NOx storage-reduction catalyst for vehicle tail gas treatment and preparation method of catalyst

A technology of catalyst and compound, which is applied in the field of automobile exhaust purification catalyst and its preparation, can solve the problems of blocking surface diffusion and desorption-re-adsorption channels, loss of adsorption and storage functions, etc., to improve NOx storage performance, improve resistance to sulfur poisoning, Conducive to the effect of NOx removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

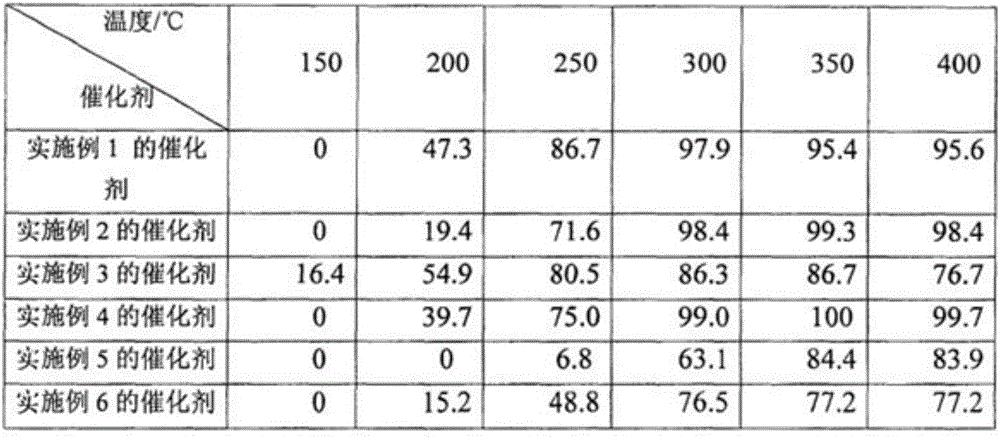

Examples

Embodiment 1

[0031] Add 100 grams of cation exchange capacity (CMC) to 0.6 mmol / g of sodium bentonite (refined sodium bentonite from Xinyang Tongchuang Bentonite Co., Ltd.) into 1000 grams of 5% by weight lithium chloride solution, adjust with sodium hydroxide solution The pH value of the system is about 7, heated and stirred at 80°C for 8 hours, filtered, dried at 120°C, and ball-milled to 200 mesh to obtain lithium-based bentonite modified with lithium with an alkali metal / alkaline earth metal content of 3.2% by weight.

[0032] CuCl by isometric impregnation 2 The above-mentioned lithium-based bentonite was impregnated with the solution, the loading amount of Cu was controlled to be 1.7% by weight, dried at 90° C. for 4 hours, and calcined at 500° C. for 2 hours to obtain Cu / lithium-based bentonite.

[0033] Then the Cu / lithium-based bentonite was impregnated with chloroplatinic acid solution by an equal volume impregnation method, and the loading amount of Pt was controlled to be 0.24%...

Embodiment 2

[0035] Add 30 grams of cation exchange capacity (CMC) to 0.6 mmol / g of sodium bentonite (refined sodium bentonite from Xinyang Tongchuang Bentonite Co., Ltd.) into 1000 grams of 8% by weight potassium chloride solution, adjust with sodium hydroxide solution The pH value of the system is about 8, heated and stirred at 60°C for 10 hours, filtered, dried at 120°C, ball milled to 200 mesh, and potassium-based bentonite modified with potassium with an alkali metal / alkaline earth metal content of 0.85% by weight is prepared.

[0036] The potassium-based bentonite was impregnated with a titanium trichloride solution by an equal-volume impregnation method to control the loading of Ti to 0.8% by weight, dried at 90°C for 4 hours, and calcined at 600°C for 2 hours to obtain Ti / potassium-based bentonite.

[0037] Then impregnate the above-mentioned Ti / potassium bentonite with chloroplatinic acid solution by an equal volume impregnation method, and control the loading amount of Pt to be 0....

Embodiment 3

[0039] Add 200 grams of cation exchange capacity (CMC) to 0.6 mmol / g of sodium bentonite (refined sodium bentonite from Xinyang Tongchuang Bentonite Co., Ltd.) into 1000 grams of 4% by weight barium chloride solution, adjust with sodium hydroxide solution The pH value of the system is about 6, heated and stirred at 70°C for 9 hours, filtered, dried at 120°C, and ball-milled to 200 mesh to obtain barium-modified barium-based bentonite with an alkali metal / alkaline earth metal content of 1.3% by weight.

[0040] Zr(NO 3 ) 4 The above-mentioned barium-based bentonite was impregnated with the solution, the loading amount of Zr was controlled to be 1.2% by weight, dried at 90° C. for 4 hours, and calcined at 600° C. for 2 hours to obtain Zr / barium-based bentonite.

[0041] Then impregnate the above-mentioned Zr / barium-based bentonite with palladium nitrate solution by equal volume impregnation method, and control the loading amount of Pd to be 0.35% by weight. Then dry at 90°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com