NO*storage-reduction catalyzer for vehicle vent gas process and preparation method thereof

A catalyst and compound technology, applied in the field of automobile exhaust gas purification catalyst and its preparation, can solve the problems of loss of adsorption and storage function, blocked surface diffusion and desorption-resorption channel, etc., and achieves improved sulfur poisoning resistance, NOx storage performance improvement, The effect of improving hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

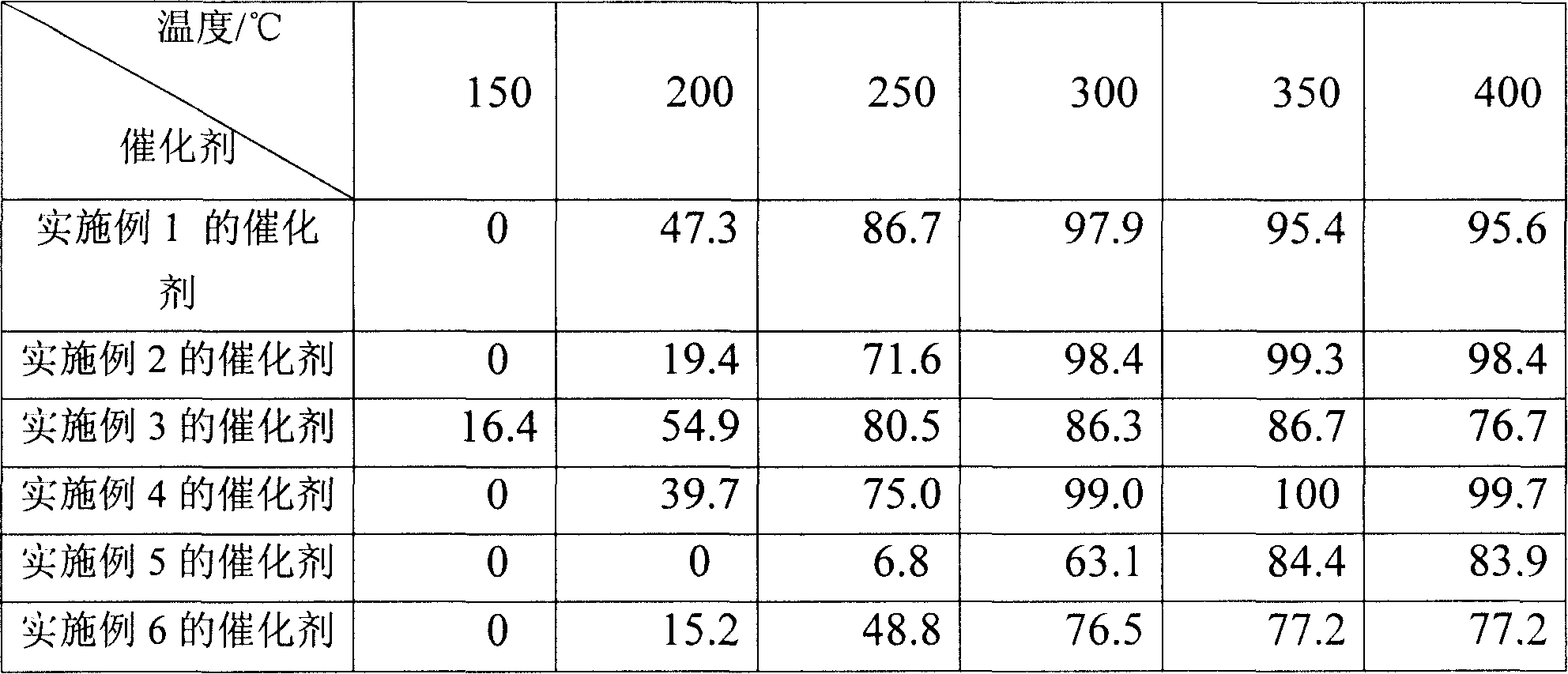

Examples

Embodiment 1

[0034] Add 100 grams of cation exchange capacity (CMC) to 0.6 mmol / g of sodium bentonite (refined sodium bentonite from Xinyang Tongchuang Bentonite Co., Ltd.) into 1000 grams of 5% by weight lithium chloride solution, adjust with sodium hydroxide solution The pH value of the system is about 7, heated and stirred at 80°C for 8 hours, filtered, dried at 120°C, and ball-milled to 200 mesh to obtain lithium-based bentonite modified with lithium with an alkali metal / alkaline earth metal content of 3.2% by weight.

[0035] CuCl by isometric impregnation 2 The above-mentioned lithium-based bentonite was impregnated with the solution, the loading amount of Cu was controlled to be 1.7% by weight, dried at 90° C. for 4 hours, and calcined at 500° C. for 2 hours to obtain Cu / lithium-based bentonite.

[0036] Then the Cu / lithium-based bentonite was impregnated with chloroplatinic acid solution by an equal volume impregnation method, and the loading amount of Pt was controlled to be 0.24%...

Embodiment 2

[0038] Add 30 grams of cation exchange capacity (CMC) to 0.6 mmol / g of sodium bentonite (refined sodium bentonite from Xinyang Tongchuang Bentonite Co., Ltd.) into 1000 grams of 8% by weight potassium chloride solution, adjust with sodium hydroxide solution The pH value of the system is about 8, heated and stirred at 60°C for 10 hours, filtered, dried at 120°C, ball milled to 200 mesh, and potassium-based bentonite modified with potassium with an alkali metal / alkaline earth metal content of 0.85% by weight is prepared.

[0039] The potassium-based bentonite was impregnated with a titanium trichloride solution by an equal-volume impregnation method to control the loading amount of Ti to 0.8% by weight, dried at 90°C for 4 hours, and calcined at 600°C for 2 hours to obtain Ti / potassium-based bentonite.

[0040] Then impregnate the above-mentioned Ti / potassium bentonite with chloroplatinic acid solution by an equal volume impregnation method, and control the loading amount of Pt t...

Embodiment 3

[0042] Add 200 grams of cation exchange capacity (CMC) to 0.6 mmol / g of sodium bentonite (refined sodium bentonite from Xinyang Tongchuang Bentonite Co., Ltd.) into 1000 grams of 4% by weight barium chloride solution, adjust with sodium hydroxide solution The pH value of the system is about 6, heated and stirred at 70°C for 9 hours, filtered, dried at 120°C, and ball-milled to 200 mesh to obtain barium-modified barium-based bentonite with an alkali metal / alkaline earth metal content of 1.3% by weight.

[0043] Zr(NO 3 ) 4 The above-mentioned barium-based bentonite was impregnated with the solution, the loading amount of Zr was controlled to be 1.2% by weight, dried at 90° C. for 4 hours, and calcined at 600° C. for 2 hours to obtain Zr / barium-based bentonite.

[0044] Then impregnate the above-mentioned Zr / barium-based bentonite with palladium nitrate solution by equal volume impregnation method, and control the loading amount of Pd to be 0.35% by weight. Then dry at 90°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com