Low-temperature selective catalytic reduction (SCR) fixed bed flue gas denitrification device and method for coal-fired boiler

A technology for coal-fired boilers and fixed beds, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as resistance to sulfur and water that are difficult to achieve, solve the problem of poisoning and inactivation, and reduce pollutants Emissions and the effect of reducing catalyst loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

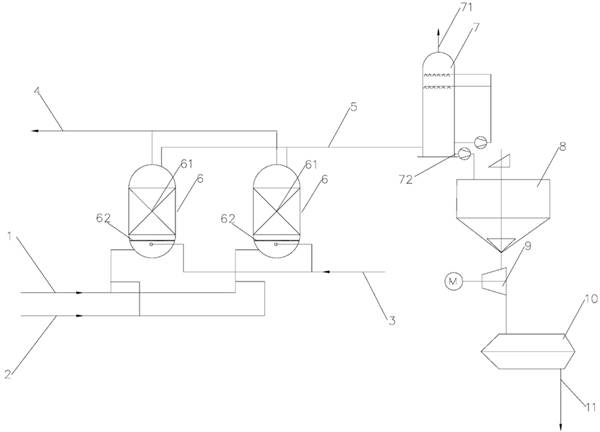

[0019] Such as figure 1 Said, the present invention is a low-temperature SCR fixed-bed flue gas denitration device for a coal-fired boiler, comprising a flue gas inlet 1, a regenerative gas inlet 2, an ammonia gas inlet 3, a flue gas outlet 4, and a regenerative gas outlet 5; including a denitrification reactor 6 , there are more than two denitrification reactors 6, and two are taken as an example in this embodiment. The denitrification reactor 6 is provided with a fixed bed catalyst 61. In this embodiment, a low temperature catalyst is selected, and a gas distributor 62 is arranged below the fixed bed catalyst 61; the flue gas inlet 1, the ammonia gas inlet 3 and the regeneration gas inlet 2 are connected to the denitrification reactor 6 In the lower part, the upper part of the denitrification reactor 6 is provided with a flue gas outlet 4 and a regeneration gas outlet 5, the regeneration gas outlet 5 is connected to the washing cooling tower 7, the upper part of the washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com