Patents

Literature

169results about How to "Reduce gas velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

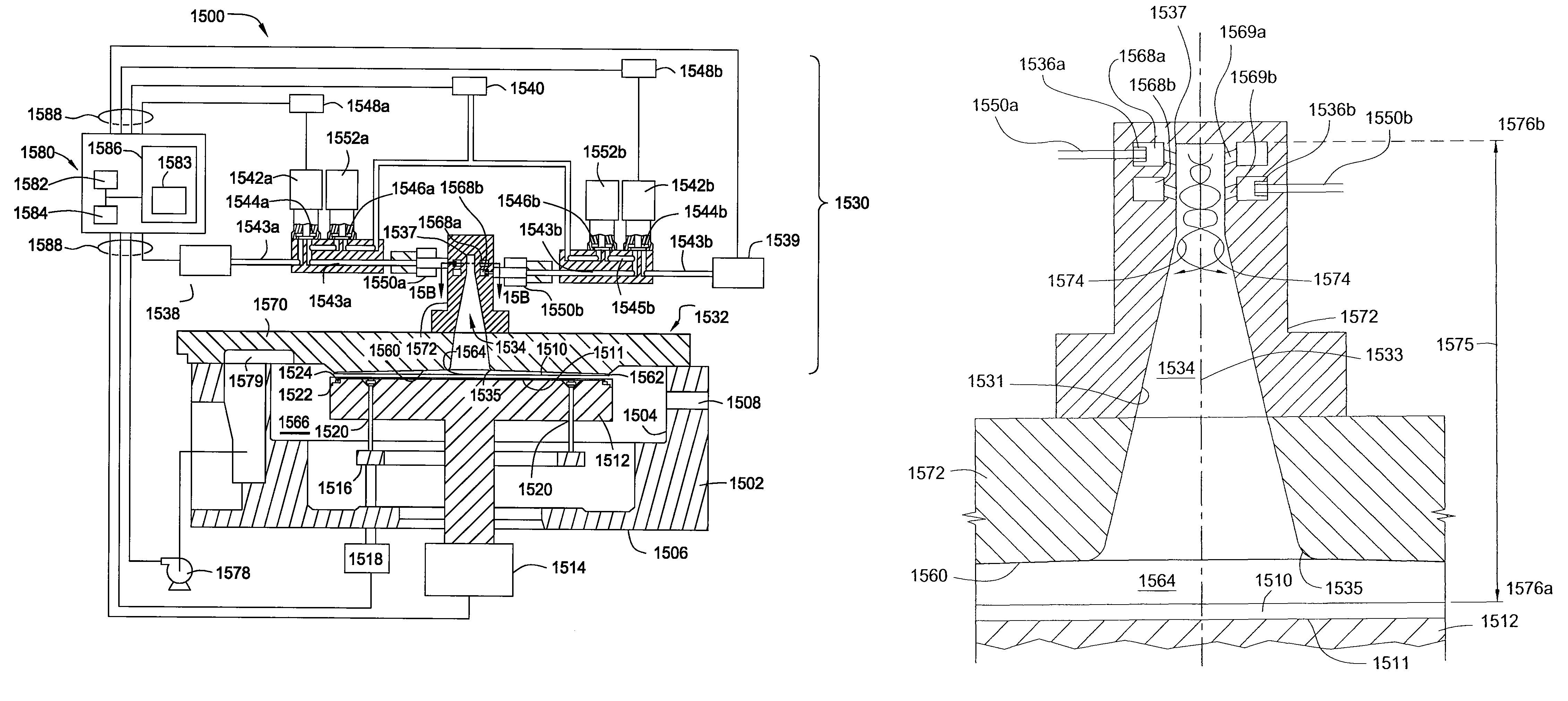

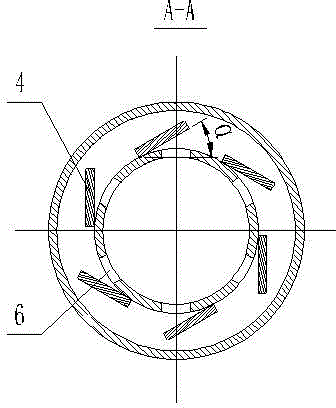

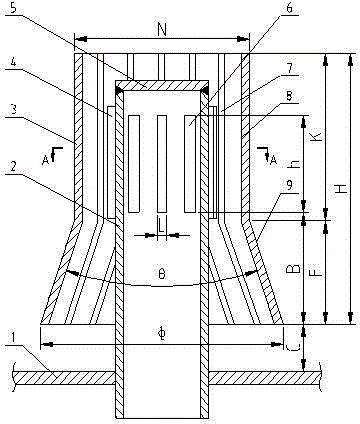

Vortex chamber lids for atomic layer deposition

InactiveUS7780789B2Reduce gas velocitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

Embodiments of the invention relate to apparatuses and methods for depositing materials on substrates during atomic layer deposition processes. In one embodiment, a chamber for processing substrates is provided which includes a chamber lid assembly containing an expanding channel extending along a central axis at a central portion of the chamber lid assembly and a tapered bottom surface extending from the expanding channel to a peripheral portion of the chamber lid assembly. The tapered bottom surface may be shaped and sized to substantially cover the substrate receiving surface. The chamber lid assembly further contains a conduit coupled to a gas passageway, another conduit coupled to another gas passageway, and both gas passageways circumvent the expanding channel. Each of the passageways has a plurality of inlets extending into the expanding channel and the inlets are positioned to provide a circular gas flow through the expanding channel.

Owner:APPLIED MATERIALS INC

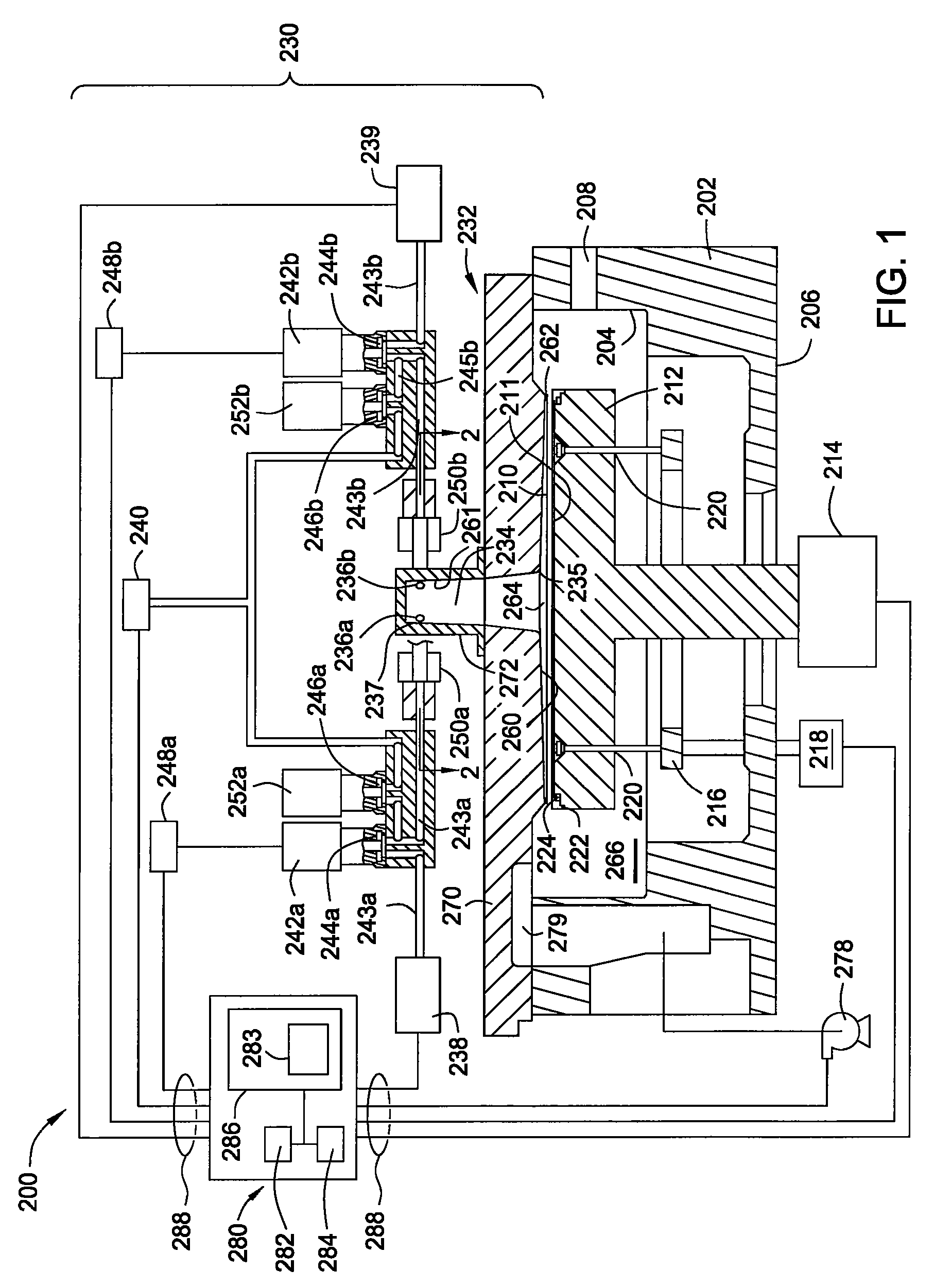

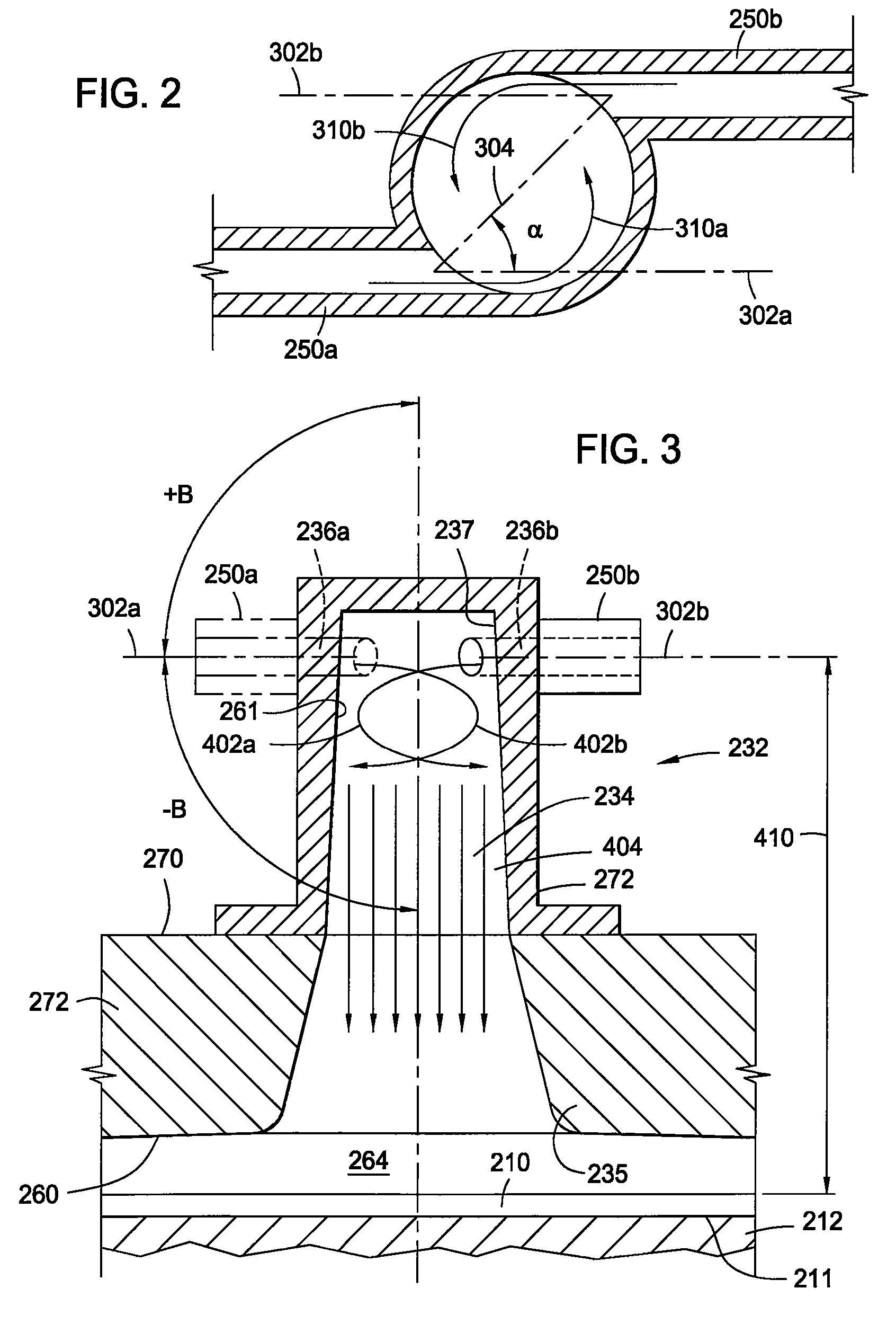

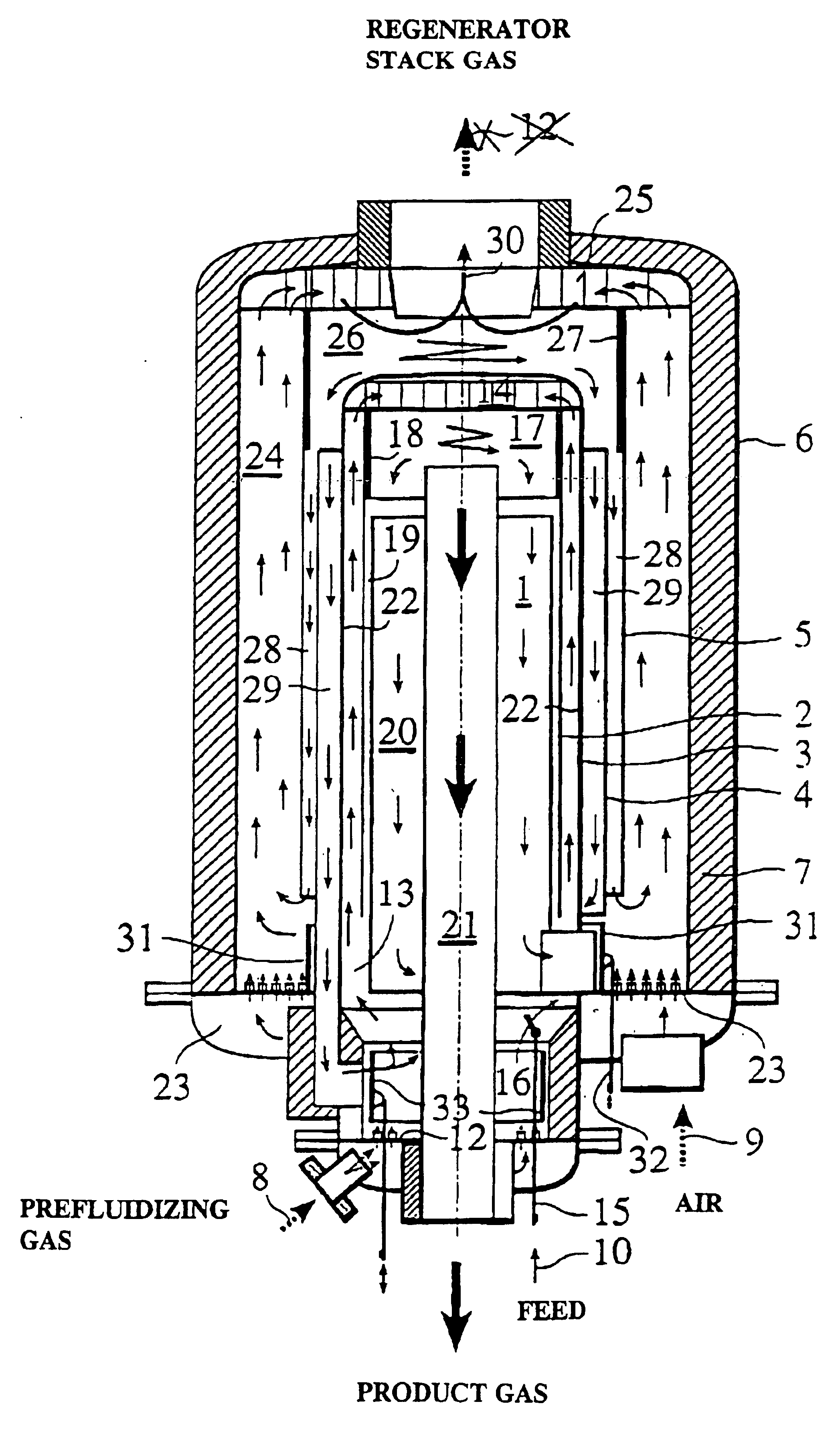

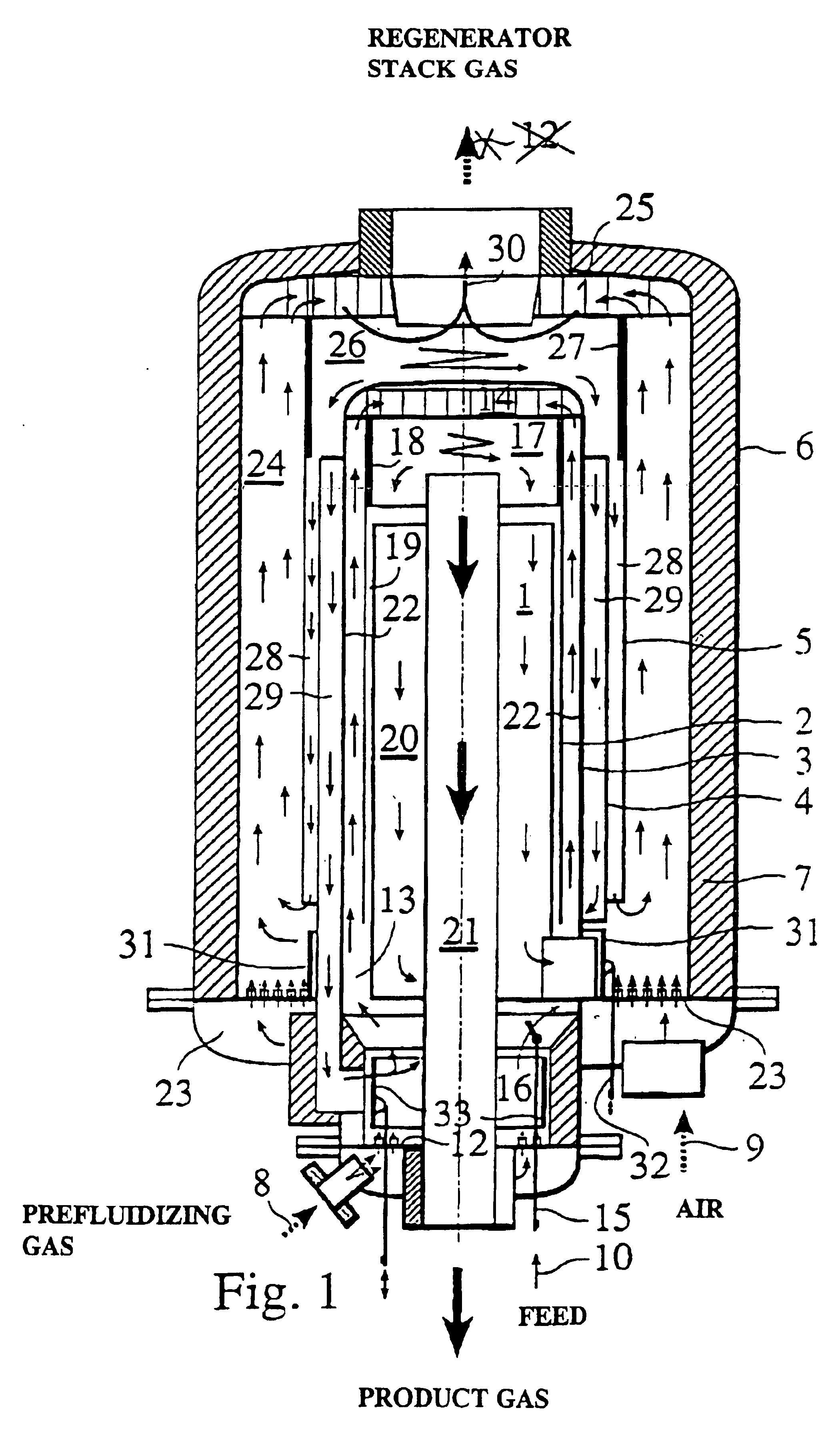

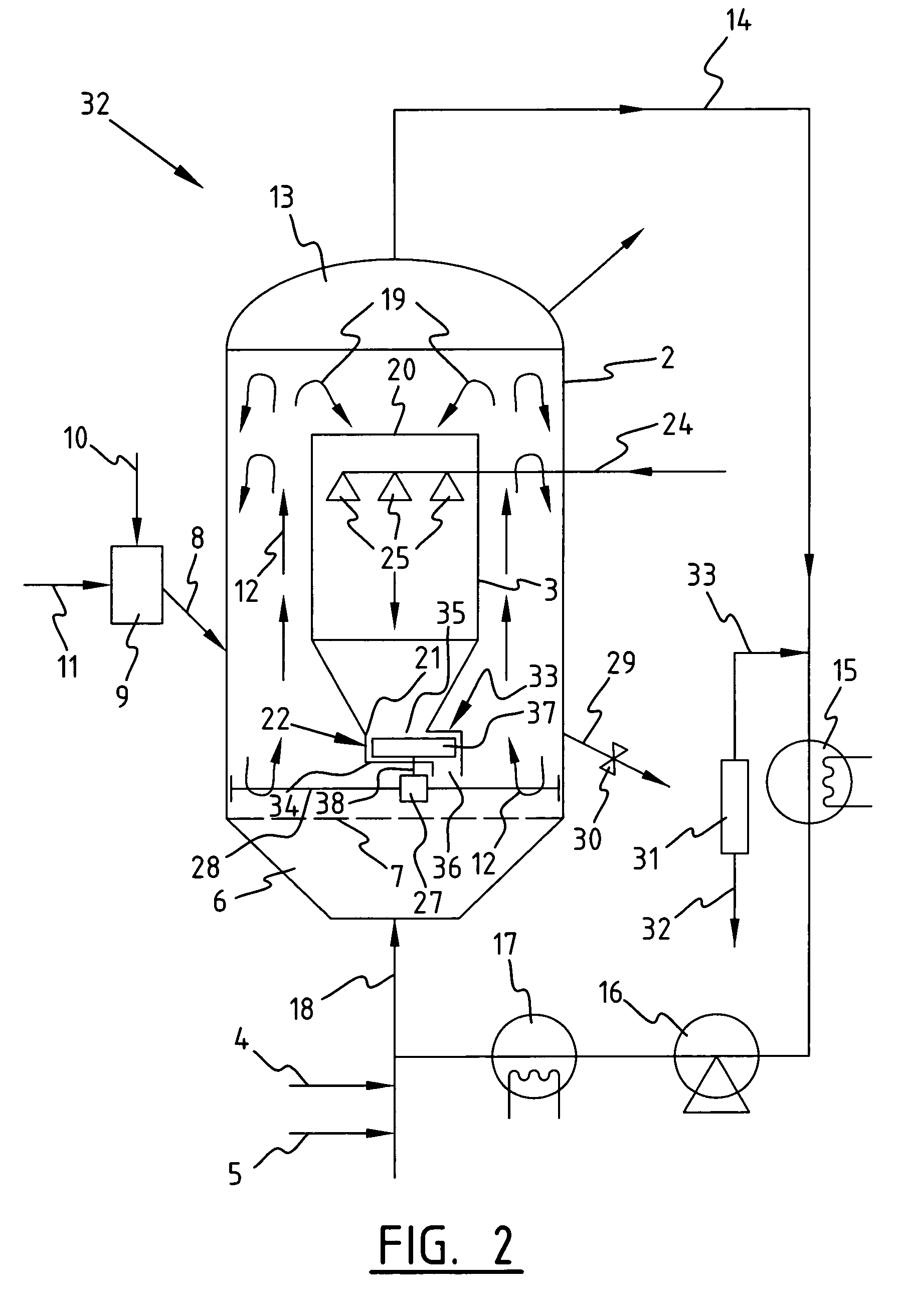

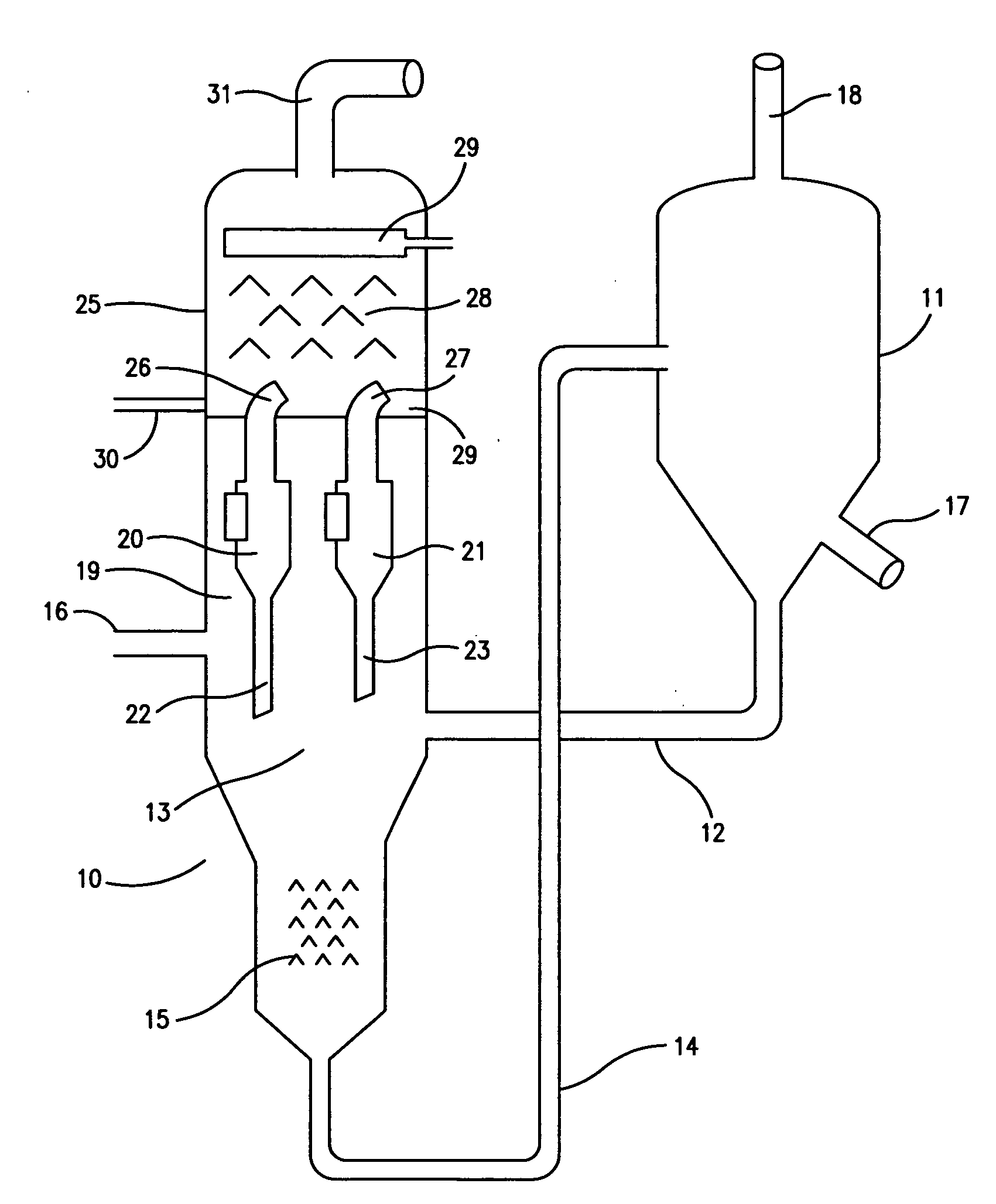

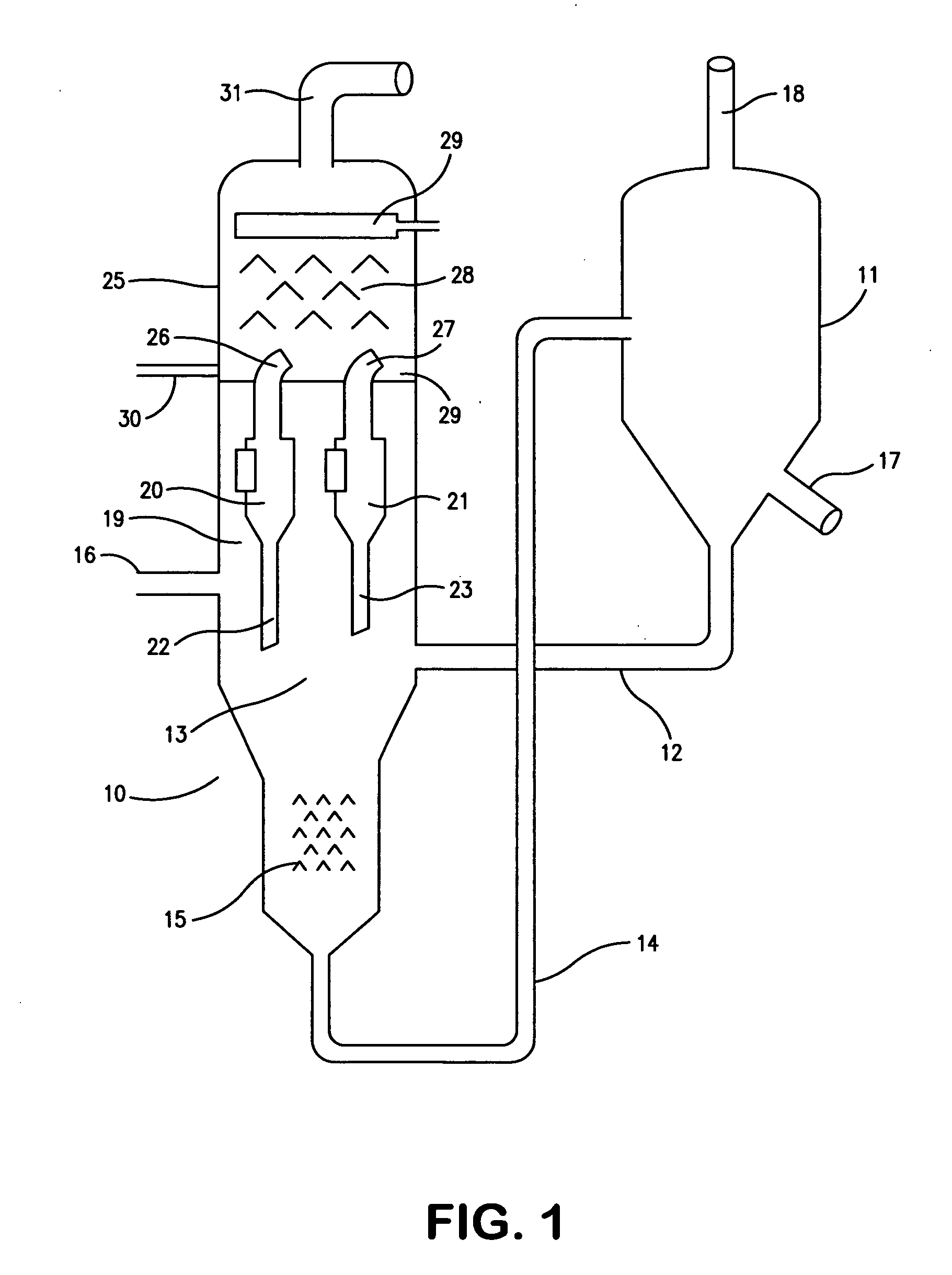

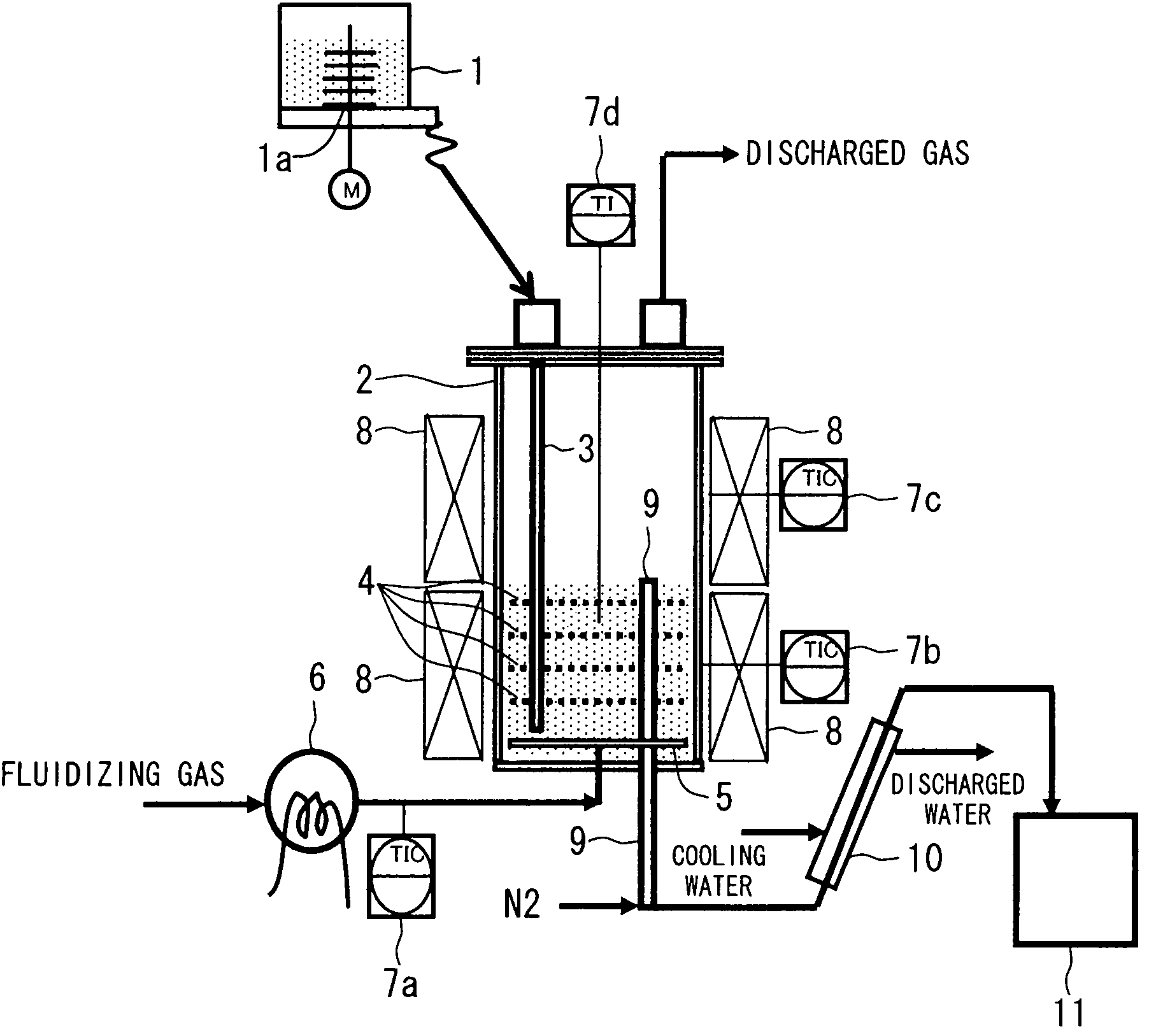

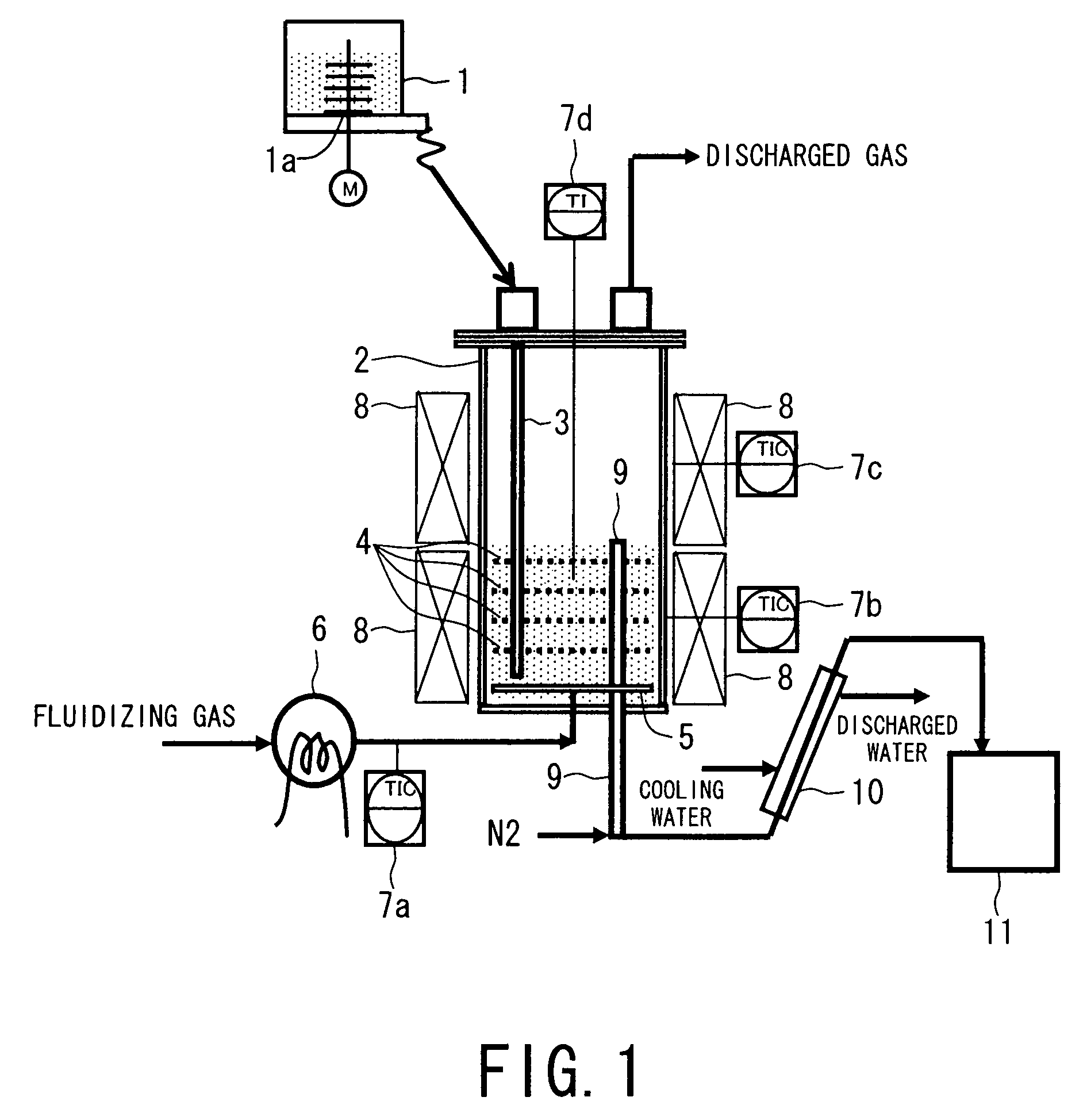

Process for pyrolyzing carbonaceous feedstocks

InactiveUS6814940B1Reduce gas velocityReduce dwell timeThermal non-catalytic crackingMuffle furnacesProcess engineeringProduct gas

The present invention concerns a process and an apparatus for thermal conversion of biomass and organic wastes. According to the invention, the feedstock is fed into a fluidized-bed reactor, wherein the feed is converted at an elevated temperature under the influence of particulate matter kept in a fluidized state by a fluidizing gas, the particulate matter is transferred from the reactor to a regenerator for regeneration and then recirculated to the reactor after the regeneration, and the converted hydrocarbon products are recovered from the reactor. Both the reactor and the regenerator comprise risers having an axially annular cross section and being equipped with multi-inlet cyclones for the separation of particulate matter. By means of the invention, it is possible to producer pyrolysis oil, the quality of which is higher than that of oil produced with the processes of the prior art. The incorporation of multi-inlet cyclones into the reactor configuration reduces gas velocities, reduces the physical size of the cyclone and shortens the residence time of gases in the cyclone.

Owner:FORTUM OY

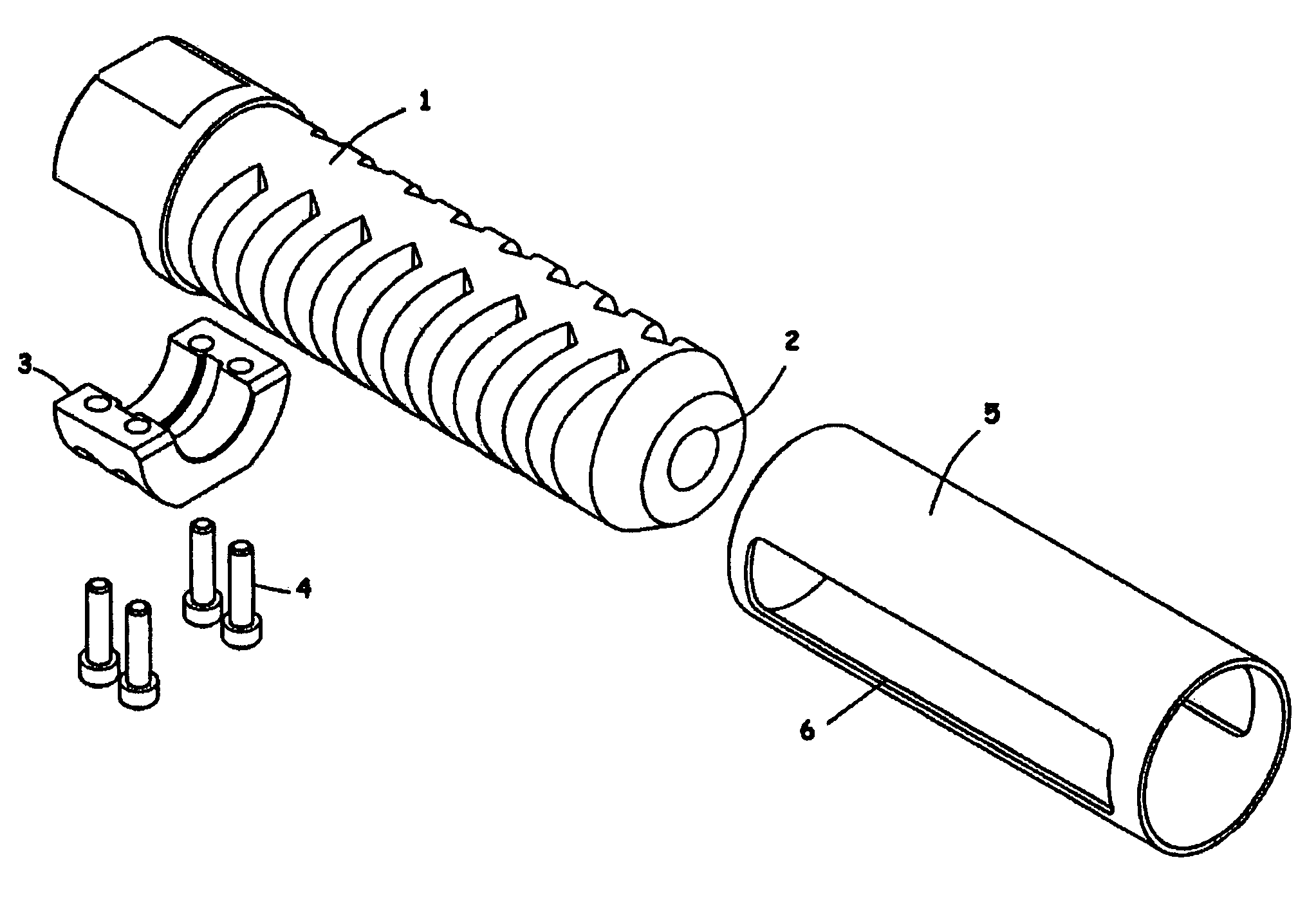

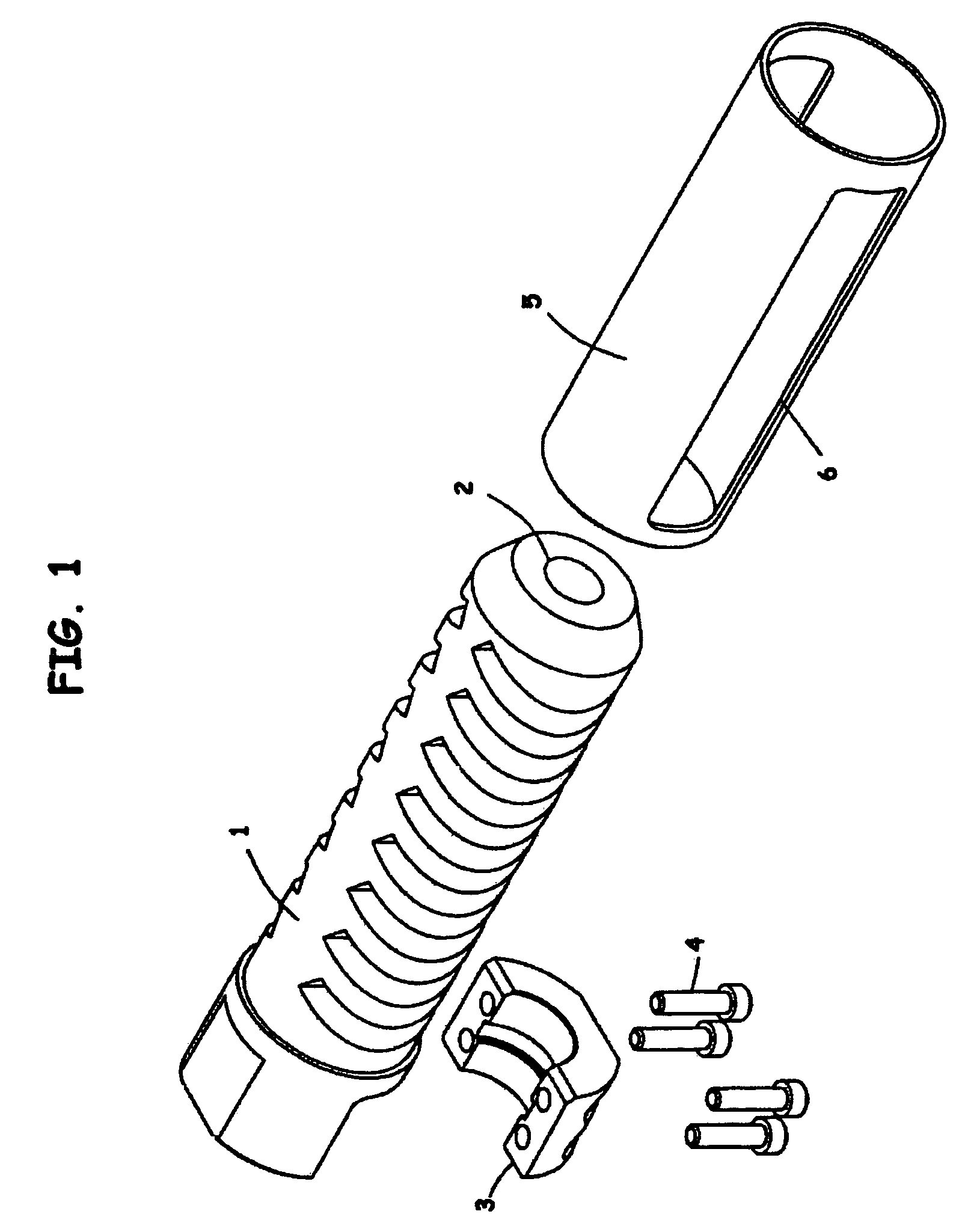

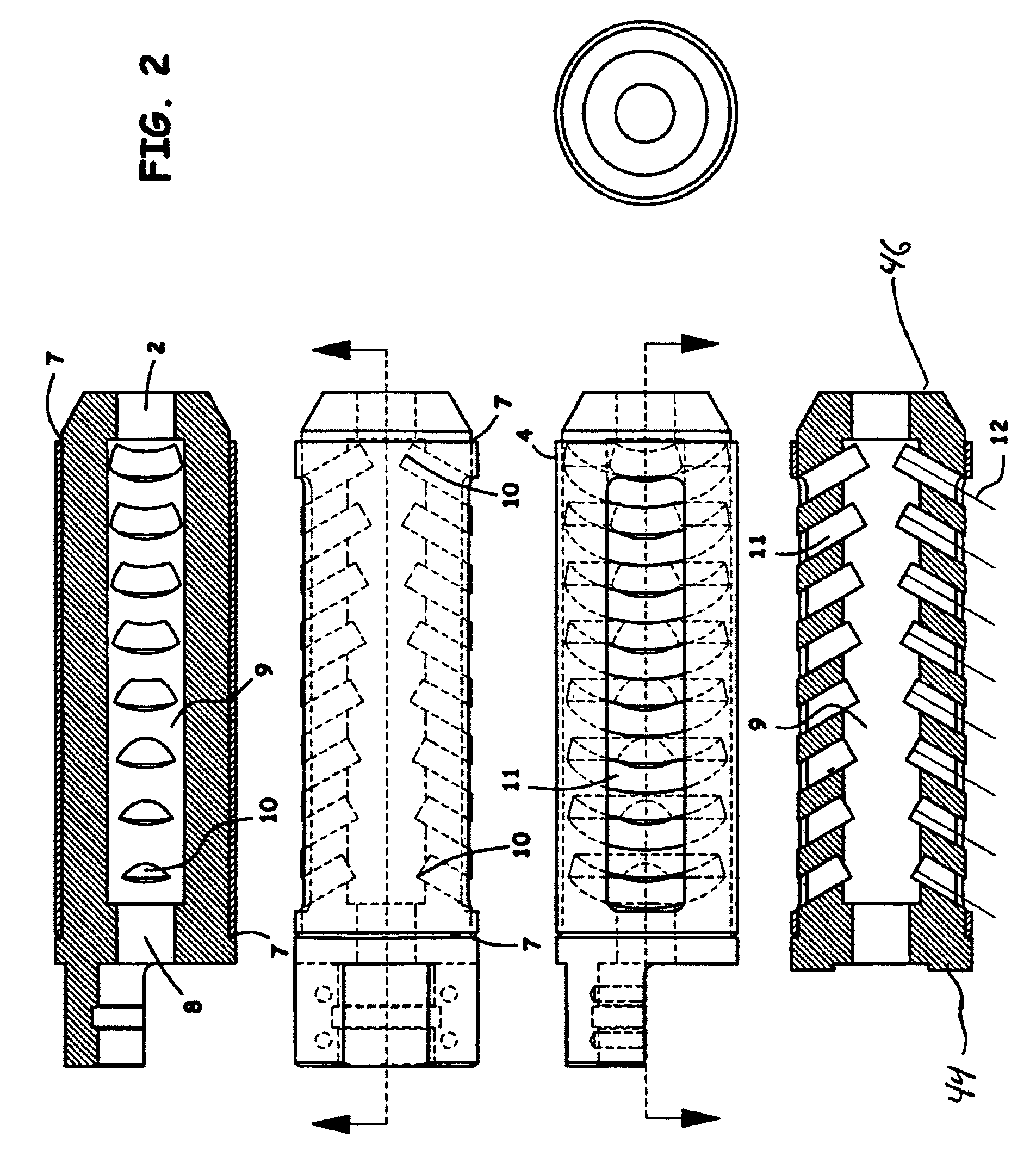

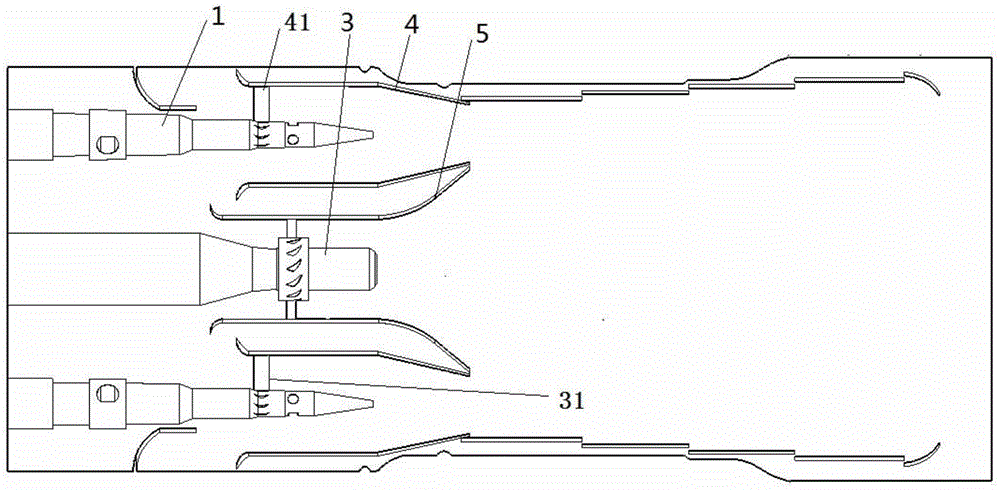

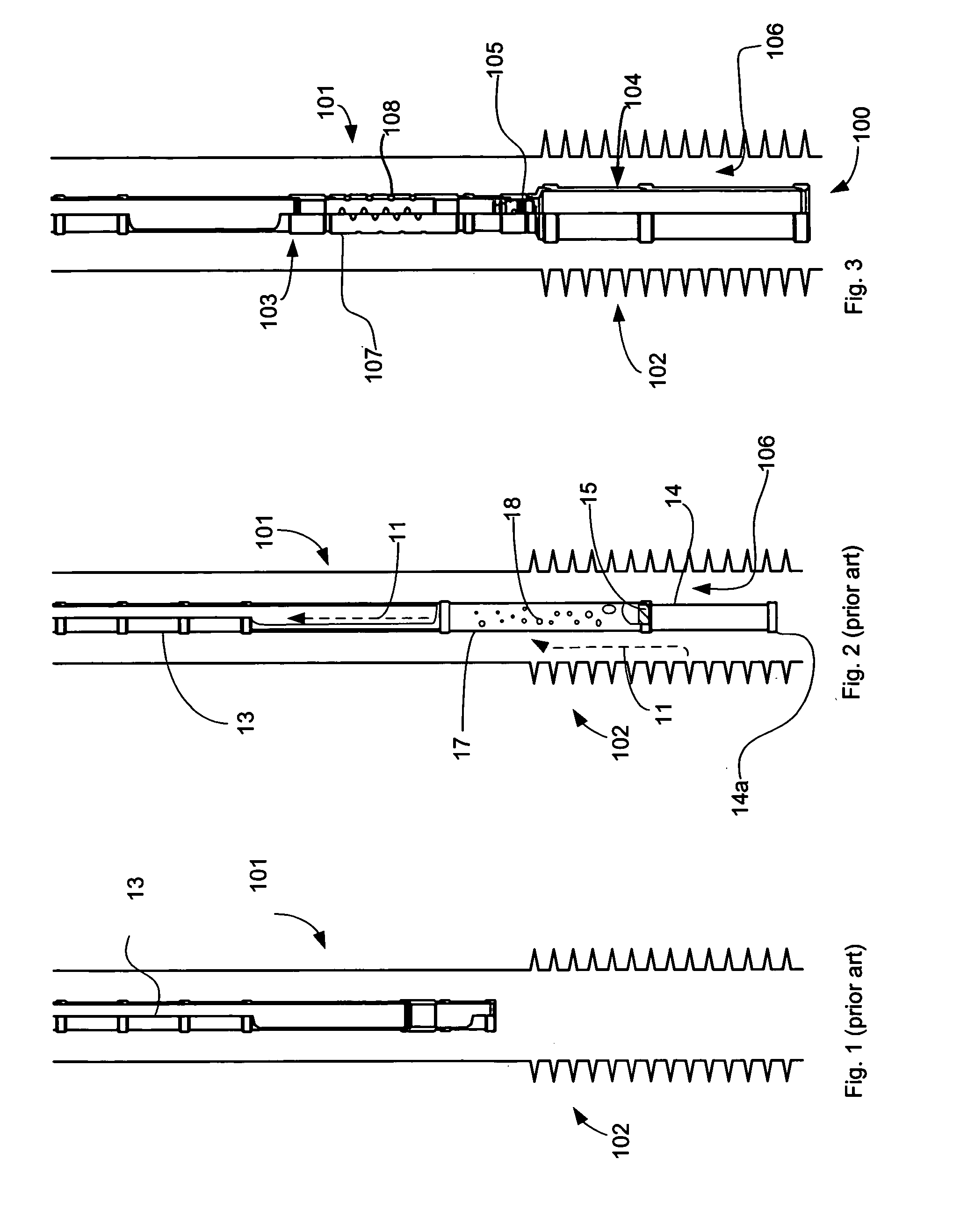

Recoil and muzzle blast dissipator

A recoil and muzzle blast dissipator may be attached to the barrel of a gun and may redirect propellant gasses. In one embodiment, a recoil and muzzle blast dissipater may include a body portion having an internal plenum and a plurality of vent slots, each vent slot having an aperture in communication with the internal plenum. Each successive vent slot may include an aperture that is larger in area than the aperture of the previous vent slot. An exterior tube may include a side port and may be arranged to overlay the body portion such that a portion of each vent slot is covered by the exterior tube, and a portion of each vent slot is in communication with the side port.

Owner:BENDER TERRENCE D

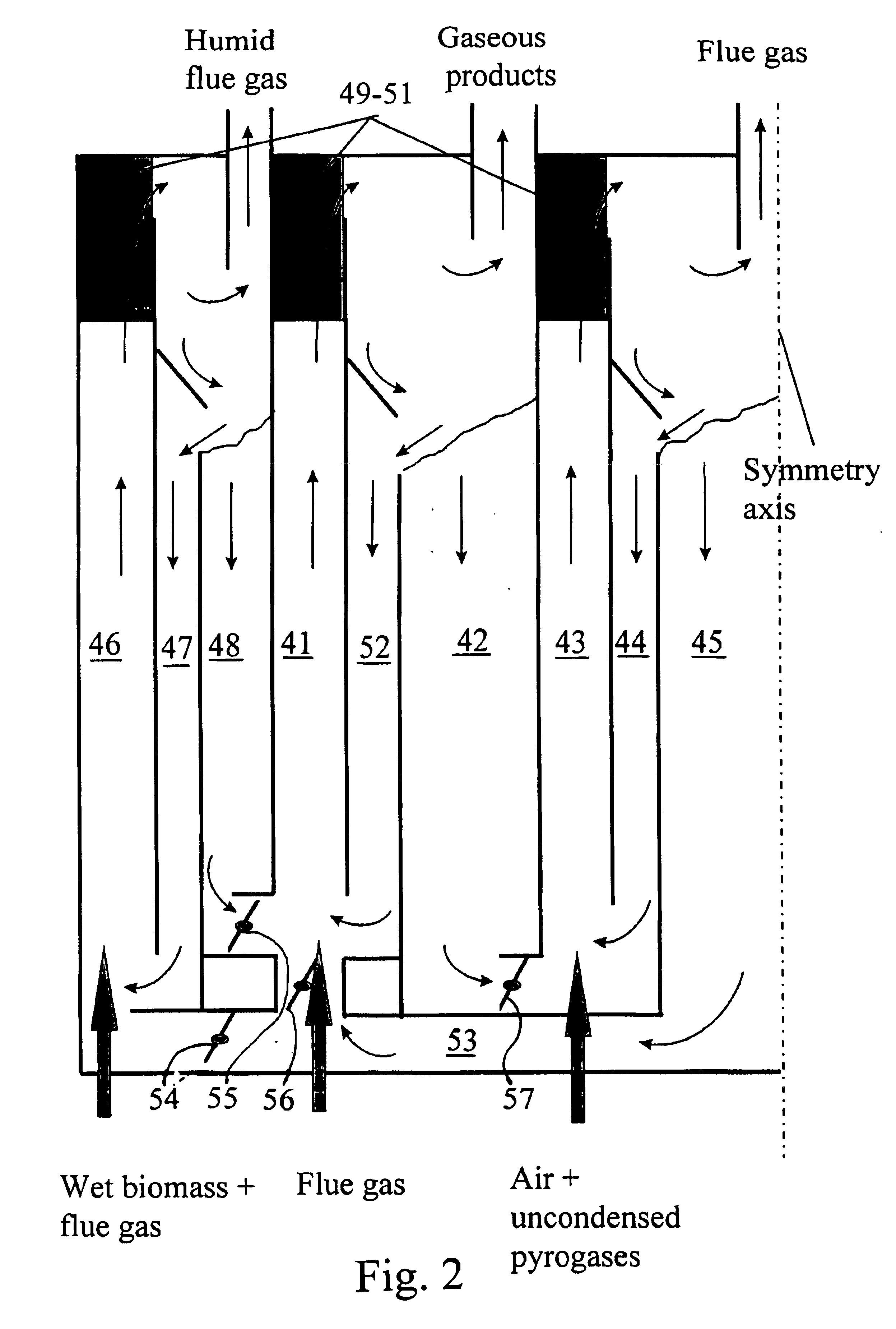

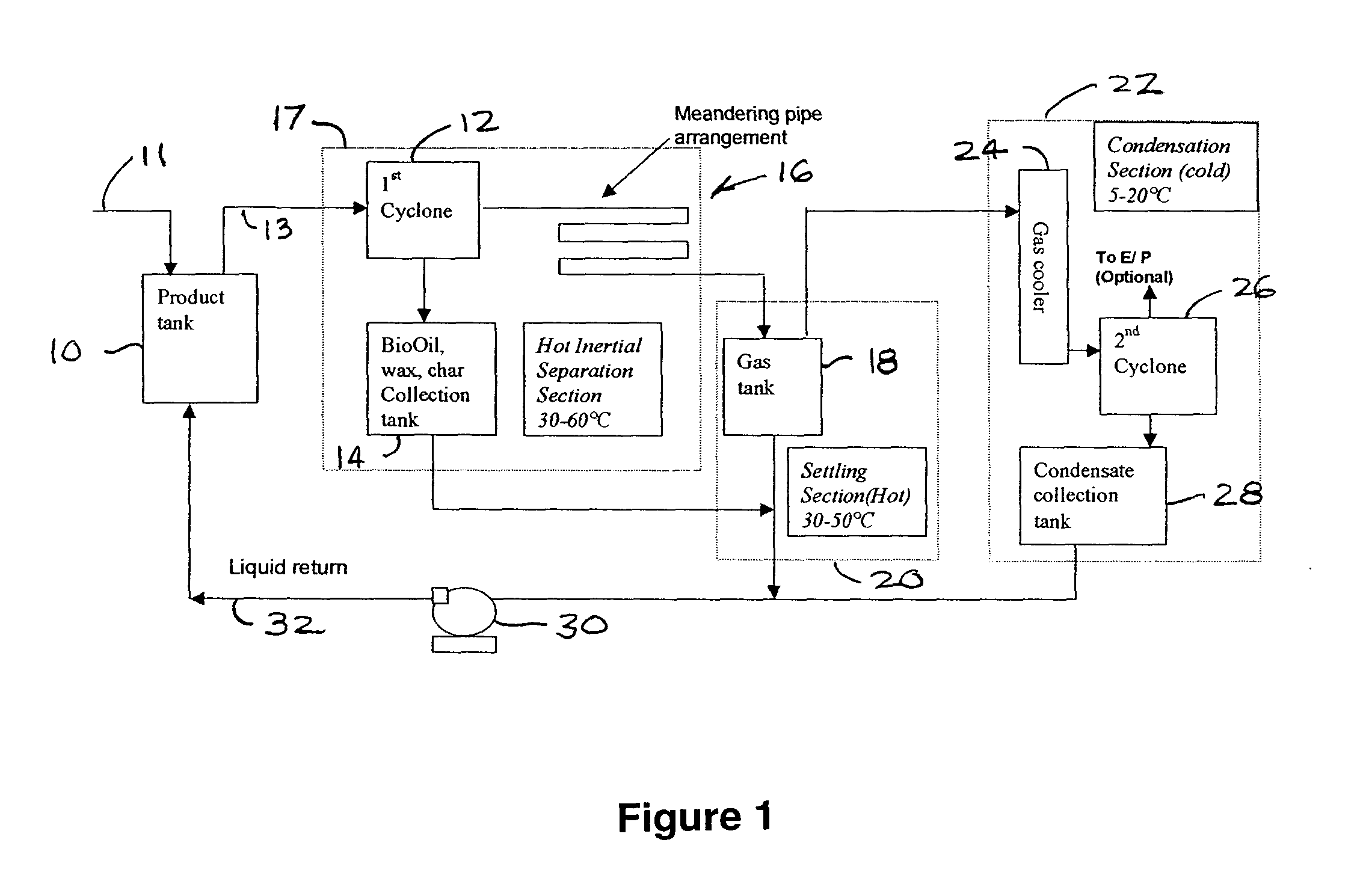

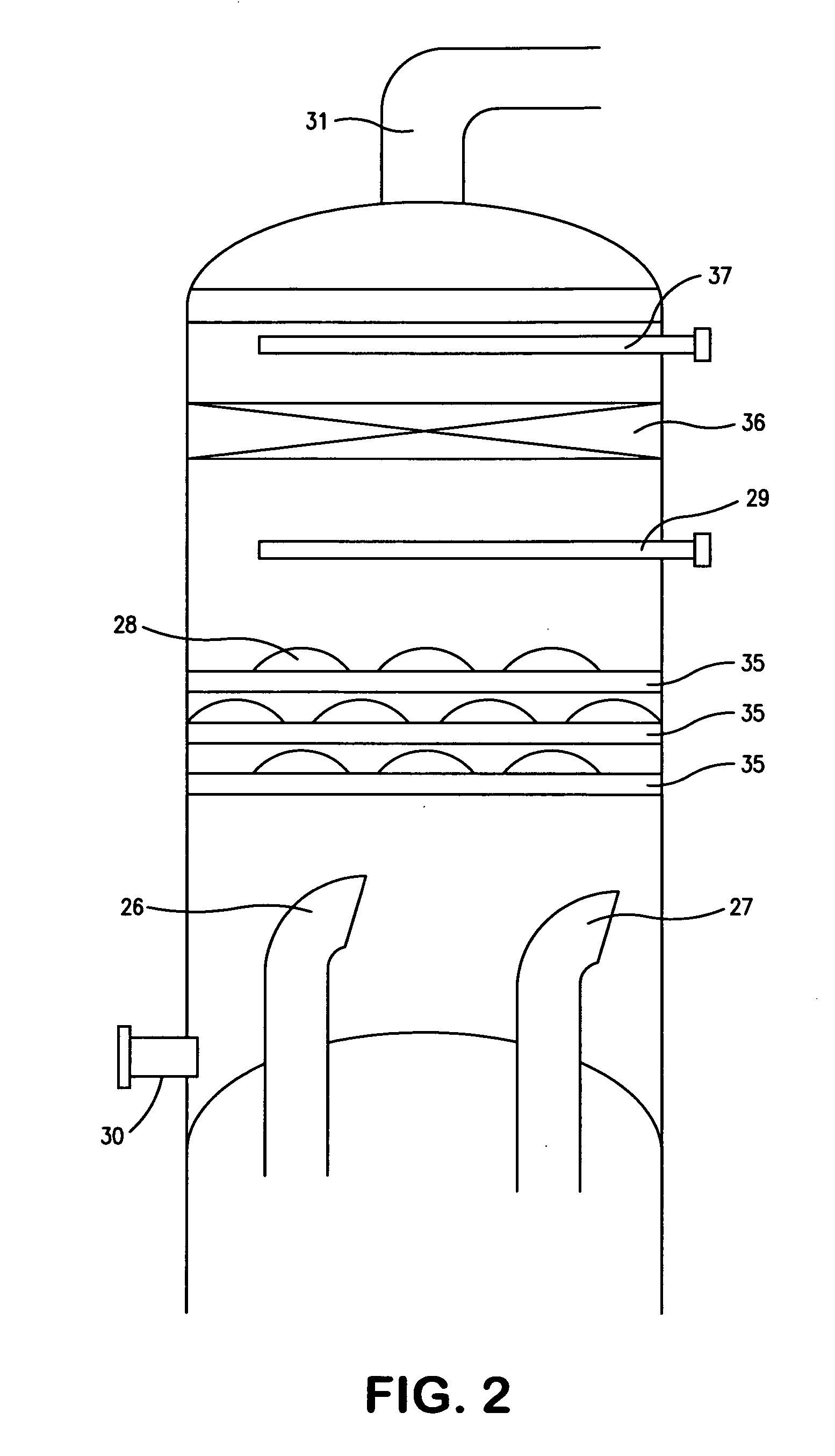

Apparatus for separating fouling contaminants from non-condensable gases at the end of a pyrolysis/thermolysis of biomass process

InactiveUS20050039599A1Avoid inefficienciesInefficient operationCombination devicesLiquid degasificationComponents of crude oilViscosity

A method of continuously capturing BioOil and its constituents from a gas stream produced in a fast pyrolysis / thermolysis process, in a usable liquid form so as to produce a non-condensable gas free of fouling contaminates. The method includes separating BioOil and its constituents from a gas stream using hot inertial separation to maintain the temperature of said BioOil and its constituents above a temperature at which the thick and / or sticky constituents cause inefficient operation of the equipment but low enough so that they do not undergo rapid degradation. Next the gas velocity is reduced to a temperature sufficiently low to allow droplets in the gas stream to settle out but high enough so that a viscosity of said droplets remains low enough to avoid inefficient operation of the separation equipment. Finally, liquid is condensed out of the gas stream.

Owner:DYNAMOTIVE ENERGY SYST CORP

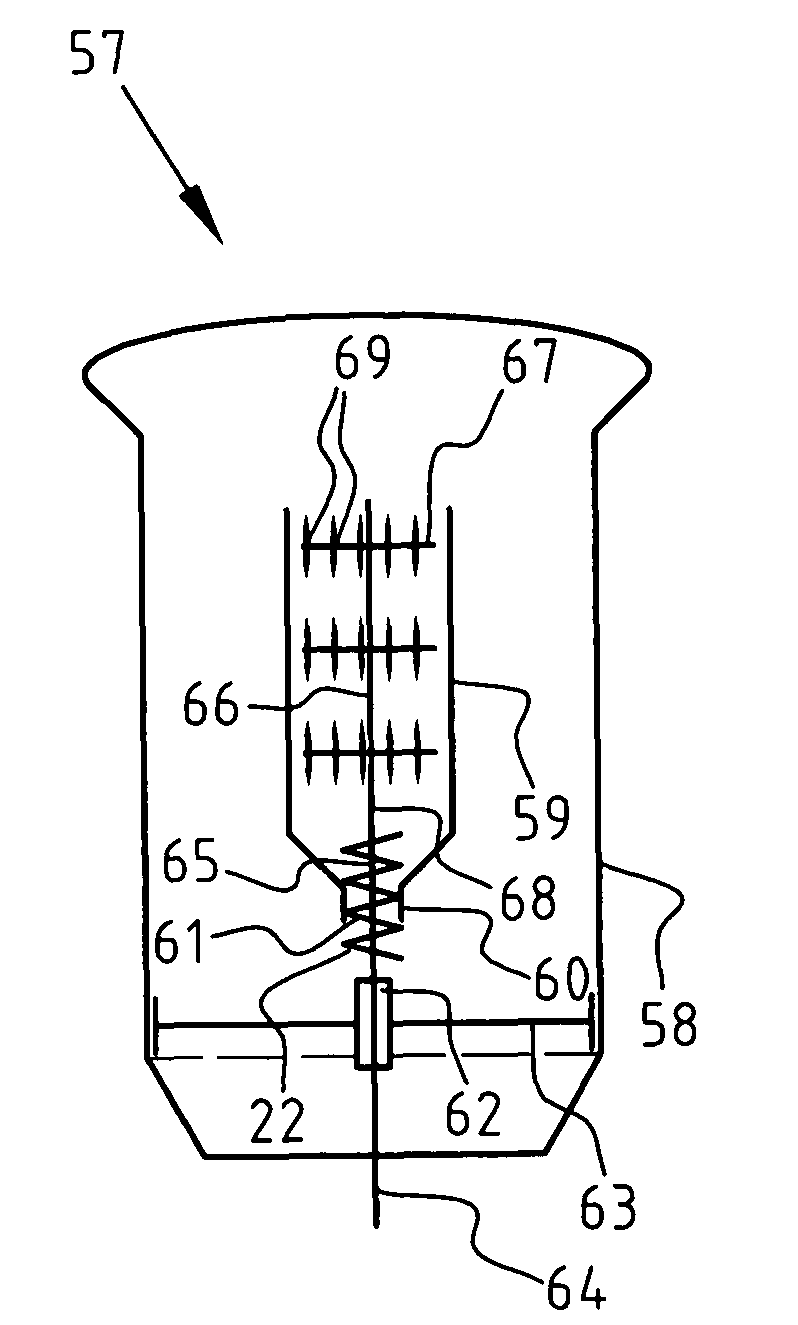

Reactor system and process for the catalytic polymerization of olefins, and the use of such reactor system in catalytic polymerization of olefins

InactiveUS8354483B2Easy to controlReduce gas velocityChemical/physical/physico-chemical stationary reactorsFluidised-bed furnacesReactor systemFluidized bed

The invention relates to a reactor system and process for the catalytic polymerization of olefin monomer and optionally comonomer(s), having one or more inlets for olefin monomer, catalyst, optionally for comonomer, chain growth controllers or chain transfer agents, and / or inert gas, an outlet for gas and an outlet for polymerized particles. The reactor system has at least one fluidized bed unit and at least one moving bed unit, wherein the fluidized bed unit has means for maintaining a fluidized bed in the fluidized bed unit and wherein the moving bed unit is provided with an inlet and an outlet which are connected to the fluidized bed unit, wherein the outlet of the moving bed unit is provided with means for displacing metered quantities of polymerized particles from the moving bed unit into the fluidized bed unit, and to the use of such reactor system.

Owner:BOREALIS TECH OY

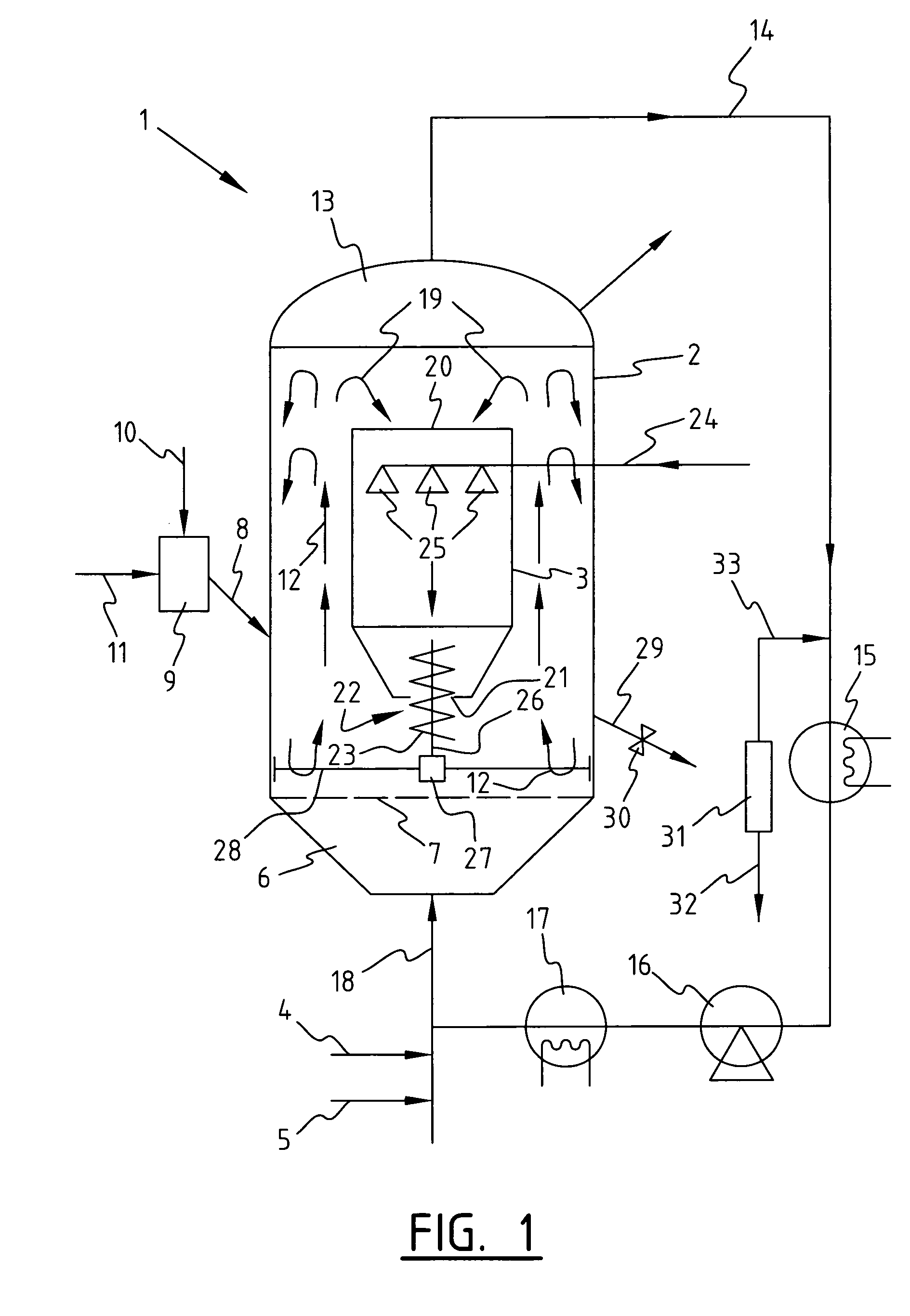

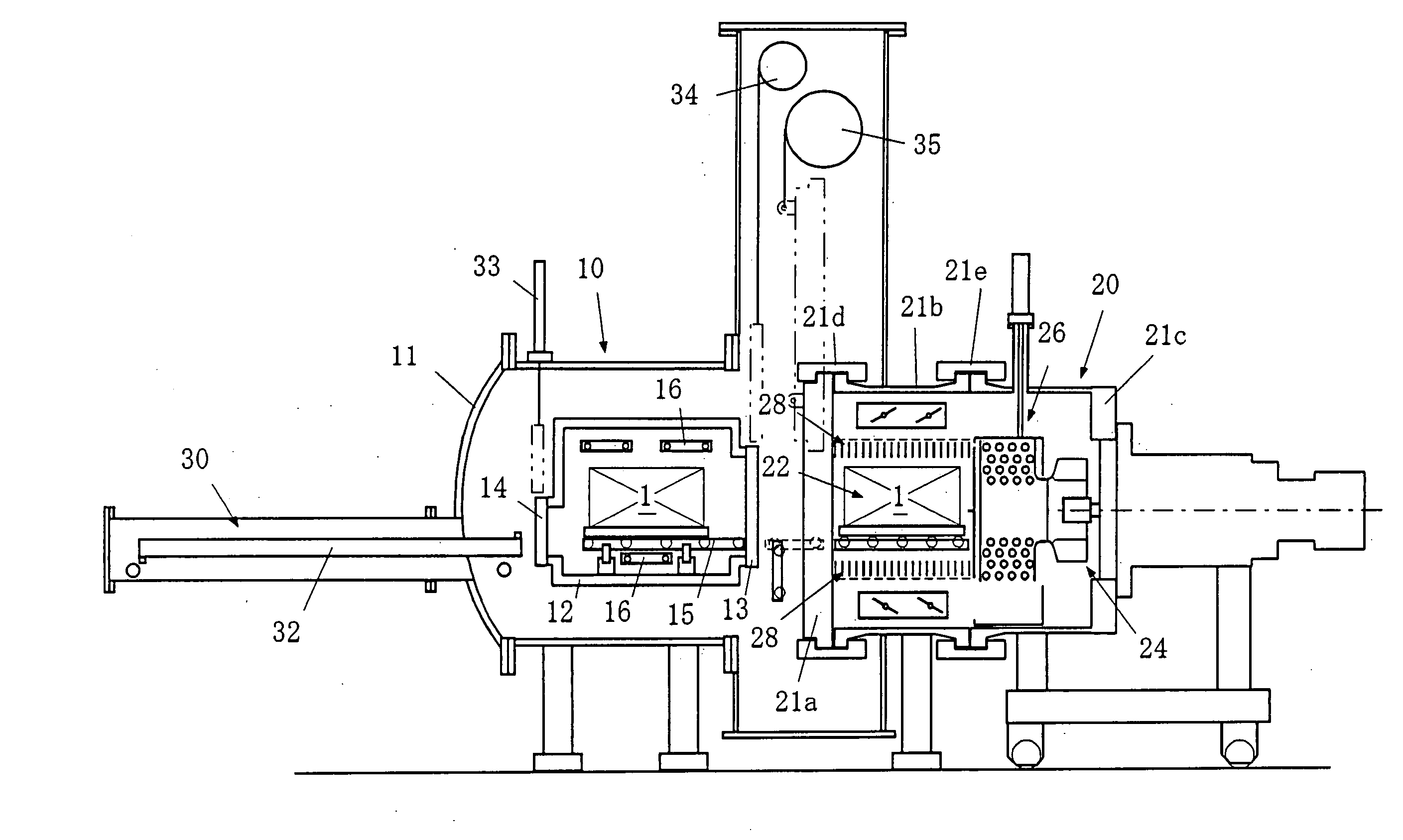

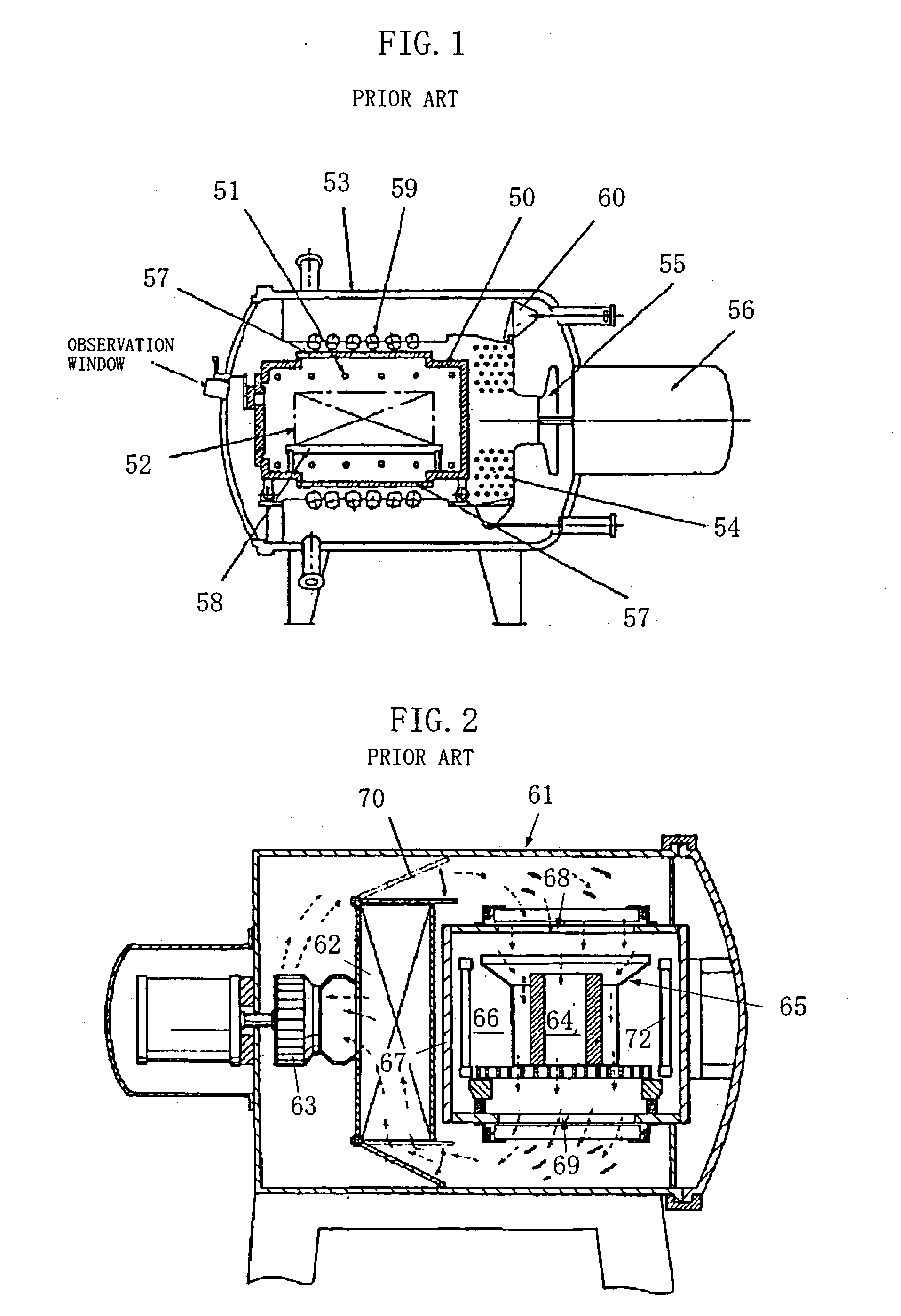

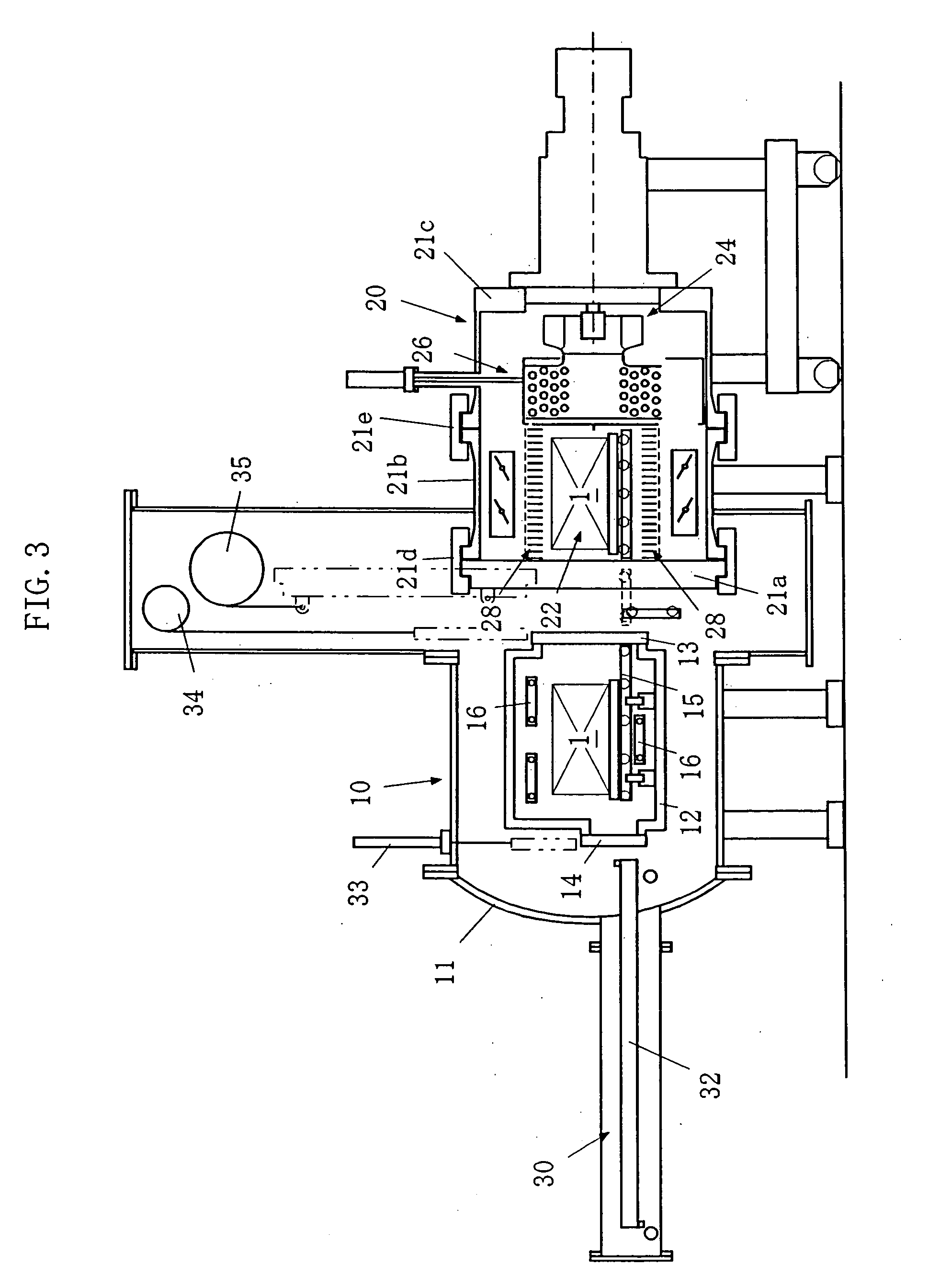

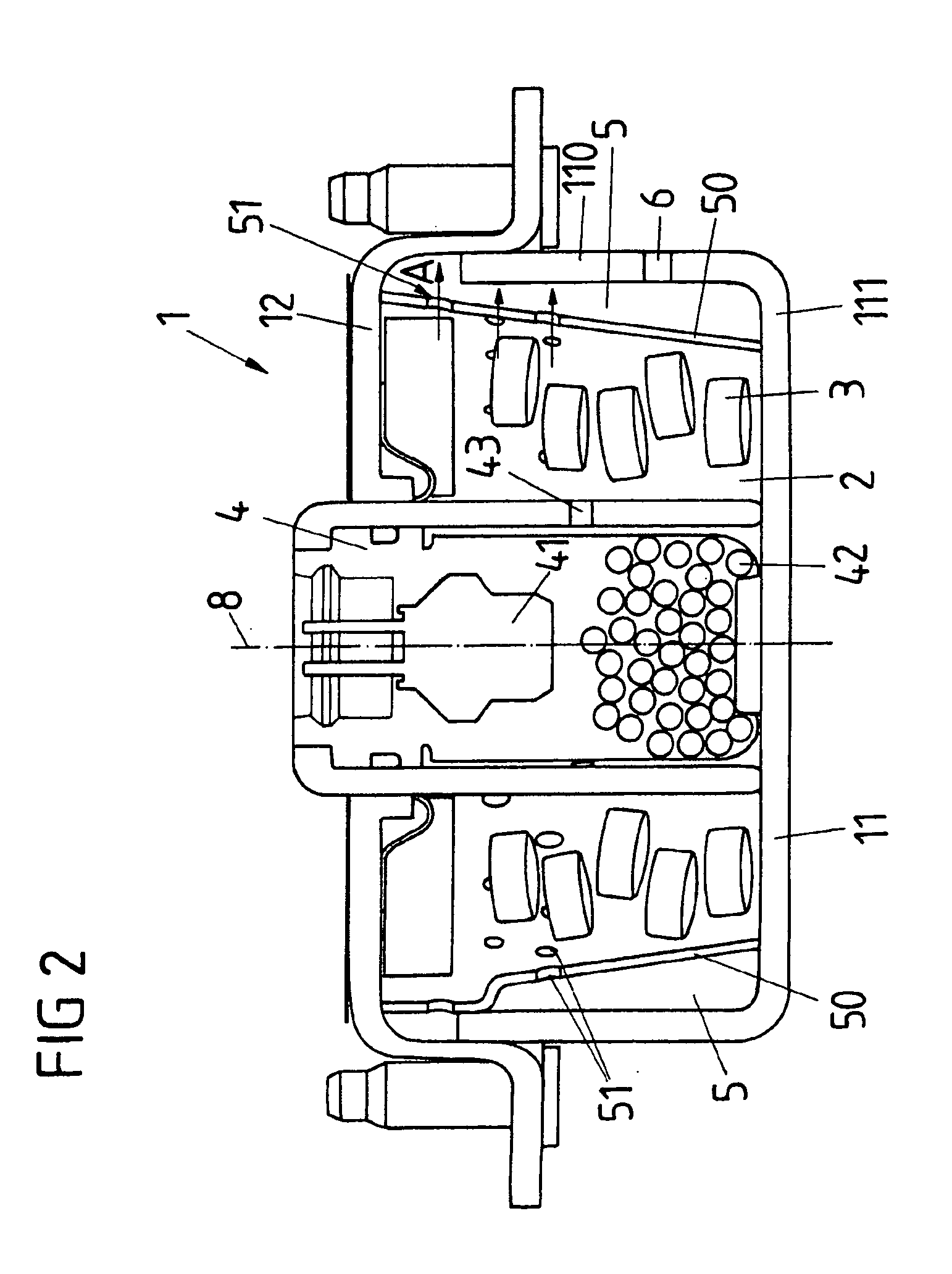

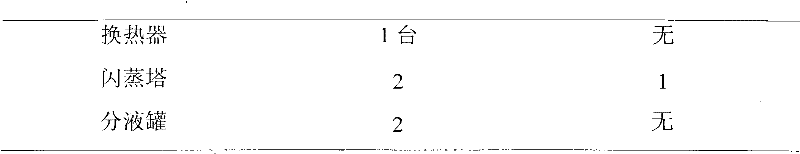

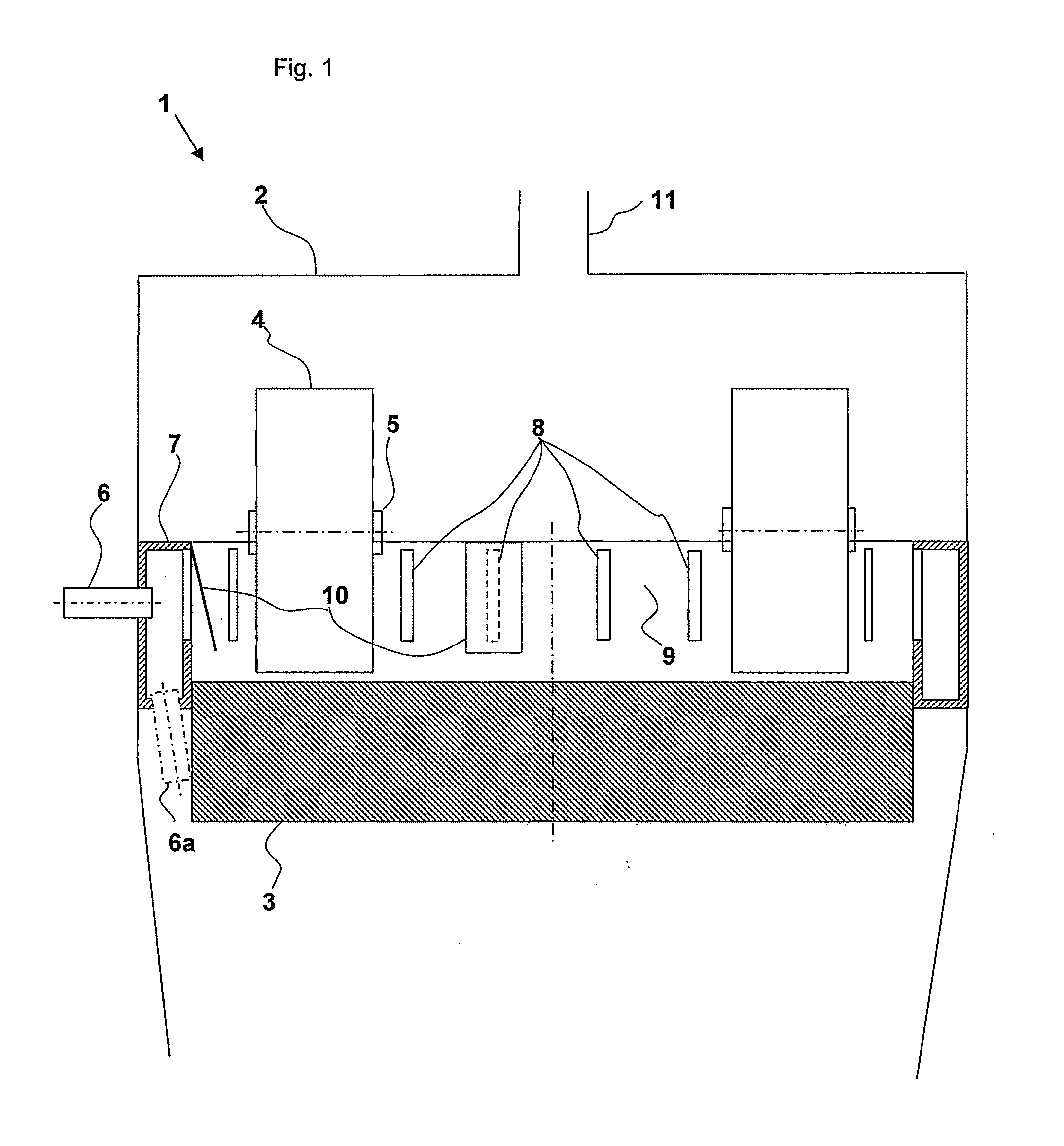

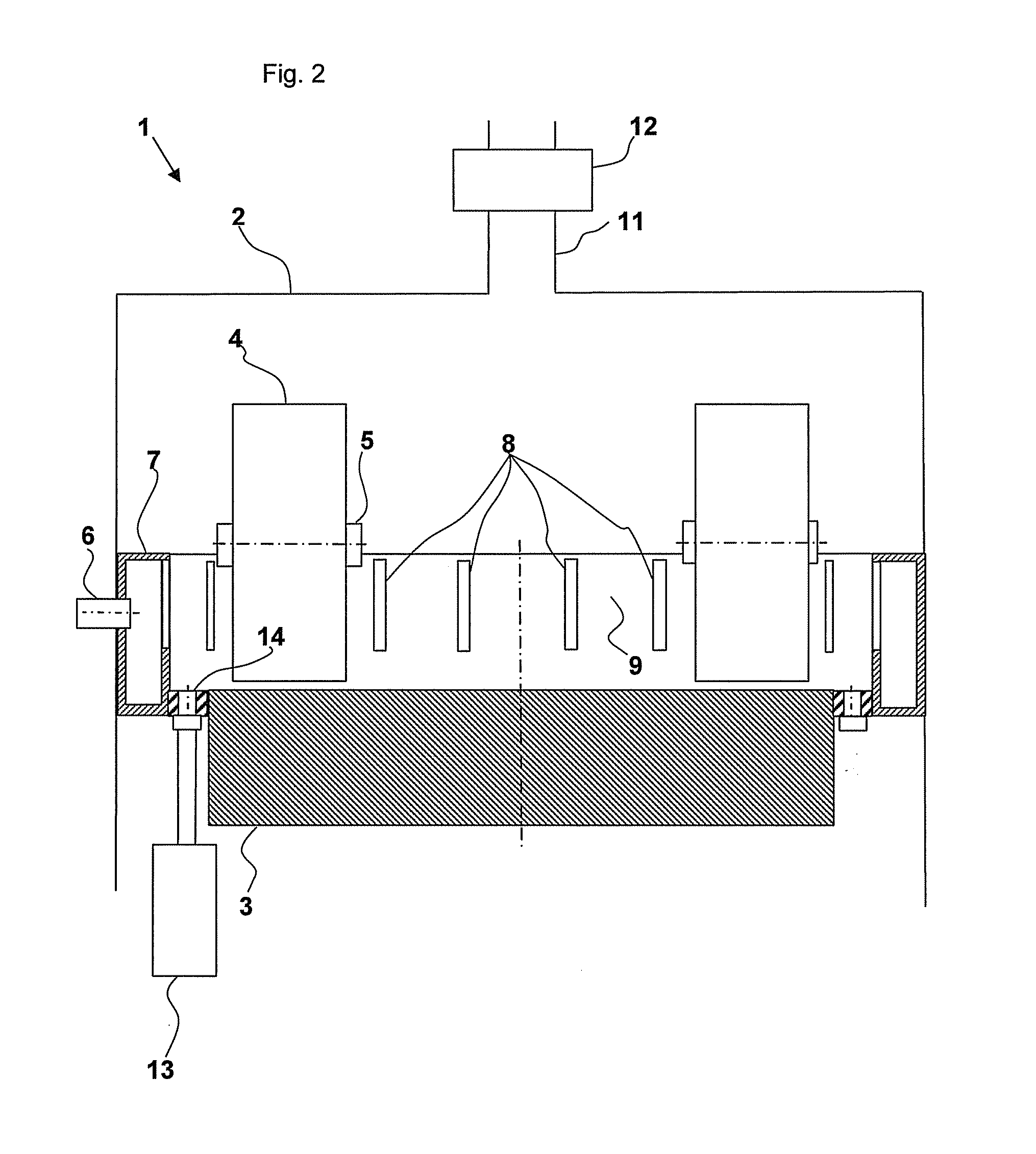

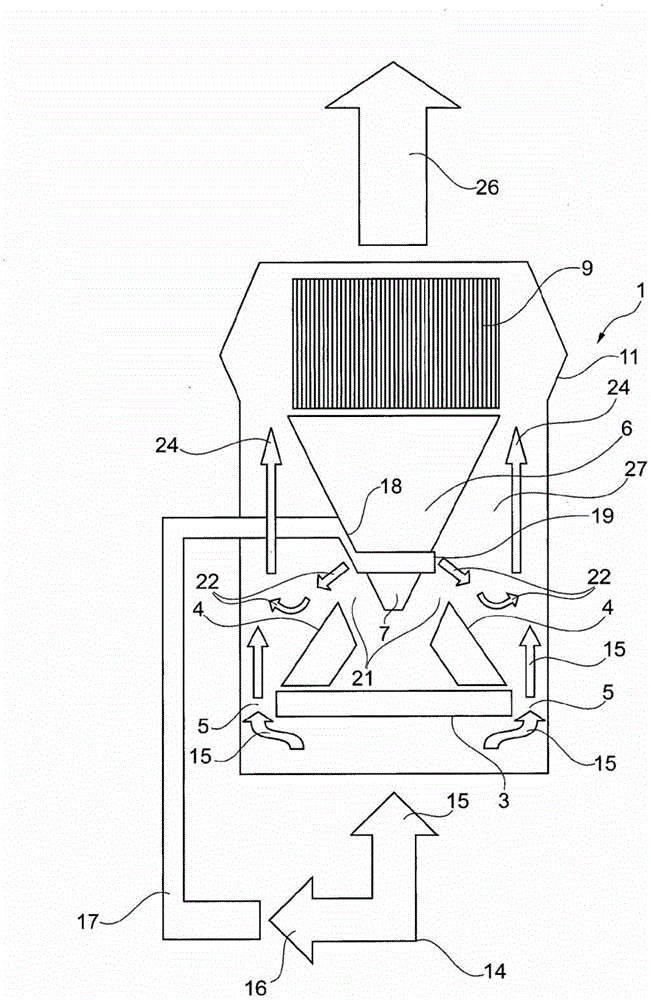

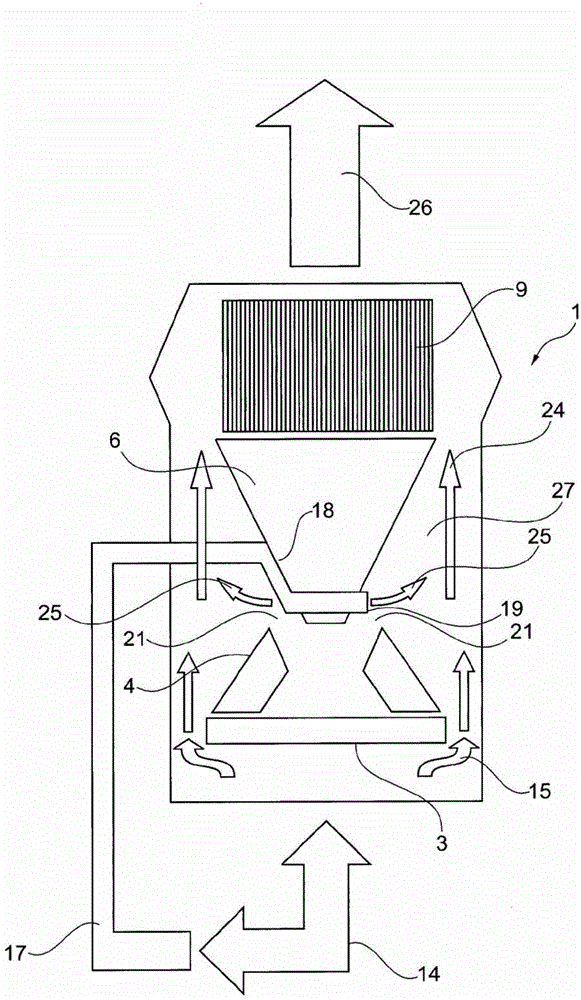

Gas cooling type vacuum heat treating furnace and cooling gas direction switching device therefor

InactiveUS20070122761A1Reduce gas velocityReduce total pressure lossMuffle furnacesMaintainance of heating chambersCooling chamberEngineering

A gas cooling type vacuum heat-treating furnace according to the present invention, includes a gas cooling furnace comprising a cooling chamber in which an article to be heat-treated is stationarily set, and defining therein a gas passage in a vertical direction, a gas cooling and circulating device for cooling and circulating gas flowing in the cooling chamber, a gas direction switching device for alternately changing over directions of gas vertically passing through the cooling chamber, and upper and lower straighteners blocking upper and lower ends of the cooling chamber, for causing a velocity distribution of the gas to be uniform.

Owner:IHI CORP

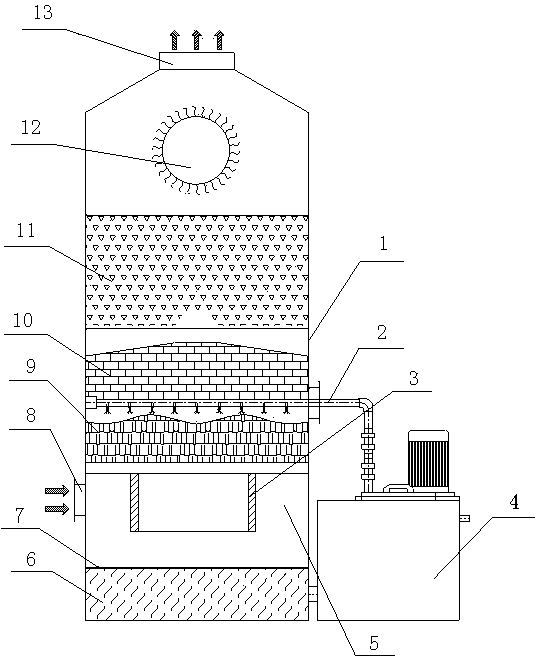

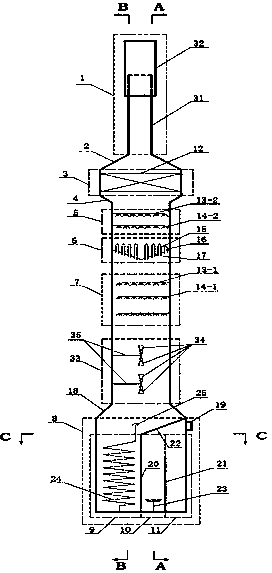

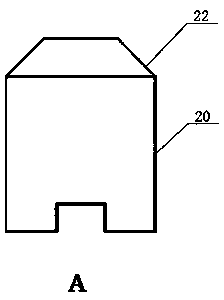

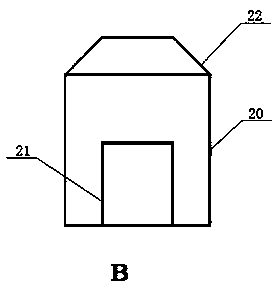

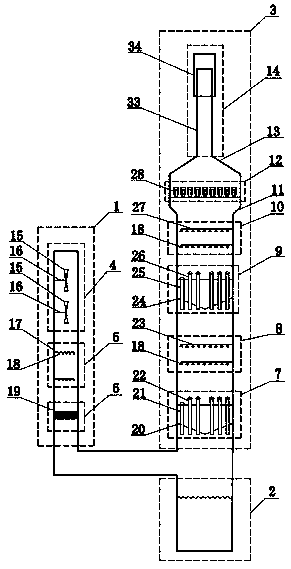

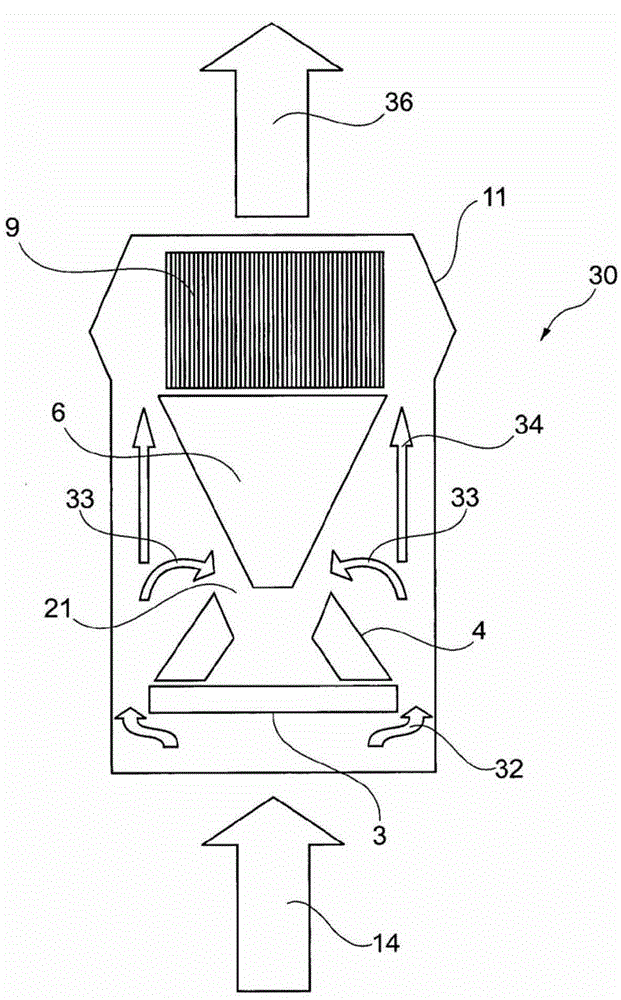

Waste gas purification tower

InactiveCN103638763ACreate pollutionReduce gas velocityCombination devicesRadiationActivated carbonExhaust fumes

The invention relates to a waste gas purification tower which comprises a purification tower body; the top of the purification tower body is provided with an exhaust hole; an air inlet hole is formed in one side surface of the bottom of the purification tower body; the purification tower body is internally and sequentially provided with a spray layer, a dehydration layer and an activated carbon layer from bottom to top; a photolysis purifier is arranged above the activated carbon layer; the bottom of the purification tower body is provided with a water storage device; a water outlet hole of the water storage device is connected with a water purification device; a water outlet hole of the water purification device is connected with a spray pipe in the spray layer. Larger particles of dust can be left on a filter screen, the speed of waste gas entering the spray layer is slowed down, small particles of the dust can be reserved by spraying, oil fume in the waste gas can be decomposed by the photolysis purifier, and formed carbon dioxide and water can be directly discharged outside; after the waste gas purification tower is adopted, the odor and bacteria in the waste gas can be removed, the waste gas is not required to be purified for a second time after being purified and can be directly discharged into the air, and the environment is not polluted.

Owner:KUNSHAN YICHENG CHEM VESSEL

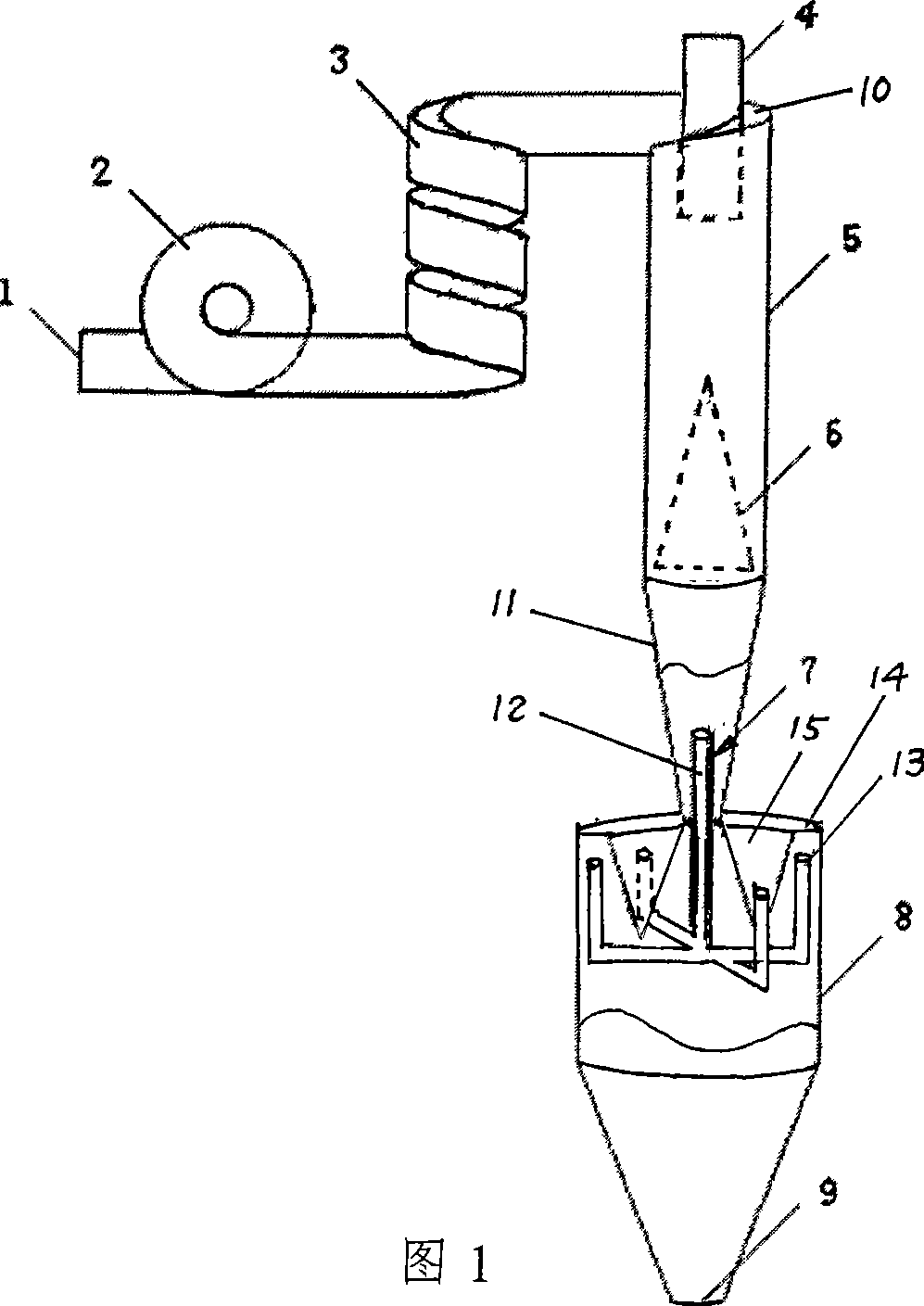

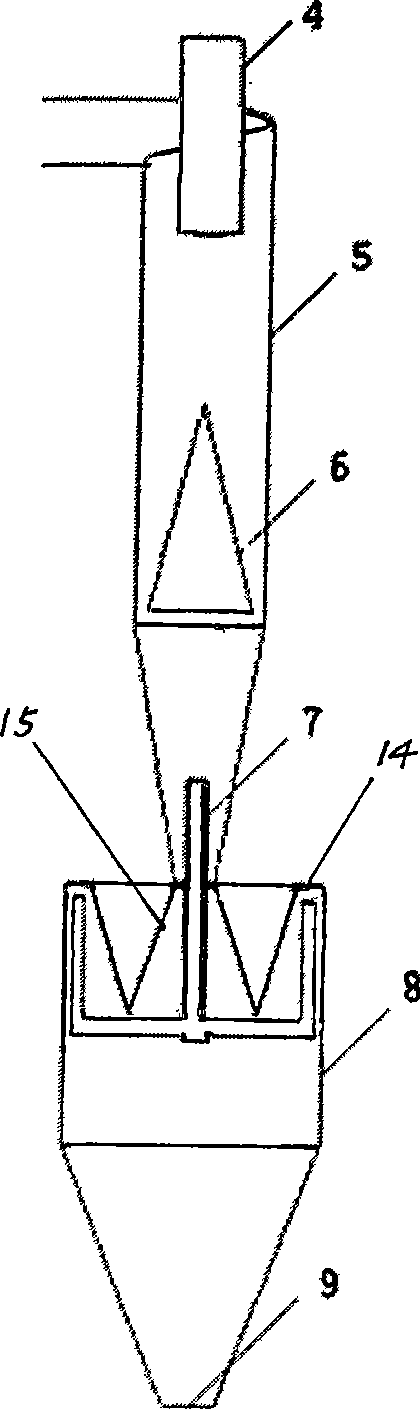

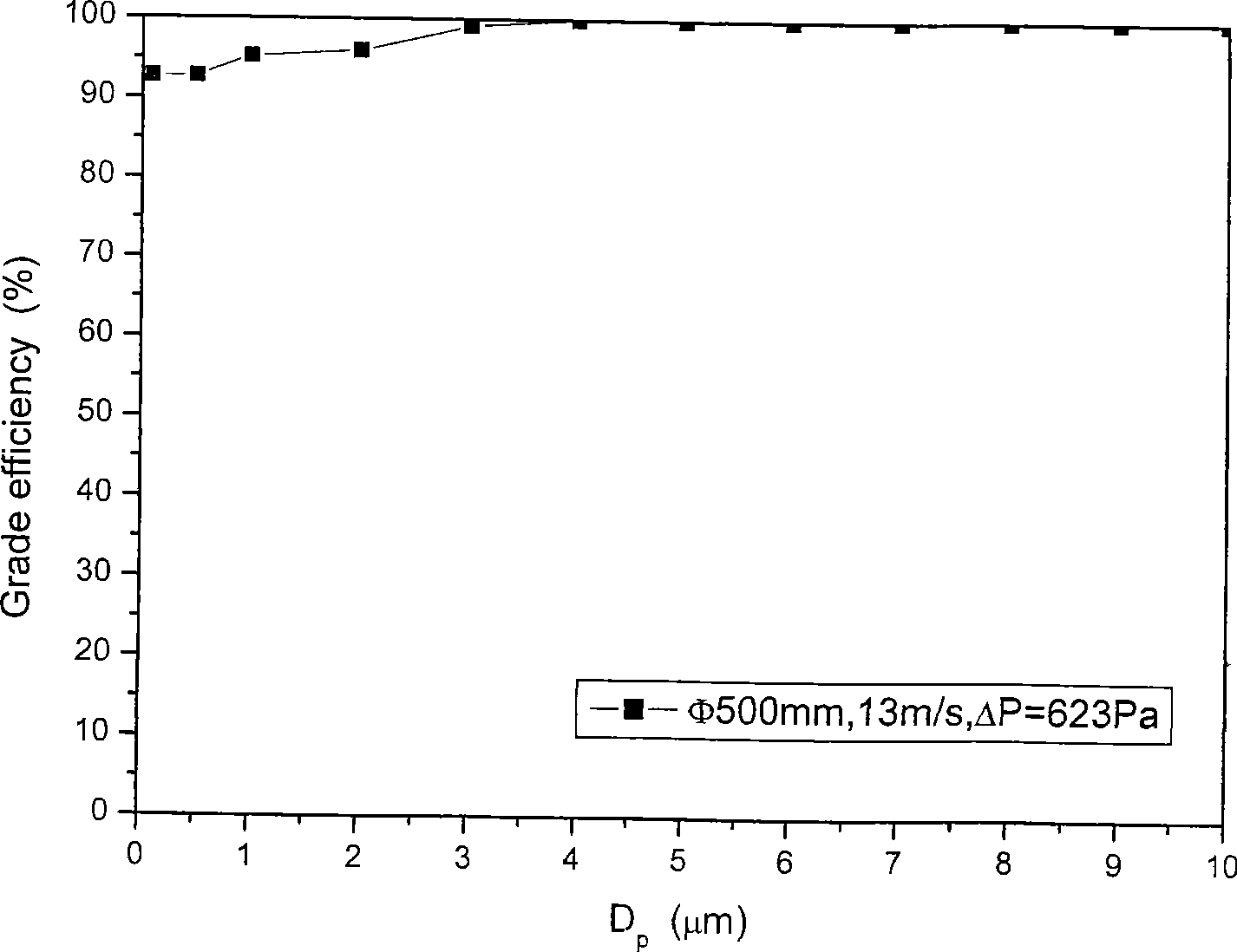

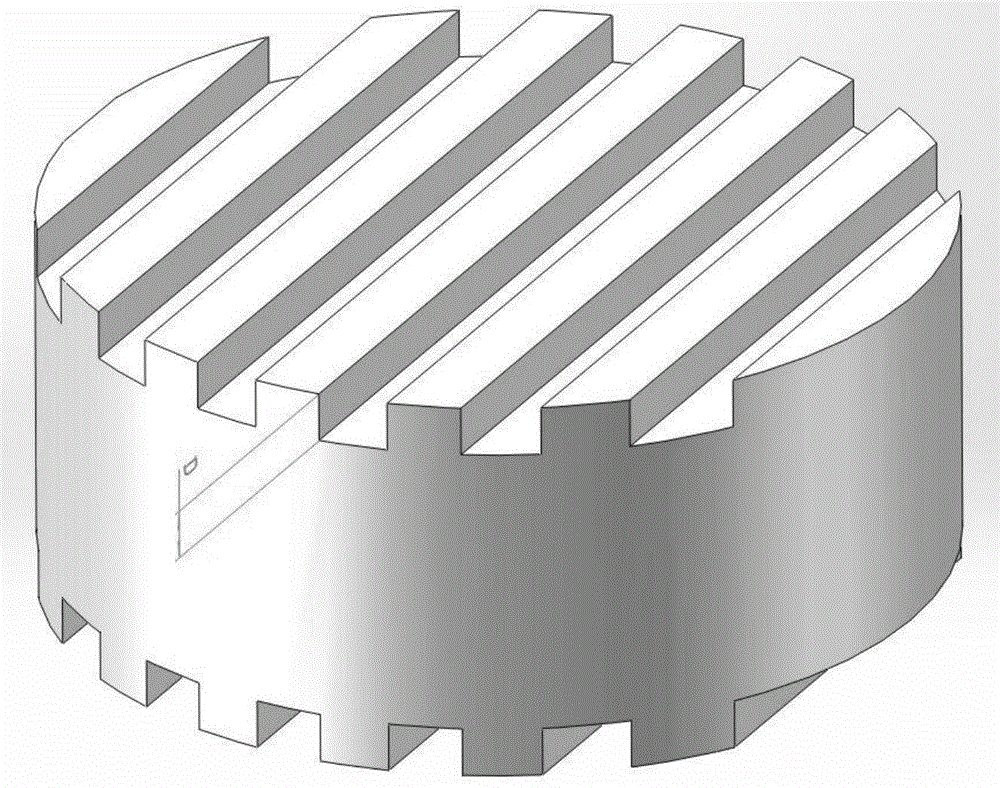

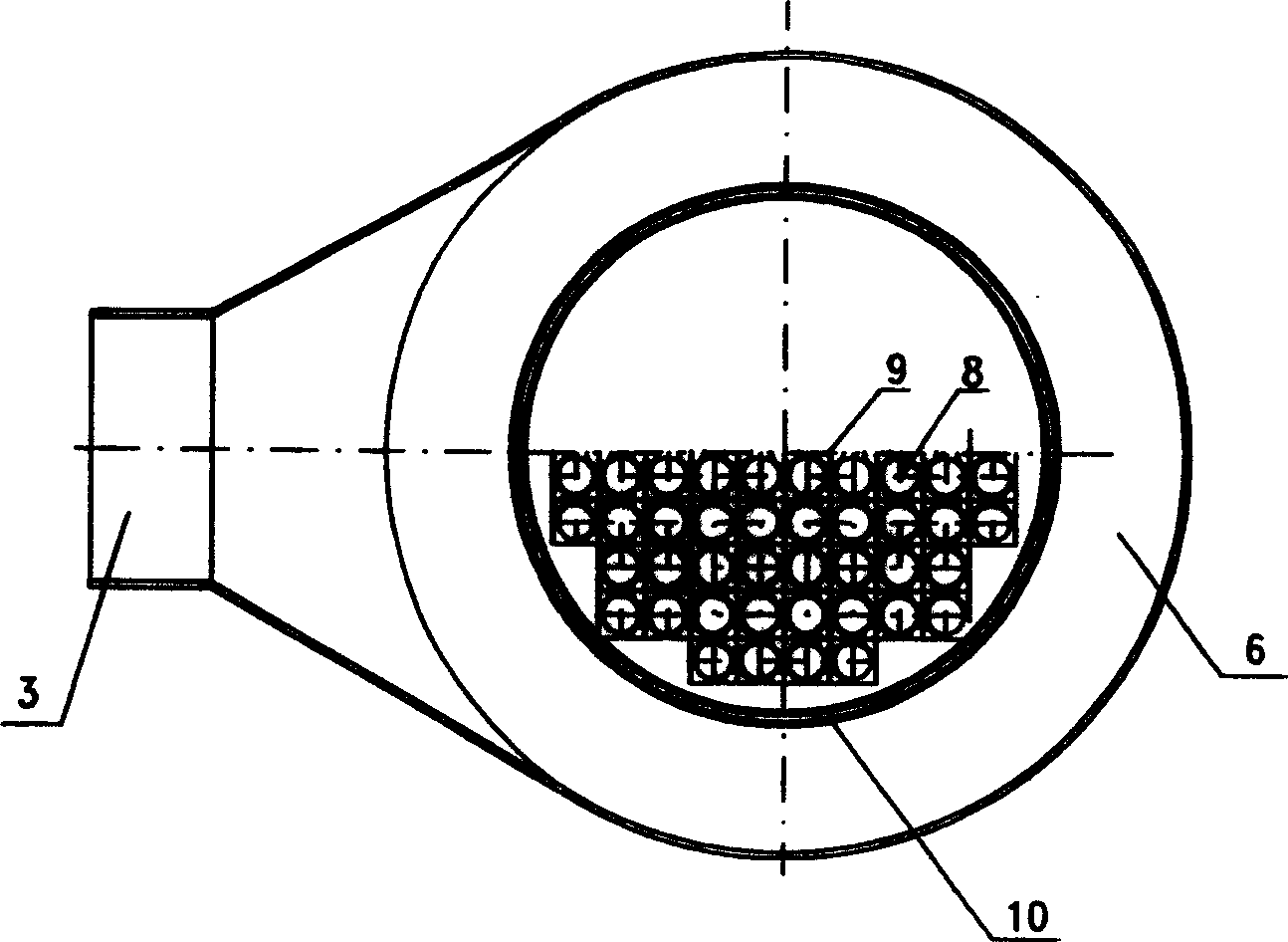

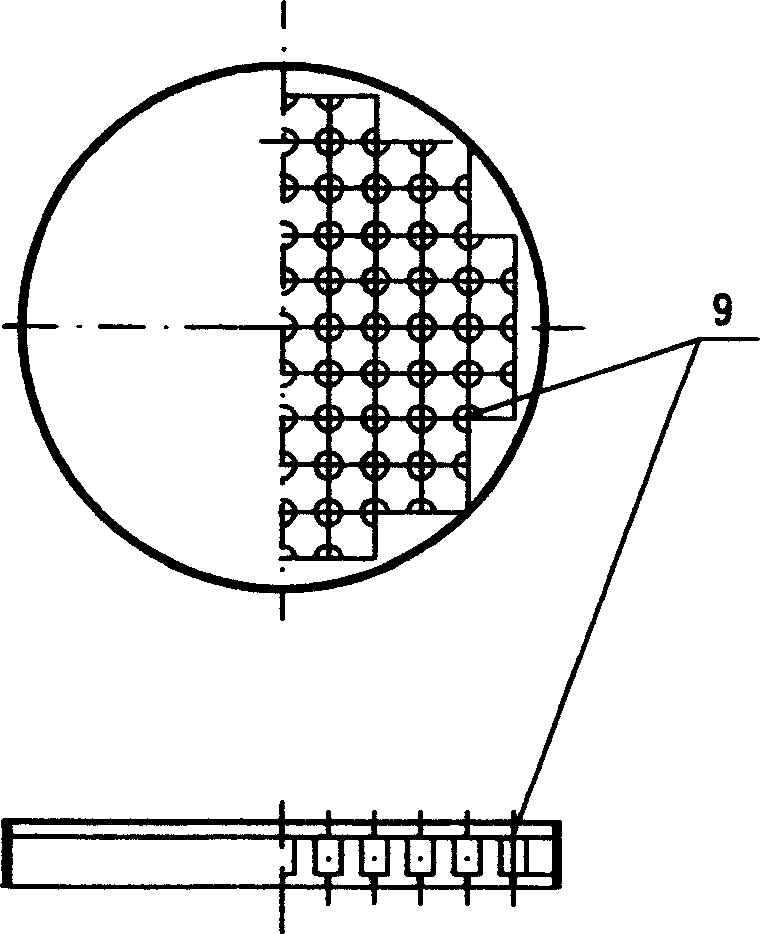

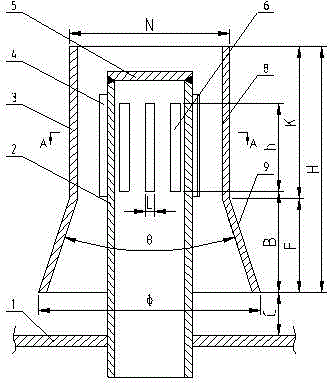

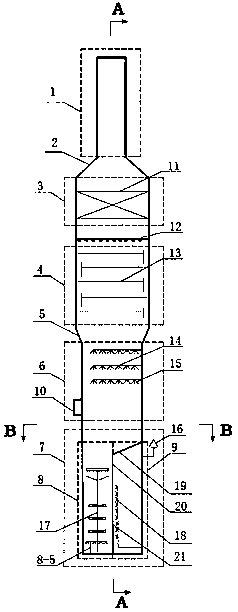

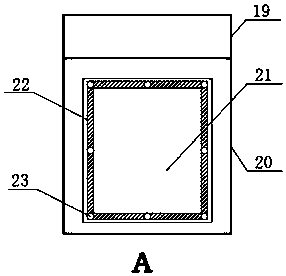

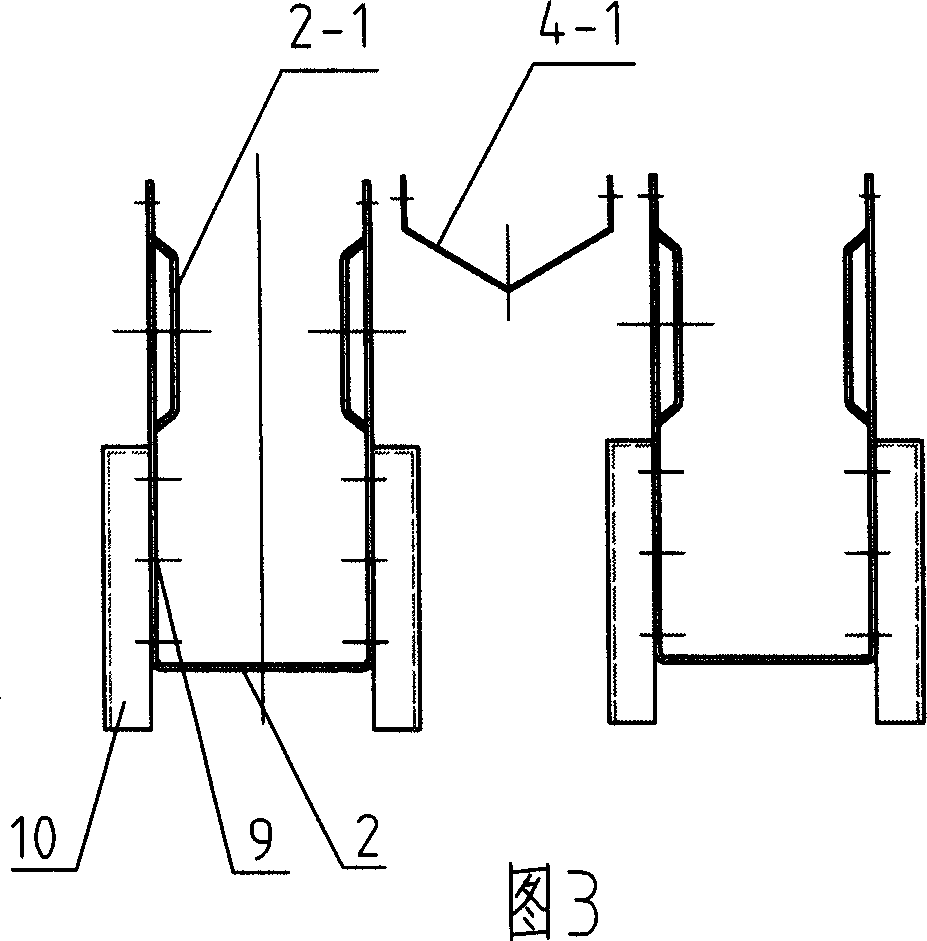

Multiple-effect cyclone separating device

InactiveCN101391239AReduce gas velocityStable flow patternReversed direction vortexCycloneEngineering

Disclosed is a multi-effect cyclone separator. A shell of a main body of the separator comprises an upper cylinder, a spiral top cover plate and a lower reverse conical cylinder. An air exhaust pipe extends into the cylinder. An ash bin is fixed at the lower end of the reverse conical shell. An air inlet is tangentially arranged at the upper end of the cylinder through a vertical Alpha-shaped first grade pre-separating spiral tube and a second grade pre-separating spiral tube sequentially connected with each other. The cross sections of the air inlet as well as the first grade pre-separating spiral tube and the second grade pre-separating spiral tube are all rectangles. The rotation angles of the first grade pre-separating spiral tube and the second grade pre-separating spiral tube are 360 degrees and 1080 degrees respectively. A throttling steady flow wimble cone is fixed at the lower part of the cylinder. A gas suction pipe is disposed at the upper part of the ash bin, and a V-shaped ring groove is arranged in the middle of a top cover plate of the ash bin. The cyclone separator has advantages of small pressure drop, high separation efficiency to submicron particles and small scaling effect. The dust concentration during air exhaust meets the environmental protection requirements. The cyclone separator effectively eliminates the secondary flow in a flow field, and has advantages of stable flow pattern, low gas velocity, low equipment abrasion and long service life. The cyclone separator can replace cloth bags and electrostatic dust collectors to undertake the tail end dust removal of dust-laden gas.

Owner:QINGDAO UNIV OF SCI & TECH

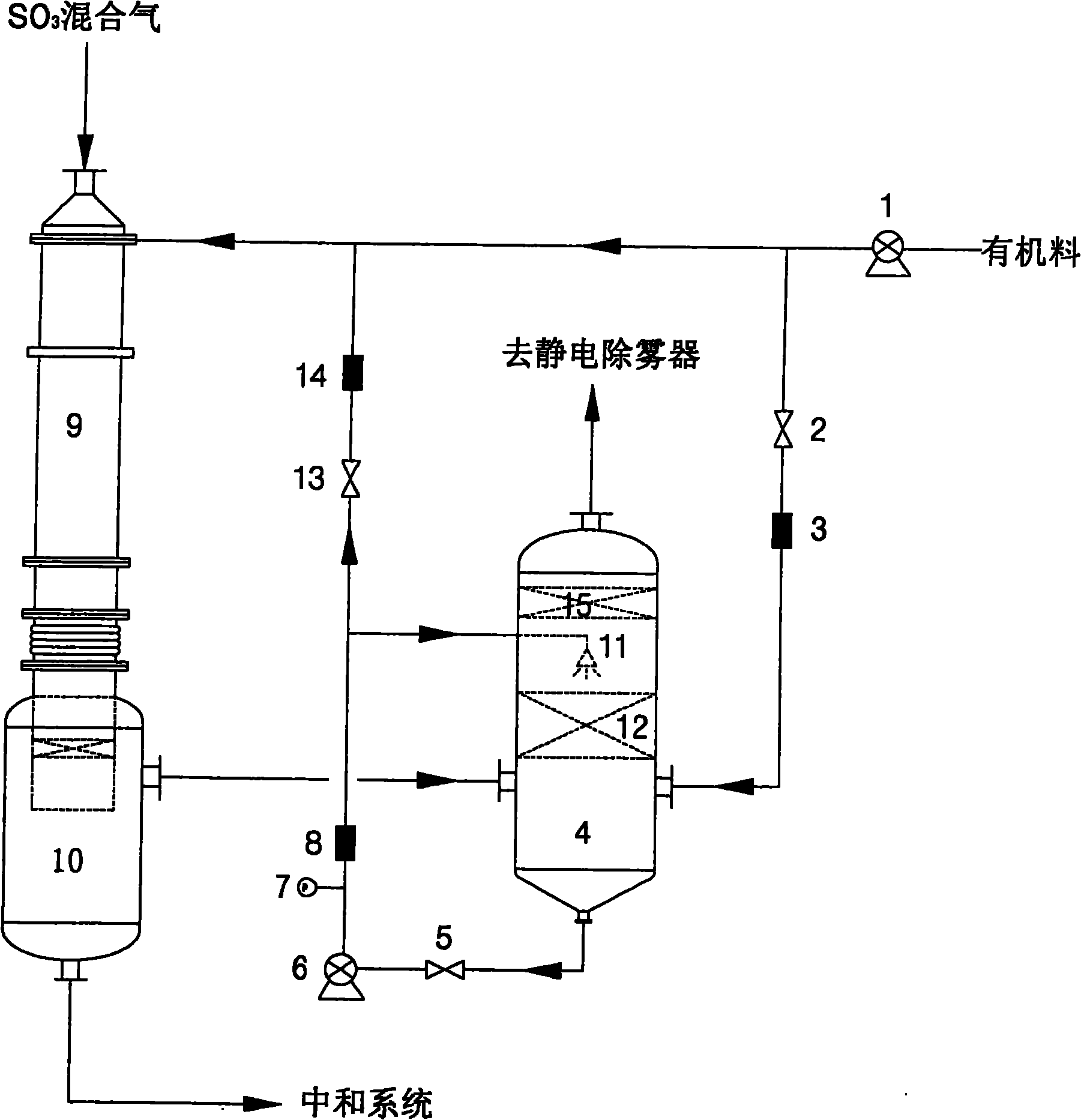

Sulfur trioxide tail gas treating device in sulfonation reaction

InactiveCN101966419AReduce gas velocityTake advantage ofDispersed particle separationLeather impregnationVapor–liquid separatorSulfur trioxide

The invention relates to a sulfur trioxide tail gas treating device in sulfonation reaction, which aims to provide a device with reasonable design and simple operation for treating the tail gas of sulphonated products. The technical scheme is that: the sulfur trioxide tail gas treating device in sulfonation reaction comprises an organic material input tube, wherein both ends of the organic material input tube are connected with a material inlet and a material pump of a sulfonation reactor. The device further comprises a tail gas absorption tower in which an upper packing layer, a spray header, a lower packing layer and a gas material cavity are arranged in sequence from top to bottom. The upper outlet at the top end of the tail gas absorption tower is connected with an electrostatic demister and the lower outlet at the bottom of the tail gas absorption tower is divided into two paths after being connected in series with a third valve and a circulating pump through the pipeline, wherein one path is connected with the spray header while the other is connected with the organic material input tube of the sulfonation reactor after being connected in series with a second valve. A tail gas inlet which is connected with the tail gas outlet of a gas-liquid separator of the sulfonation reactor and a material inlet which is connected with the organic input tube of the sulfonation reactor are arranged on the wall of the gas material cavity.

Owner:ZANYU TECH GRP CO LTD

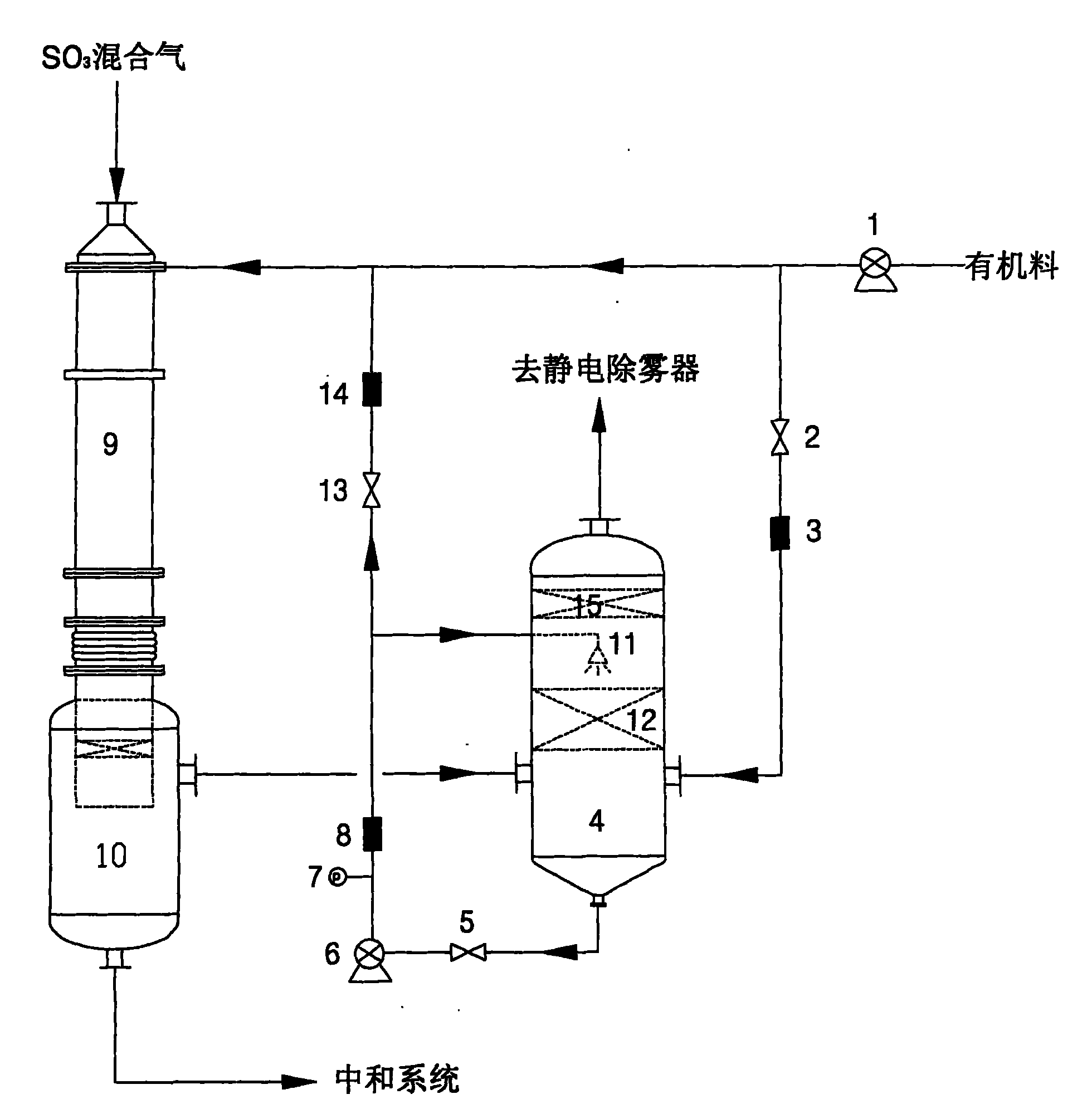

CO boiler having dustproof function and denitration function

ActiveCN103776042AImprove utilization efficiencyEfficient use ofCombination devicesLighting and heating apparatusFlueCoal

The invention relates to a CO boiler having the dustproof function and the denitration function. The CO boiler having the dustproof function and the denitration function comprises a flue, a combustion chamber, steam drums, an evaporation section and an economizer section. The CO boiler further comprises an ammonia spraying and mixing mechanism and a dustproof denitration reactor. The ammonia spraying and mixing mechanism is arranged above the evaporation section or between the evaporation section and the denitration reactor. The dustproof denitration reactor is arranged between the evaporation section and the economizer section and comprises a mixed-smoke inlet section, a denitration section and a purified-smoke discharging section, wherein an ash removal section is arranged between the mixed-smoke inlet section and the denitration section, ash baffles are arranged in the ash removal section, an ash bin is arranged in the denitration section, the center line of the ash bin and the center line of the reactor coincide, and the lower end of the ash bin is connected with an ash discharging pipeline. According to the CO boiler having the dustproof function and the denitration function, the denitration reactor is arranged in the CO boiler, so that the utilization rate of smoke heat is increased; due to the fact that the ash removal section is arranged in the reactor, smoke dust of mixed smoke can be removed before the mixed smoke enters denitration units, catalyst hole channels are prevented from being blocked, and the denitration efficiency and the denitration effect are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

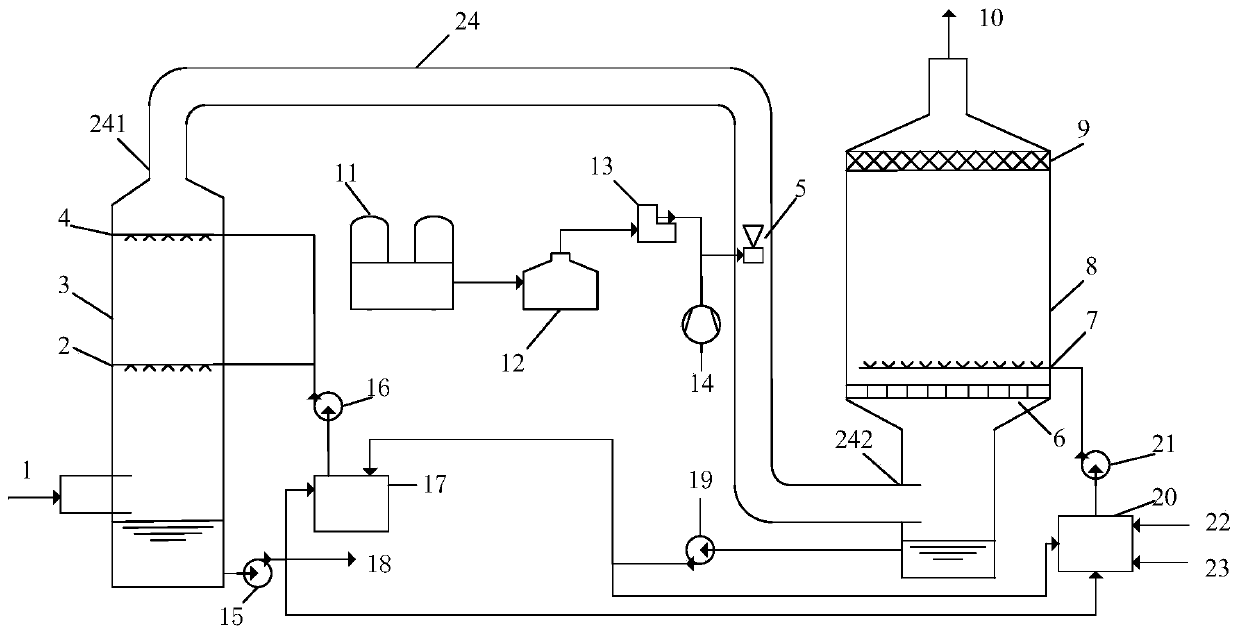

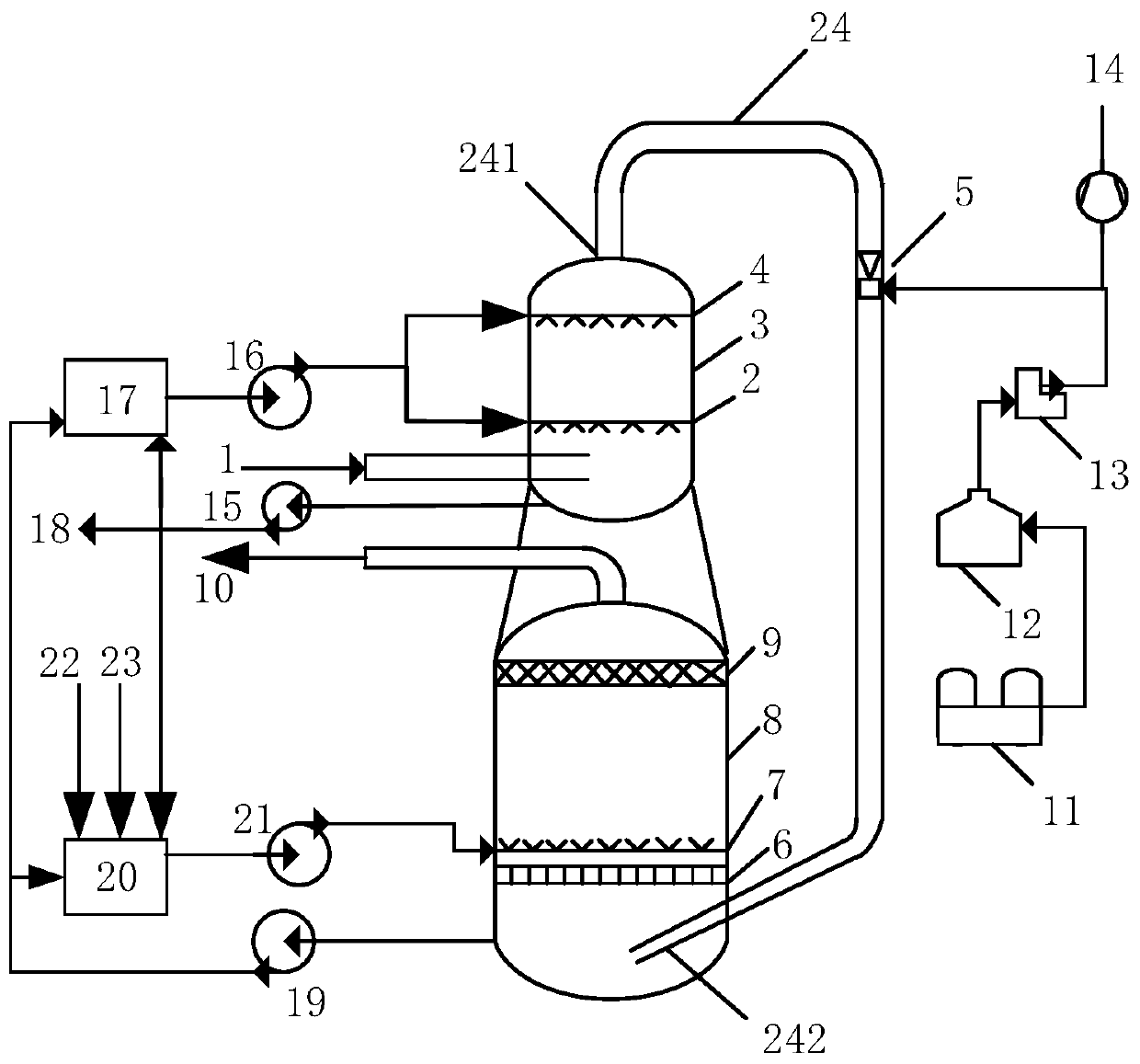

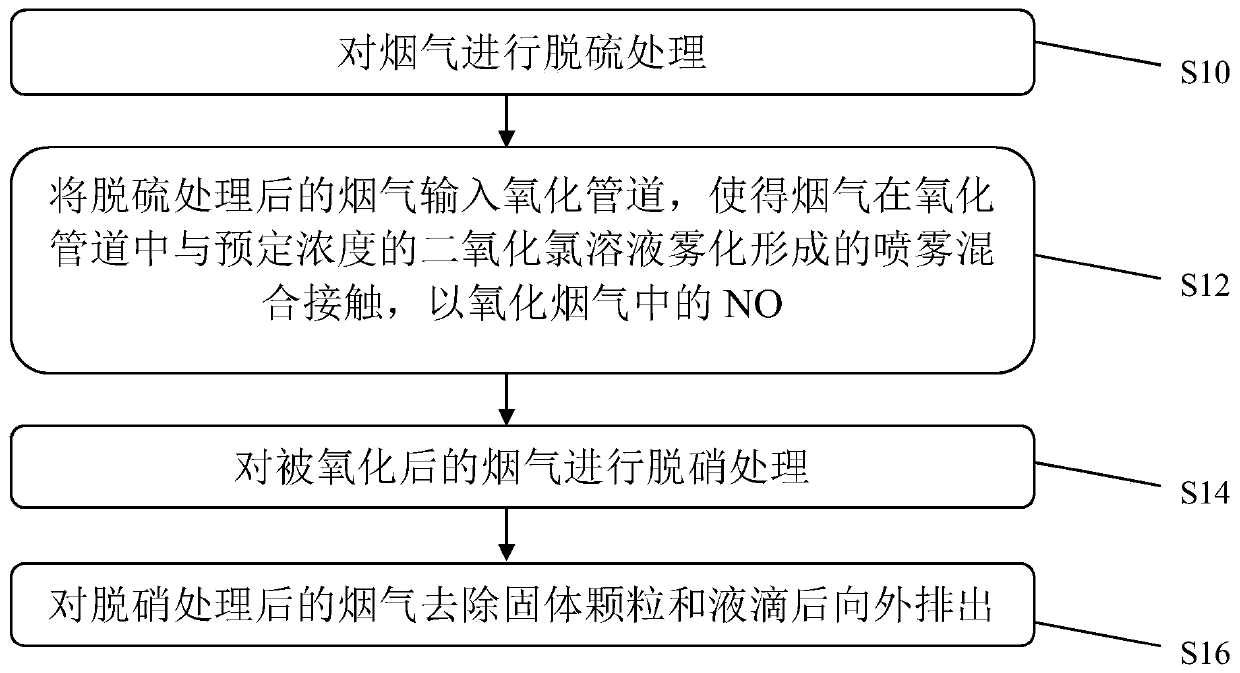

Flue gas desulfurization and denitration device and method

ActiveCN109718653AHigh gas velocityOxidation achievedDispersed particle separationChlorine dioxideFlue gas

The invention discloses a flue gas desulfurization and denitration device and method. The device comprises: a desulfurization container, the bottom of which is equipped with a desulfurization liquid material storage area, above which a flue gas inlet is disposed, with a flue gas washing and desulfurization structure being arranged above the flue gas inlet; a denitration container, the bottom of which is equipped with a denitration liquid material storage area, above which a flue gas washing and denitration structure is arranged, with a separation structure for removing solid particles and liquid drops being disposed above the flue gas washing and denitration structure, and a gas outlet being disposed at the top of the denitration container; an oxidization pipeline for communicating the desulfurization container and the denitration container; an atomization spray structure that is disposed in the oxidization pipeline and capable of providing structure connection together with chlorine dioxide, with the chlorine dioxide mist sprayed by the atomization spray structure being mixed with the flue gas in the oxidization pipeline. The flue gas desulfurization and denitration device and method provided by the invention can realize high efficiency and high utilization oxidation of ClO2 to NO, are safe and convenient to operate, and are convenient for industrial application.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

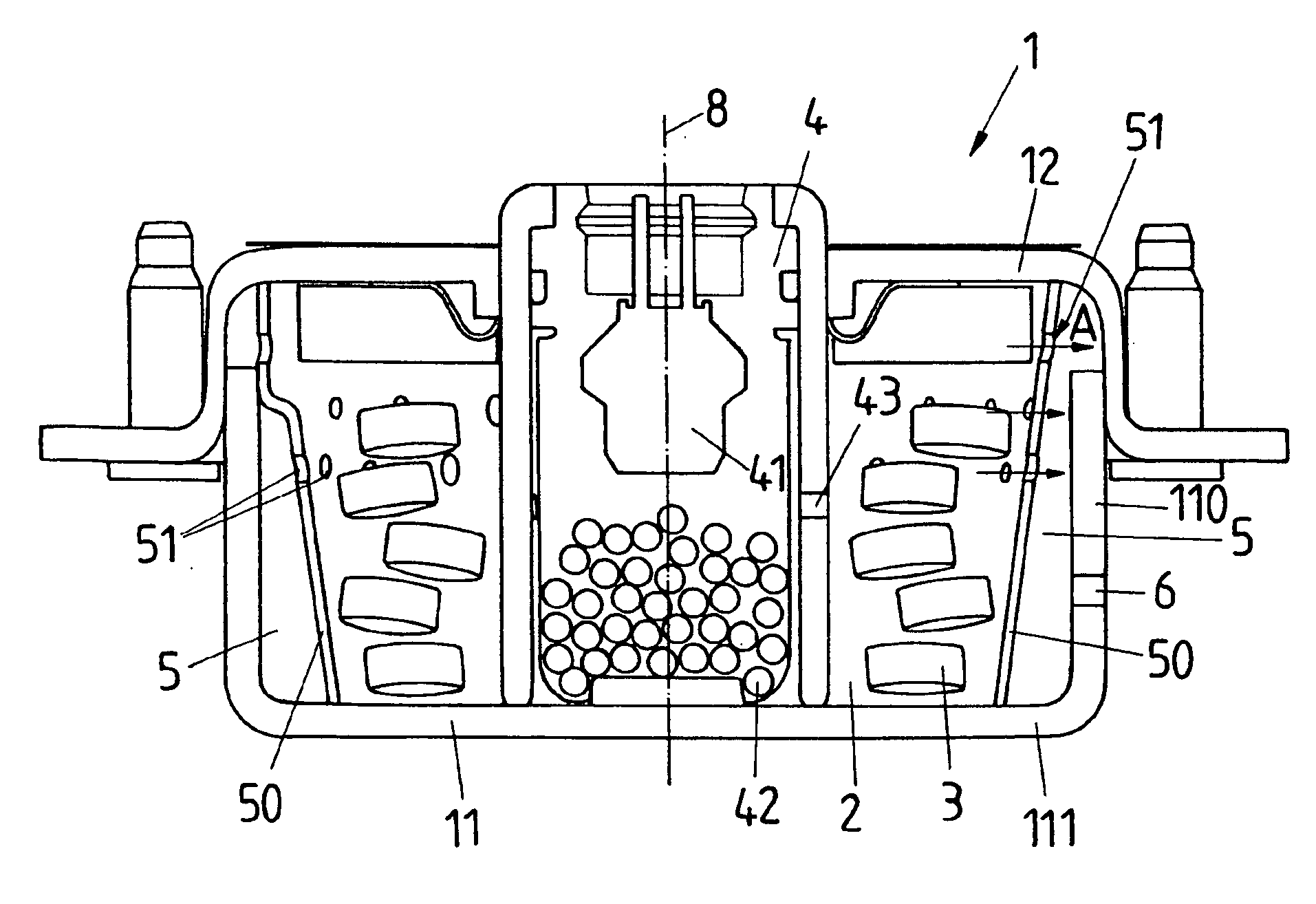

Gas generator for a vehicle passenger protection device and process for removing solids and liquid burned residues in a gas stream

InactiveUS20100117344A1Reduce gas velocityShorten speedPedestrian/occupant safety arrangementPressure gas generationCombustion chamberGas passing

A gas generator for a vehicle passenger protection device. The gas generator includes a combustion chamber in which a gas-generating charge is arranged. A conical deposition chamber is provided that has a first wall, within which a plurality of gas through-holes are formed, and at least one second wall which extends at an angle from the first wall and within which at least one blow-off hole is formed. Gas generated inside the combustion chamber enters the deposition chamber through the gas through-holes and leaves the deposition chamber through the at least one blow-off hole.

Owner:TAKATA PETRI AG

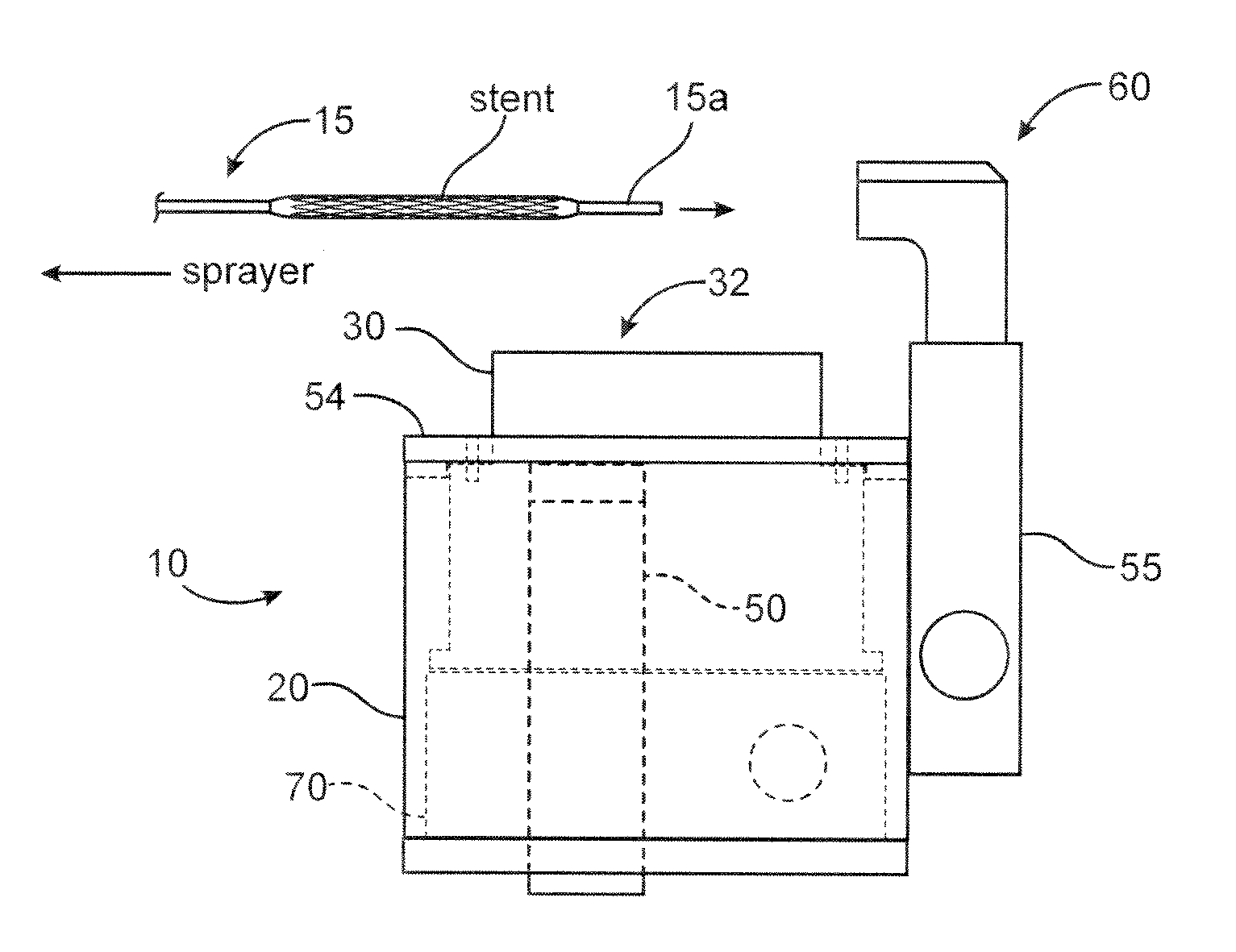

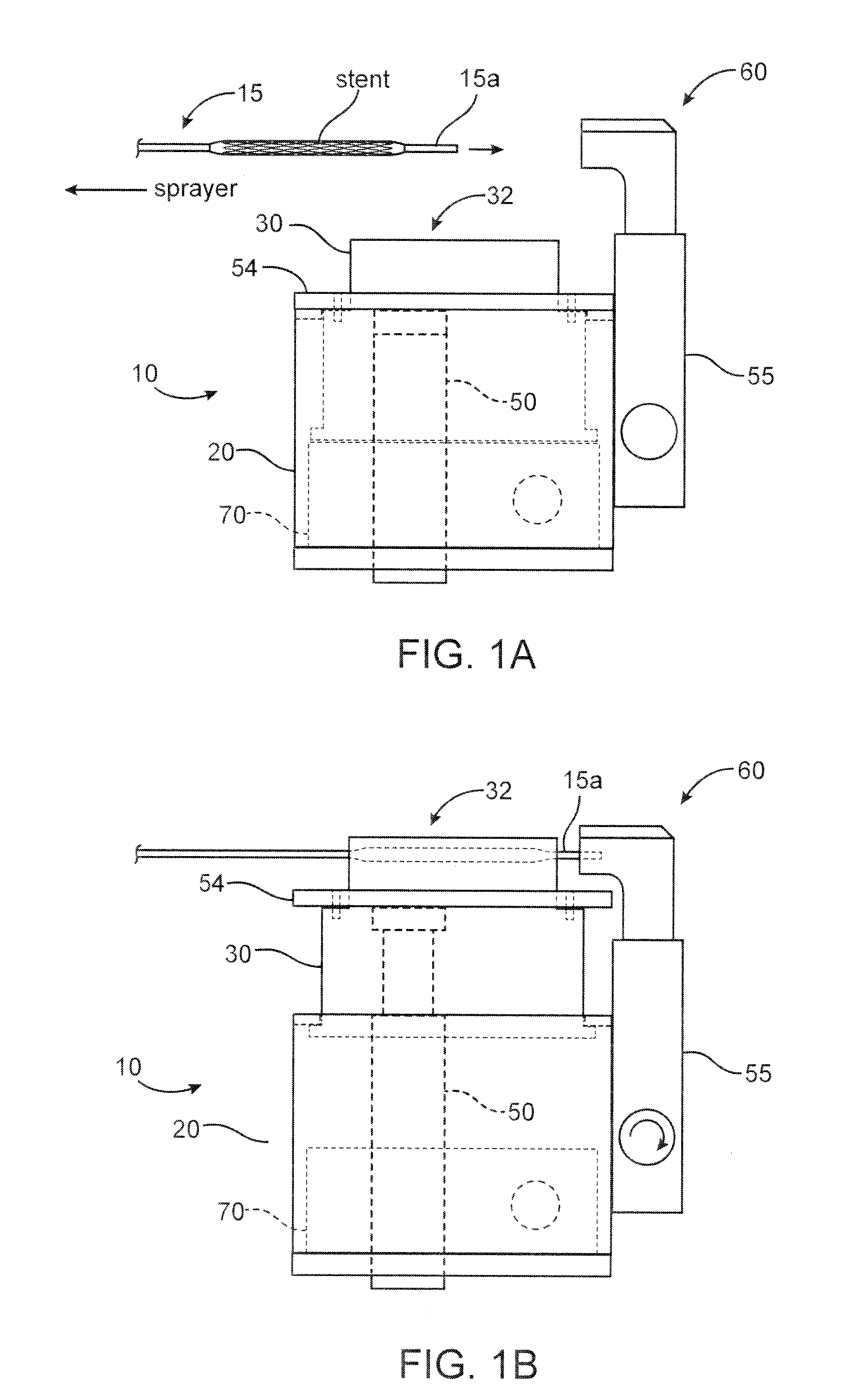

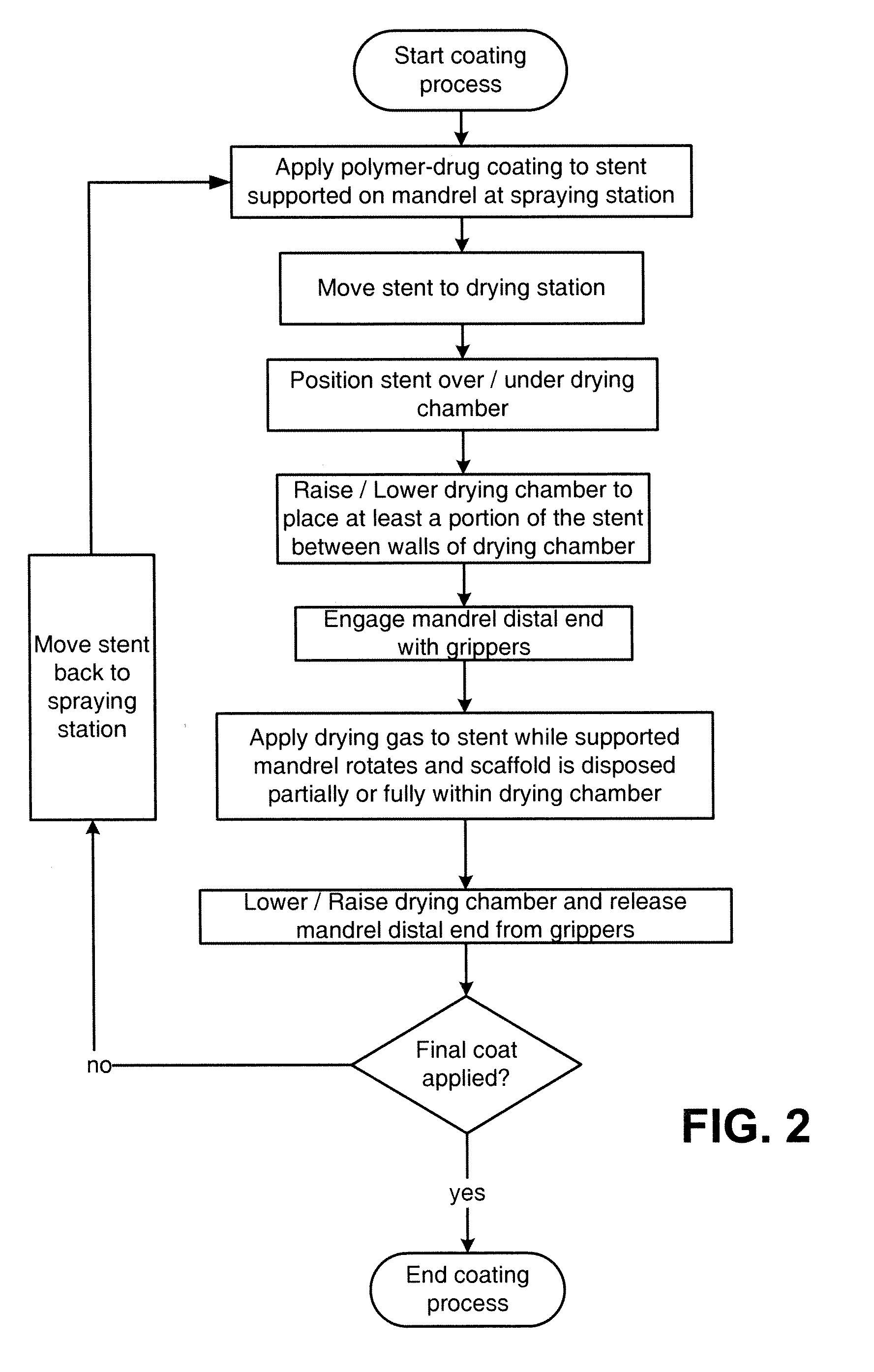

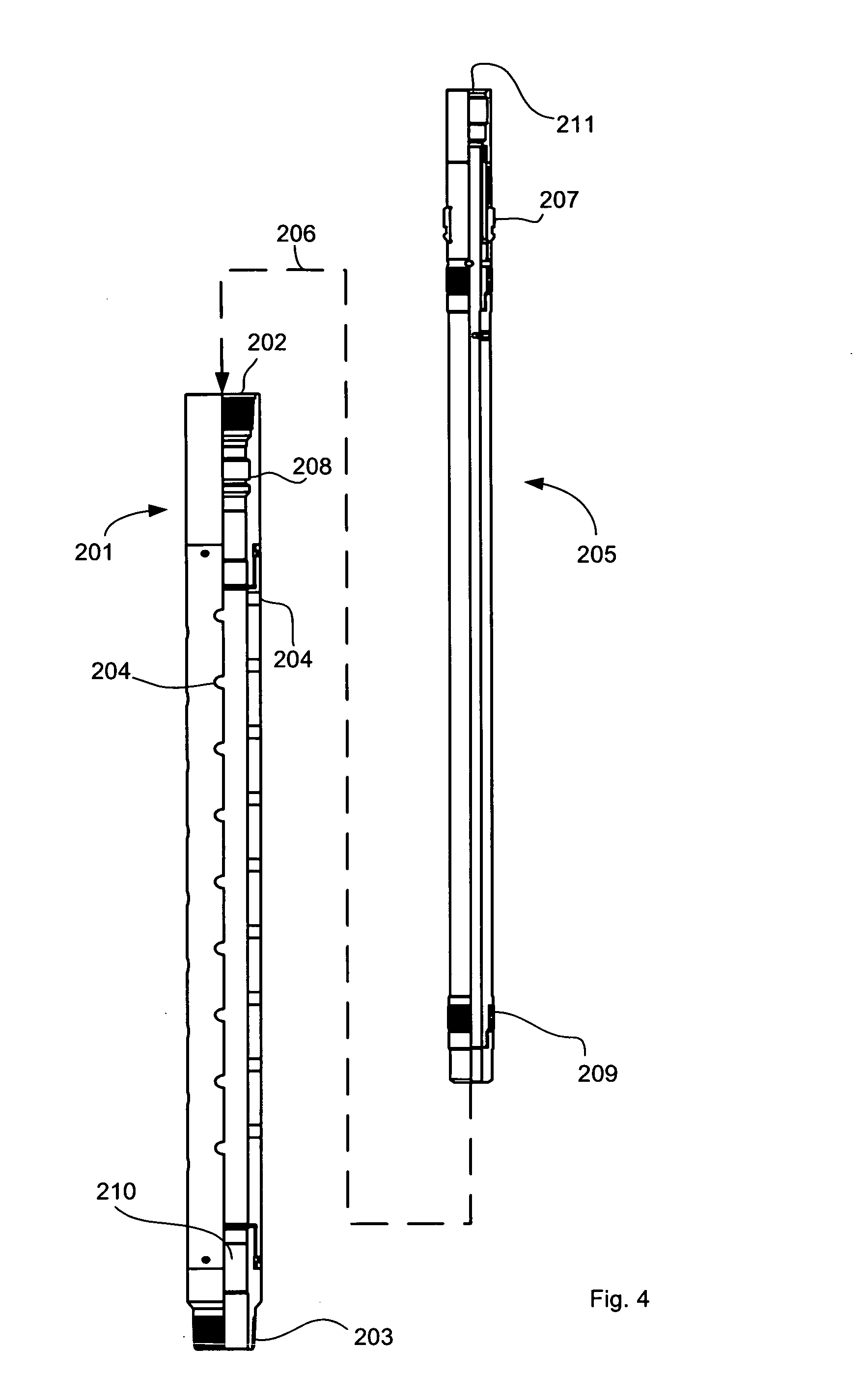

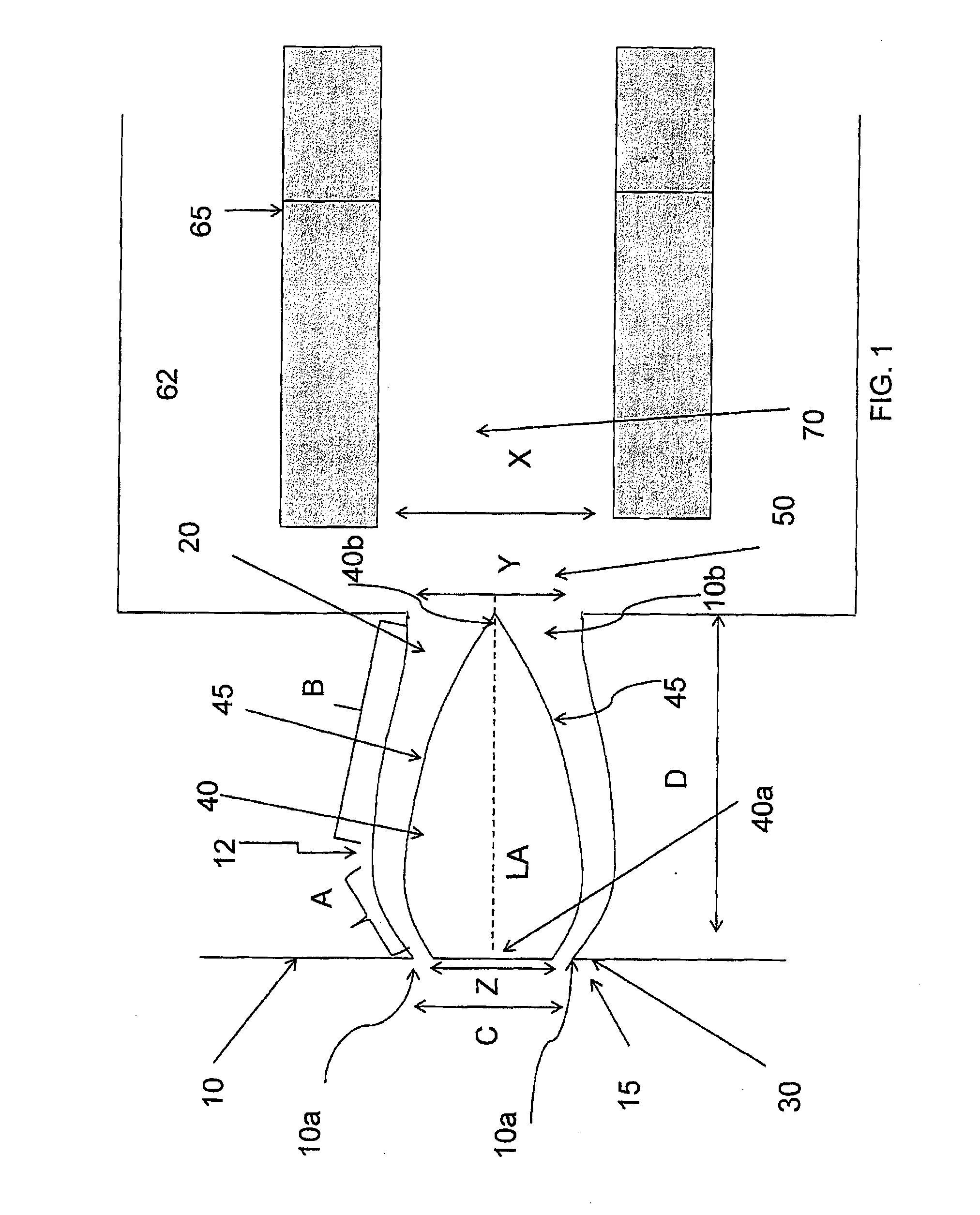

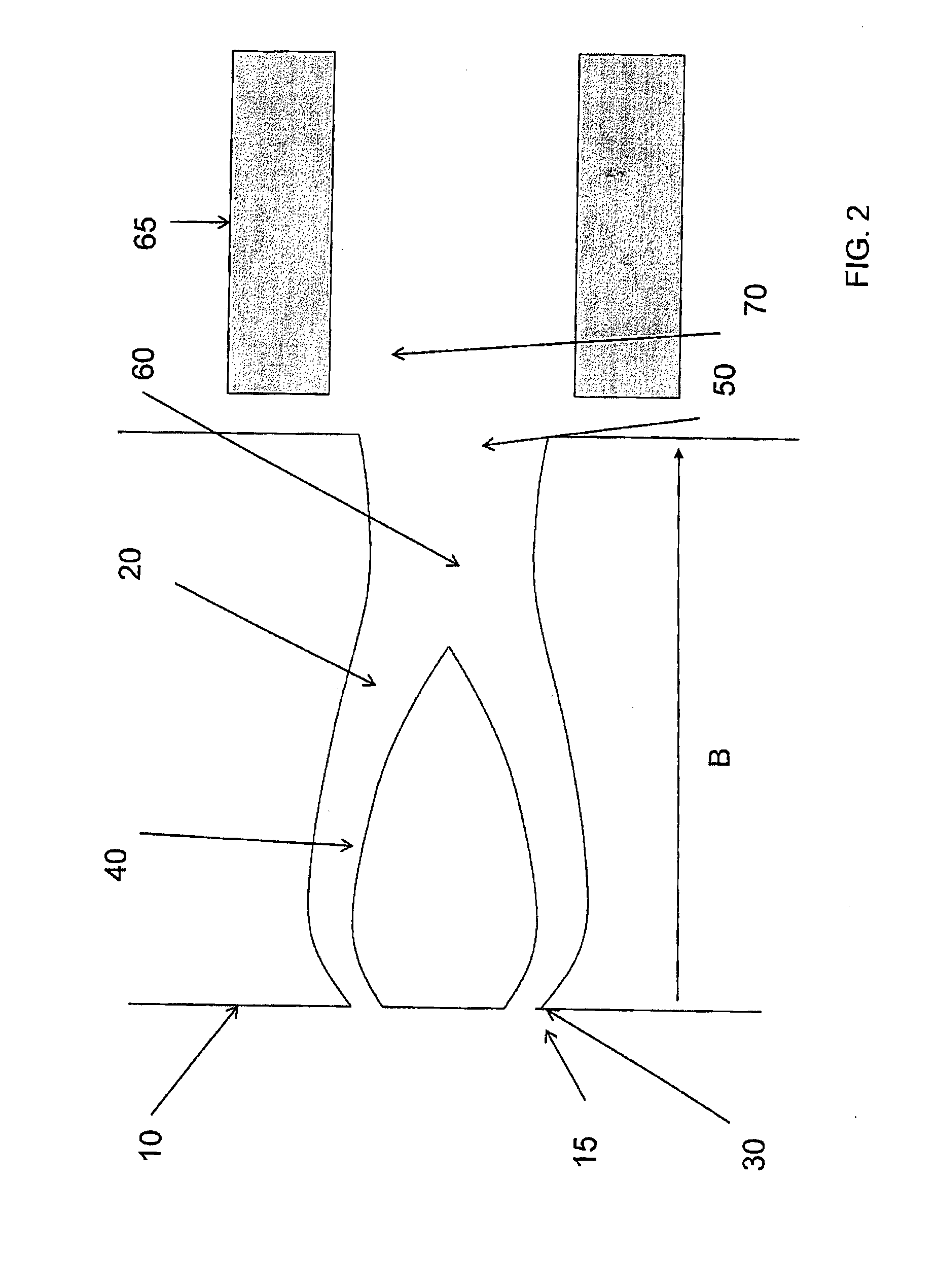

Dryers For Removing Solvent From A Drug-Eluting Coating Applied To Medical Devices

InactiveUS20130071549A1Maximizing in-process drying efficiencyMaximizing uniformityPharmaceutical containersPretreated surfacesDrug release rateSolvent

A coating device for coating a medical device with a drug-eluting material uses an in-process drying station between coats to improve a drug release profile. The drying station includes a dryer having a telescoping plenum which provides a drying chamber for the stent or scaffold to reside while a heated gas is passed over the stent / scaffold. The drying chamber improves efficiency in drying, predictability or drug release rate, uniformity of coating material properties lengthwise over the stent / scaffold and provides a platform that can effectively support stents that are over 40 mm in length.

Owner:ABBOTT CARDIOVASCULAR

Flue gas desulfurization and regeneration integral tower and flue gas desulfurization method

ActiveCN110559804AAchieve recyclingReduce moisture contentGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a flue gas desulfurization and regeneration integral tower and a flue gas desulfurization method. The flue gas desulfurization and regeneration integral tower comprises a fluegas discharge zone, a demisting zone, a secondary spraying zone, a liquid holding groove zone, a primary spraying zone, a quenching cooling zone and an absorbed liquid regeneration zone, wherein the absorbed liquid regeneration zone is divided into a preheating zone, a steam stripping zone and a liquid collection ozone from left to right in sequence by using a vertical partition plate I, a partition plate II and a partition plate III; the preheating zone communicates with the primary spraying zone; the preheating zone communicates with the steam stripping zone through an opening in the bottomof the partition plate I; the height of the partition plate II is lower than that of the partition plate I; the steam stripping zone communicates with the liquid collection zone through a space at theupper part of the partition plate II; at the tops of the steam stripping zone and the liquid collection zone, the steam stripping zone and the liquid collection zone are completely partitioned from the spraying zone through the partition plate III; a heat exchange tube group is arranged in the preheating zone; a flue gas is fed into a tower through the heat exchange tube pipe; and an outer sleeveis arranged at the top of a chimney arranged in the flue gas discharge zone. The tower is capable of achieving SO2 recycling and deep demisting in the flue gas, is short in process course, simple inequipment and low in operation cost, and has wide application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

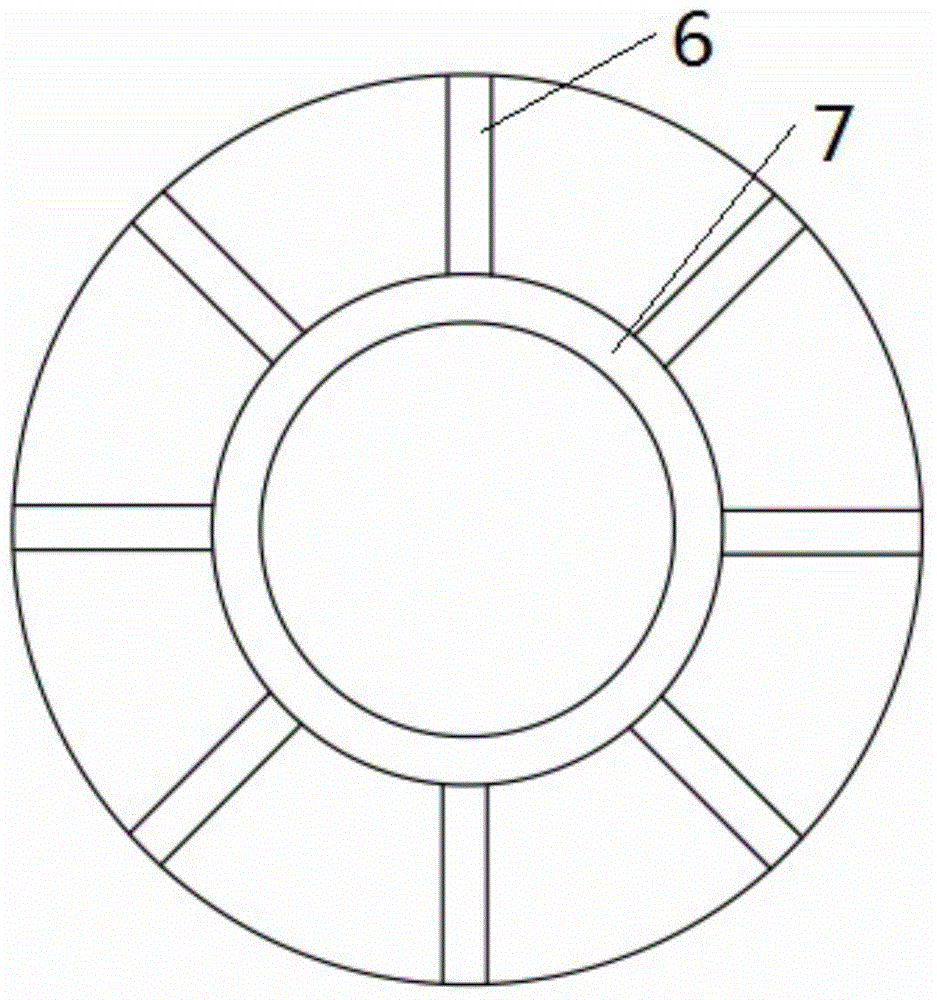

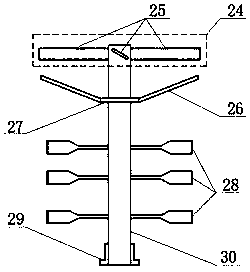

Flame holder and ground gas turbine combustion chamber with same

ActiveCN104896510AWell mixedEliminate local hot spotsContinuous combustion chamberCombustion chamberEngineering

The invention discloses a flame holder and a ground gas turbine combustion chamber with the same. The flame holder comprises a central ring and a plurality of radial struts fixed on the outer circular face of the central ring along the radial direction uniformly. A ring body of the central ring and the radial struts are formed by members in groove structures, and groove opening directions of the central ring and the radial struts are identical. Gas flow channels are formed in the members in groove structures and are communicated with the outside through a plurality of gas spray holes in the bottoms of the grooves. The gas flow channel in the central ring and the gas flow channels in the radial struts are communicated to form a gas flow cavity with the shape corresponding to the shape of the flame holder. By means of the flame holder, fuel gas can be burnt stably on the flame holder even under the impact of high-speed gas flows.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

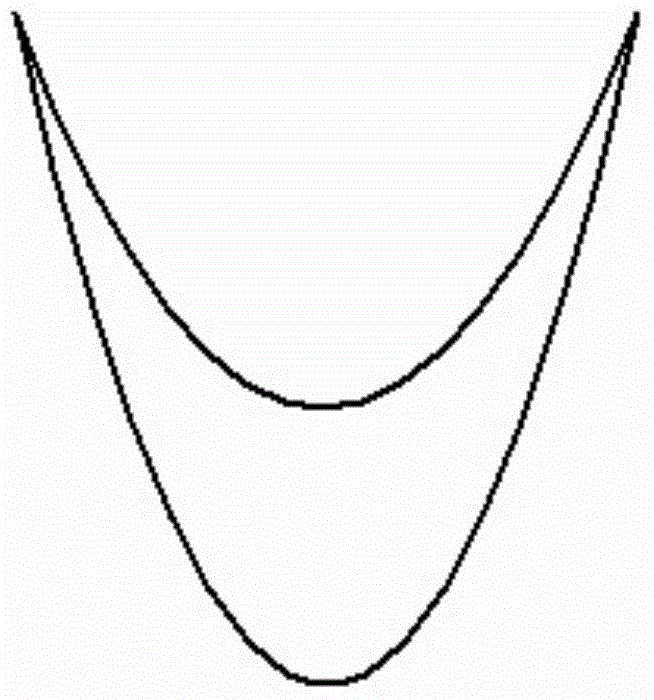

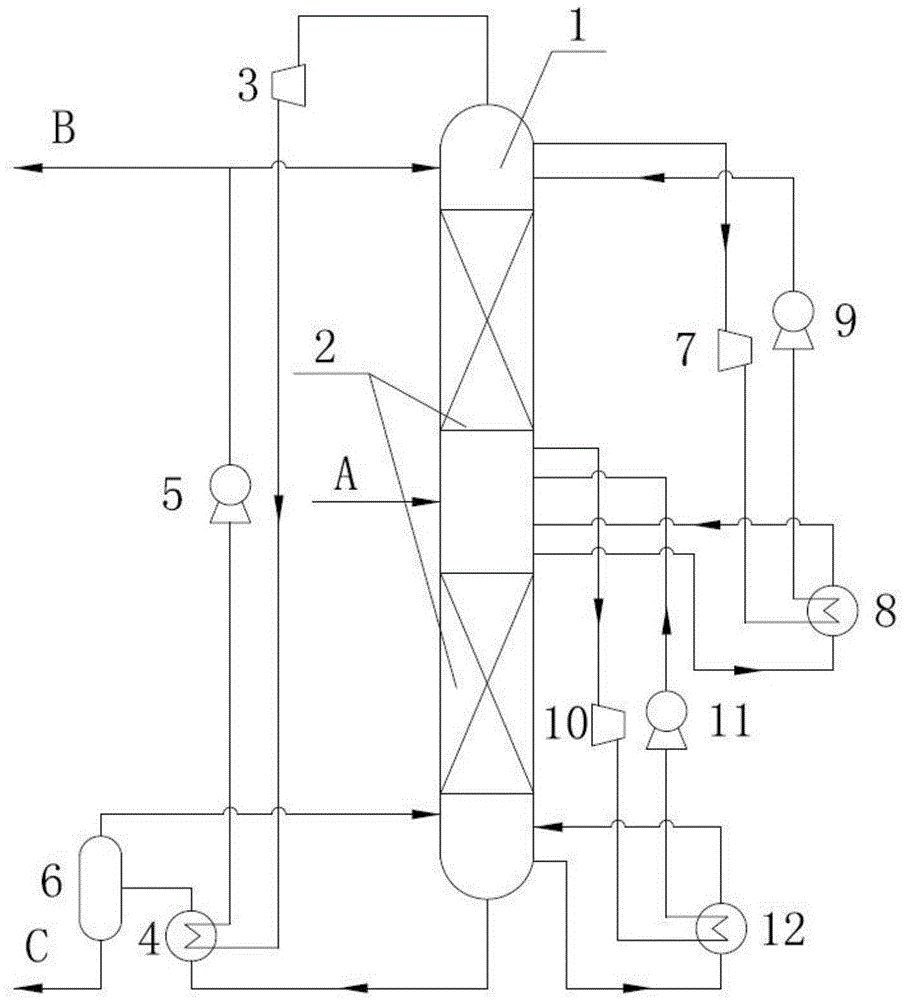

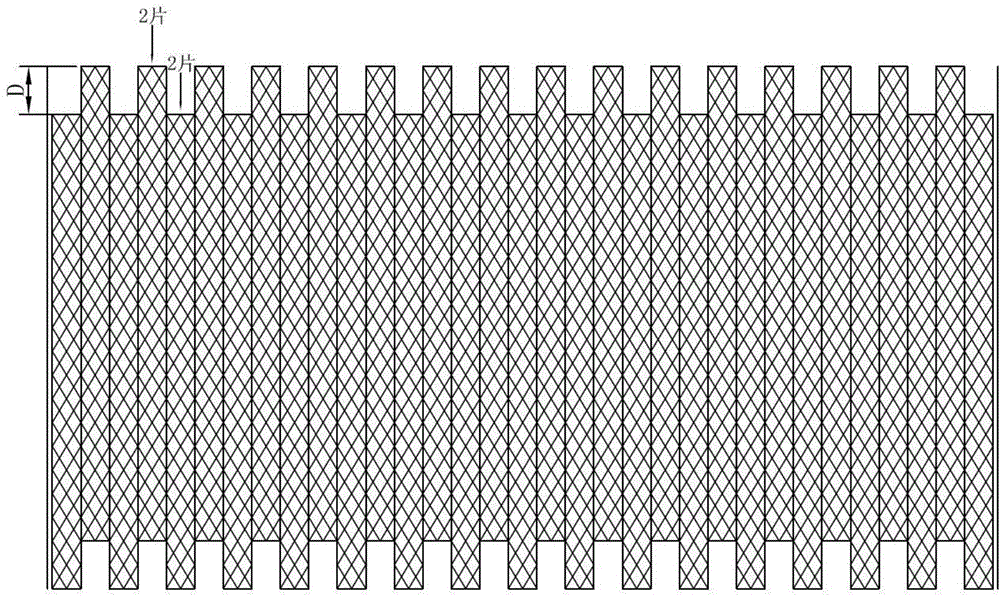

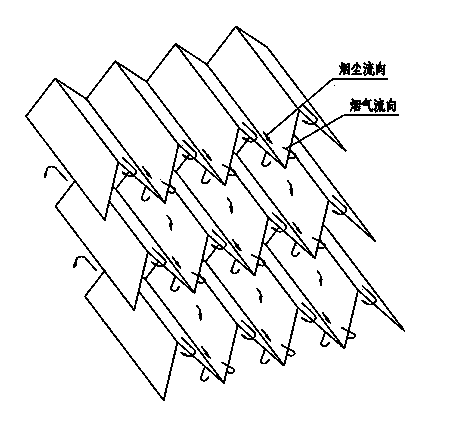

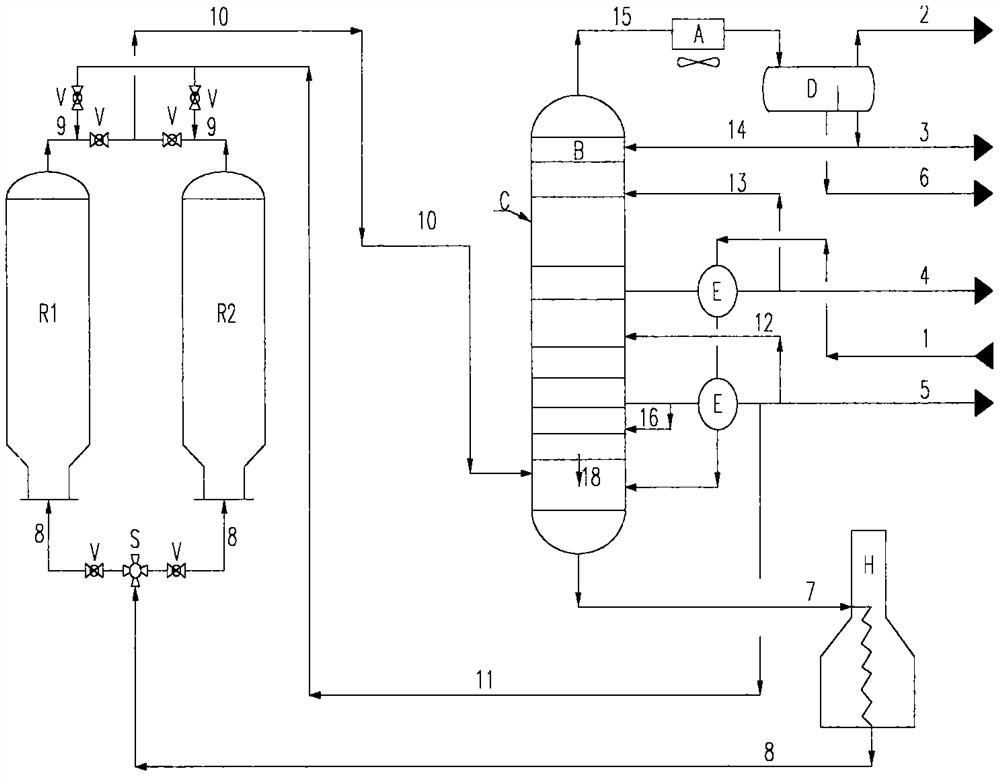

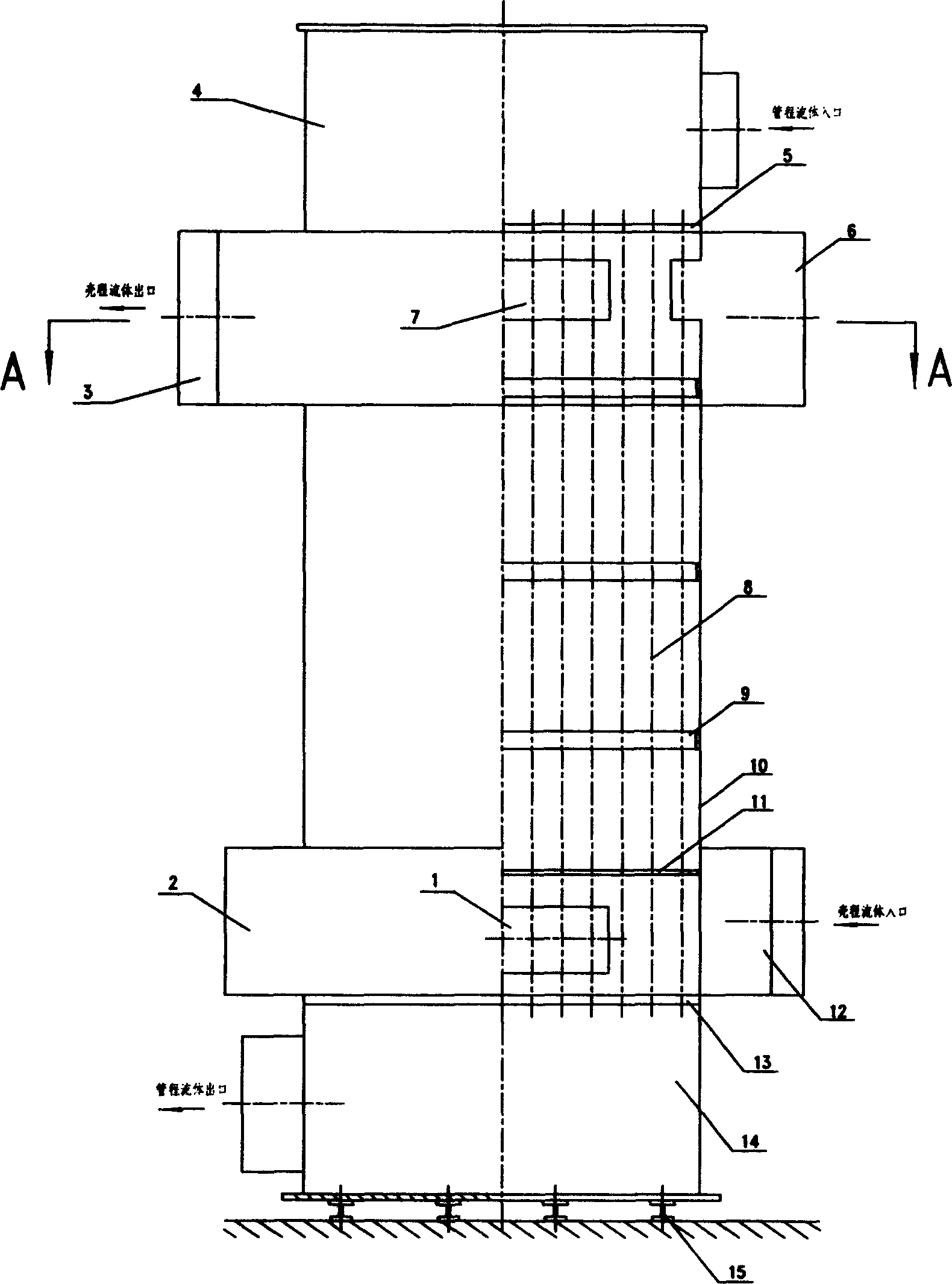

Rectification method and apparatus for propylene and propane separation

InactiveCN103980081AEnhanced liquid collection capacityImprove separation efficiencyDistillation purification/separationFractional distillationGas phaseTotal investment

The invention relates to a rectification method for propylene and propane separation. The apparatus comprises a multiple heat pump rectification system including a whole tower heat pump distillation system, a rectification system of a rectifying section and a heat pump rectification system of a stripping section, also comprises a tower top stream reflux pump, a stream reflux pump of the rectifying section and a stream reflux pump of the stripping section. Liquefied hydrocarbon enters into a propane and propylene rectification tower from a liquid hydrocarbon concentrate pump through a liquefied hydrocarbon tank; propylene is discharged from the tower top, and propane is discharged from the tower bottom; the propylene concentration at the tower top is 99-99.9%, and the propylene concentration at the bottom of the tower is 1.5-3%; a novel staggered structured packing of window diversion structured packing in highly alternate arranged optimizes radial distribution of the gas and liquid in the rectification tower, buffers the gas phase flow among the filler plates, and plays the role of collecting liquid flow, so as to improve the separation efficiency of propylene and propane. The multiple heat pump rectification system optimizes energy coupling among gas streams in the tower, and reduces energy consumption; and compared with the traditional method, the apparatus reduces the energy consumption by 30% and the total investment for the process.

Owner:TIANJIN UNIV

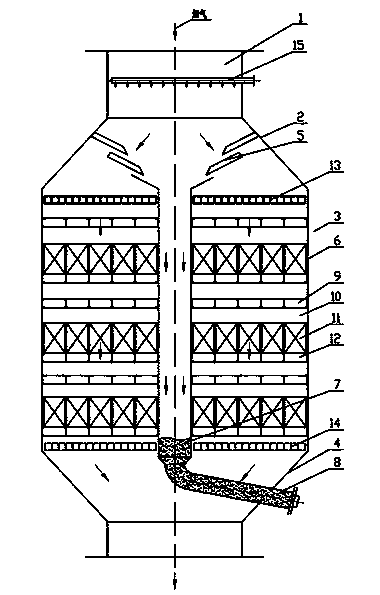

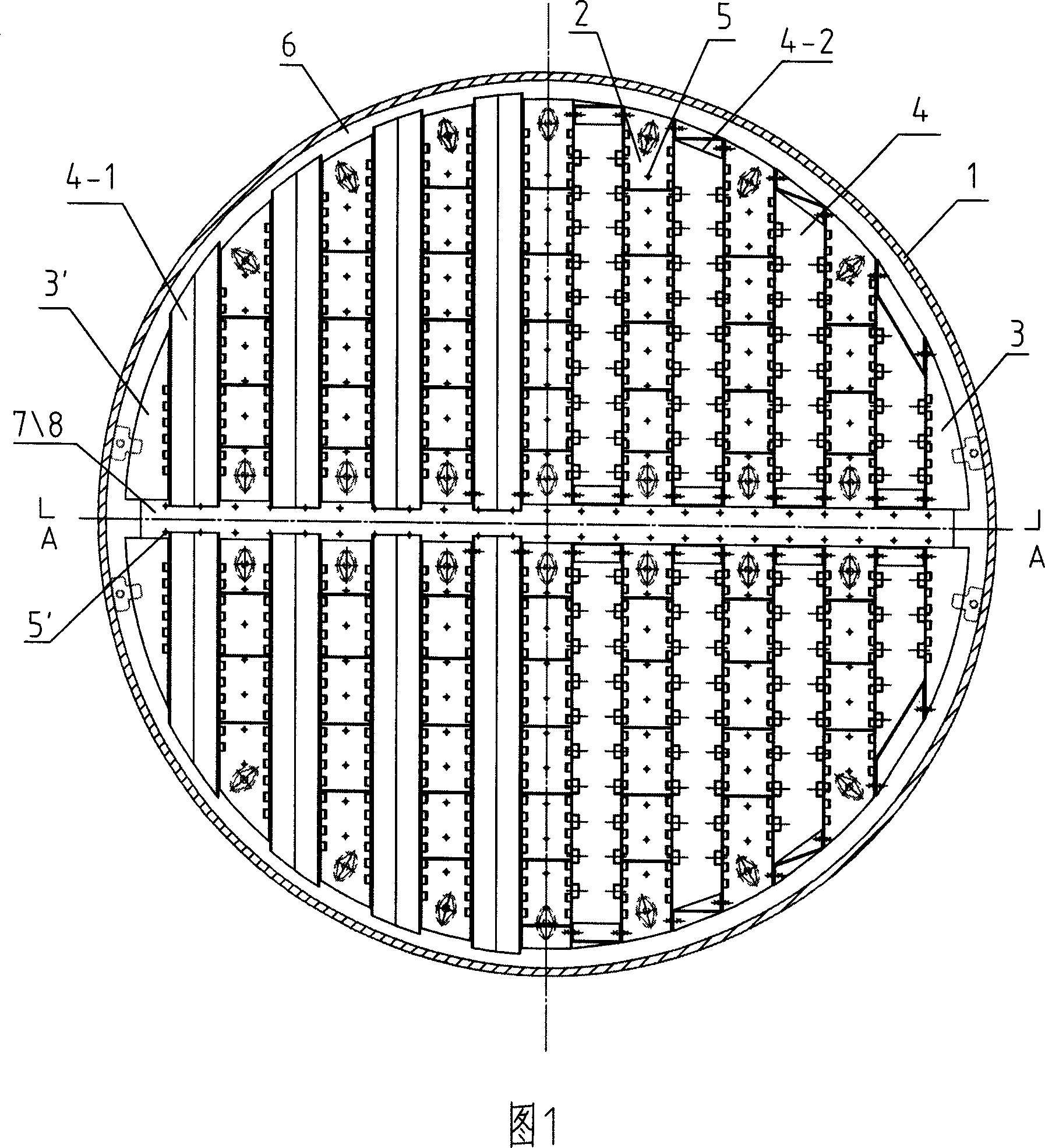

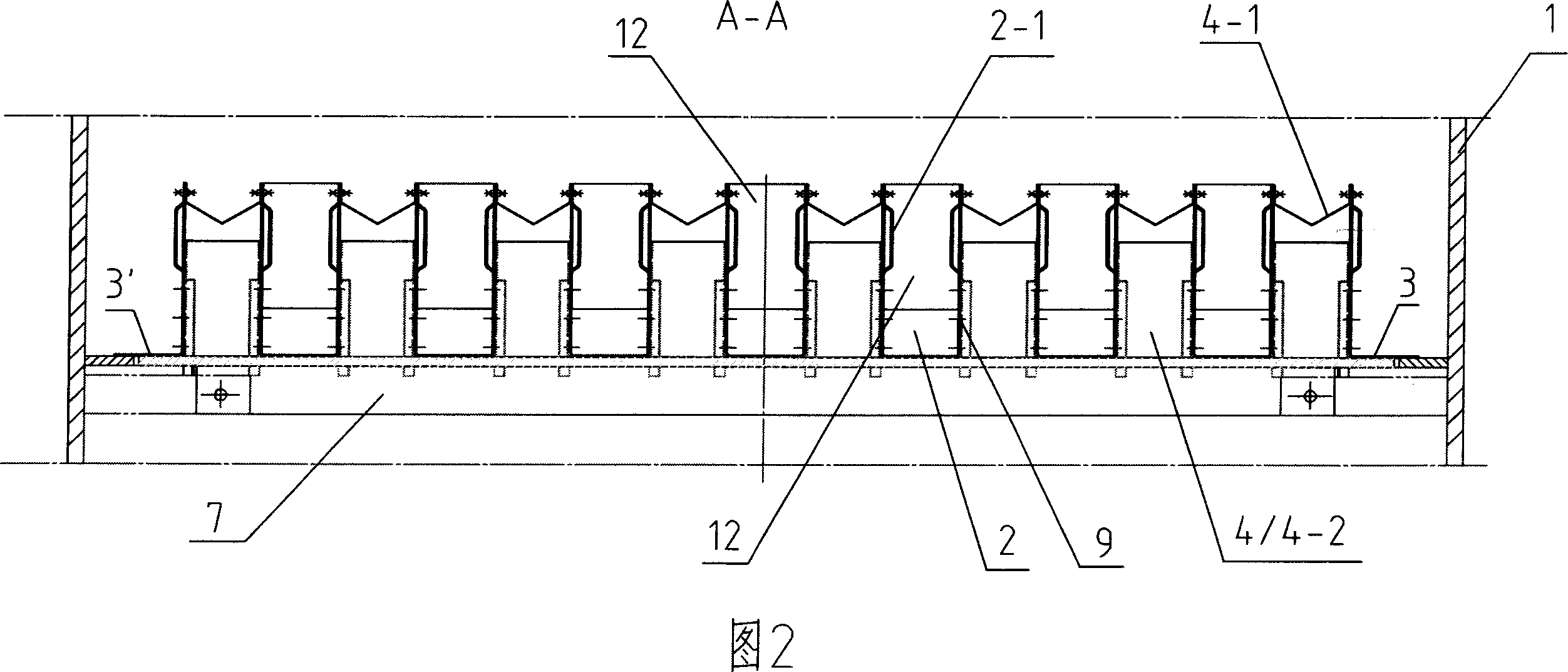

FCC regenerated flue gas dustproof denitration reactor

ActiveCN103768930ALarge flow areaReduce gas velocityDispersed particle separationFlue gasProcess engineering

The invention relates to a FCC regenerated flue gas dustproof denitration reactor. The FCC regenerated flue gas dustproof denitration reactor comprises a mixed flue gas inlet segment, a denitration segment, and a purified flue gas exhaust segment; the denitration segment is provided with a denitration unit; a dedusting segment is arranged between the mixed flue gas inlet segment and the denitration segment; dust blocking plates are arranged in the dedusting segment; the dust blocking plates are corrugated blocking plates which are arranged in a multi-layer staggered manner; a dust collector is arranged in the denitration segment; the center line of the dust collector and the center line of the FCC regenerated flue gas dustproof denitration reactor are overlapped; and the lower end of the dust collector is connected with a dust discharging pipeline. According to the FCC regenerated flue gas dustproof denitration reactor, the dust blocking plates are arranged in the FCC regenerated flue gas dustproof denitration reactor, so that flue dust in the mixed flue gas is removed effectively before the mixed flue gas is delivered into the denitration unit, blocking of catalyst channels in the denitration unit by flue dust is avoided, denitration efficiency and denitration effects are improved; and the FCC regenerated flue gas dustproof denitration reactor is provided with drainage grilles and rectifier grilles, so that laminar flow states of the flue gas in the FCC regenerated flue gas dustproof denitration reactor are maintained, and denitration efficiency is increased further.

Owner:CHINA PETROLEUM & CHEM CORP +1

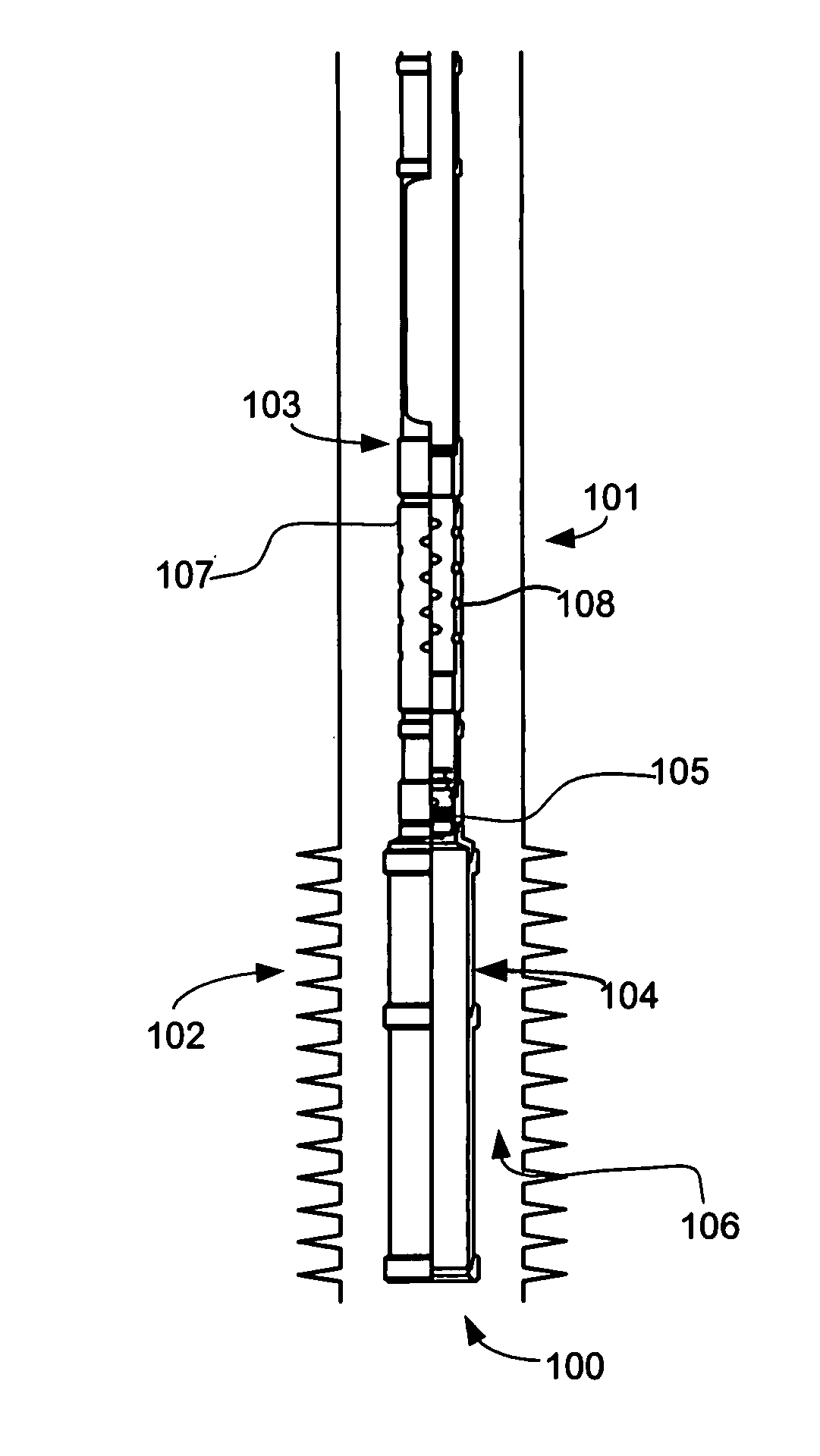

Critical velocity reduction in a gas well

ActiveUS20070158074A1Reducing critical velocity of gasReduce gas velocityDrilling rodsFluid removalBlowing agentReagent

Disclosed herein is a system for enhancing the recovery of gas in a perforated interval of a gas well. The system features a tubing string having a dead string attached for reducing the flow area of the annulus in the perforated interval, thereby reducing the critical velocity of the gas, i.e., the velocity required to overcome backpressure due to fluids in the well column. The system includes a ported member for receiving gas from the annulus into the tubing string. The ported member and the dead string are isolated from each other by a retrievable plug. The disclosed system provides access from the surface through the dead string for diagnostic or corrective operations. The system also provides delivery of reagents such as foamers to the perforated region to further reduce the critical velocity.

Owner:WEATHERFORD TECH HLDG LLC

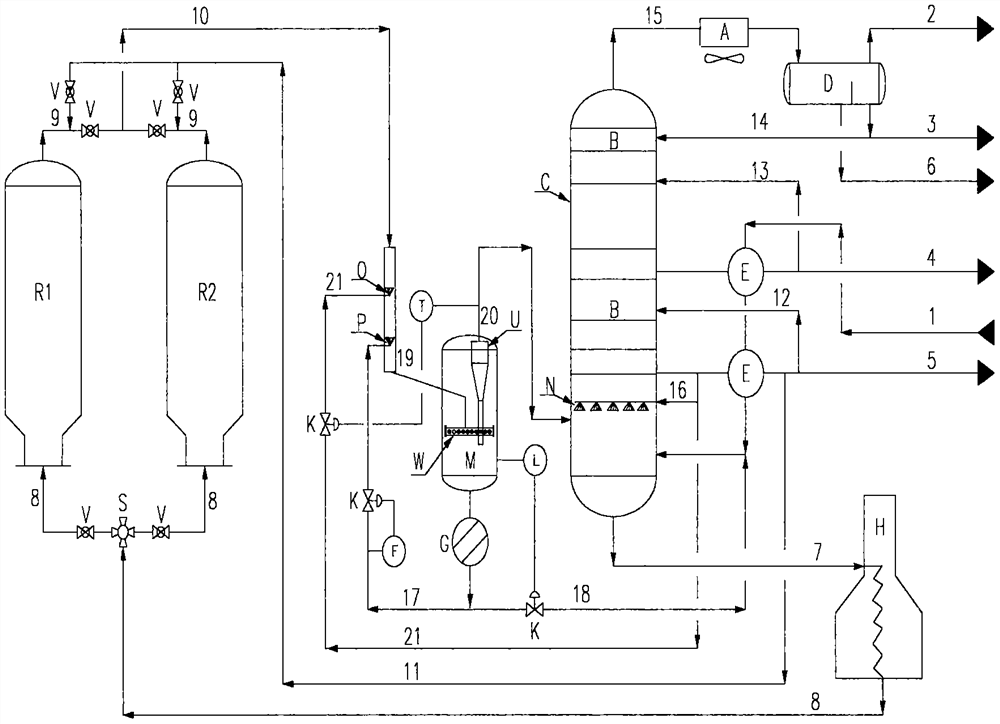

Process and device for reducing coke powder of delayed coking fractionating tower

ActiveCN112048330AIncrease sinking spaceReduce gas velocityCoking carbonaceous materialsFluid phaseCoke

According to a process and a device for reducing the coke powder of a delayed coking fractionating tower, provided by the invention, an oil-gas-wax oil heat exchange spray head, an oil-gas circulatingoil washing spray head, a gas-liquid separation distributor, a gas-liquid separation tank, a cyclone liquid remover and the like are arranged before reaction oil gas enters the fractionating tower; and the reaction oil gas is subjected to process treatment such as cooling, washing, coke powder capture, gas-liquid separation, liquid removal and coke powder removal, most coke powder carried in thereaction oil gas is washed into liquid-phase circulating oil, and the coke powder in the circulating oil is removed through a filter, so that the coke powder content of the reaction oil gas entering the fractionating tower is reduced. The quantity of oil gas entering the fractionating tower is reduced, the temperature of the oil gas is reduced, the linear speed of the oil gas at the lower part ofthe fractionating tower is reduced, a heat exchange plate for adjusting the circulation ratio at the lower part of the fractionating tower is saved, and the settling space of coke powder in the oil gas is increased; and a wax oil downward return spraying distributor is arranged to supplement the wash oil gas, so the coke powder content of fractionating tower side line and tower top products is further reduced. According to the invention, the amount of the coke powder entering the fractionating tower along with oil gas and the amount of coke powder entering the side line product along with oilgas can be effectively reduced, so that the product quality of a delayed coking device is improved, the operation period of the delayed coking device and downstream devices is prolonged, and the operation cost is saved.

Owner:北京奥博斯工程技术有限公司

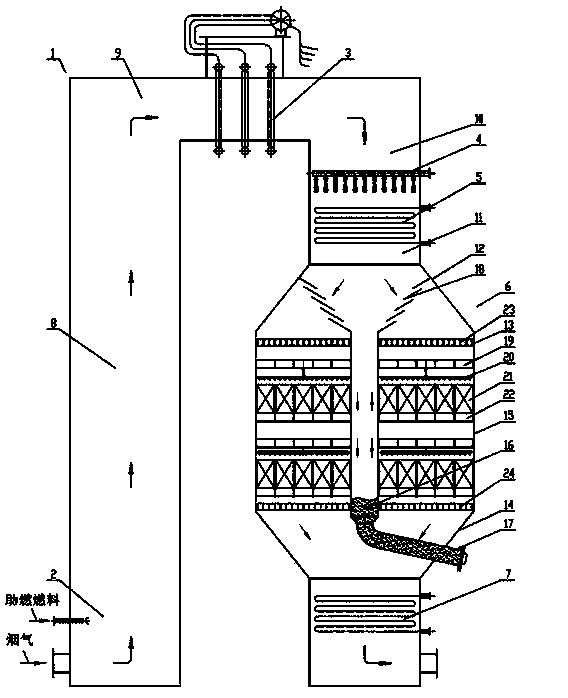

Flue gas dedusting and desulfurizing tower and flue gas dedusting and desulfurizing method

ActiveCN108686490ARealize rapid cooling and coolingReduce the burden onGas treatmentUsing liquid separation agentQuenchingProcess engineering

The invention discloses a flue gas dedusting and desulfurizing tower and a flue gas dedusting and desulfurizing method. The flue gas dusting and desulfurizing tower comprises a pretreatment unit, an advanced treatment unit and a tower bottom liquid tank area, and the pretreatment unit is communicated with the advanced treatment unit by a flue gas pipeline. The pretreatment unit sequentially comprises a quenching and spraying area, a first-stage spraying area and a Venturi grating washing area from top to bottom; and the advanced treatment unit sequentially comprises a middle liquid tank area,a second-stage spraying area, an upper liquid tank area, a third-stage spraying area, a demisting area and a flue gas discharging area from bottom to top. The white smoke phenomenon of wet desulfurization is eliminated, so the white smoke phenomenon of a smoke discharging opening is significantly reduced; and the triple functions of flue gas dedusting, desulfurizing and advanced demisting are achieved in the tower, and all functional areas cooperate with each other and promote each other, so the occupied area of the tower is greatly reduced, and the cost for construction and reconstruction ofthe tower is significantly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

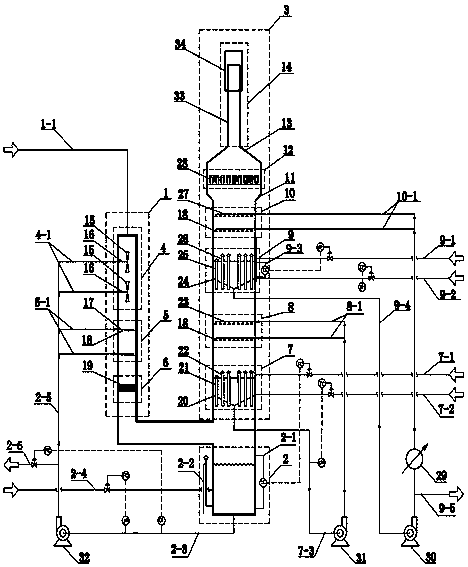

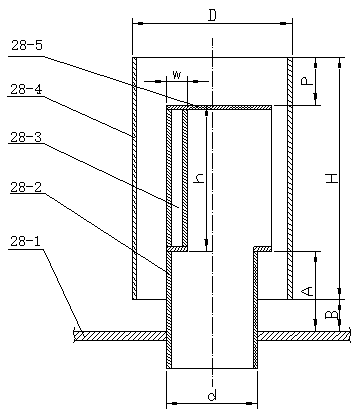

Shell and tube type heat exchanger with sharply enlarged accelerated flow zooming tube bundle and hollow ring

InactiveCN1558177AReduce resistanceReduce gas velocityStationary tubular conduit assembliesHeat transfer modificationMaterial consumptionEngineering

The heat exchanger consists of three sections of annular shell pass inlet section, axial flow section and annular shell pass outlet section; and includes mainly shell, hollow annular web plate, shell pass inlet gas flow distributing plate, abruptly expanding accelerated flow contracting-expanding tube bundle, shell pass fluid inlet and outlet, upper and lower tube plates, annular gas inlet and outlet sleeve, gas inlet and outlet slots, upper and lower end covers and support. It has abruptly expanding accelerated flow contracting-expanding tubes as heat transferring tubes and hollow annular web plate as support article between tubes, has the advantages of high heat transfer coefficient, small fluid resistance, less apparatus material consumption, low cost, etc., and is suitable for low density, great volume flow rate and deep heat exchange.

Owner:SOUTH CHINA UNIV OF TECH

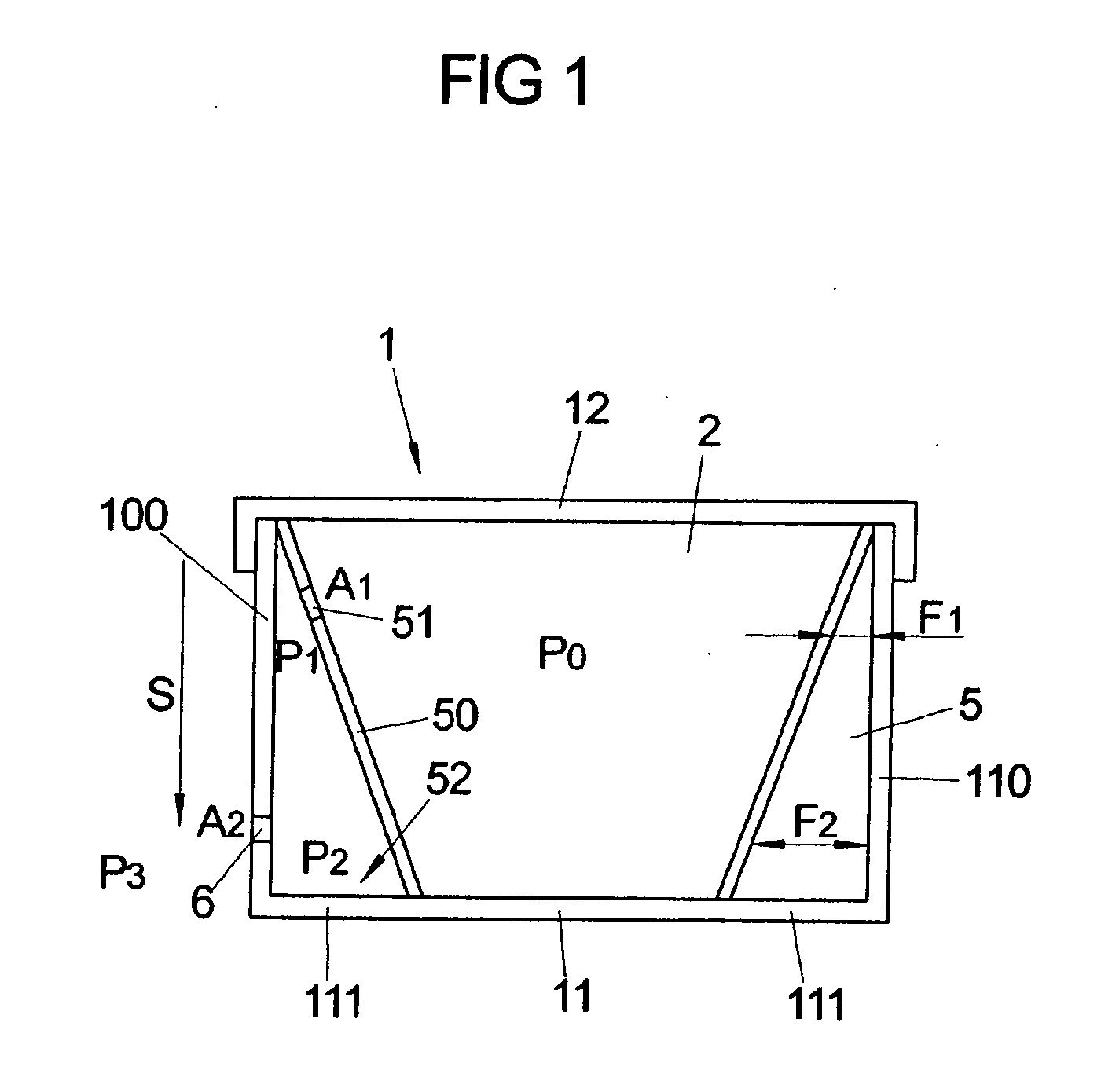

Scrubber for fluid coker unit

ActiveUS20100078305A1Reduce fouling rateReduce temperatureCombination devicesUsing liquid separation agentScrubberAirflow

Fouling in the scrubber section of a fluid coker unit is reduced by providing baffles to improve the uniformity of the gas flow profile in the scrubber by reducing the gas velocity of the cyclone outlet gases in the scrubber section of the unit. These baffles are located with the objective of reducing the rotational component of the gas flow in the scrubber created by the alignment of the gas outlets of the cyclones. The baffles are preferably located in the shed section of the scrubber and comprise upstanding perforated plates located at the periphery of the scrubber section to disrupt high velocity gas jets in the region of the interior wall of the scrubber.

Owner:EXXON RES & ENG CO

Flow baffling type demister

ActiveCN104606961ASimple structureSmall pressure dropDispersed particle separationChemical industrySeparation process

The present invention discloses a flow baffling type demister, which comprises a plurality of demisting assemblies aligned in parallel, wherein each demisting assembly comprises a gas rising pipe and an outer cylinder, the outer cylinder is arranged on the outer side of the gas rising pipe and is at the same axis line as the gas rising pipe, the gas rising pipe is fixed on a tower disk, the top portion of the gas rising pipe is provided with a sealing cover plate, the circumference of the gas rising pipe is provided with a plurality of seams, the gas rising pipe circumference close to each seam is provided with tangential diversion wings, and the outer cylinder comprises the straight cylinder section on the upper portion and the taper cylinder section on the lower portion. According to the flow baffling type demister, the separation of the liquid droplet and the gas is achieved through the flow baffling during the fluid flowing process; and the flow baffling type demister has characteristics of simple structure, easy installation and effective gas-liquid separation achieving, and is suitable for the gas-liquid separation process in the fields of chemical industry, environmental protection, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

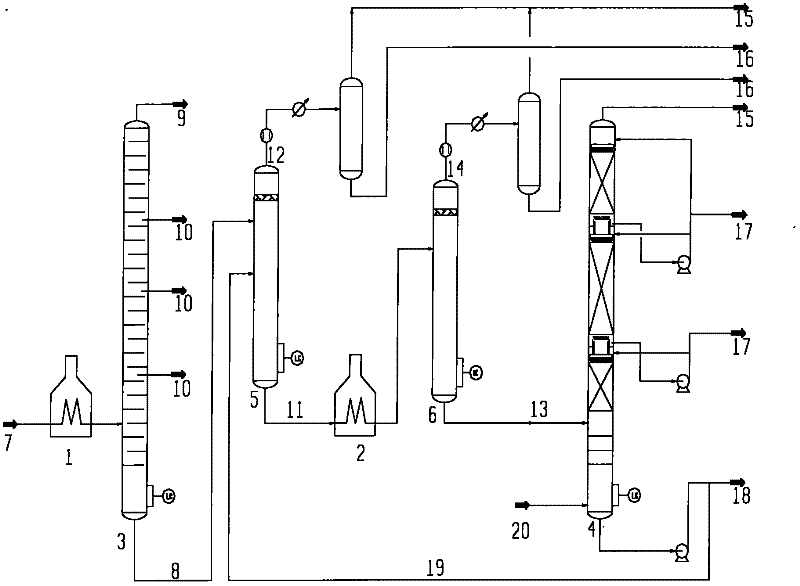

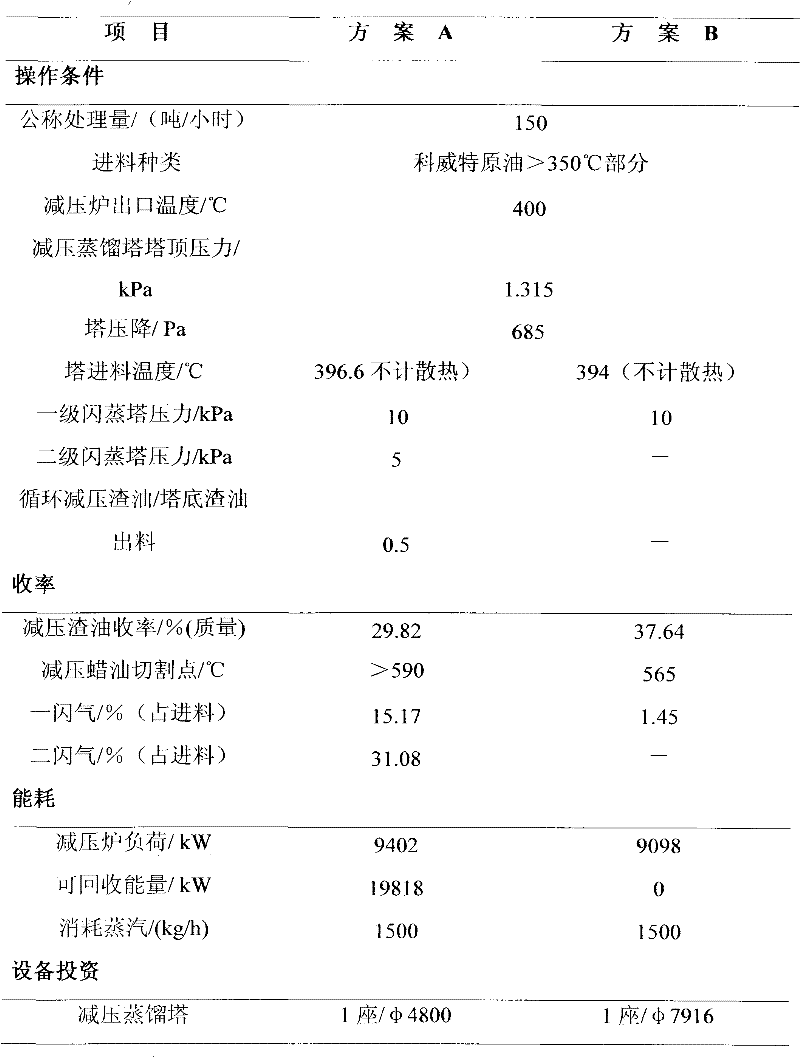

Crude oil distillation method

The invention discloses a crude oil distillation method. A primary flash distillation tower is arranged between a normal pressure distillation tower and a pressure reduction furnace, a pressure reduction oil line from an outlet of the pressure reduction furnace to a pressure reduction distillation tower is omitted, a secondary flash distillation tower is arranged between the pressure reduction furnace and the pressure reduction distillation tower, tower bottom heavy oil of the normal pressure distillation tower, i.e. normal bottom oil enters the primary flash distillation tower after being mixed with cyclic pressure reduction slag oil, the tower top gas phase of the primary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, bottom oil of the primary flash distillation tower enters the secondary flash distillation tower through being heated by the pressure reduction furnace, the tower top gas phase of the secondary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, and bottom oil of the secondary flash distillation tower is introduced into a flash distillation section of the pressure reduction distillation tower for pressure reduction distillation. Compared with the prior art, the method has the advantages that on one hand, the yield of the pressure reduction slag oil is reduced, and the economic benefits of devices are improved; and on the other hand, the load of the pressure reduction furnace and the pressure reduction distillation tower is reduced, the device investment is saved, and the energy consumption of the devices is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Roller Mill With Gas Duct

ActiveUS20110127360A1Reduce total pressure lossReduce energy consumptionGas current separationCement productionAnnular ductMechanical engineering

A roller mill for grinding particulate material such as cement raw materials, cement clinker and similar materials comprises a mill housing surrounding a substantially horizontal grinding table, a number of rollers each rotating about a roller shaft and configured for interactive operation with the grinding table and at least one mechanism or device for introducing gases into the mill housing. The at least one mechanism or device for introducing gases into the mill housing comprises an annular duct having openings in a wall facing the grinding table and being located around the outer circumference of the grinding table. As a consequence hereof, a significant reduction of the pressure loss in a roller mill and thus a significant reduction of energy consumption will be ensured.

Owner:F L SMIDTH & CO AS

Method and vertical mill for grinding a product to be milled

The invention relates to a vertical mill for grinding a product to be milled and a method therefor, wherein the vertical mill has a grinding plate and one or more grinding rolls. A blade ring annular channel is provided for a transport gas flow rising around the grinding plate. An annular gap is provided between a downwards projecting middlings cone and the upper range of the grinding rollers through which gap even a fines content is recirculated back to the grinding plate. To overcome this disadvantage, a barrier gas flow is provided flowing from the inside towards the outside, by means of which the recirculation of ground particles of a defined size can be prevented.

Owner:LOESCHE GMBH

Flue gas desulfurizing tower and flue gas desulfurization and wastewater treatment method

ActiveCN108619872AWell mixed contactReduce energy consumptionUsing liquid separation agentWaste water treatment from gaseous effluentsFlocculationFlue gas

The invention discloses a flue gas desulfurizing tower and a flue gas desulfurization and wastewater treatment method. The flue gas desulfurizing tower sequentially comprises a flue gas exhaust area,a demist area, a tower tray area, a spraying area and a wastewater treatment area from top to bottom; the flue gas exhaust area and the demist area are connected through a cone deformation diameter, the tower tray area and the spraying area are connected through an inverted cone deformation diameter; the wastewater treatment area is divided by a vertical partition plat I from the center into an oxidation flocculation area and a circulation clear liquid area, the circulation clear liquid area is completely separated from the oxidation flocculation area and the spraying area through a partitionplate II from the top part of the circulation clear liquid area; the oxidation flocculation area is provided with a stirring device; and the vertical partition plate I is provided with a filter medium. The flue gas is subjected to dust removal, desulfurization and wastewater treatment in one tower, the flue gas is used to stir the wastewater to implement the operations of oxidation flocculation and concentration, the difference of the liquid levels of the two sides of the vertical partition plate is used as a driving force to filter the desulfurization wastewater, the occupied area is greatlyreduced, and the costs for the construction and transformation of the device and the operation cost of the device are obviously lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas diffuser ion inlet

ActiveUS20140353496A1Reduce velocity of gasIncrease cross-sectional areaSamples introduction/extractionDust removalAirflowMass analyzer

In some embodiments, a gas diffuser for use in a mass spectrometer is disclosed that can provide a controlled expansion of an ion-containing gas so as to reduce gas velocity for entry into subsequent stages of the mass spectrometer, e.g., a mass analyzer. In some embodiments, the controlled expansion of the gas is provided by flowing the gas through a channel whose cross-sectional area change, e.g. progressively increases, in the direction of the gas flow so as to provide controlled expansion of the gas.

Owner:DH TECH DEVMENT PTE

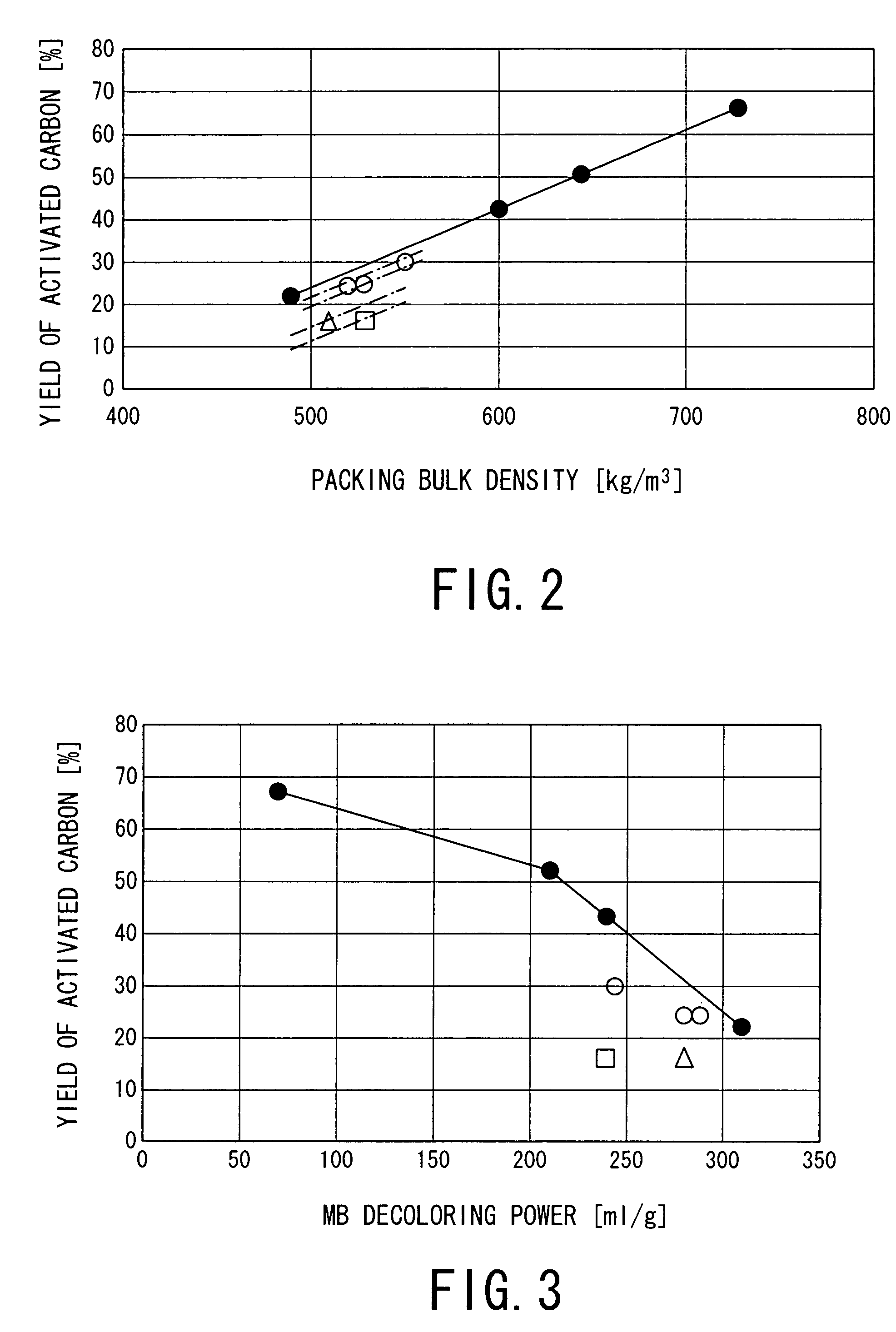

Continuous operation type active charcoal producing apparatus and process

InactiveUS7771668B2Prolonged activation processHigh yieldPigmenting treatmentPhysical/chemical process catalystsActivated carbonProduct gas

Owner:KUREHA KAGAKU KOGYO KK

Gas-liquid allotter with supporting and mass transfer function

InactiveCN1919399ASimple structureEasy to makeDispersed particle separationFractional distillationMass transferEngineering

The invention discloses a gas-liquid distributor with support and mass transfer function, which consists of multiple liquid phase distributing grooves to arrange parallelly along radial direction and multiple liquid phase distributing semi-grooves on two sides of liquid phase distributing groove, wherein each gap of liquid phase distributing groove and semi-groove is gas phase distributing channel, which interconnects each liquid phase distributing groove and semi-groove, the mass transfer hole is opened on the liquid phase distributing groove and semi-groove, which is compatible with mass transfer function for distributor.

Owner:褚雅志

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com