Patents

Literature

272results about How to "Improve denitrification performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

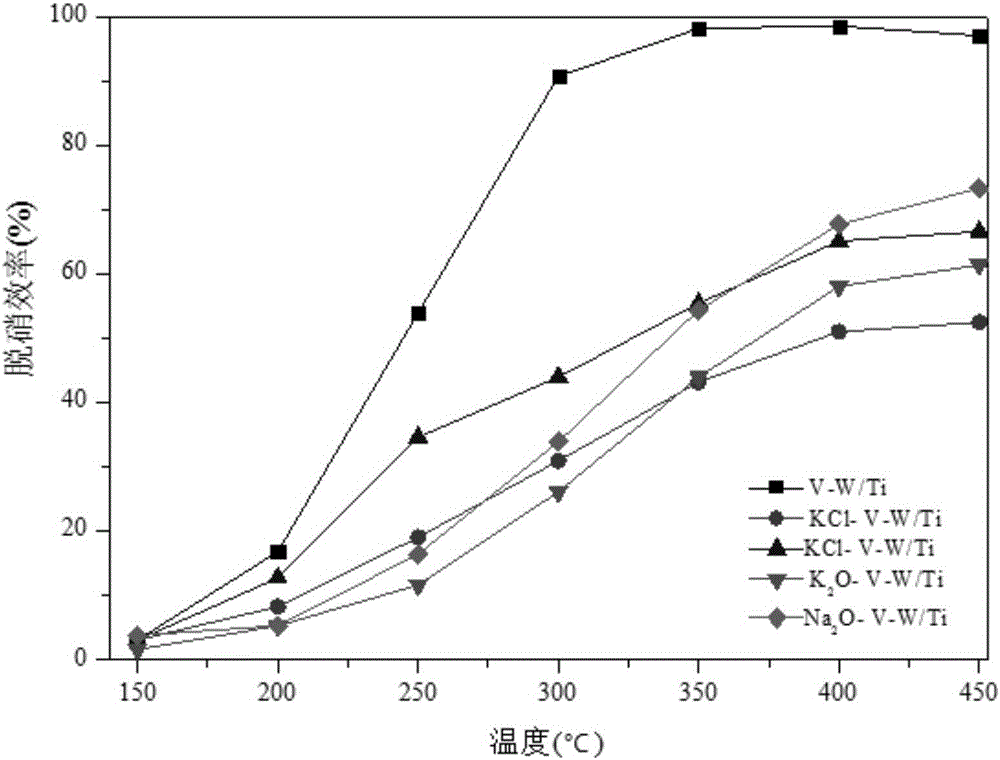

Flue-gas denitration catalyst incapable of being deactivated by basic metallic oxides, preparation method thereof and applications thereof

InactiveCN103861628AStrong acidAvoid poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberActive component

The invention discloses a flue-gas denitration catalyst incapable of being deactivated by basic metallic oxides, a preparation method thereof and applications thereof. The catalyst comprises following components by weight: 70-85% of nanometer titanium dioxide, 1-3% of V2O5, 5-15% of heteropoly acid, 3-15% of glass fiber and 4-10% of an inorganic binder. In the preparation method, active components and the heteropoly acid are loaded step by step. The catalyst has high denitration performance and high performance of resistance to deactivation by the basic metallic oxides, and is particularly suitable for flue gas denitration of a power plant, an industrial boiler, an incinerator, a cement kiln, and the like, wherein the power plant, the industrial boiler, the incinerator, the cement kiln, and the like adopt biomass as fuel and contain a large amount of basic metallic oxides in flue gas.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH +1

Catalytic agent for denitrating smoke and preparation technology thereof

ActiveCN102166516AGuaranteed denitrification effectImprove denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSurface-active agentsCoal

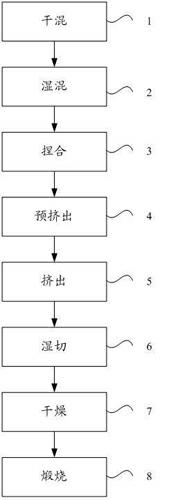

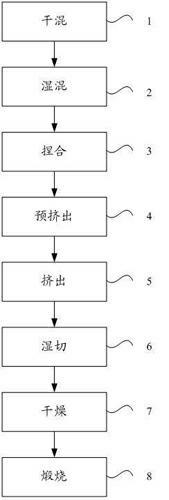

The invention provides a catalytic agent for denitrating smoke and a preparation technology thereof. The catalytic agent for denitrating the smoke comprises the raw materials based on parts by weight as follows: 60%-90% of titanium dioxide, 3%-9% of tungsten trioxide, 0.5-3% of vanadium pentoxide, 2%-5% of organic binder, 10%-20% of inorganic binder, 7%-10% of glass fiber, 2%-4% of plasticizer, 20%-40% of water, 2%-4% of lubricant, 0.1%-1% of surface active agent and 3%-9% of neutralizer. After the content of the tungsten trioxide is reasonably proportioned, on the premise of guaranteeing thedenitration performance of the catalytic agent for denitrating the smoke, the absorption to sulfur dioxide is reduced, the SO2 / SO3 conversion percentage is reduced, and the high-sulfur and high-ash use requirement of the coal quality in China is met.

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

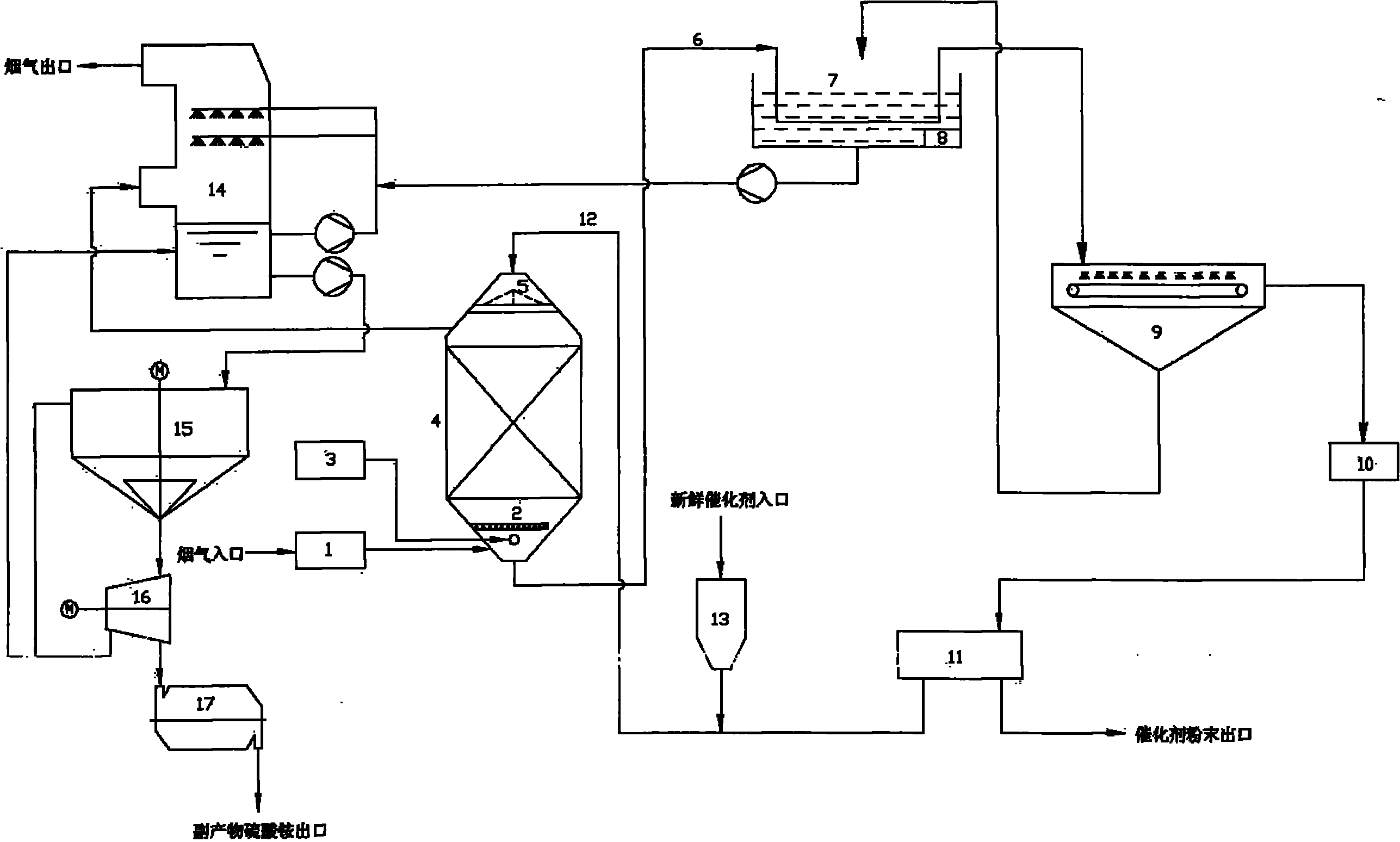

Low temperature SCR moving bed flue gas denitration method for coal-fired boiler

InactiveCN102008893AImprove denitrification performanceImprove denitrification efficiencyDispersed particle separationProcess engineeringFlue gas

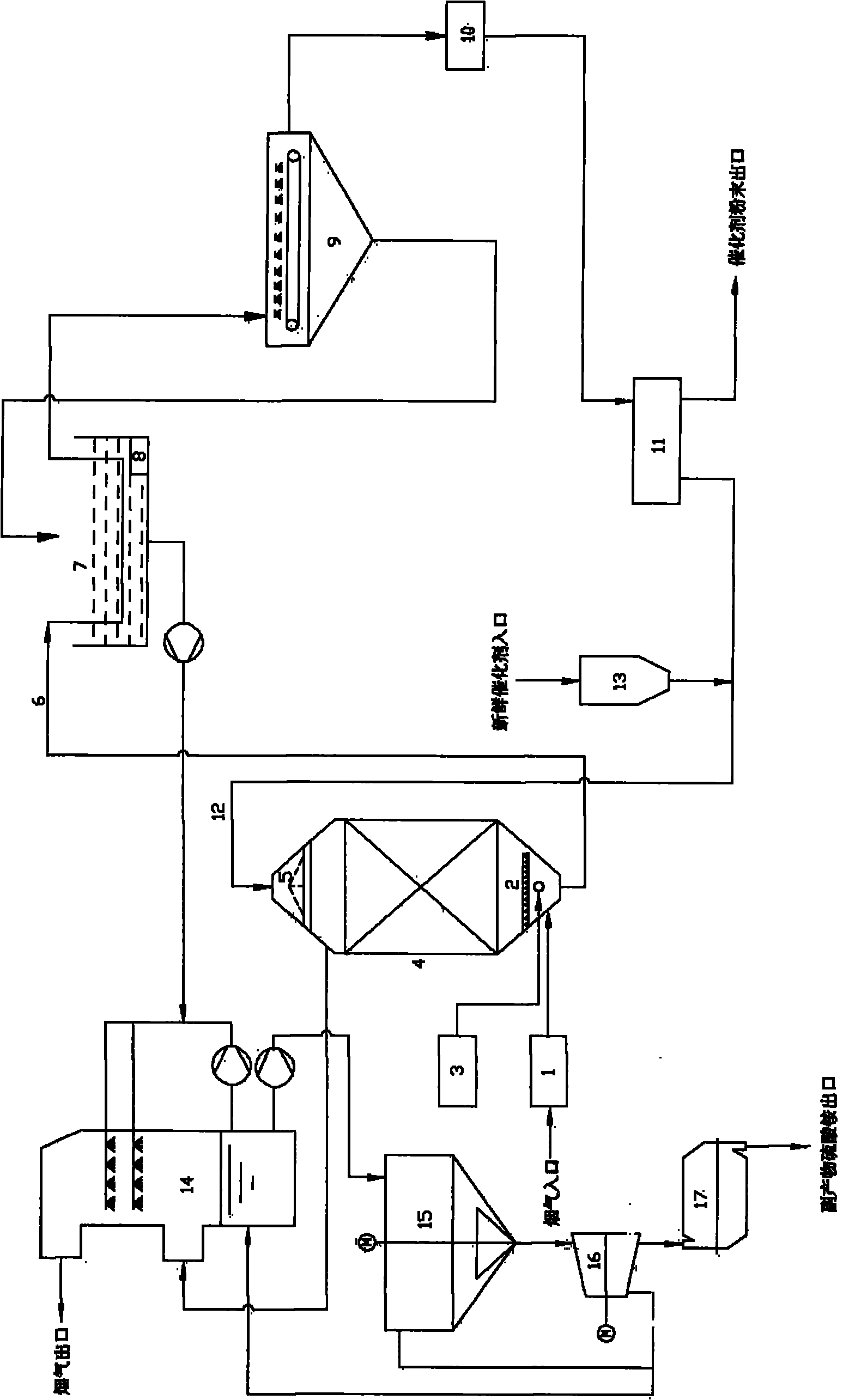

The invention relates to a low temperature selective catalytic reduction (SCR) moving bed flue gas denitration method for a coal-fired boiler. Boiler flue gas subjected to dust removal and a denitration reducer NH3 are introduced into a denitration reactor respectively; a low temperature SCR catalyst is continuously input from one end of the denitration reactor and continuously output from the other end of the denitration reactor to form a moving bed; the flue gas and the NH3 are in gas-solid contact with the catalyst which moves directionally in a countercurrent or crosscurrent mode in the reactor; NOx and NH3 in the flue gas are reacted with each other and the generated N2 and water vapor are discharged out of the denitration reactor along with the denitrified flue gas; in the process, parts of SO2 and NH3 in the flue gas are reacted with each other and the generated sulfate is deposited on the catalyst; and an inactivated catalyst which is continuously output from the denitration reactor enters a regenerative process, the regenerated catalyst returns to the reactor and the steps are continuously and repeatedly circulated by the method. By continuously regenerating the catalyst, the method solves the problem of catalyst poisoning and improves the denitration efficiency and running stability of a system.

Owner:GUODIAN SCI & TECH RES INST +1

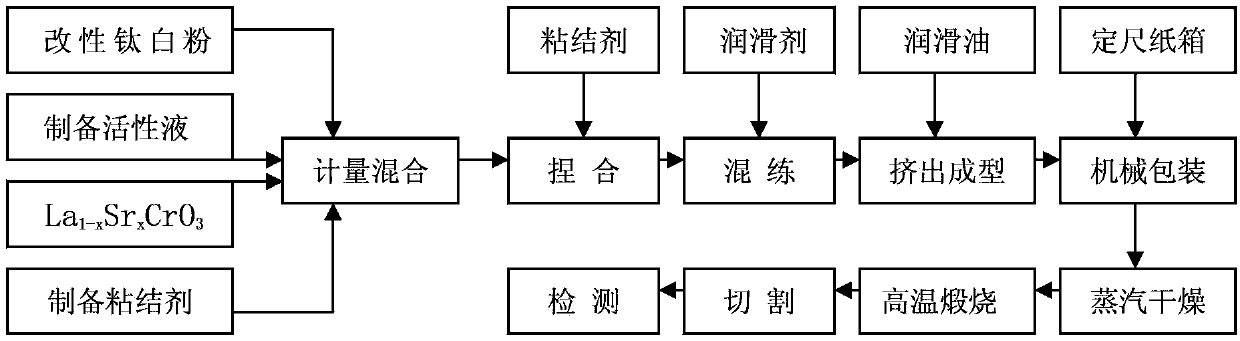

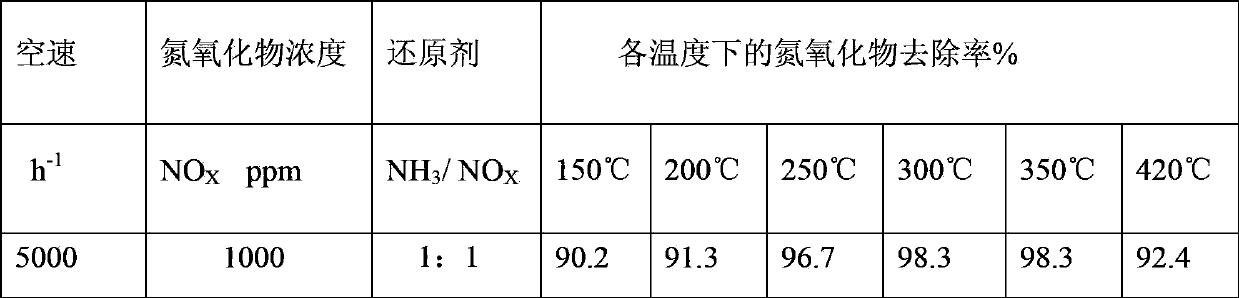

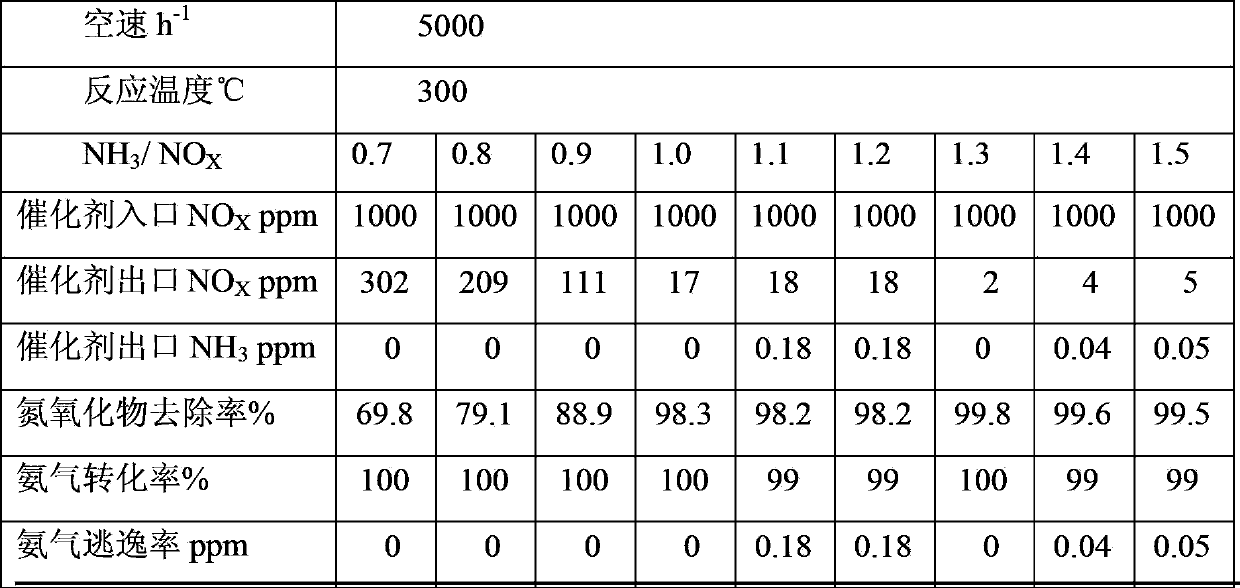

Perovskite-type substance La<1-x>Sr<x>CrO<3>, heat-engine plant denitration composite catalyst, and preparation methods of perovskite-type substance La<1-x>Sr<x>CrO<3> and heat-engine plant denitration composite catalyst

InactiveCN103861581AImprove performanceUltra-fine crystal shape lowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPhosphateHoneycomb like

The invention discloses perovskite-type substance La<1-x>SrCrO<3>, a heat-engine plant denitration composite catalyst, and preparation methods of the perovskite-type substance La<1-x>SrCrO<3> and the heat-engine plant denitration composite catalyst, and belongs to the technical field of flue gas denitrification catalyst. The preparation method of the perovskite-type substance La<1-x>SrCrO<3> is used for solving a problem that existing preparation method of the perovskite-type substance is complex. According to the preparation method of the perovskite-type substance La<1-x>SrCrO<3>, lanthanum nitrate, strontium nitrate, and chromium nitrate are taken as raw material precursors, and are dissolved in water, and then are subjected to high-temperature roasting so as to obtain finished products. The preparation methods of the heat-engine plant denitration composite catalyst is used for solving a problem of existing denitration catalyst that ammonia is released in denitration processes. According to the preparation methods of the heat-engine plant denitration composite catalyst, a titanium dioxide mixture, an active liquid, water, glycerin, ethylene glycol, glass fiber, and aluminium dihydrogen phosphate are subjected to kneading so as to obtain ceramic clay; the ceramic clay is subjected to vacuum extrusion so as to obtain honeycomb ceramic blank; and the honeycomb ceramic blank is subjected to steam drying and roasting so as to obtain products. The heat-engine plant denitration composite catalyst is high in denitration rate, and is capable of solving a problem of ammonia escaping.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH +1

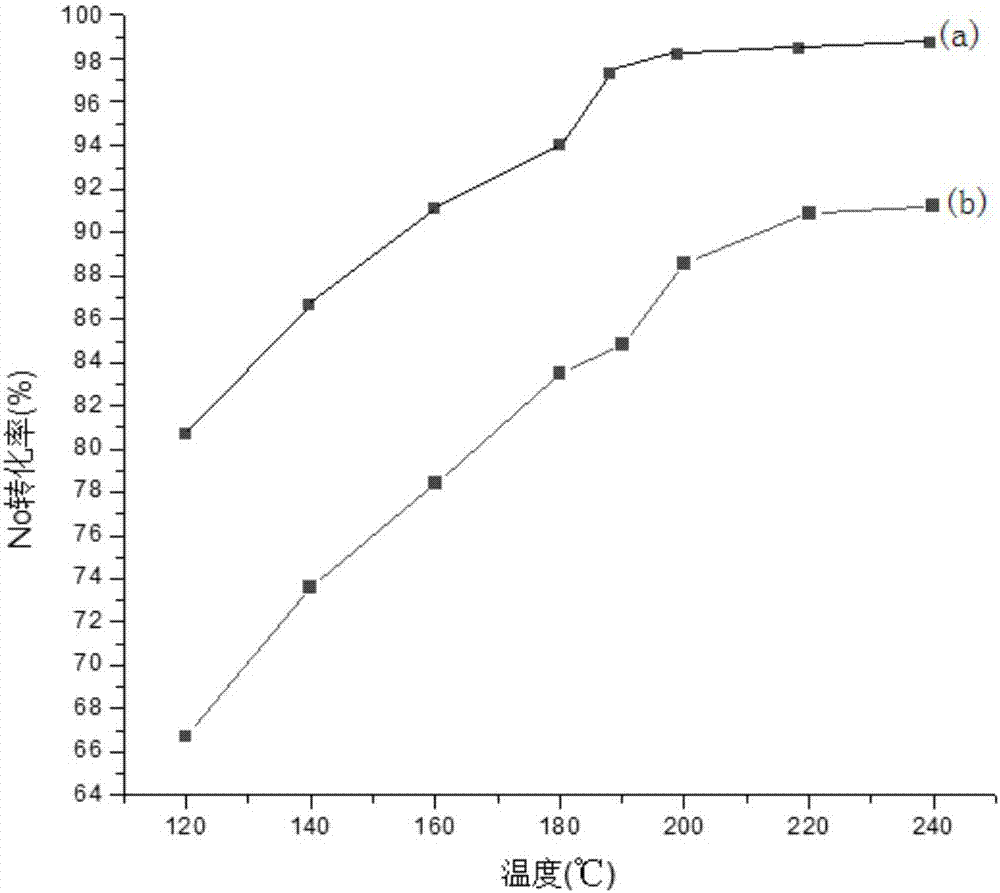

Heteropoly-acid-doped cerium oxide SCR denitration catalyst, preparation method therefor and application of catalyst

InactiveCN106582739AExtended service lifeLarge specific surface areaPhysical/chemical process catalystsDispersed particle separationGlass fiberSulfur

The invention discloses a heteropoly-acid-doped cerium oxide SCR denitration catalyst. The heteropoly-acid-doped cerium oxide SCR denitration catalyst is characterized in that heteropoly acid is Keggin-type phosphotungstic acid HPW, and the doped amount of the heteropoly acid is 5wt% to 15wt%. According to the catalyst, anatase TiO2 serves as a carrier, a mixture of cerium oxide CeO2 and the Keggin-type phosphotungstic acid HPW loaded to the carrier serves as an active component, and the catalyst is represented as CeO2-HPW / TiO2. The catalyst contains the following ingredients by content: 65wt% to 85wt% of TiO2 and glass fibers, 5wt% to 20wt% of CeO2 and 5wt% to 15wt% of HPW. The invention further discloses a preparation method for the catalyst and an application of the catalyst. The catalyst has relatively high catalytic oxidation-reduction power and acidic sites and achieves relatively high catalyst reaction activity at relatively low reaction temperatures, so that the low-temperature denitration efficiency and sulfur resistance are effectively improved.

Owner:LONGYAN ZIJIN INNOVATION RES INST

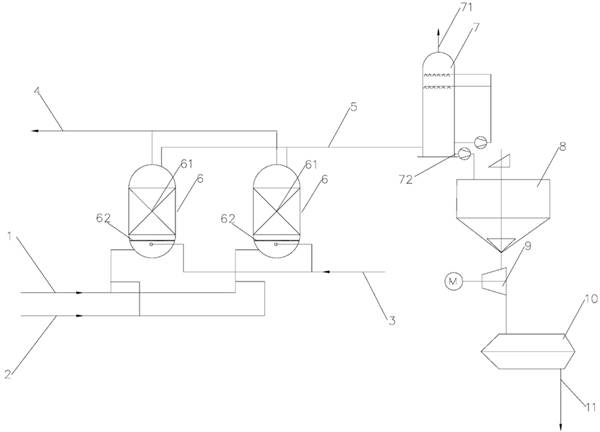

Low-temperature selective catalytic reduction (SCR) fixed bed flue gas denitrification device and method for coal-fired boiler

InactiveCN102658013ASmall space requirementHigh space requirementsDispersed particle separationAmmonium sulfatesFlue gasSulfate

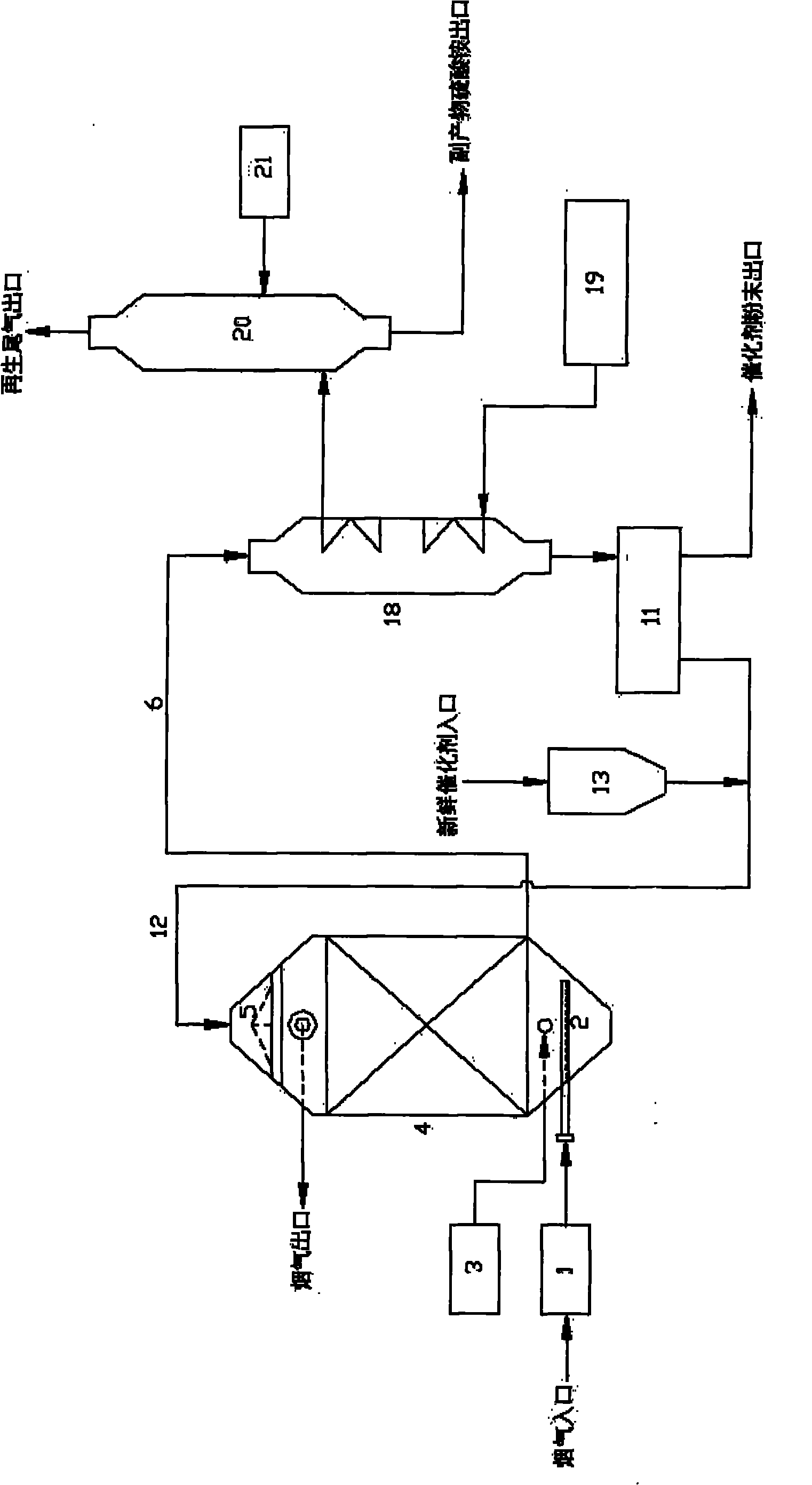

The invention relates to a low-temperature selective catalytic reduction (SCR) fixed bed flue gas denitrification method and a low-temperature SCR fixed bed flue gas denitrification device for a coal-fired boiler. The method comprises the following steps of: introducing flue gas and ammonia gas serving as a denitrification reducing agent into one denitrification reactor, wherein the denitrification device is provided with more than two denitrification reactors; depositing sulfate generated by reacting SO2 in the flue gas with the ammonia gas on a catalyst to inactivate the catalyst; stopping the denitrification work of the denitrification reactor in which the catalyst is inactivated, starting another denitrification reactor for denitrification reaction, introducing regeneration gas into the denitrification reactor in which the catalyst is inactivated to regenerate the catalyst, replacing the denitrification reactor in which the catalyst is inactivated with the denitrification reactor in which the catalyst is regenerated, and recycling; and decomposing the SO2 and the ammonia gas in the regeneration process, and discharging the decomposed gas from the denitrification reactor. In order to overcome the difficulty of the conventional low-temperature SCR technology in practical application, the invention provides the low-temperature SCR device and the low-temperature SCR method for the coal-fired boiler, which are feasible and wide in application range.

Owner:NORTH CHINA POWER ENG

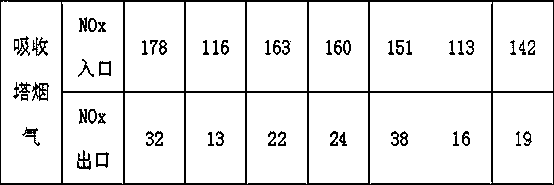

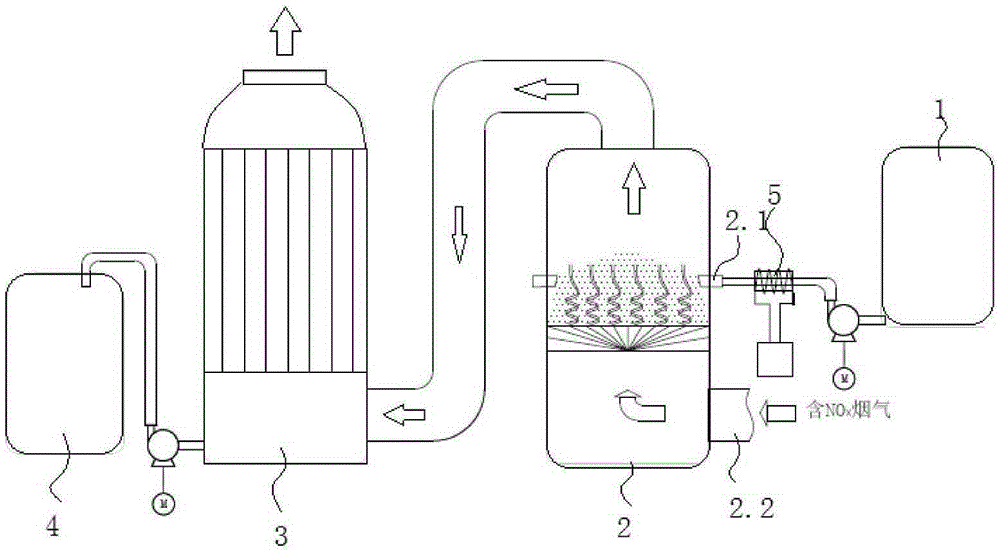

Treatment method for removing nitrogen oxides by virtue of ozone function

InactiveCN104128079AEffective oxidationImprove oxidation efficiencyDispersed particle separationOzone generatorFlue gas

The invention relates to a treatment method for removing nitrogen oxides by virtue of an ozone function. The method comprises the following steps: (1) flue gas containing the nitrogen oxides is introduced into a flue and an ozone adding distributor is additionally arranged; (2) a gas source is introduced into an ozone generator, ozone is generated and diluted and then is mixed in a mixer to obtain ozone diluted uniformly, and the ozone diluted uniformly enters the ozone adding distributor; (3) the ozone diluted uniformly and the flue gas containing the nitrogen oxides are mixed in the ozone adding distributor and are subjected to oxidation reaction, NO in waste gas is converted into high-valent nitrogen oxides and then the high-valent nitrogen oxides enter an absorption tower; and (4) the flue gas is absorbed by the absorption tower and absorption liquid and is purified to obtain tail gas, and the tail gas is exhausted from a chimney. The treatment method for removing the nitrogen oxides has the high efficiency, the low energy consumption and the convenience in use.

Owner:山西易通环保技术有限公司

SCR (Selective Catalytic Reduction) de-nitration catalyst based on natural manganese iron ore as well as preparation method and application method thereof

InactiveCN107282066AImprove denitrification effectExtended service lifeHeterogenous catalyst chemical elementsDispersed particle separationNitrationManganese oxide

The invention discloses an SCR (Selective Catalytic Reduction) de-nitration catalyst based on natural manganese iron ore as well as a preparation method and application method thereof, and belongs to the technical field of atmospheric pollution. The SCR de-nitration catalyst is characterized in that the natural manganese iron ore containing ferric oxide, manganese oxide and aluminum oxide is taken as a raw material, and is smashed, ground, screened, and calcined to obtain powder-like particles; during de-nitration, SCR de-nitration catalyst powder is covered with heat preservation cotton and is fixedly arranged at the axis of an entrance of a flue gas pipe behind an ESP (Electrostatic Precipitator). The SCR de-nitration catalyst is convenient to produce, is easy to use, has a relatively good de-nitration effect at low temperature, capability of solving the problems of relatively low de-nitration efficiency and slightly-high application temperature section existing in an conventional de-nitration catalyst, and contribution to prolonging the service life of the catalyst, and the cost is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Adsorbent for boiler fume treatment

ActiveCN105597701AGood dust removal, desulfurization and denitrification effectSimple preparation processGas treatmentOther chemical processesMANGANESE ACETATESilica gel

The invention belongs to the technical field of environmental protection and discloses an adsorbent for boiler fume treatment. The adsorbent is prepared from the following raw materials: manganese acetate, humic acid, ferric trichloride, silica-gel powder, zeolite powder, dolomite, bentonite, phenolic resin, peanut shell, wheat bran, a 2M sodium carbonate solution, turfy soil and water. The adsorbent disclosed by the invention has a relatively good adsorption effect on main harmful gases such as NOx, SO2 and dust in fume.

Owner:恒源工业炉(靖江)有限公司

Desulfurization and denitration ammonia-removing system

ActiveCN108479344ACapturePrevent escapeGas treatmentDispersed particle separationActivated carbonDesorption

The invention discloses a desulfurization and denitration ammonia-removing system. The system comprises an adsorption tower, a desorption tower, a distributor, a first activated carbon conveyer and asecond activated carbon conveyer. One side of the adsorption tower is provided with a smoke inlet A, and the other side of the adsorption tower is provided with a smoke outlet B, the interior of the adsorption tower is provided with an adsorption cavity and an ammonia-removing cavity, the adsorption cavity is installed at one side adjacent to the smoke inlet A, the ammonia-removing cavity is installed at one side adjacent to the smoke outlet B, the first activated carbon conveyer is connected with a discharging port of the adsorption tower and a feeding port of the distributor, the second activated carbon conveyer is connected with a discharging port of the desorption tower and a feeding port of the adsorption cavity, a discharging port of the distributor is respectively connected with a feeding port of the ammonia-removing cavity and a feeding port of the desorption tower. The system adopts a mode that the adsorption tower is divided to two functional areas. The adsorption reaction cavity is capable of achieving the functions of desulfurization, denitration, dust removal and the like. The ammonia-removing cavity is filled with fresh activated carbon or acidic activated carbon, andis capable of gathering ammonia in smoke passing through an adsorption reaction layer, and effectively preventing the ammonia at the outlet from escaping.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

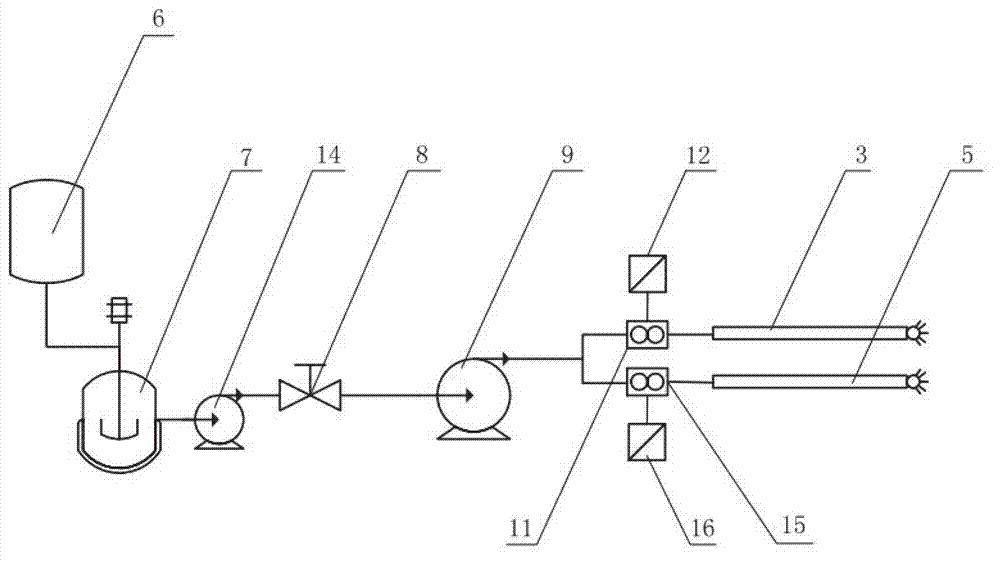

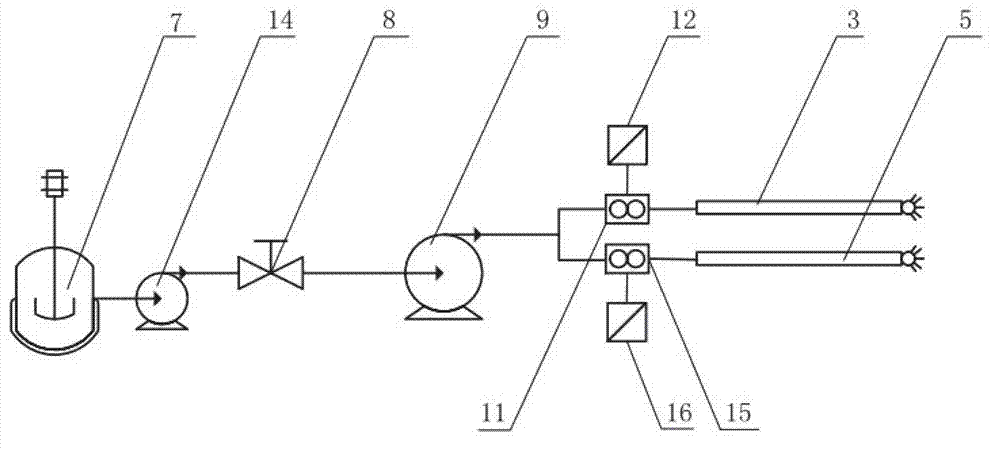

SNCR (selective non-catalytic reduction) denitration device and method for rotary cement kiln

ActiveCN102806003ALow costMeet the requirements of emission standardsDispersed particle separationNitric oxideCement kiln

The invention discloses an SNCR (selective non-catalytic reduction) denitration device and an SNCR denitration method for a rotary cement kiln and belongs to the technical field of rotary cement kiln pollutant discharge control. The device comprises a reducing agent preparation and storage system, a reducing agent transporting system, a reducing agent spraying system and a control system, wherein the reducing agent preparation and storage system consists of a reducing storage tank and a reducing agent dissolving tank, the reducing agent transporting system consists of a conveying pump and a conveying pipeline, the reducing agent spraying system consists of a booster pump and two stages of spray guns, and the control system consists of two flow meters and two flow meter controllers; and the device further comprises NOx on-line detection instruments respectively positioned in a position with the distance being 10 to 20m from the downstream parts of the two-stage spray guns. The method is realized by using the device, ammonia, urea or alkaline industrial waste liquid is used as a reducing agent, the proportion of the quantity of nitric oxide substances in smoke of a decomposing furnace and the quantity of nitrogen element substances in the reducing agent is determined according to the condition of NOx purified by each stage of spray gun, and the reducing agent is sprayed into the decomposing furnace. The SNCR denitration device and the SNCR denitration method have the advantages that economy and environment protection are realized, the operation is simple, the control is flexible, and the denitration performance is high.

Owner:TSINGHUA UNIV

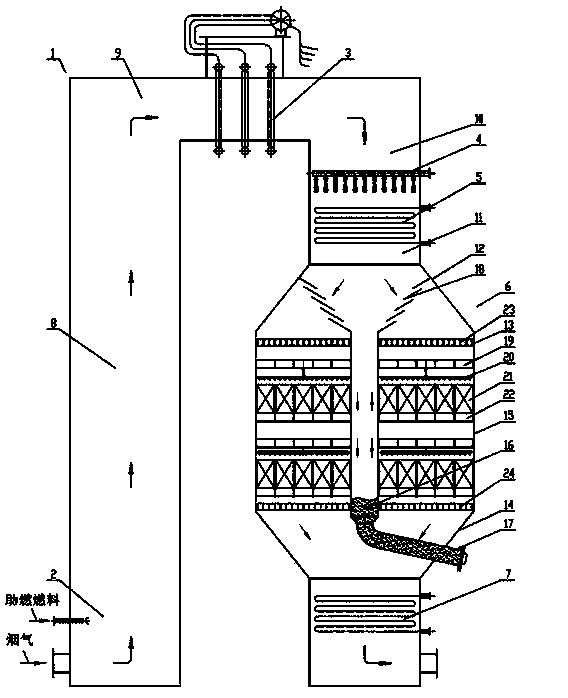

CO boiler having dustproof function and denitration function

ActiveCN103776042AImprove utilization efficiencyEfficient use ofCombination devicesLighting and heating apparatusFlueCoal

The invention relates to a CO boiler having the dustproof function and the denitration function. The CO boiler having the dustproof function and the denitration function comprises a flue, a combustion chamber, steam drums, an evaporation section and an economizer section. The CO boiler further comprises an ammonia spraying and mixing mechanism and a dustproof denitration reactor. The ammonia spraying and mixing mechanism is arranged above the evaporation section or between the evaporation section and the denitration reactor. The dustproof denitration reactor is arranged between the evaporation section and the economizer section and comprises a mixed-smoke inlet section, a denitration section and a purified-smoke discharging section, wherein an ash removal section is arranged between the mixed-smoke inlet section and the denitration section, ash baffles are arranged in the ash removal section, an ash bin is arranged in the denitration section, the center line of the ash bin and the center line of the reactor coincide, and the lower end of the ash bin is connected with an ash discharging pipeline. According to the CO boiler having the dustproof function and the denitration function, the denitration reactor is arranged in the CO boiler, so that the utilization rate of smoke heat is increased; due to the fact that the ash removal section is arranged in the reactor, smoke dust of mixed smoke can be removed before the mixed smoke enters denitration units, catalyst hole channels are prevented from being blocked, and the denitration efficiency and the denitration effect are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

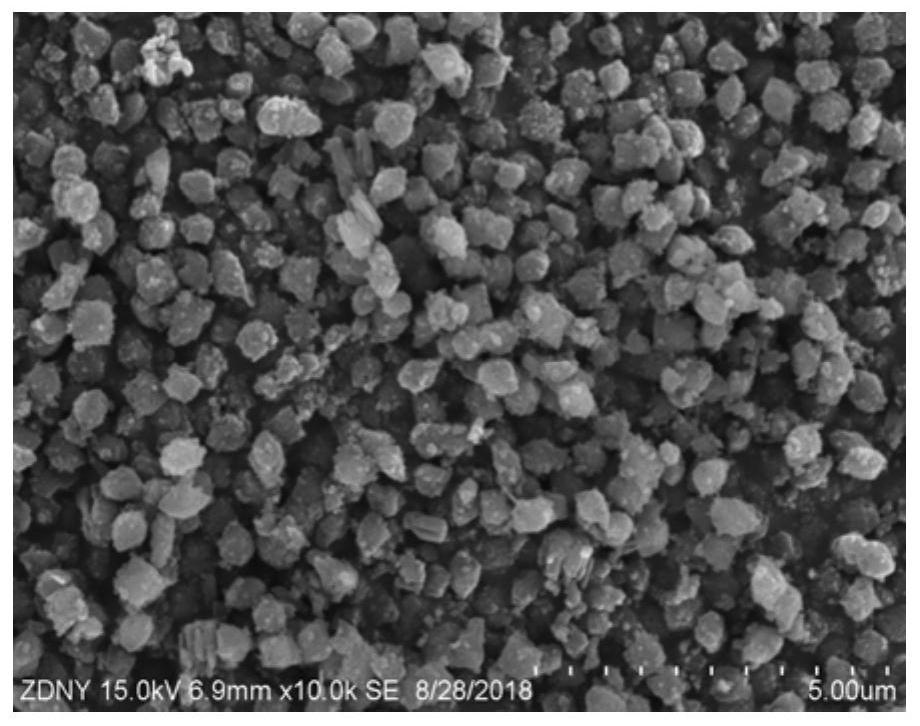

Selective catalytic reduction low-temperature denitration catalyst and preparation method thereof

InactiveCN104815671AGood low temperature denitrification activityImprove denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationStrong acids

The invention relates to a catalyst capable of performing catalytic oxidation on nitric oxides in industrial smoke gas under a low-temperature condition and a preparation process thereof. The preparation method comprises the following steps: (1) dissolving strong acid into water to prepare a strong acid solution; (2) pouring potassium permanganate or soluble salt of iron or cerium into the strong acid solution, stirring to sufficiently mix and dissolve the potassium permanganate or a soluble salt of iron or cerium; (3) performing hydrothermal reaction on the solution; (4) after the hydrothermal reaction, performing suction filtration to obtain oxide precipitates, and washing the oxide precipitates with the acid solution and distilled water respectively; (5) drying the obtained sample; and (6) grinding the dried sample to obtain the required selective catalytic reduction low-temperature denitration catalyst. According to the method, the preparation process is simple, and the selective catalytic reduction low-temperature denitration catalyst with good performance can be prepared by simply weighing, mixing, reacting, filtering and drying, the synthesis temperature is relatively low, roasting is not required, requirements of high-temperature reaction to instruments and equipment are lowered, risks to body safety are avoided, and the advantages are remarkable.

Owner:WUHAN UNIV OF TECH

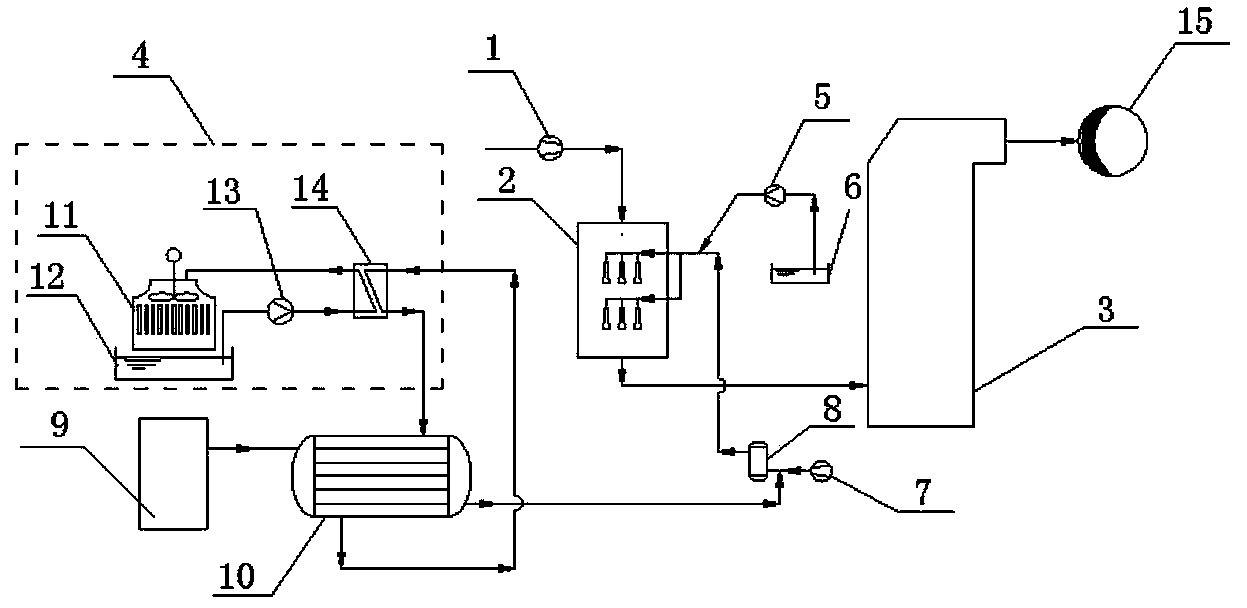

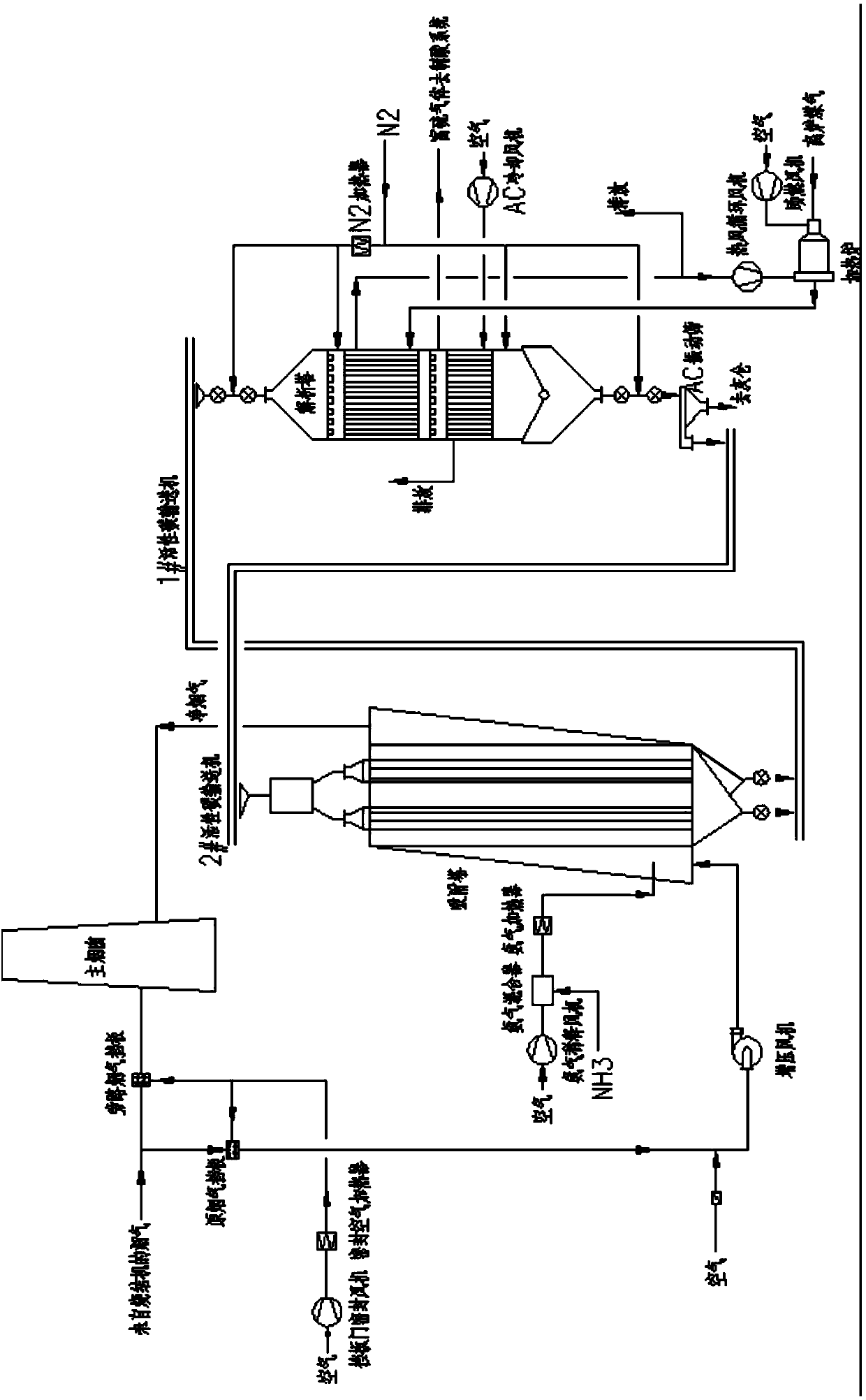

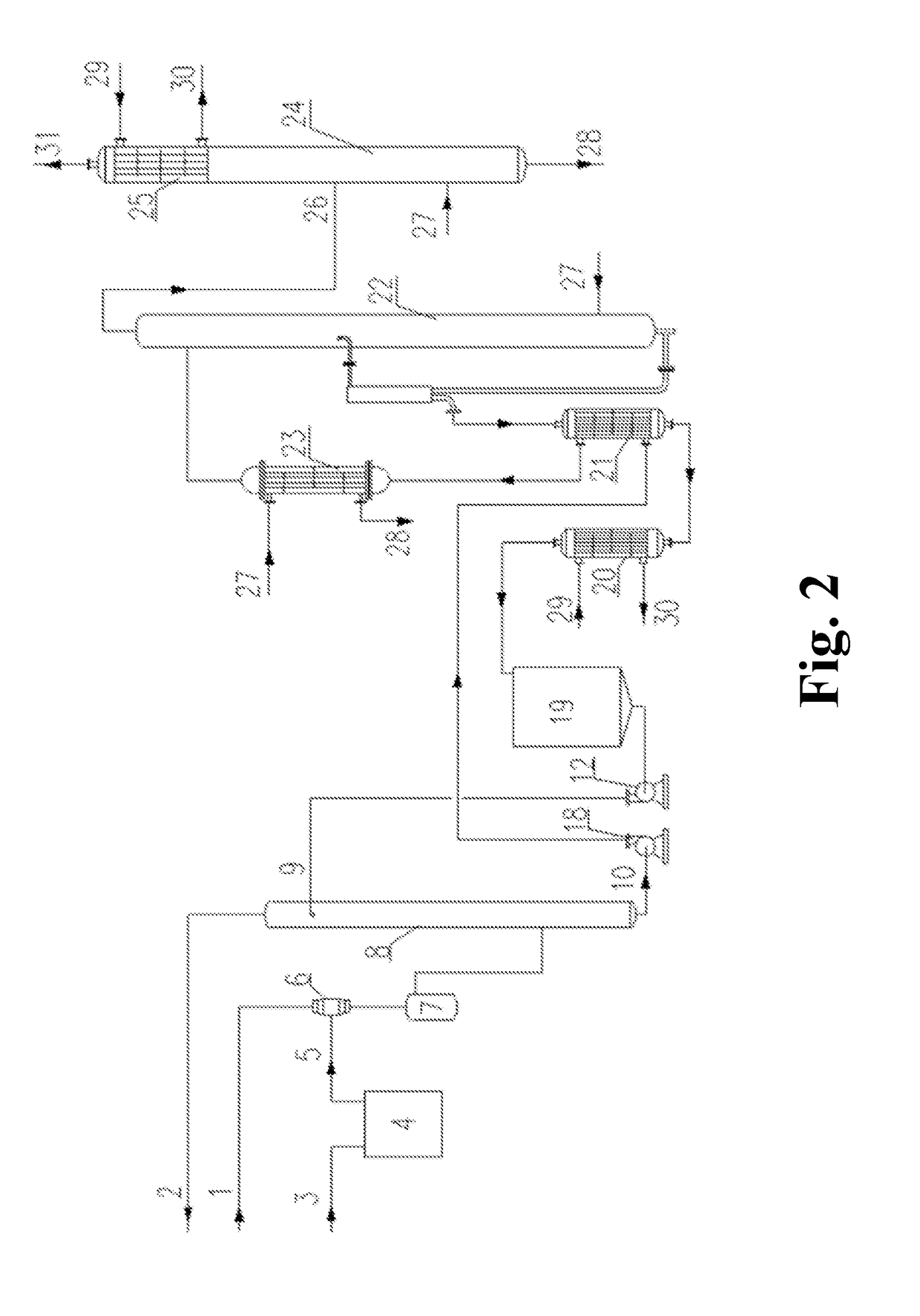

Nitric oxide efficient control system and control method of gas internal combustion engine

ActiveCN108049946AReduce escape rateImprove uniformityInternal combustion piston enginesExhaust apparatusExternal combustion engineLithium bromide

The invention relates to a nitric oxide efficient control system and control method of a gas internal combustion engine. An outlet of the internal combustion engine is communicated with a first-stageammonia spraying device through a No.1 pipeline; the first-stage ammonia spraying device communicates with one end of a No.2 pipeline; the other end of the No.2 pipeline passes through a high-pressuregenerator; the other end of the No.2 pipeline is communicated with an inlet of an SCR reactor; an outlet of the SCR reactor is communicated with one end of a No.3 pipeline; the other end of the No.3pipeline passes through a low-pressure generator; a reducing agent storage groove is communicated with a dilution fan through a No.4 pipeline; one end of the No.5 pipeline is communicated with the dilution fan; one end of a No.6 pipeline and one end of a No.7 pipeline are communicated with the other end of the No.5 pipeline; the other end of the No.6 pipeline is communicated with the first-stage ammonia spraying device; the other end of the No.7 pipeline is communicated with the second-stage ammonia spraying device. The ammonia-nitrogen ratio distribution uniformity degree is improved; the denitration efficiency is improved; the ammonia escape rate is reduced; the refrigeration effect of a lithium bromide refrigeration unit is not influenced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

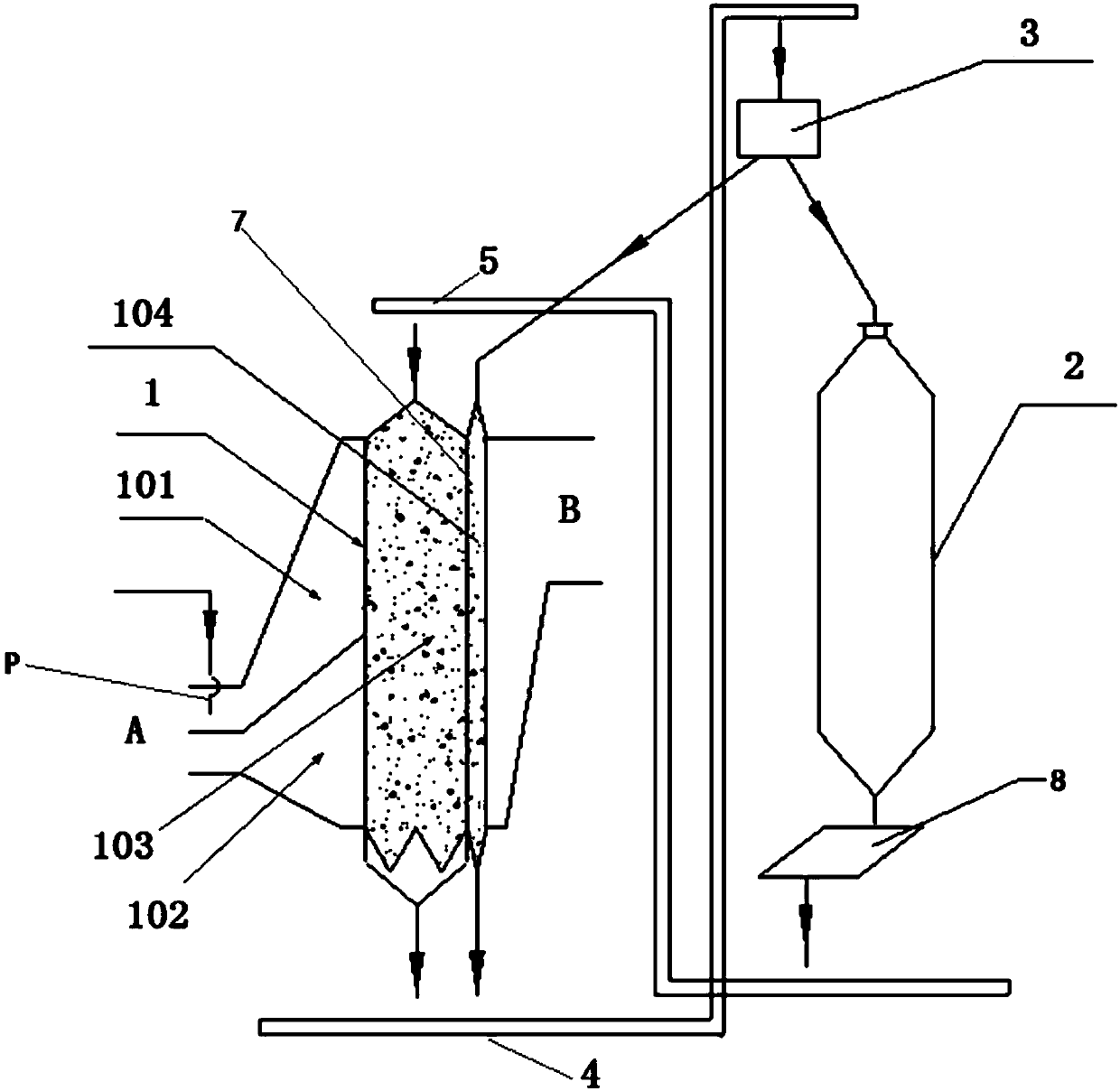

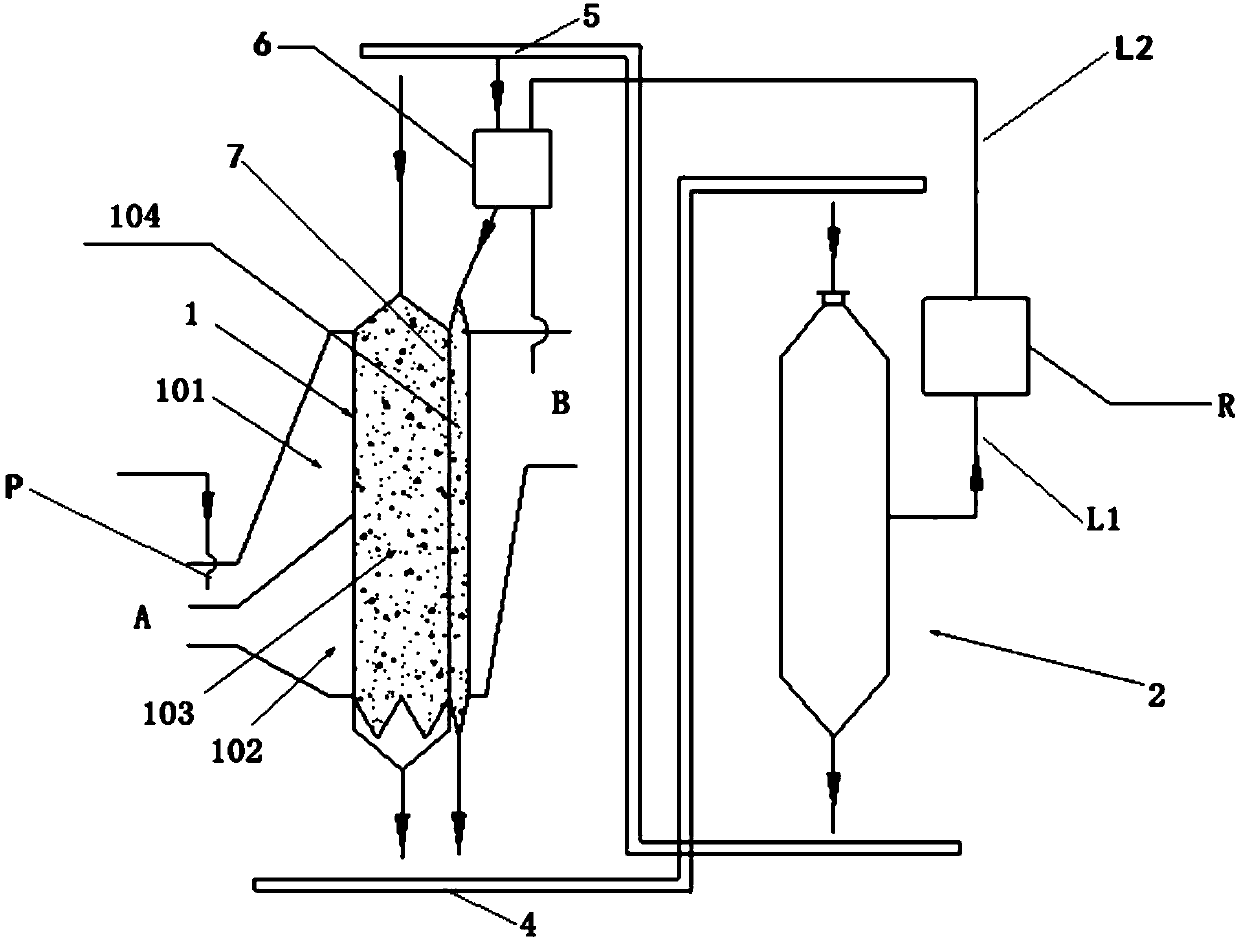

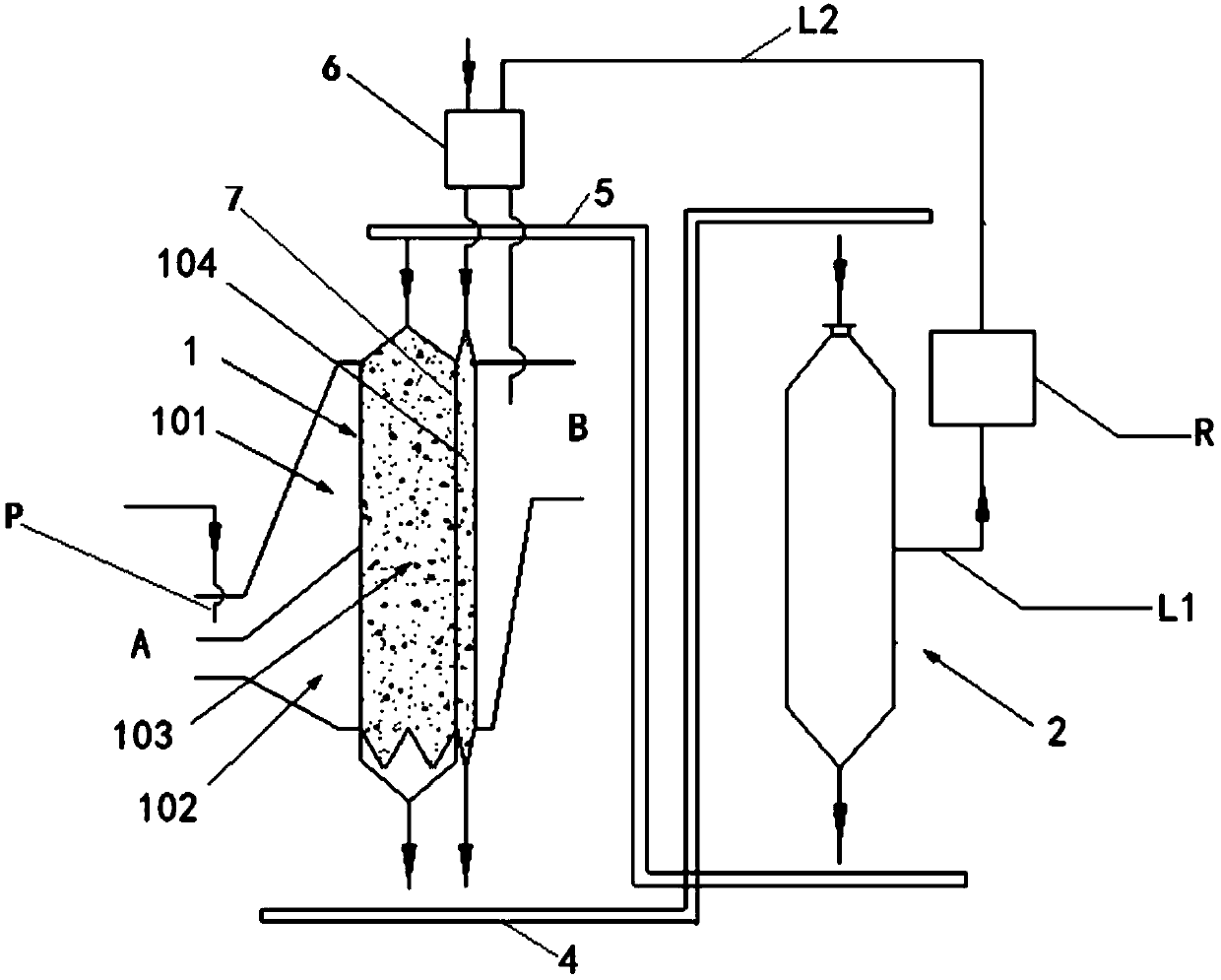

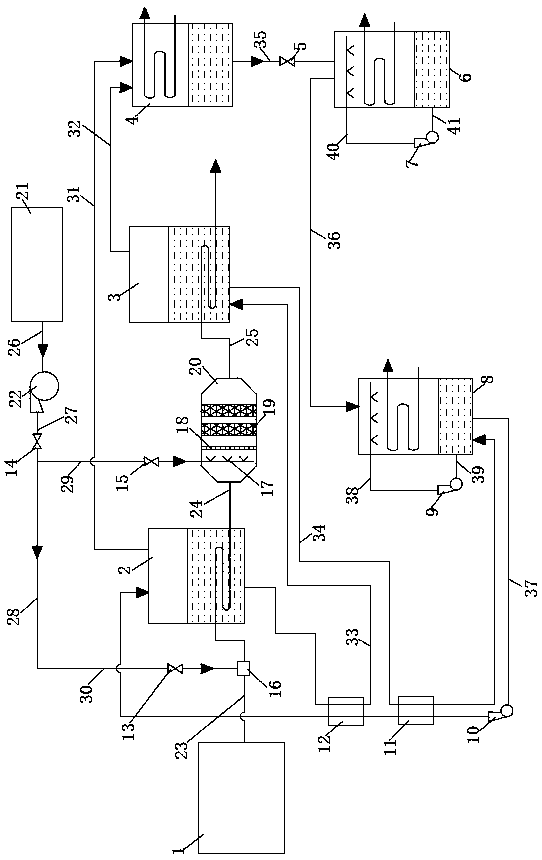

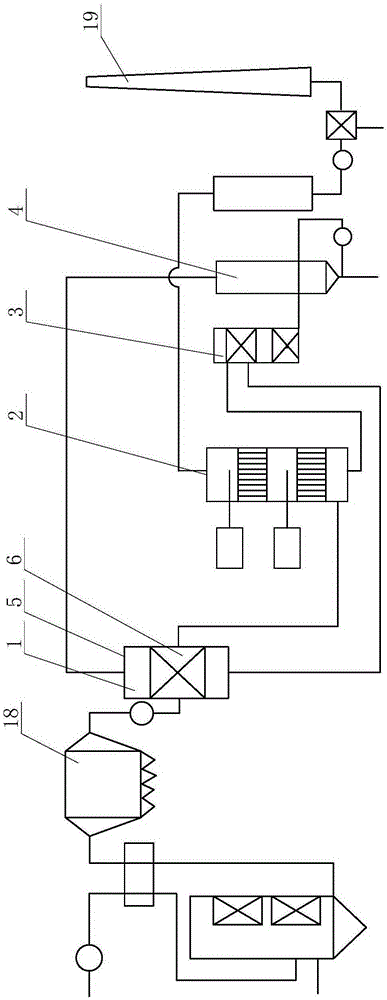

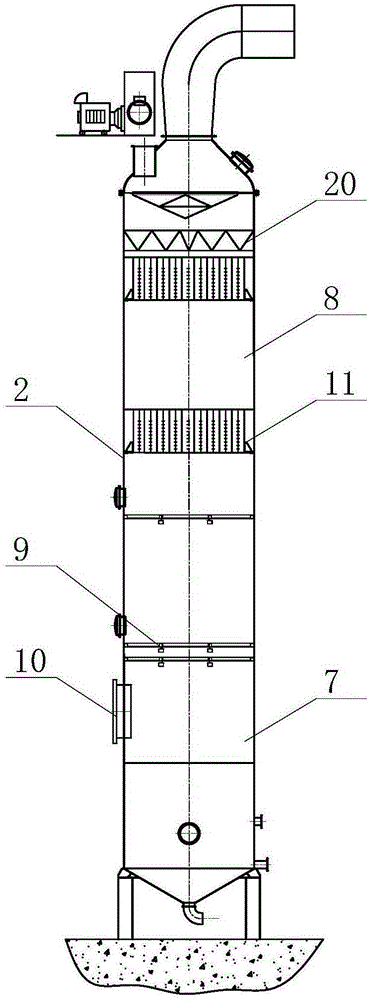

Desulfurization and denitration device for efficient denitration

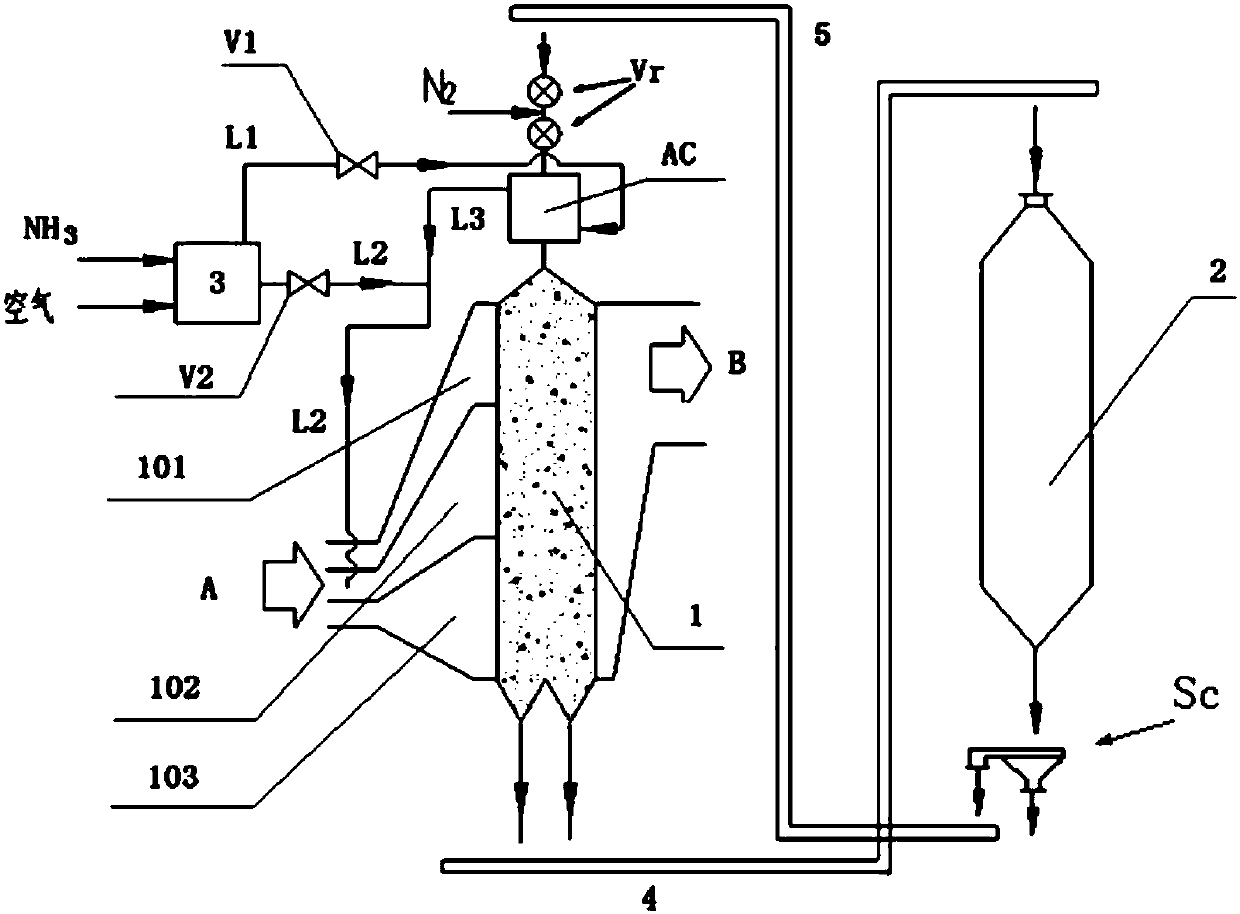

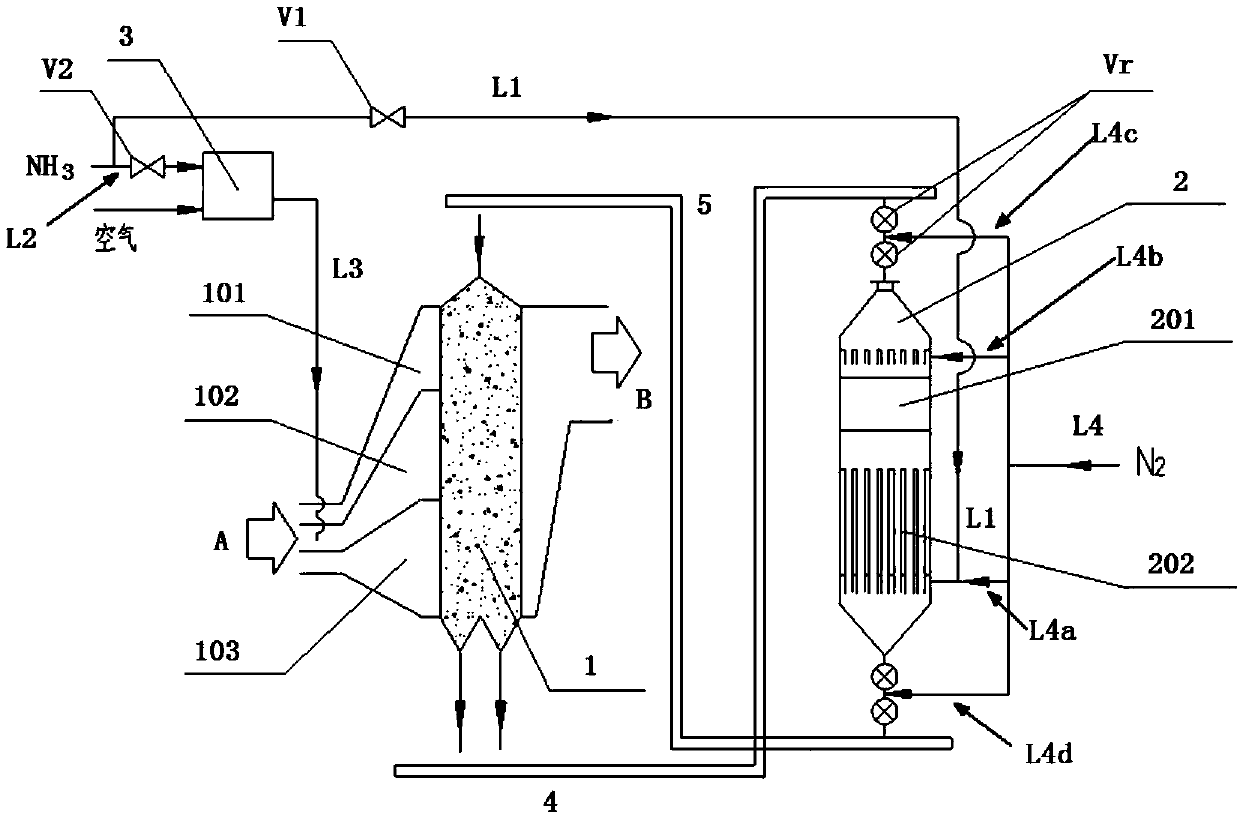

ActiveCN108371872AImprove denitrification performanceReduce escapeGas treatmentDispersed particle separationActivated carbonDesorption

The invention relates to a desulfurization and denitration device for efficient denitration. The device comprises an adsorption tower (1), a desorption tower (2), a gas mixer (3), a first activated carbon conveyor (4), a second activated carbon conveyor (5) and an activated carbon material bin (AC) arranged above the adsorption tower (1), wherein a smoke inlet (A) is formed in one side of the adsorption tower (1), a smoke outlet (B) is formed in the other side of the adsorption tower (1), a first gas pipeline (L1) led out from the gas outlet of the gas mixer (3) is connected with the gas inletof the activated carbon material bin (AC), a second gas pipeline (L2) led out from the gas outlet of the gas mixer (3) is connected with the smoke inlet (A), and a third gas pipeline (L3) led out from the gas outlet of the activated carbon material bin (AC) converges with the second gas pipeline (L2). The desulfurization and denitration device provided by the invention adopts activated carbon foradsorbing partial ammonia in advance; meanwhile, partial ammonia is sprayed into the middle part of the adsorption tower again for enhancing a denitration effect.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

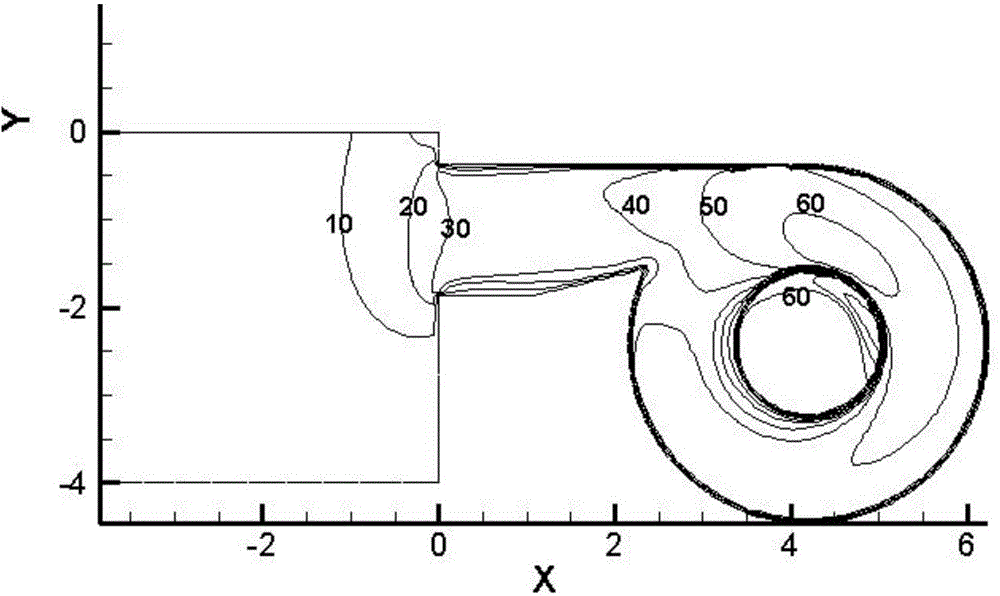

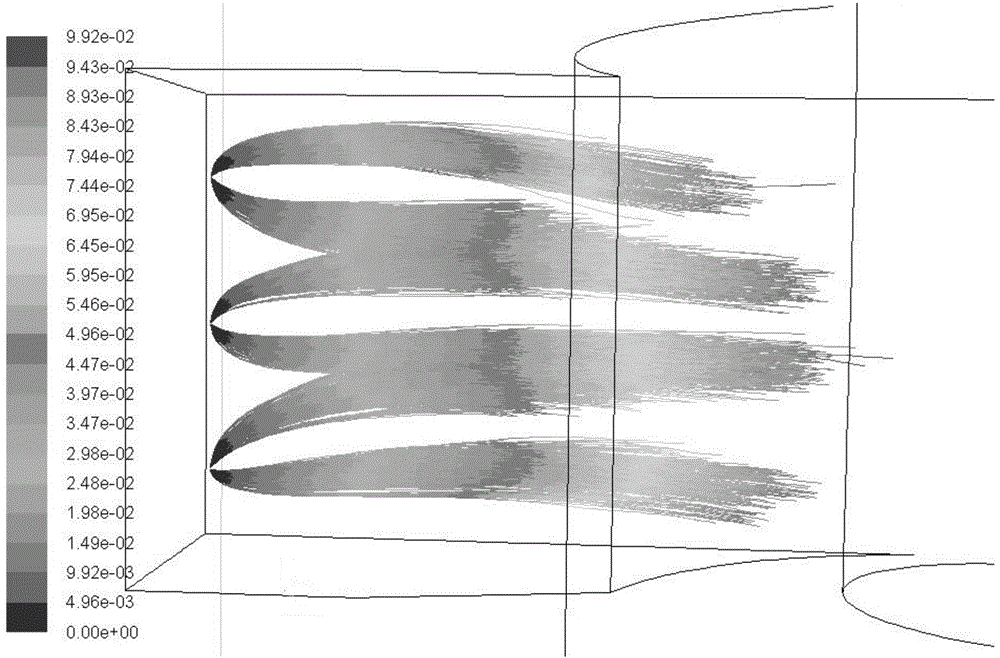

Fluent-based method for arranging selective non-catalytic reduction (SNCR) spray gun on circulating fluidized bed boiler

InactiveCN104147916AImprove denitrification performanceDispersed particle separationFluePhysical model

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

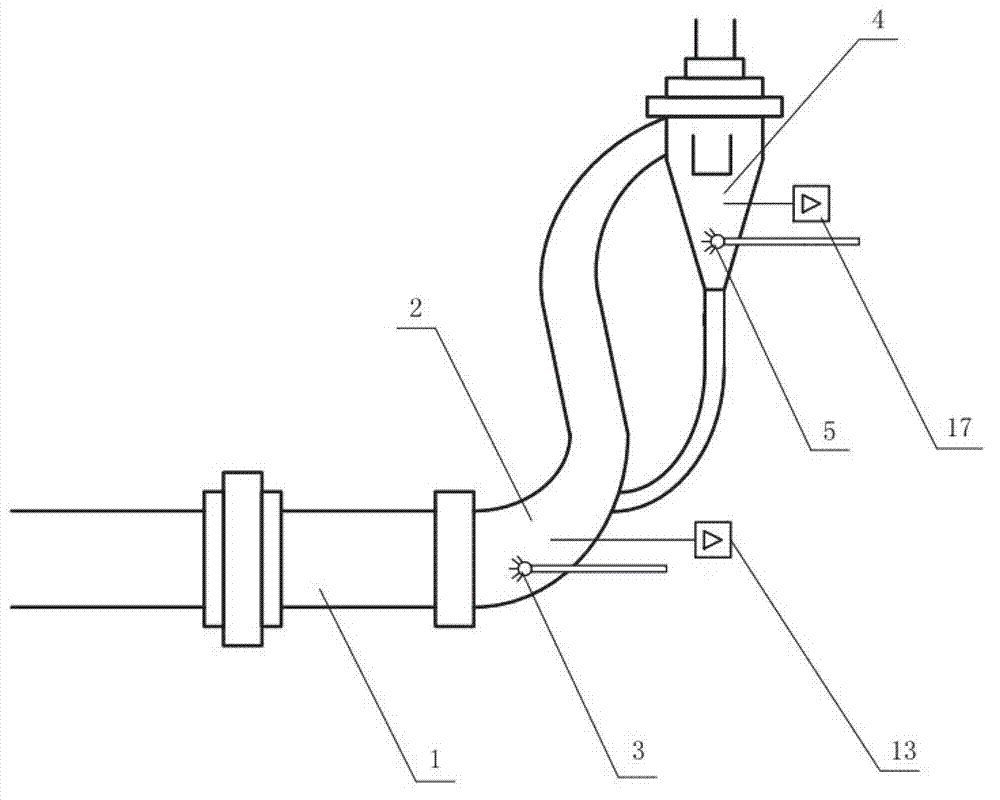

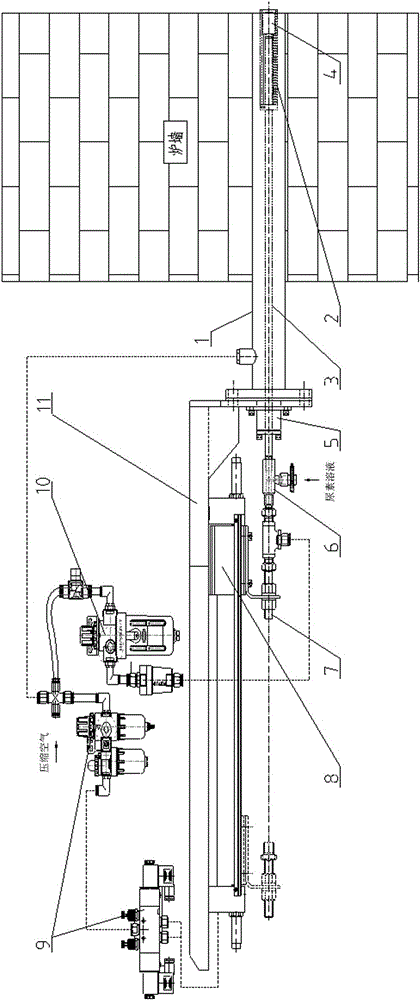

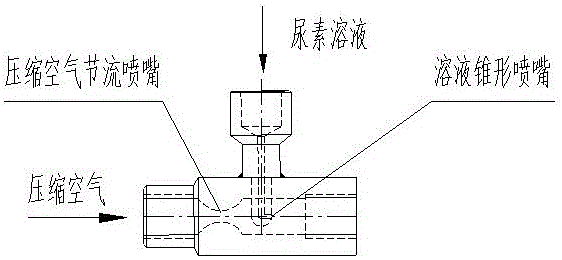

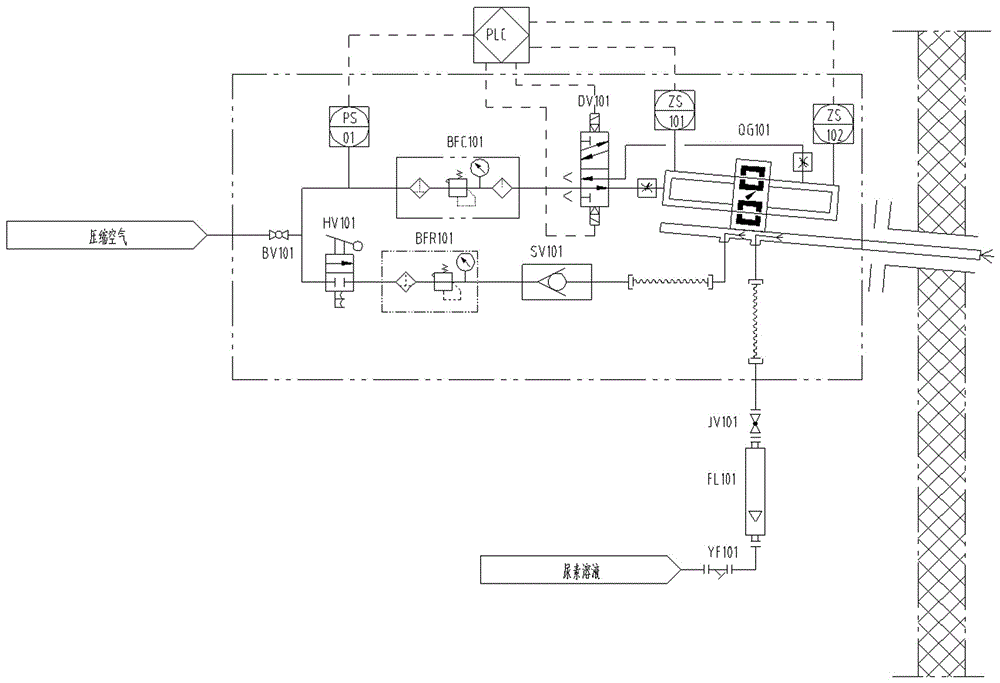

Front-end atomizing automatic-stretching spray gun of SNCR (Selective Non-Catalytic Reduction) system

InactiveCN106237822AImprove denitrification performanceExtended service lifeGas treatmentDispersed particle separationEngineeringCentrifugal fan

The invention discloses a front-end atomizing automatic-stretching spray gun of an SNCR (Selective Non-Catalytic Reduction) system. The front-end atomizing automatic-stretching spray gun comprises a spray pipe, a nozzle, an adjustment lead screw, a cylinder assembly, a pneumatic assembly, a compressed air source assembly and a base, wherein the cylinder assembly, the pneumatic assembly and the compressed air source assembly are connected, the cylinder assembly comprises a rodless cylinder; the spray pipe is fixed to a slipway of the rodless cylinder through the adjustment lead screw; and the movement of the slipway is controlled, so that the action that the spray pipe is put in a furnace chamber or stretches from the furnace chamber is realized. The front-end atomizing automatic-stretching spray gun of the SNCR system has the following beneficial effects that compressed air is used for replacing a centrifugal fan as an atomizing air source, and the structure of the spray gun is matched, so that the atomizing effect of a urea solution is increased, the spraying uniformity is improved, the spraying distance is enlarged, the denitration effect of the SNCR system is effectively guaranteed and improved, normal operation of a garbage incineration plant is guaranteed, and the disorderly closedown rate is reduced; the service life of the spray gun is prolonged; and the occurrence frequency of blocking of the nozzle is reduced.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

Comprehensive utilization device for desulfurization and denitrification

ActiveCN105169905AIncrease concentrationImprove desulfurization efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationEngineering

The invention provides a comprehensive utilization device for desulfurization and denitrification. The device comprises an evaporator, a desulfurization and denitrification tower, an ammonia water tank, a concentration and separation tower, wherein a desulfurization chamber and a denitration chamber are arranged inside the desulfurization and denitration tower; the denitrification chamber is arranged above the desulfurization chamber; an ammonia-water atomization spray nozzle is arranged inside the desulfurization chamber; a flue gas inlet of the desulfurization and denitration tower is arranged below the ammonia-water atomization spray nozzle; an ozone and flue gas mixer is arranged inside the denitration chamber and communicates with an ozone source arranged outside of the desulfurization and denitration tower; the ozone and flue gas mixer is composed of a horizontal coil pipe and a vertical straight pipe; the horizontal coil pipe is arranged outside of the vertical straight pipe; the lower side of the horizontal coil pipe is provided with a plurality of first gas jet outlets; the inner side of the horizontal coil pipe is provided with a plurality of first cylindrical pins; the vertical straight pipe is provided with a plurality of second gas jet outlets; the outer side wall of the vertical straight pipe is provided with a plurality of second cylindrical pins; and the first gas jet outlets and the second jet outlets form a downward inclined angle a. The comprehensive utilization device provided by the invention has good desulfurization and denitrification rates, can obtain an ammonium sulfate solution with higher concentration at the same time, facilitates to production of a high-grade ammonia fertilizer, and achieves comprehensive utilization of desulfurization and denitrification of the flue gas.

Owner:SHANDONG HUANNENG DESIGN INST

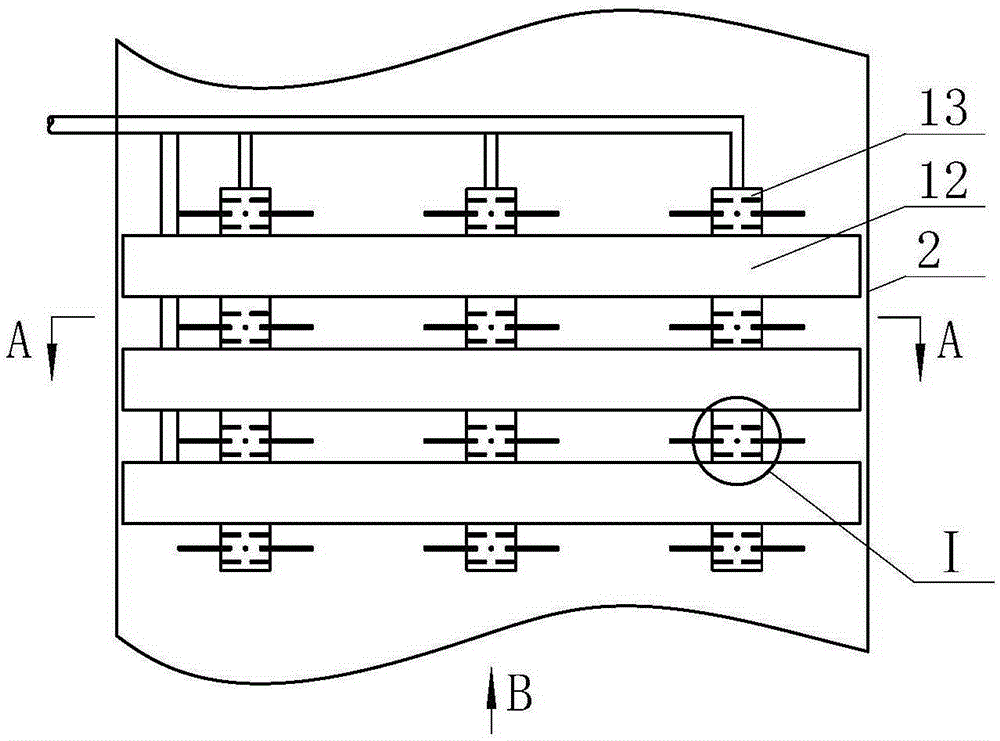

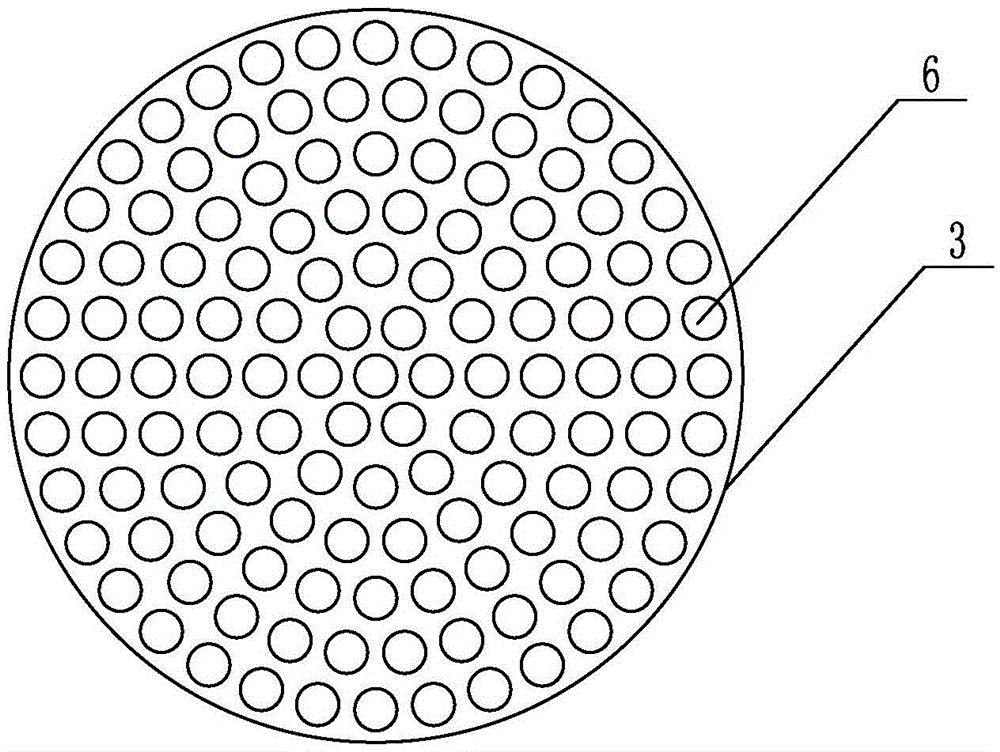

Urea powerful mixing device for SCR system of small and medium-sized ship

ActiveCN105464763AImprove pyrolysis efficiencyEfficient mixingExhaust apparatusSilencing apparatusFlue gasConcentration ratio

The invention relates to the field of ship flue gas denitrification equipment, in particular to a urea powerful mixing device for an SCR system of a small and medium-sized ship. The urea powerful mixing device for the SCR system of the small and medium-sized ship comprises a tube body, a porous plate, a urea nozzle and a mixing device, wherein the porous plate, the urea nozzle and the mixing device are arranged in the tube body from bottom to top; a flow rectifying device is the porous plate where a plurality of round holes are distributed, and a flow disturbing device is the mixing device; and the device has the beneficial effects that the flow rectifying device (porous plate) is arranged at the upstream position of the urea nozzle, the flow disturbing device is arranged at the downstream position of the urea nozzle, and due to the structure, smoke and sprayed urea mist can be more sufficiently mixed in the limited space, the urea nozzle can absorb more smoke gas waste heat in a short time so as to improve the decomposition speed, and therefore it can be ensured that the concentration ratio of NH3 / NOX meets the reaction requirement when mixed smoke gas enters an SCR reactor inlet.

Owner:ZHEJIANG UNIV

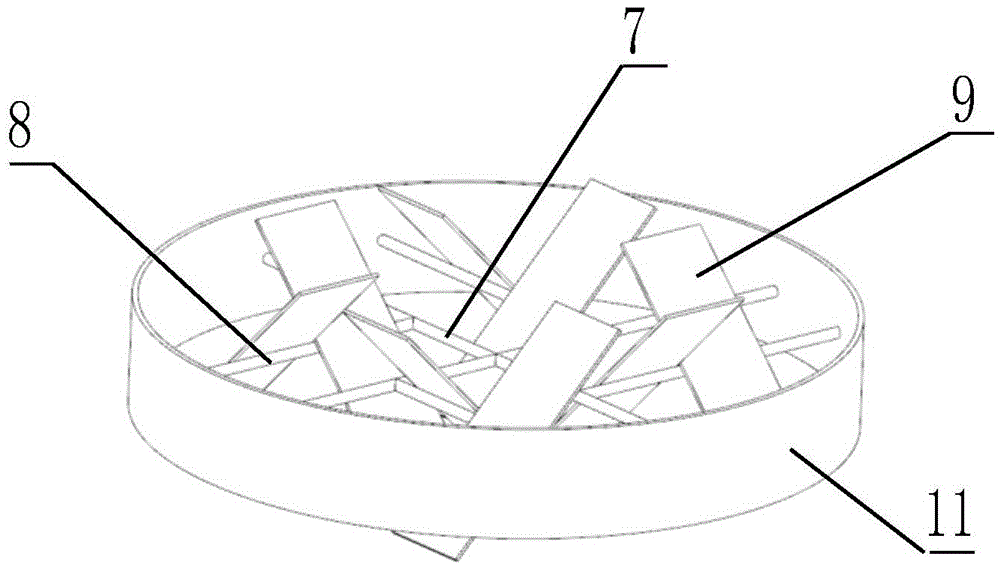

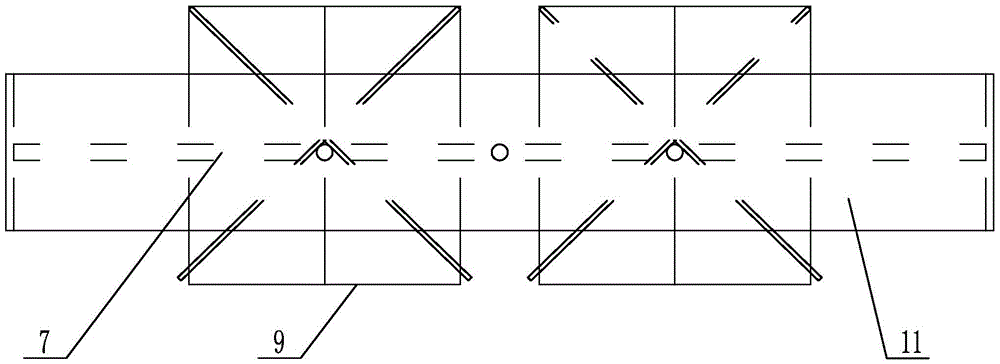

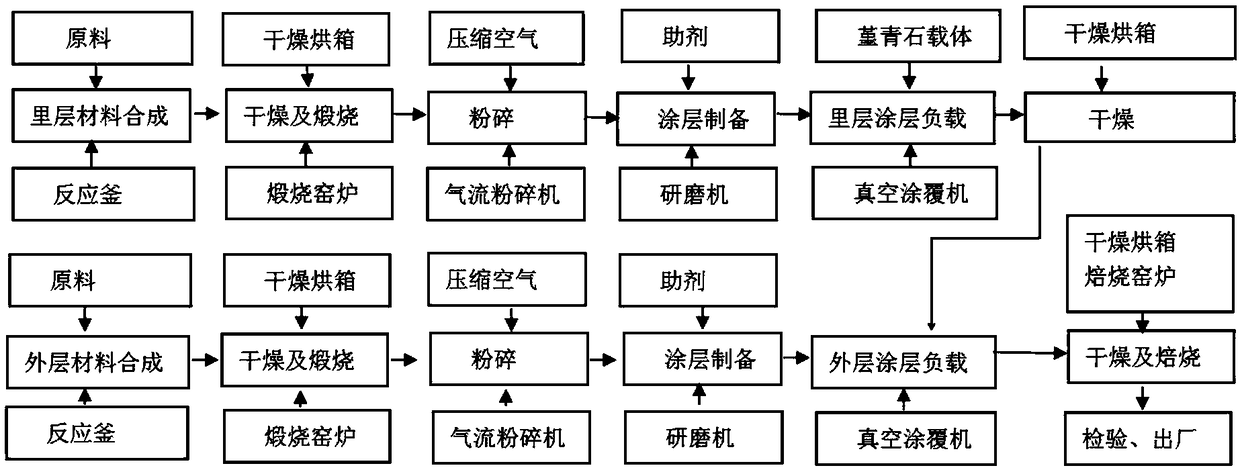

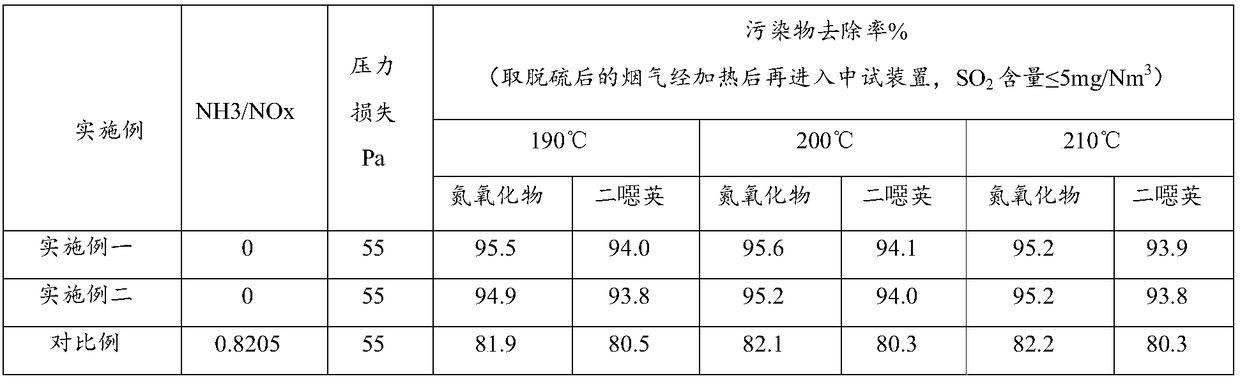

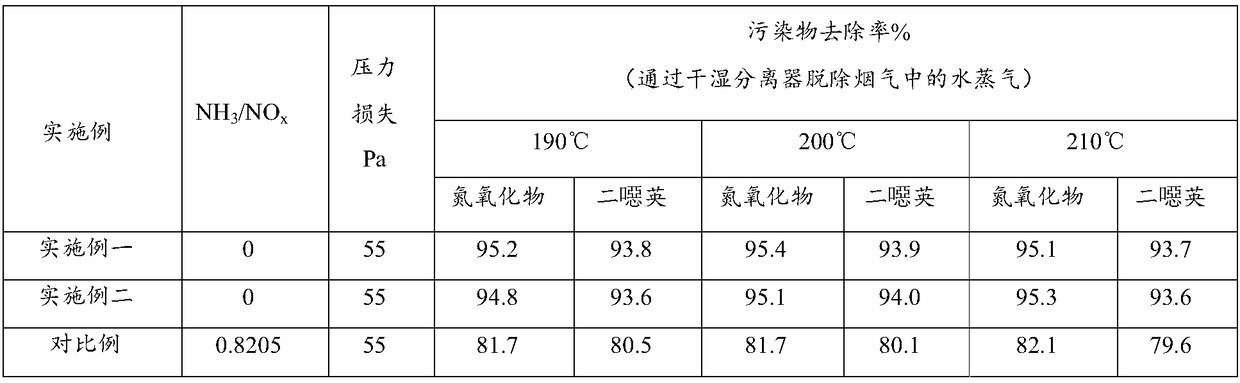

Denitration and dioxin removal composite catalyst and preparation method

ActiveCN108837830AImprove denitrification performanceImprove water and sulfur resistanceGas treatmentHeterogenous catalyst chemical elementsSulfurFlue gas

The invention discloses a denitration and dioxin removal composite catalyst applied to flue gas of a steel sintering machine and a preparation method thereof. The flue gas contains CO; the catalyst comprises a carrier, and a dioxin removing inner layer and a denitrating outer layer which are sequentially loaded onto the carrier, wherein the dioxin removing inner layer comprises a first active substance for removing dioxin; the denitrating outer layer comprises a second active substance for removing nitrogen oxide; the CO in the flue gas reacts with the second active substance and can be used as a reducing agent for removing the nitrogen oxide. The denitration and dioxin removal composite rear earth-based catalyst prepared by the preparation method provided by the invention, has greatly improved denitration performance and water and sulfur resistance under a low-temperature working condition of the steel sintering machine; the CO in the flue gas is used as the reducing agent, and NH3 isnot required to be sprayed, so that the operating cost is reduced; efficient selectivity for dioxin removal is achieved.

Owner:江苏浩日朗环保科技有限公司

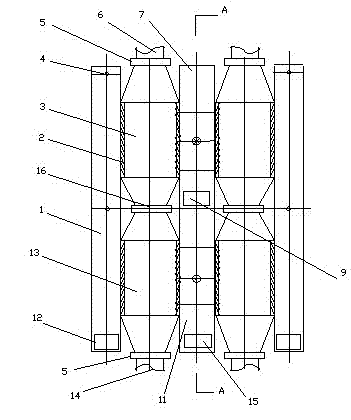

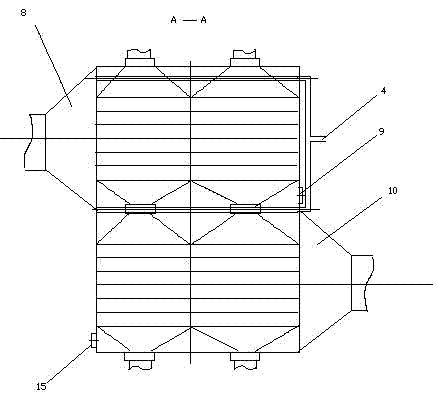

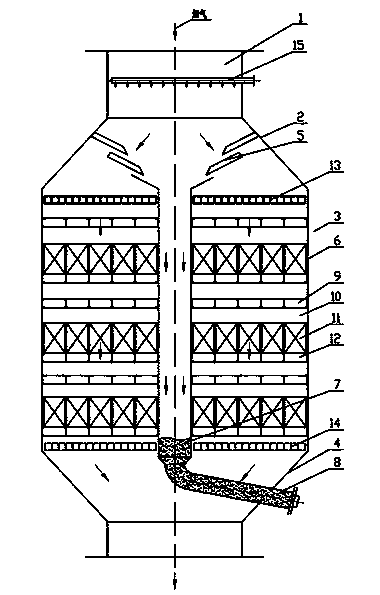

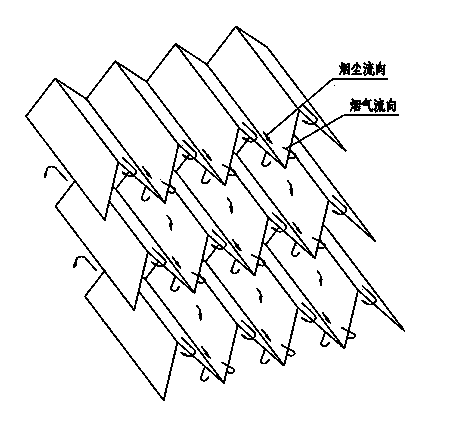

High-efficiency dry-method desulphurization, denitration and flue gas purification device

InactiveCN103239968AQuality improvementImprove denitrification performanceDispersed particle separationSorbentFlue gas

The invention discloses a High-efficiency dry-method desulphurization, denitration and flue gas purification device, which is composed of an upper adsorption reaction chamber 3, a lower adsorption reaction chamber 13, a flue gas upper collection chamber 7, a flue gas lower collection chamber 11 and a flue gas channel 1. By utilizing a principle that adsorbent active coke is capable of adsorbing and desorbing pollutants SO2 and NOx in flue gases, the active coke is used for dynamically adsorbing SO2 in the flue gas lower collection chamber, and dynamically adsorbing NOx in the flue gas upper collection chamber. For raising a denitration effect, a reaction device of denitration agent ammonia gas with flue gases with NOx is added, to obtain good desulphurization and denitration effects, wherein the desulphurization effect reaches more than 95%, and the denitration effect reaches more than 80%, thereby raising flue gas purifying quality. In the invention, the adsorbent active coke is regenerated by a heating regeneration technology, adsorptivity of regenerated active coke is recovered, and the adsorbent active coke can be repeatedly regenerated and recycled without secondary pollution.

Owner:山西鼎圣精工机械制造股份有限公司

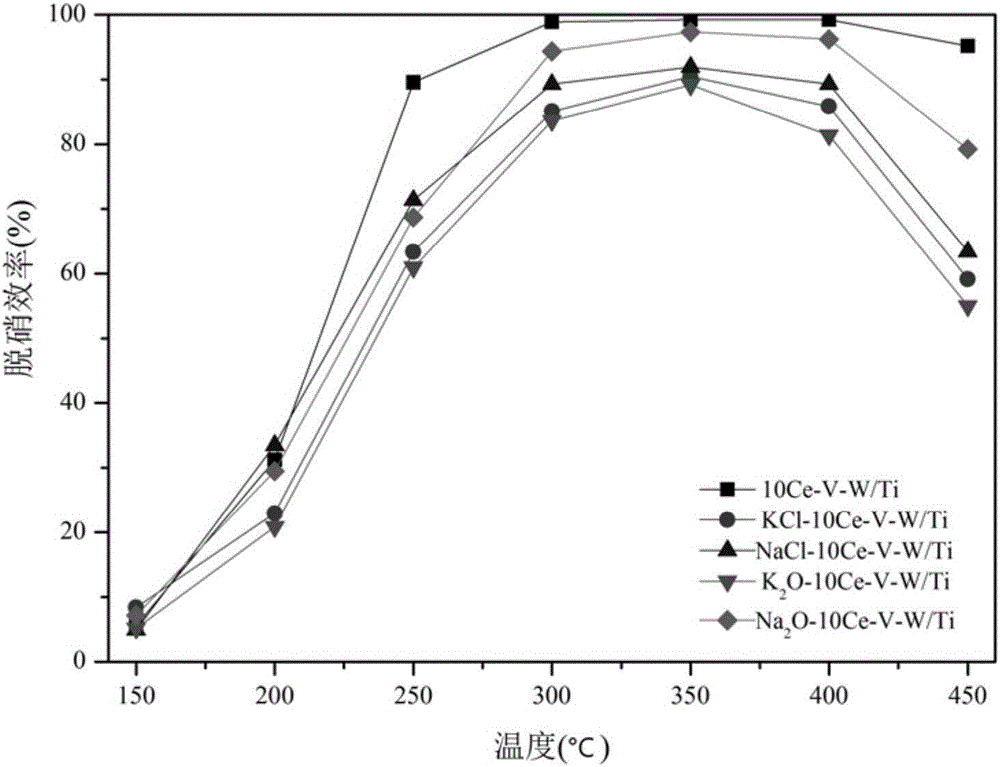

Medium-high temperature SCR denitrification catalyst with effect of resisting alkali metal poisoning and preparation method of medium-high temperature SCR denitrification catalyst with effect of resisting alkali metal poisoning

InactiveCN106268779ALow temperature dependenceImprove denitrification activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFlue gasActive component

The invention discloses a medium-high temperature SCR denitrification catalyst with an effect of resisting alkali metal poisoning and a preparation method of the medium-high temperature SCR denitrification catalyst with the effect of resisting the alkali metal poisoning. The catalyst is prepared from the following components in percentage by mass: 1 percent of V2O5, 5 percent of WO3, 10 percent of CeO2, and the balance of TiO2. The preparation method of the catalyst comprises four steps: preparation of impregnation liquid, supporting of active components, ultrasonic impregnation and roasting. The catalyst disclosed by the invention is modified by the added CeO2; more surface acid sites and chemical adsorption oxygen are formed to facilitate adsorption and oxidation of NH3 on the surface of the catalyst; by using a V-O-Ce active center formed by a synergistic effect between V and Ce, the active center of the V can be effectively prevented from being damaged by alkali metal, and further denitrification performance and performance of resisting the alkali metal poisoning are greatly improved. The preparation method of the catalyst, disclosed by the invention, is simple, distinct in flow, easy to operate and safe; the prepared catalyst has remarkable advantage in flue gas of which the content of the alkali metal is higher.

Owner:CHONGQING UNIV

Ruthenium-based ultralow-temperature denitration catalyst

ActiveCN109718767AImprove surface defectsIncrease the active siteDispersed particle separationCatalyst activation/preparationCeriumRuthenium

The invention discloses a ruthenium-based ultralow-temperature denitration catalyst, and belongs to the technical field of denitration catalysts. The denitration catalyst is prepared by sectional dipping and roasting and comprises the following components in percentage by mass: 1.22-2.84% of cerium element, 10.42-11.7% of manganese element, 1.14%-2.68% of ruthenium element and 45.84%-47.02% of titanium element. Compared with an existing Ce-Mn / TiO2 catalyst, the catalyst disclosed by the invention has the advantages that the denitration effect is good under an ultralow-temperature of 80-120 DEGC, anti-poisoning performance is remarkably improved, the service life is long, and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

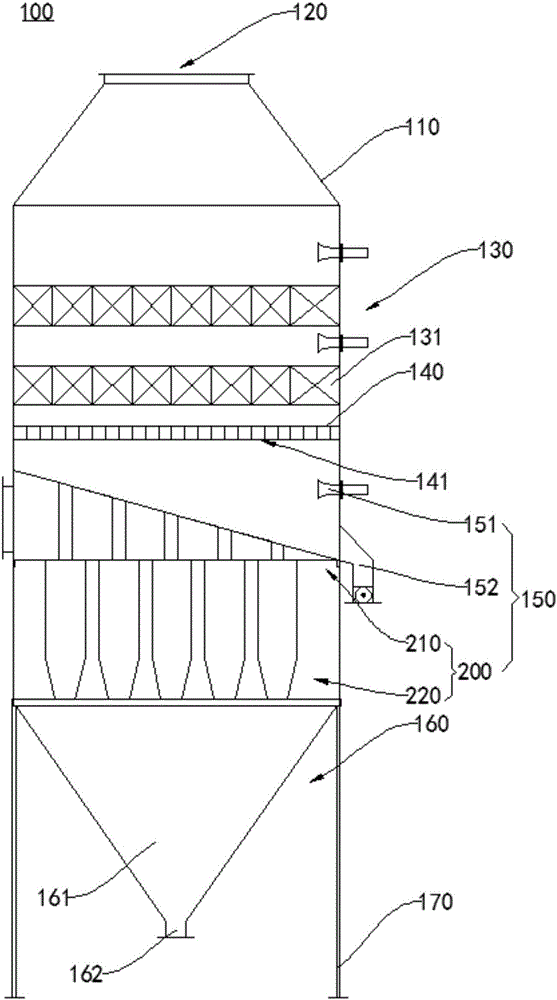

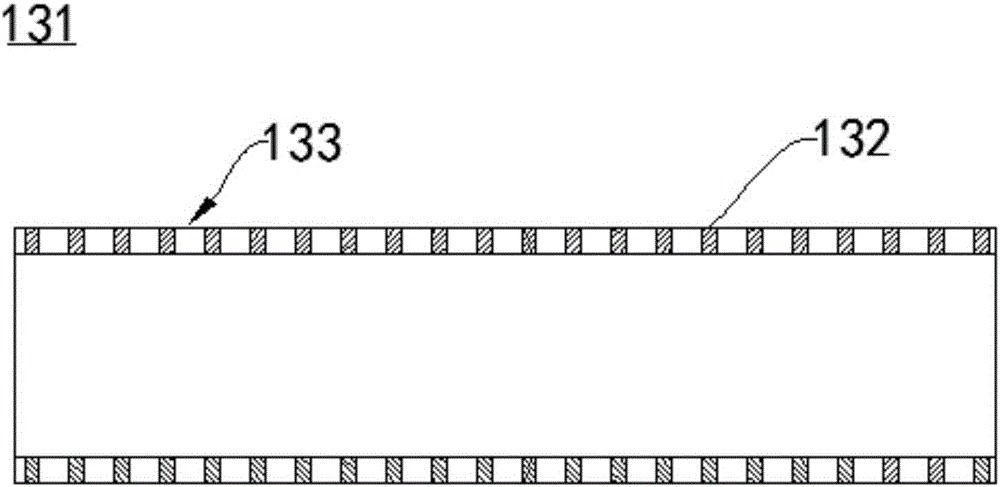

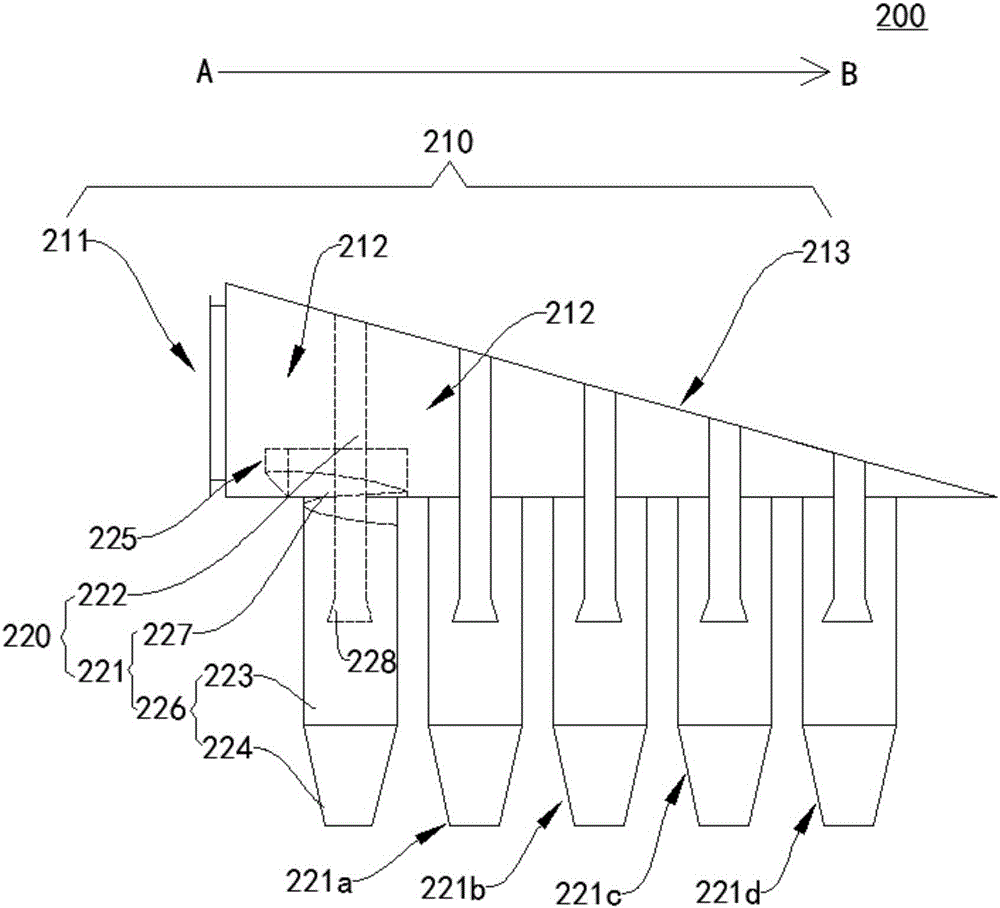

Gas-solid separator, as well as denitration and dust-removing device

ActiveCN106422543AIncrease flow speedIncrease throughputGas treatmentDispersed particle separationProcess engineeringCyclonic separation

The invention relates to environmental protection equipment and a denitration and dust-removing device, in particular to a gas-solid separator, as well as a denitration and dust-removing device. The gas-solid separator comprises a smoke gas distribution chamber. The smoke gas distribution chamber is provided with a smoke gas inlet for introducing a to-be-separated gas in a first direction; a plurality of gas cavities which are communicated mutually are distributed in the smoke gas distribution chamber in the first direction; and the volume of the plurality of the gas cavities is gradually reduced in the first direction. The smoke gas distribution chamber is connected with a plurality of cyclone separation assemblies which are in one-to-one correspondence with the plurality of gas cavities; each separation assembly comprises a cyclone cylinder and a gas discharge pipe which are matched mutually; the cyclone cylinder is provided with a gas inlet and flow guide end which is used for input gas and positioned in the gas cavities; and the gas discharge pipe partially stretches into the cyclone cylinder and penetrates through the smoke gas separation chamber. The denitration and dust-removing device comprises a shell and the gas-solid separator. The gas-solid separator, as well as the denitration and dust-removing device, protects a catalyst and prolongs the service life of the catalyst to finally realize the technical effects of improving the denitration effect and reducing the cost.

Owner:SHANDONG TIANLI ENERGY SAVING ENG

Preparation method and application of catalyst containing low-silicon composite metal Beta molecular sieve

ActiveCN111617800AImprove performanceImprove denitrification performanceGas treatmentMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a preparation method and application of a catalyst containing a low-silicon composite metal Beta molecular sieve. The Fe-Beta molecular sieves with different morphologies are prepared by a one-step method by controlling the composition of synthesis raw materials and a structure-directing agent under the condition of no template agent, so that the acidity and pore channels of the molecular sieves are optimized, and the purpose of optimizing the performance of the molecular sieves is achieved. Lanthanum salt is used for further modifying the Fe-Beta molecular sieve for the first time by adopting an impregnation method, so that the denitration temperature interval of the Fe-Beta molecular sieve is greatly widened, the denitration performance and hydrothermal stabilityof the Fe-Beta molecular sieve are improved, and the Fe-Beta molecular sieve is relatively good in sulfur poisoning resistance and relatively low in cost. The low-silicon composite metal Beta molecular sieve catalyst disclosed by the invention is mainly used for treating NOx-containing tail gas and flue gas, and has excellent NOx selective reduction capability, good hydrothermal stability and HC carbon deposition resistance and sulfur poisoning resistance in a low-temperature range.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

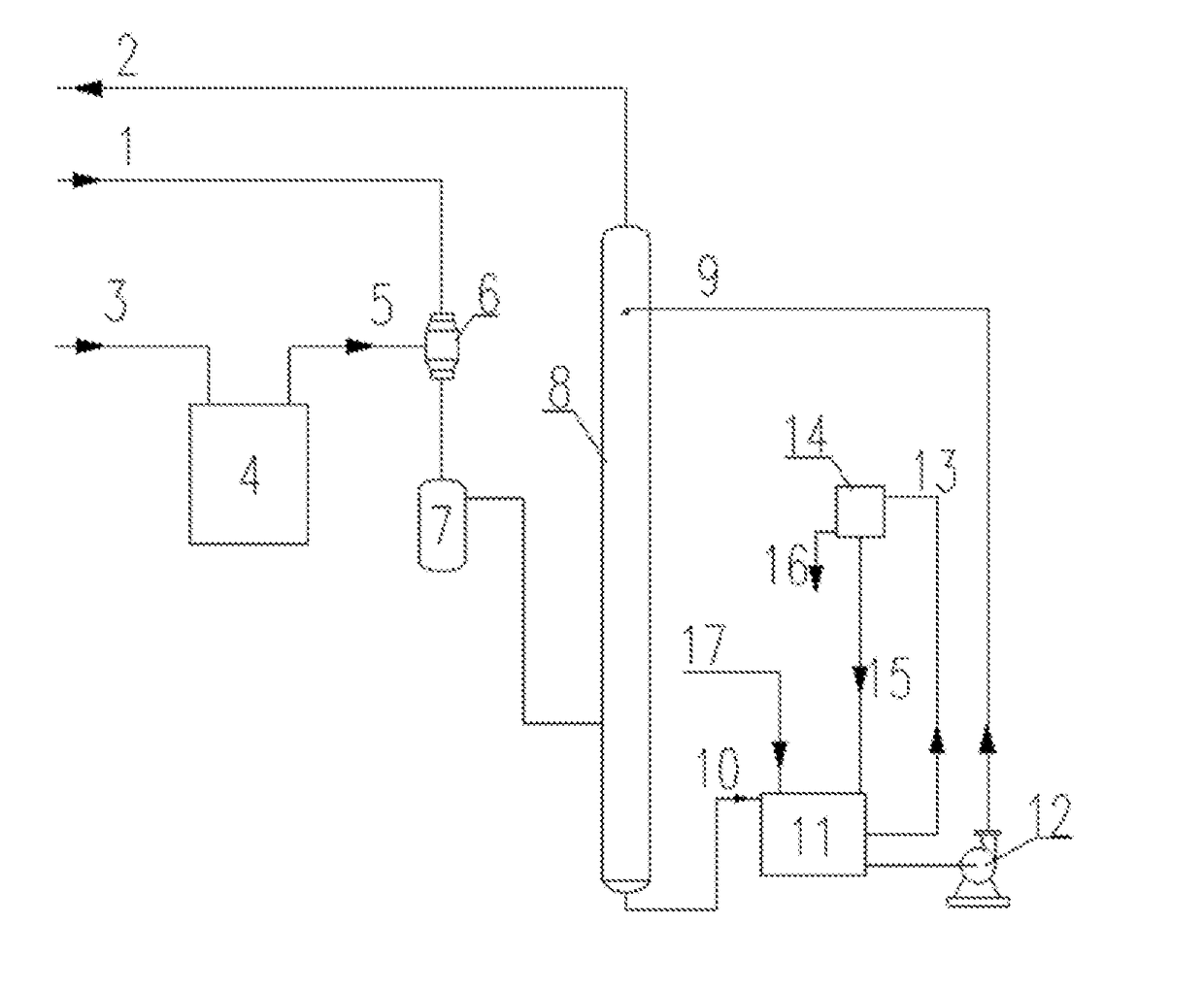

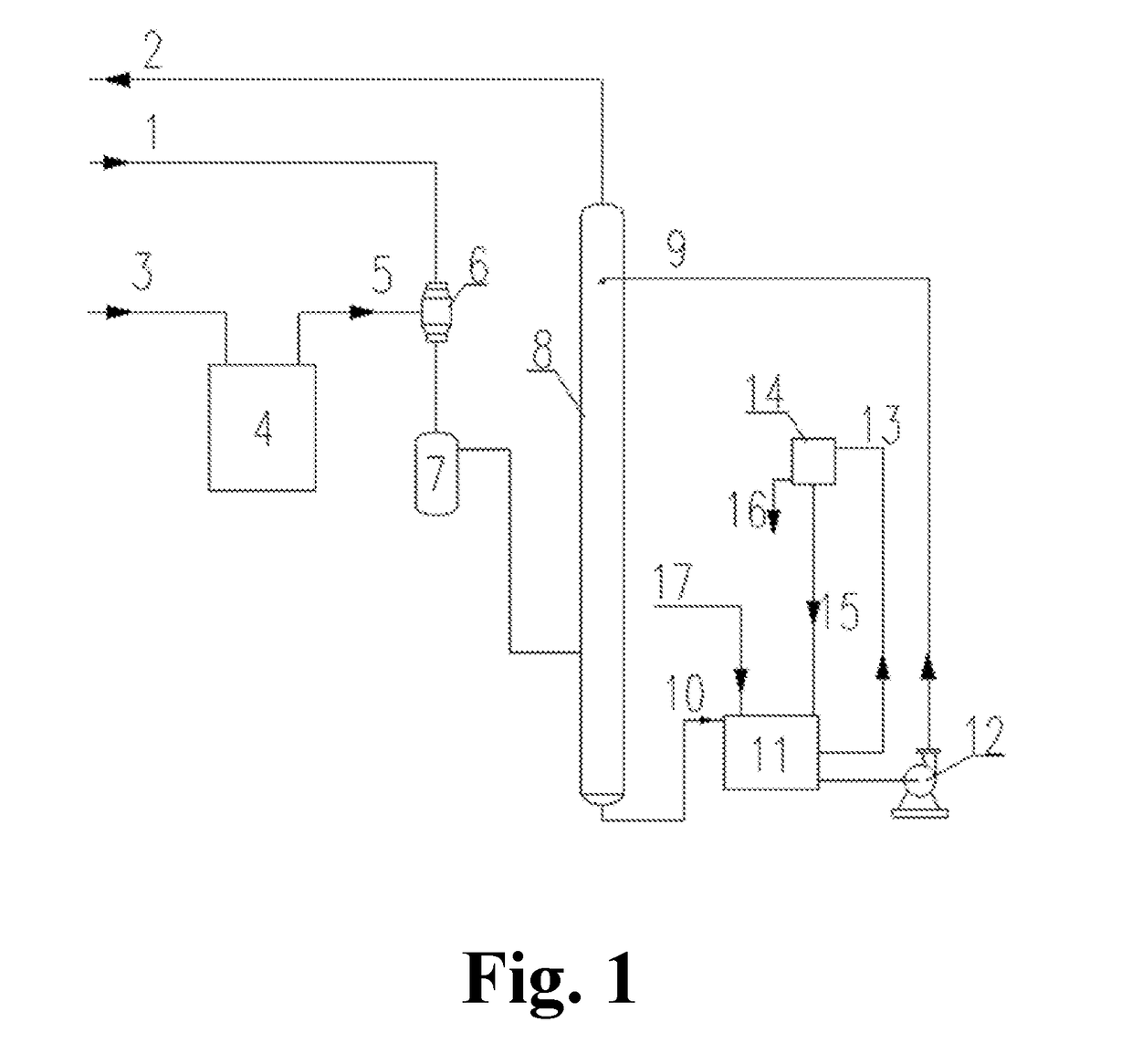

Hydrogen peroxide denitration process and denitration system

InactiveCN105289263AImprove denitrification performanceThe principle is simpleDispersed particle separationNitrous acidFlue gasNitrogen oxide

The invention relates to a hydrogen peroxide denitration process and a corresponding denitration system. According to the denitration process, hydrogen peroxide is taken as an oxidant; .OH is generated through high-temperature and high-pressure catalysis of hydrogen peroxide; .OH is mixed with flue gas, so that nitrogen oxides in the flue gas can be oxidized and recovered; finally, the obtained mixture is subjected to gas-liquid separation, denitration by-products, namely nitric acid and a nitrous acid liquid, are recovered, and the flue gas subjected to denitration is discharged to the outside. The denitration process and the denitration system have the advantages that hydrogen peroxide is taken as the denitration oxidant; through the mixing of hydrogen peroxide and high-temperature steam, hydrogen peroxide tends to be decomposed into hydroxy radical.OH and HO2., so that the nitrogen oxides oxidation and recovery effects are improved, the denitration rate is increased, and the temperature limitation is avoided.

Owner:湖北蔚天环保科技有限公司

Gas denitration process and apparatus

ActiveUS20180099245A1Improve denitrification performanceHigh purityGas treatmentDispersed particle separationProduct gasOxidizing agent

A process and an apparatus for gas denitration, involving first the use of an oxidizing agent to oxidize NO in a gas to NO2, then using a denitration agent to absorb the NO2 in the gas, thus achieving the purpose of denitration.

Owner:BEIJING BOYUAN HENGSHENG HIGH TECH

FCC regenerated flue gas dustproof denitration reactor

ActiveCN103768930ALarge flow areaReduce gas velocityDispersed particle separationFlue gasProcess engineering

The invention relates to a FCC regenerated flue gas dustproof denitration reactor. The FCC regenerated flue gas dustproof denitration reactor comprises a mixed flue gas inlet segment, a denitration segment, and a purified flue gas exhaust segment; the denitration segment is provided with a denitration unit; a dedusting segment is arranged between the mixed flue gas inlet segment and the denitration segment; dust blocking plates are arranged in the dedusting segment; the dust blocking plates are corrugated blocking plates which are arranged in a multi-layer staggered manner; a dust collector is arranged in the denitration segment; the center line of the dust collector and the center line of the FCC regenerated flue gas dustproof denitration reactor are overlapped; and the lower end of the dust collector is connected with a dust discharging pipeline. According to the FCC regenerated flue gas dustproof denitration reactor, the dust blocking plates are arranged in the FCC regenerated flue gas dustproof denitration reactor, so that flue dust in the mixed flue gas is removed effectively before the mixed flue gas is delivered into the denitration unit, blocking of catalyst channels in the denitration unit by flue dust is avoided, denitration efficiency and denitration effects are improved; and the FCC regenerated flue gas dustproof denitration reactor is provided with drainage grilles and rectifier grilles, so that laminar flow states of the flue gas in the FCC regenerated flue gas dustproof denitration reactor are maintained, and denitration efficiency is increased further.

Owner:CHINA PETROLEUM & CHEM CORP +1

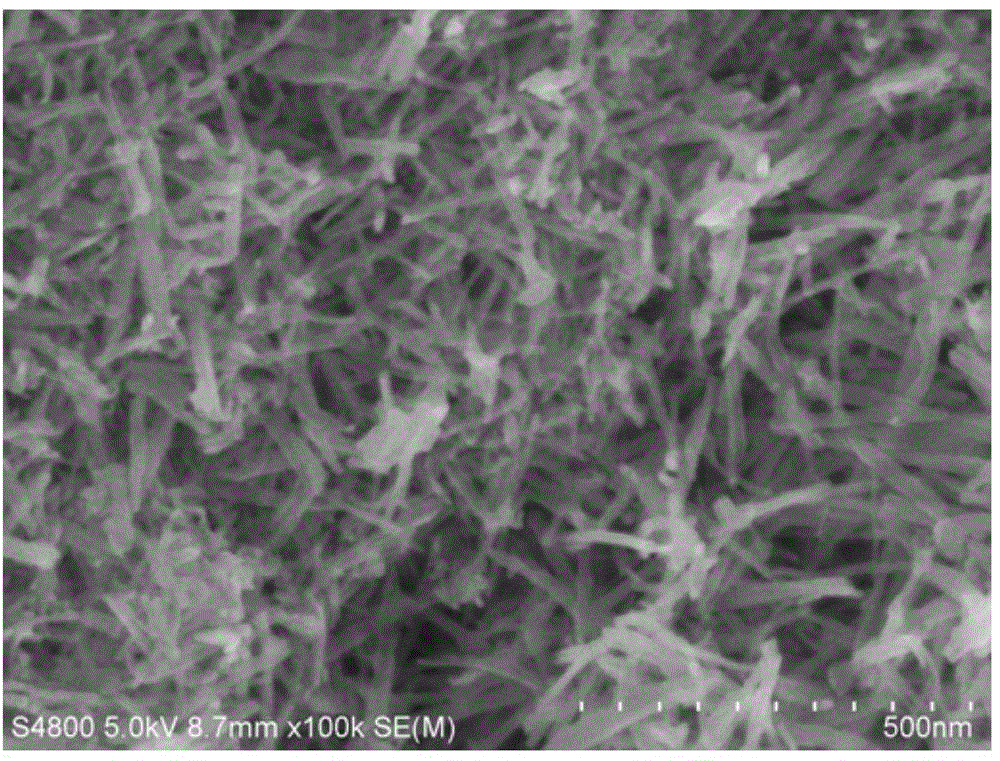

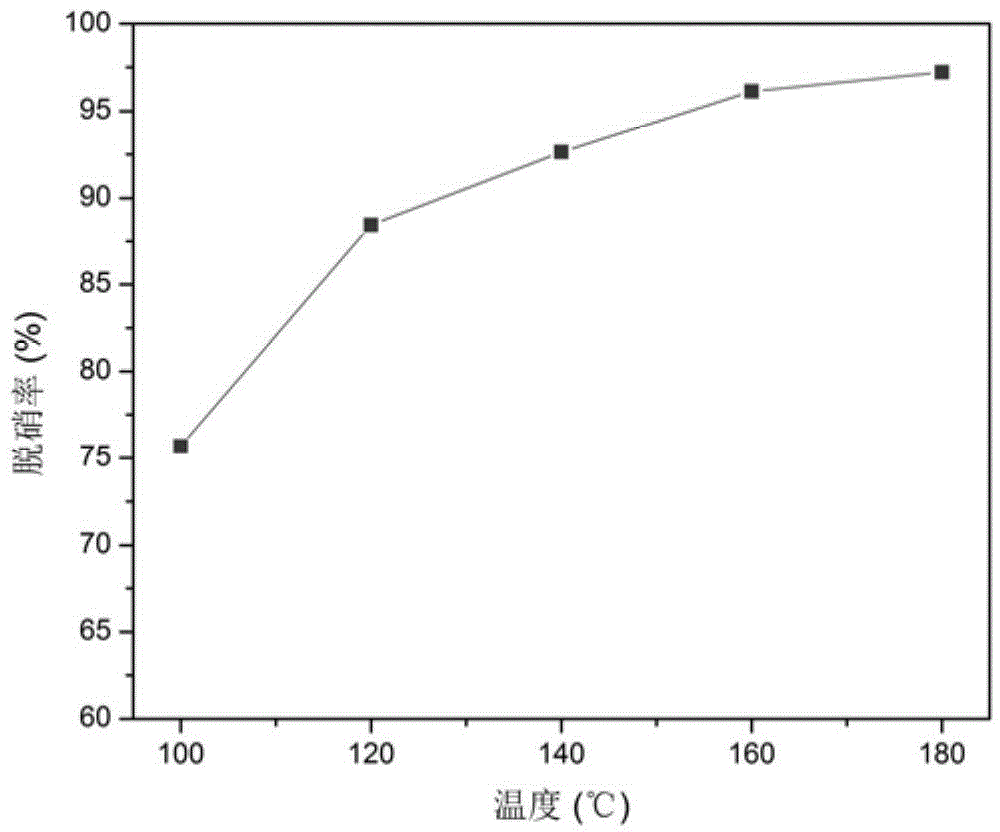

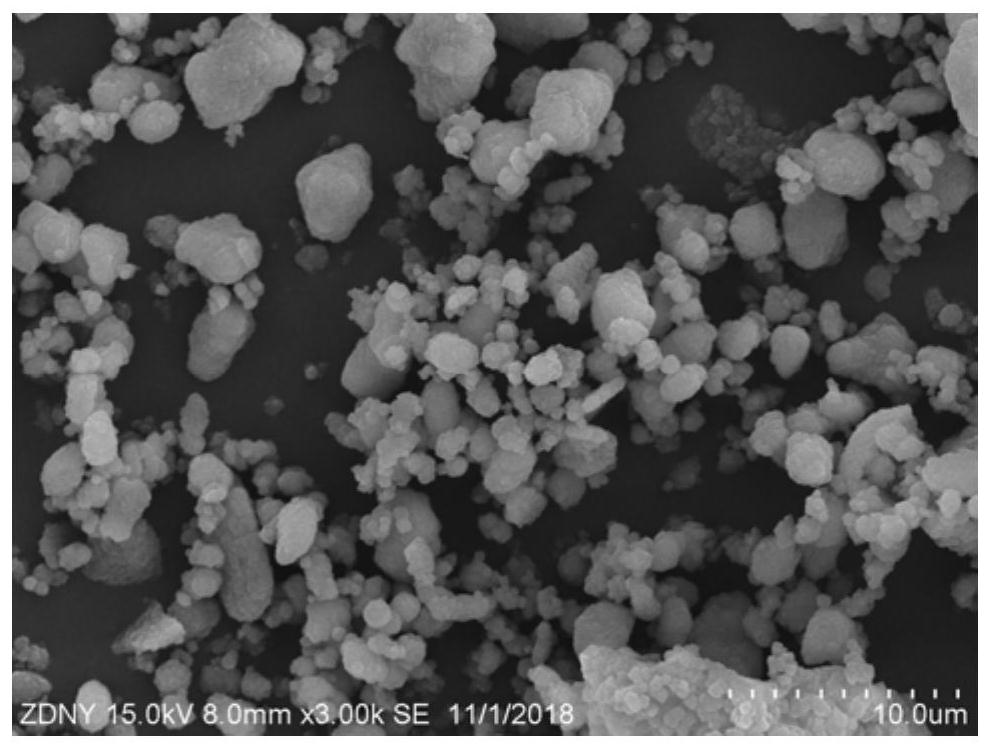

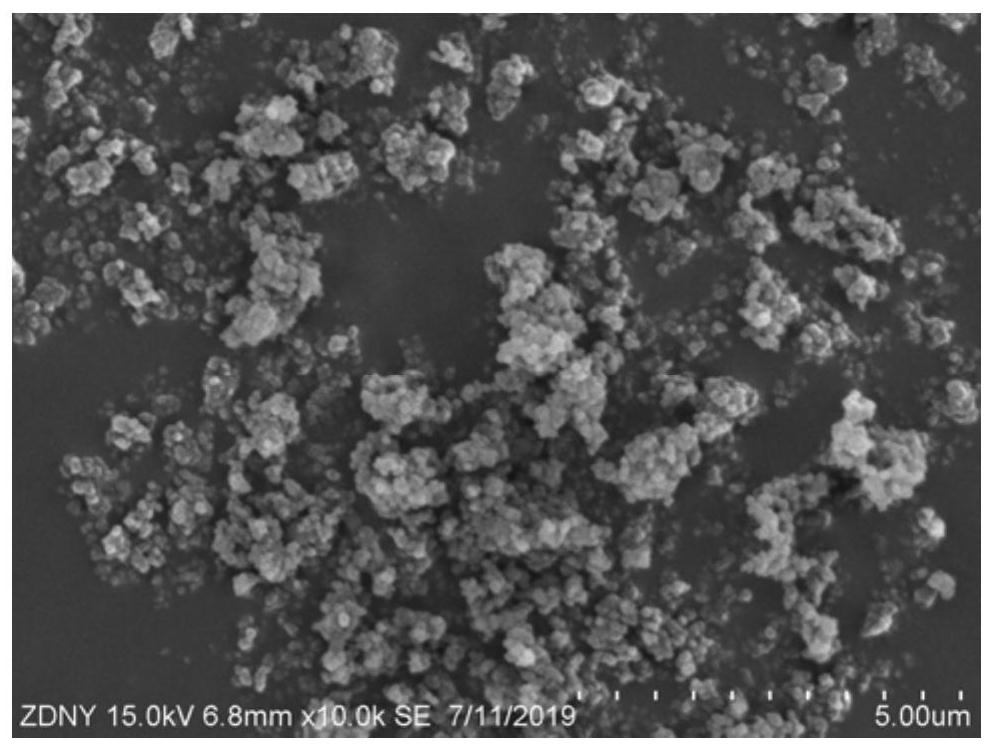

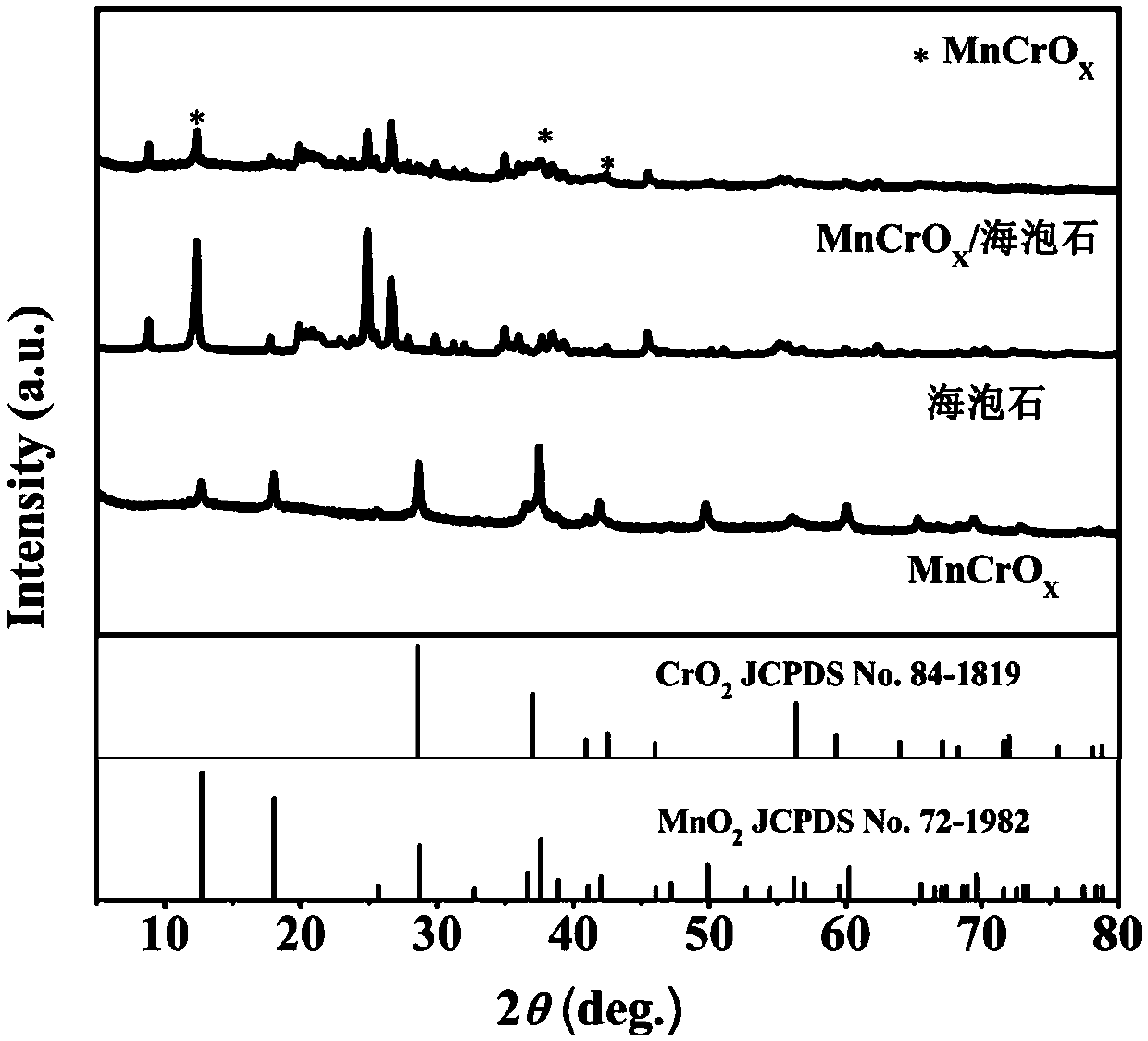

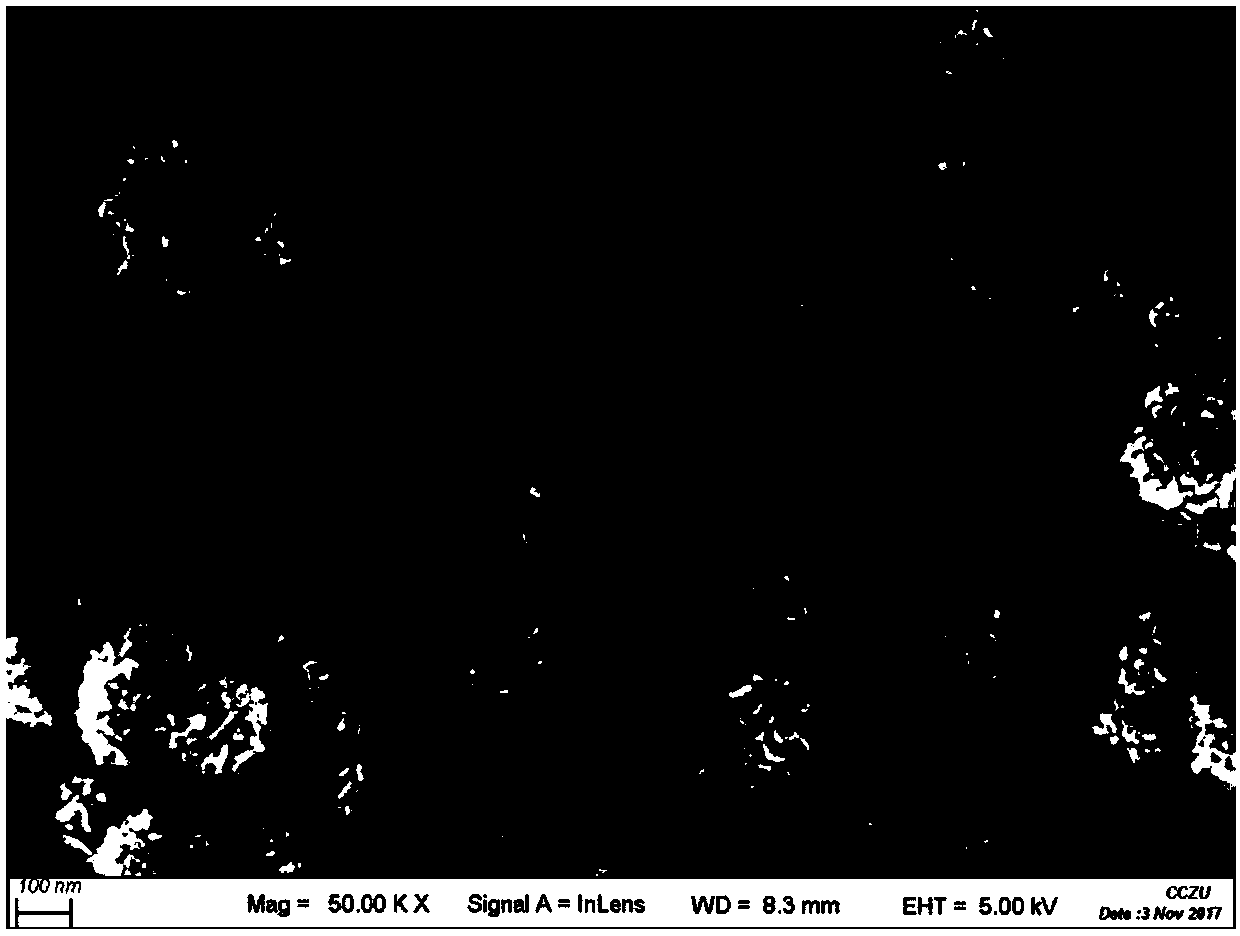

3D nanoflower-shaped MnCrOX-coated sepiolite low-temperature denitration catalyst and preparation method thereof

ActiveCN108097240AStable structureEasy to shapeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentFlue gas

The invention belongs to the field of flue gas denitration, particularly relates to a 3D nanoflower-shaped MnCrOX-coated sepiolite low-temperature denitration catalyst and a preparation method thereof. The method prepares a nanoflower-shaped MnCrOX coated with the clay sepiolite to form a three-dimensional structure catalyst. The catalyst uses low-cost clay sepiolite as a carrier, and uses a hydrothermal method for in-situ growth of flower-shaped MnCrOX as an active component, and coats the surface of the sepiolite to form a 3D structure catalyst for low-temperature denitration. The 3D nanoflower-shaped MnCrOX-coated sepiolite low-temperature denitration catalyst and the preparation method thereof has the advantages of a preparation process is simple, economical, and does not require any template, the catalyst is easy to be molded, a specific surface area and the redox ability of the catalyst are enhanced, the activity reaction temperature is effectively reduced, the denitration activity and the sulfur resistance are improved, and the activity window is wide, and the like.

Owner:CHANGZHOU UNIV

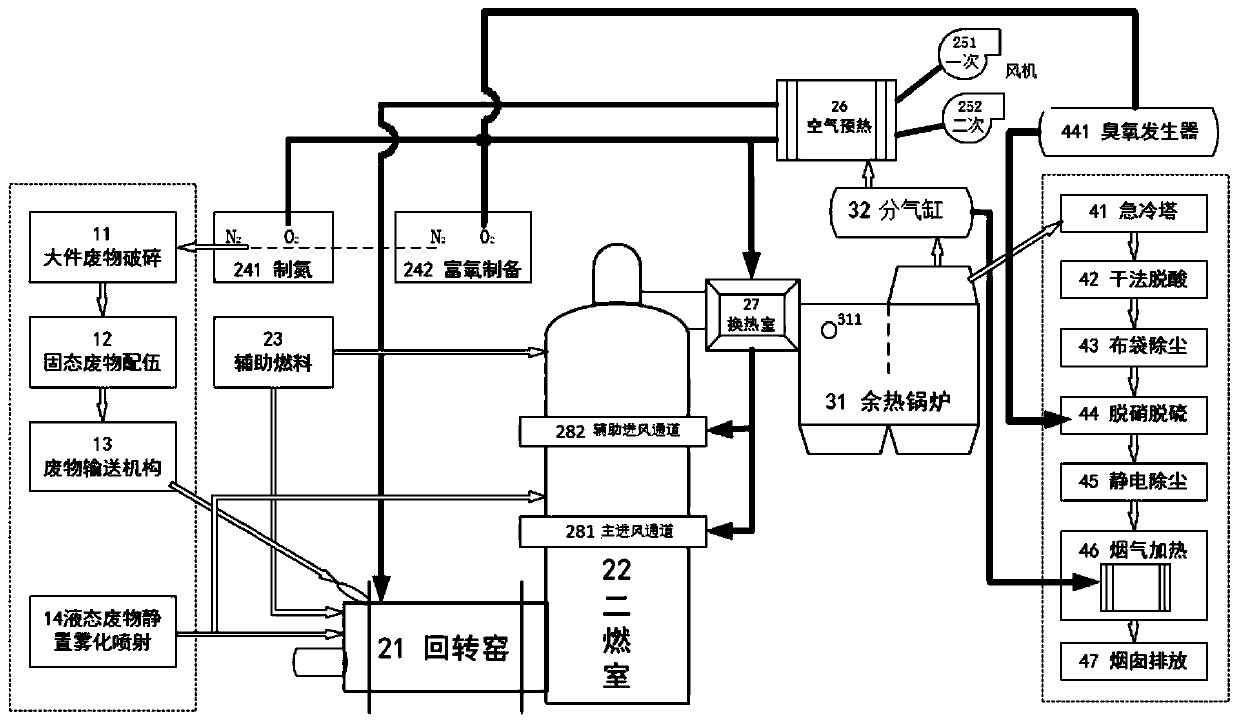

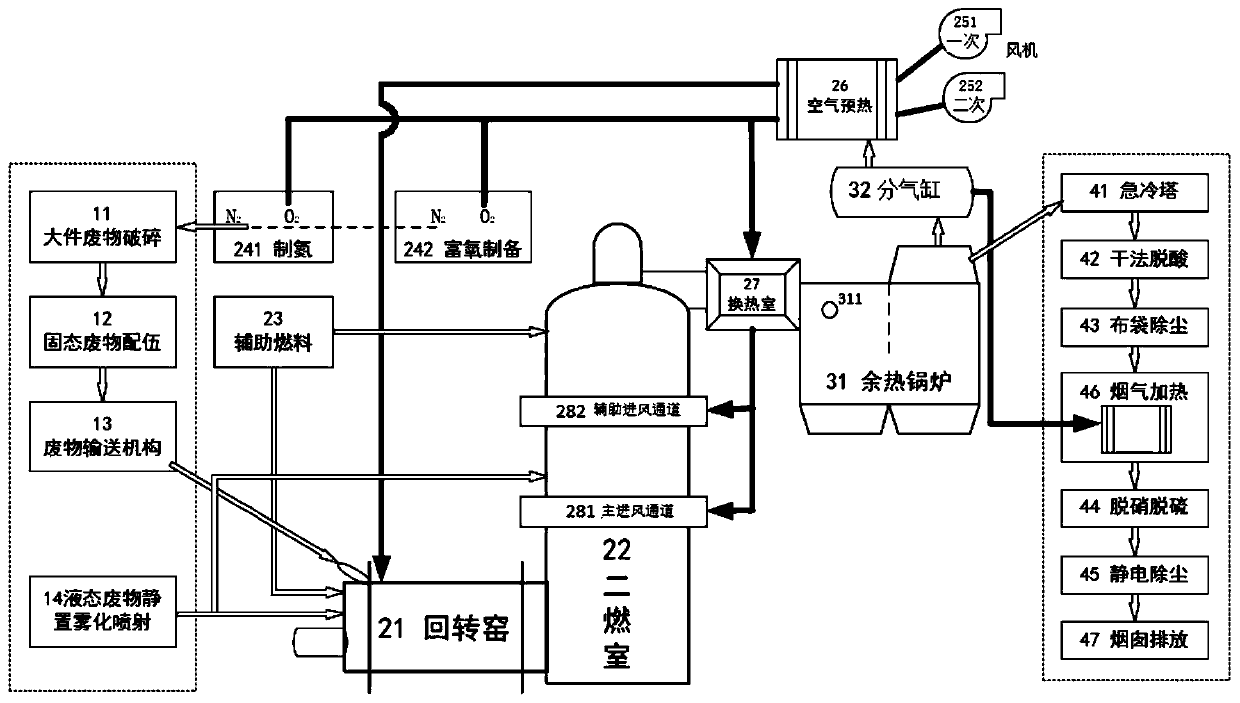

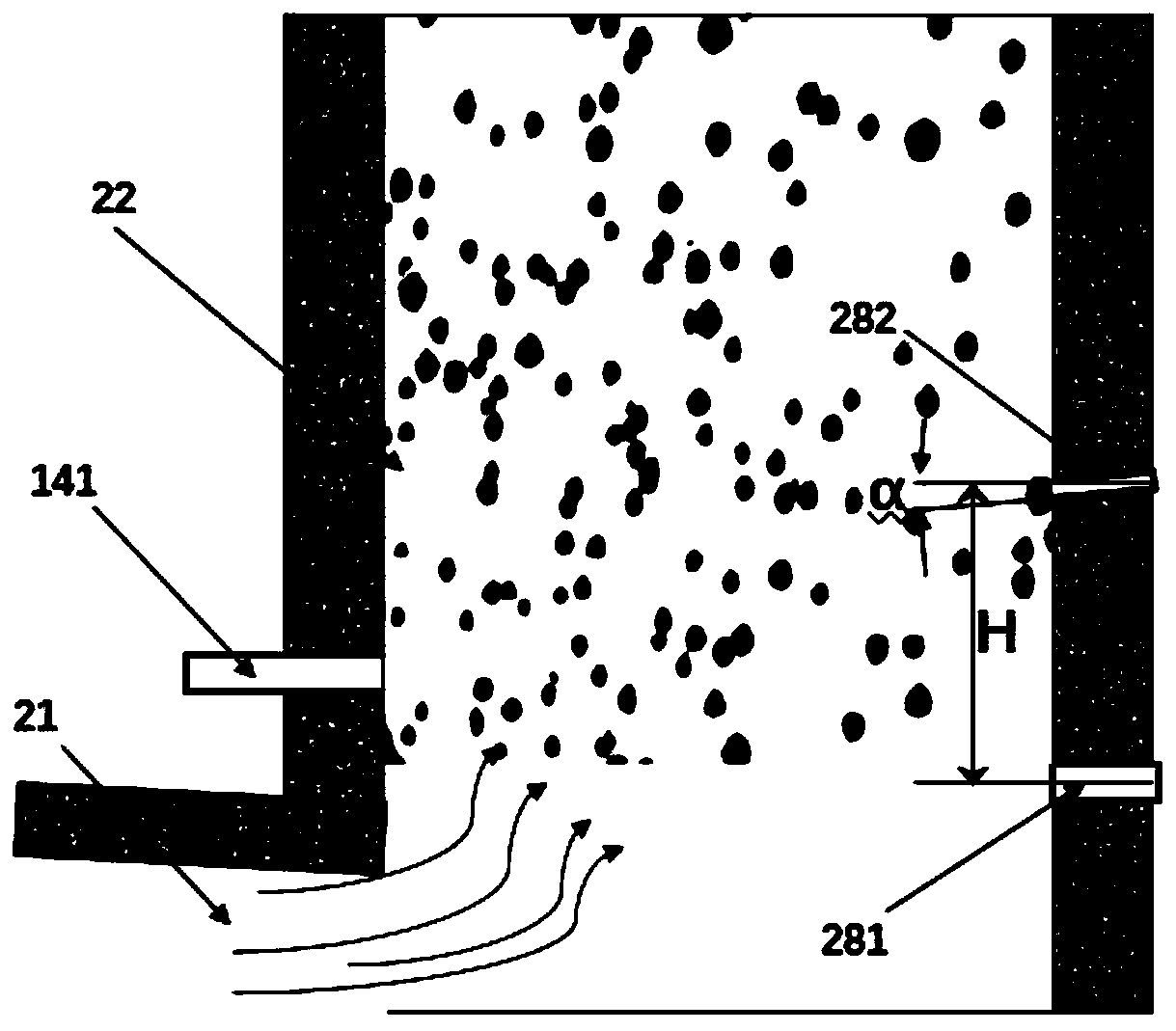

Green and efficient incineration method for hazardous waste in rotary kiln based on oxygen enriched air supply in secondary combustion chamber

PendingCN111306549ARaise the incineration temperatureInhibit synthesisEnergy inputIndirect carbon-dioxide mitigationLiquid wasteCombustion chamber

The invention discloses a green and efficient incineration method for hazardous waste in a rotary kiln based on oxygen enriched air supply in a secondary combustion chamber. The method comprises the steps of (1) adding solid waste, liquid waste and a first combustion-supporting gas to the rotary kiln for performing treatment; (2) feeding the waste and the liquid waste which are treated by means ofthe rotary kiln and a second combustion-supporting gas into a secondary combustion chamber for performing combusting treatment; and (3) exhausting the gas which is obtained after the combustion in the secondary combustion chamber, wherein the second combustion-supporting gas is formed by mixing air and an oxygen enriched gas; the incineration temperature in the secondary combustion chamber is risen to 1,100 to 1,200 DEG C; the oxygen concentration of the second combustion-supporting gas is 23 to 28 percent; the oxygen content of a combustion environment in the secondary combustion chamber isimproved, and a technical means of the preheating is effectively utilized, which are beneficial to removing nitrogen oxides from flue gas in a waste heat utilization system under the condition of ensuring complete decomposition of the harmful substances, such as dioxin; the production and emission of secondary environment pollution substances in an incineration processing process are avoided or remarkably reduced; and efficient and green treatment of maximum reduction of the hazardous waste is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com