Hydrogen production catalyst, preparation and its uses

A catalyst and oxide carrier technology, applied in the fields of hydrogen production catalysts and reforming hydrogen production catalysts, can solve the problems of harsh conditions, many steps, complex catalyst preparation methods, etc., and achieve easy production, low production costs, and high resistance to sulfur poisoning. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

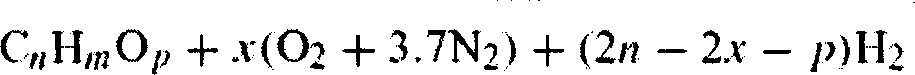

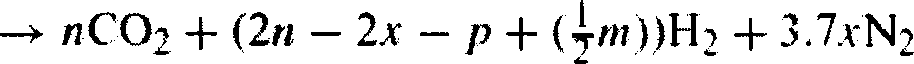

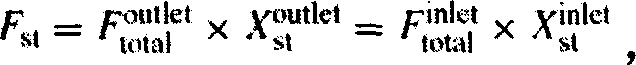

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Pt / Ce 0.8 Gd 0.2 o 1.9 catalyst:

[0038] The first step: the chemical formula is Ce prepared by citric acid sol-gel method 0.8 Gd 0.2 o 1.9 composite oxides with oxygen ion conductivity. Take by weighing 12.08 grams of citric acid and 8.06 grams of ethylene glycol and add 200 milliliters of deionized water to form a solution, then weigh 19.97 grams of Ce(NO 3 ) 3 ·6H 2 O and 5.19 g of Gd(NO 3 ) 3 ·6H 2 Add O to the above solution one by one, stir at room temperature for 1 hour, then concentrate at 70-80°C under stirring until viscous colloid, the formed gel is dried at 110°C, and roasted in air at 500°C for 2 hours to obtain the oxide product. N 2 -The specific surface area measured by BET is 59m 2 / g. XRD analysis has a perovskite structure.

[0039] Step 2: Preparation of 2wt% Pt / Ce by incipient wetness impregnation 0.8 Gd 0.2 o 1.9 catalyst. Weigh out 0.53 g H 2 PtCl 6 ·6H 2 O was added to 30 milliliters of deionized water to for...

Embodiment 2

[0041] The first step: exactly the same as the first step in Example 1.

[0042] Step 2: Preparation of 0.5 wt% Pt / Ce by incipient wetness impregnation 0.8 Gd 0.2 o 1.9 Catalyst, weighed 0.13 g H 2 PtCl 6 ·6H 2 O was added to 30 ml of deionized water to form a solution, and 9.95 g of the oxide prepared in the first step of Example 1 was weighed and added to the above solution to obtain an incipient wetness impregnated catalyst precursor, which was dried and calcined at 800°C 0.5wt% Pt / Ce produced in 2 hours 0.8 Gd 0.2 o 1.9 Catalyst product, expressed as 0.5Pt / CGO-800, catalyst specific surface area is 40m 2 / g.

Embodiment 3

[0044] The first step: exactly the same as the first step in Example 1.

[0045] In the second step in the embodiment, the calcination temperature of the catalyst is 600°C, and the rest are the same as in Example 1. The catalyst is expressed as 2Pt / CGO-600, and the specific surface area of the catalyst is 57m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com