Hydrogen peroxide denitration process and denitration system

A technology of hydrogen peroxide and denitrification, which is applied in the direction of nitric acid, nitrous acid, nitrogen oxides/oxygen acid, etc., can solve the problems of harshness, low exhaust gas temperature, temperature requirements, etc., achieve complete denitrification, simple principle, and improve denitrification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

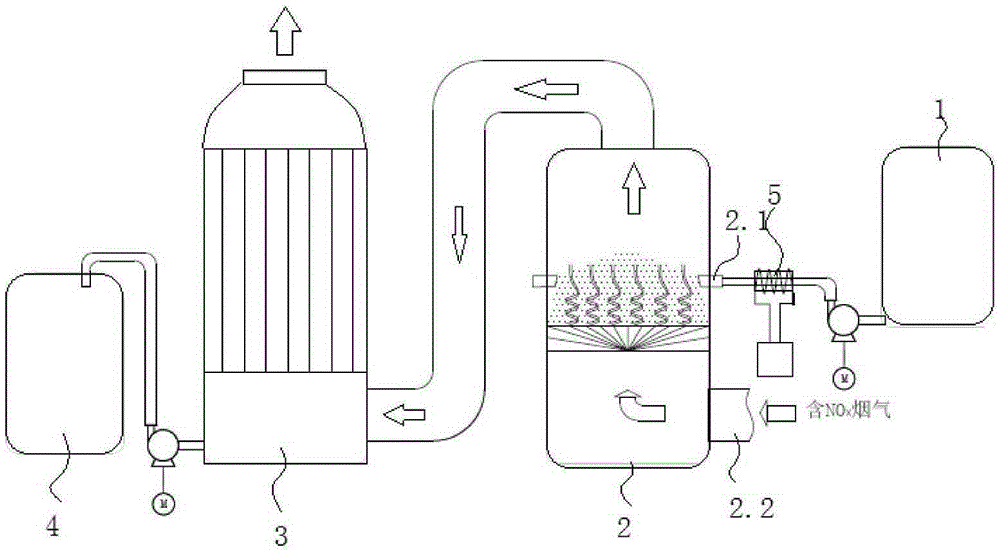

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] A hydrogen peroxide denitrification process, using 50% hydrogen peroxide as an oxidant, catalyzing hydrogen peroxide to generate OH through high temperature and high pressure. High temperature and high pressure is to directly heat hydrogen peroxide to 400-500 °C, and the extra pressure generated by hydrogen peroxide is 1.6-2.0KPa, OH Mixing with flue gas affects the nitrogen oxides in flue gas (mainly NO and NO 2 etc.) for oxidation recovery, and finally the mixture is separated by gas and liquid to recover the denitrification by-products nitric acid and nitrous acid liquid, and the flue gas after denitrification can be directly discharged;

[0023] The specific chemical reaction formula is

[0024] h 2 o 2 →2·OH

[0025] h 2 o 2 +·OH→HO 2 ·+H 2 o

[0026] NO+HO 2 ·→NO 2 +·OH

[0027] NO 2 +·OH→HNO 3

[0028] NO+·OH→HNO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com