Method and vertical mill for grinding a product to be milled

A grinding machine, a technology to be ground, applied in the direction of grain processing, etc., can solve the problems of high pressure loss, increased pressure loss, burden, etc., to achieve the effect of reducing the overall burden, reducing pressure loss, and improving pneumatic conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

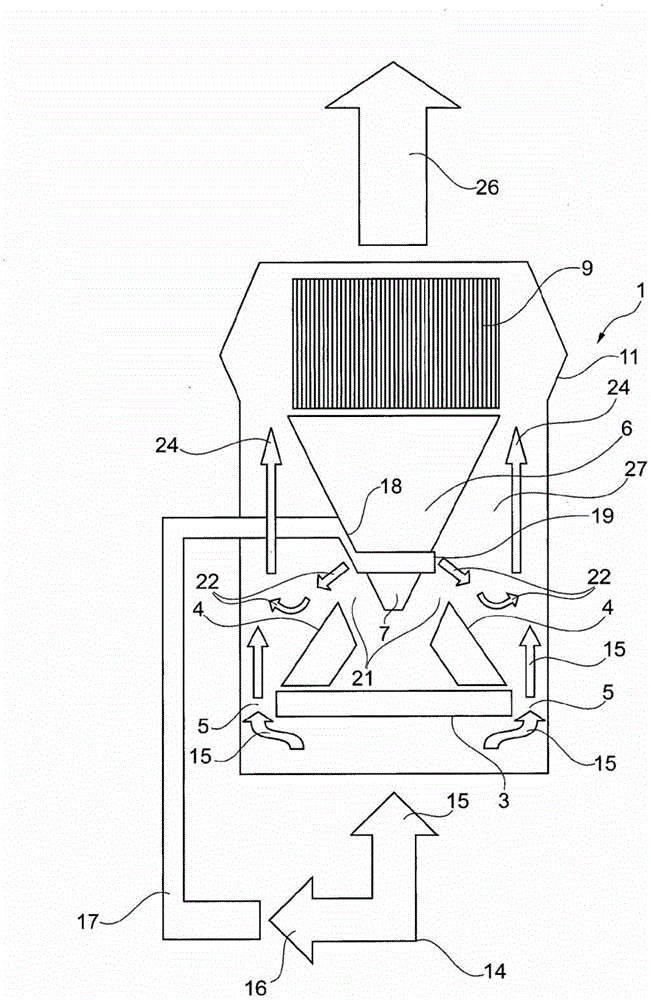

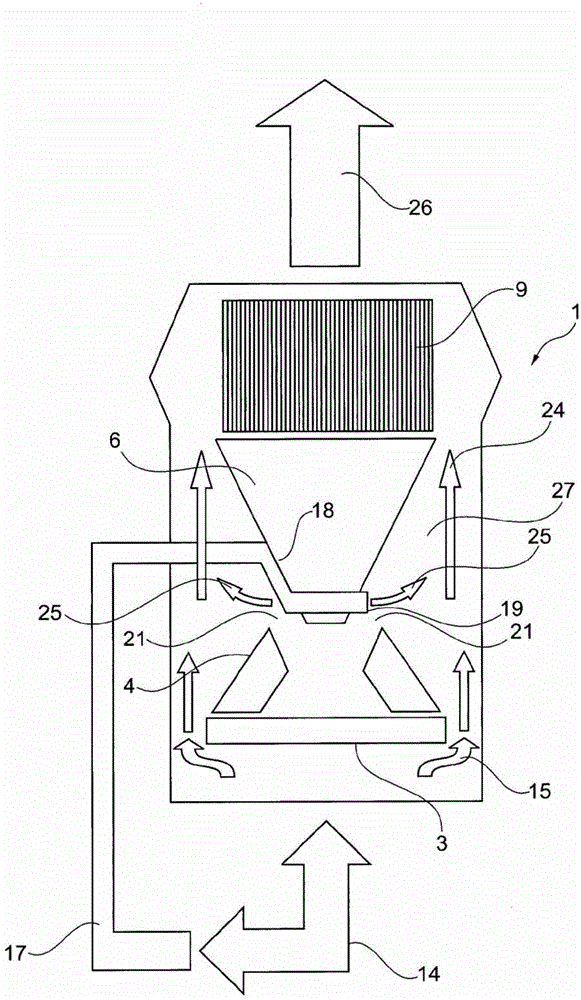

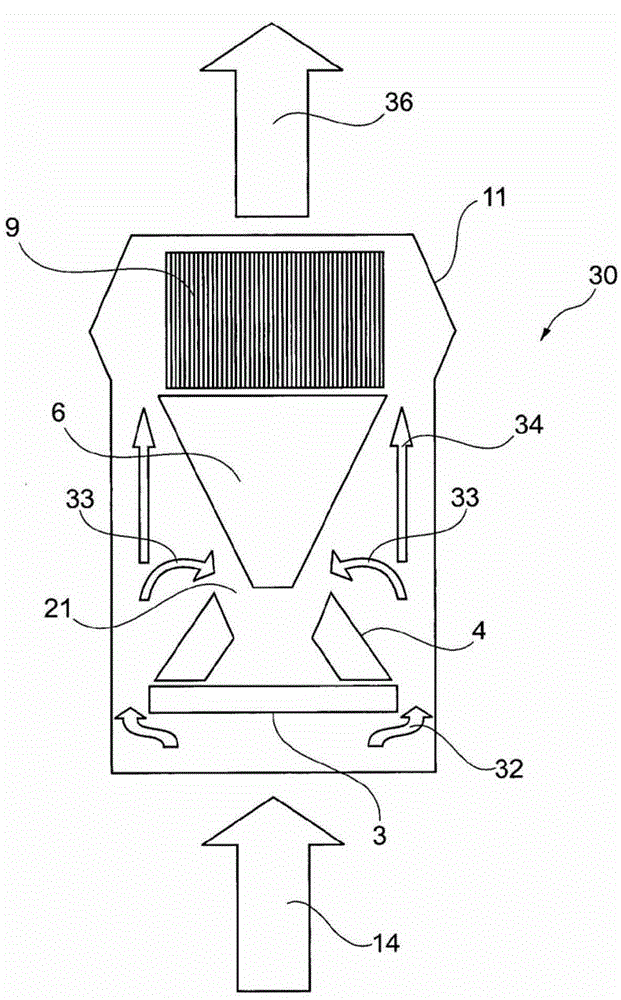

[0045] figure 1 , figure 2 and image 3 The main components of the vertical mills shown in are all of the same construction, such as the grinding table 3, the grinding rollers 4, the oversized material cone 6 and the classifier 9 arranged above and the surrounding mill housing Body 11.

[0046] Problematic recirculation flow 33 ( image 3 ) and its diversion into the annular gap 21, can be constructed in a simple manner and by according to figure 1 and figure 2 The solution method to overcome.

[0047] in accordance with figure 1 In the embodiment of the vertical grinding machine 1, a part of the air flow is diverted from the main air flow 14 via the branch line 17.

[0048] When the grinding process carried out in the vertical grinding mill is a grinding-drying process (for example for moist raw coal), hot air is generated in the hot gas generator and fed as main air flow 14 below the grinding table 3 to the vertical grinding mill. Grinder 1. A part of the air flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com