FCC regenerated flue gas dustproof denitration reactor

A technology for denitrification reactors and flue gas regeneration, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as uneven distribution of flue gas, ammonia escape, and impact on denitrification efficiency, so as to promote separation and reduce The effect of flue gas flow rate and increasing inlet cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

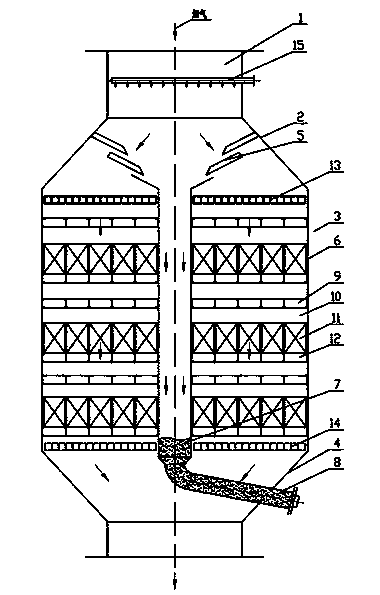

[0024] The specific scheme and usage mode of the present invention will be further described below in conjunction with the accompanying drawings.

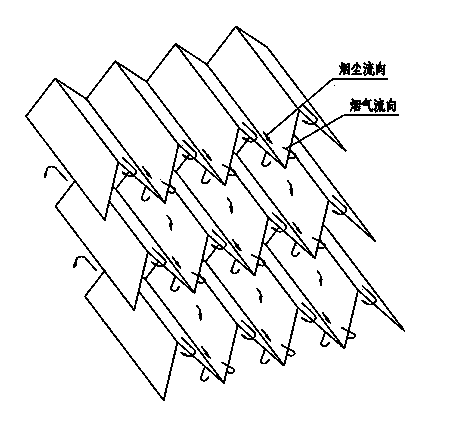

[0025] A dust-proof FCC regenerative flue gas denitration reactor, the denitrification reactor includes a mixed flue gas intake section, a denitration section and a purified flue gas exhaust section, wherein the denitration section is provided with a denitration unit, and the denitration unit includes a hanging beam , a soot blower, a catalyst module, and a catalyst support beam; it is characterized in that: an ash removal section is set between the mixed flue gas intake section and the denitration section, and the ash baffle is a corrugated structure baffle arranged in multiple layers staggered, Ash baffles are set in the ash removal section, and ash bins are set in the denitrification section. The center line of the ash bin coincides with the center line of the reactor, and the lower end of the ash bin is connected to the ash disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com