium oxychloride powder into 20L of concentrated ammonia water in sequence, then slowly add 2040g of ascorbic acid and 4080g of sodium citrate and stir evenly, then slowly add 40L containing 1852g of tetrabutyl titanate After stirring the ethanol solution of the ester, add 150L of 5mol / L sodium hydroxide solution, and react for 24h under the hydrothermal condition of 200℃; ℃ drying for 12 hours, and finally calcination in air at 550 ℃ for 2 hours to obtain titanium cerium zirconium composite nanotubes.

[0059] (2) Dissolve 119g ammonium heptamolybdate, 152g ferric nitrate and 30g samarium sulfate in 300ml, 400ml and 500ml water respectively, then add ammonium heptamolybdate solution and ferric nitrate solution to the prepared titanium cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com