Gas-liquid allotter with supporting and mass transfer function

A gas-liquid distributor and functional technology, applied in the field of gas-liquid distributor, can solve problems such as single function and complex structure, and achieve the effects of reducing tower height, increasing load-bearing capacity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

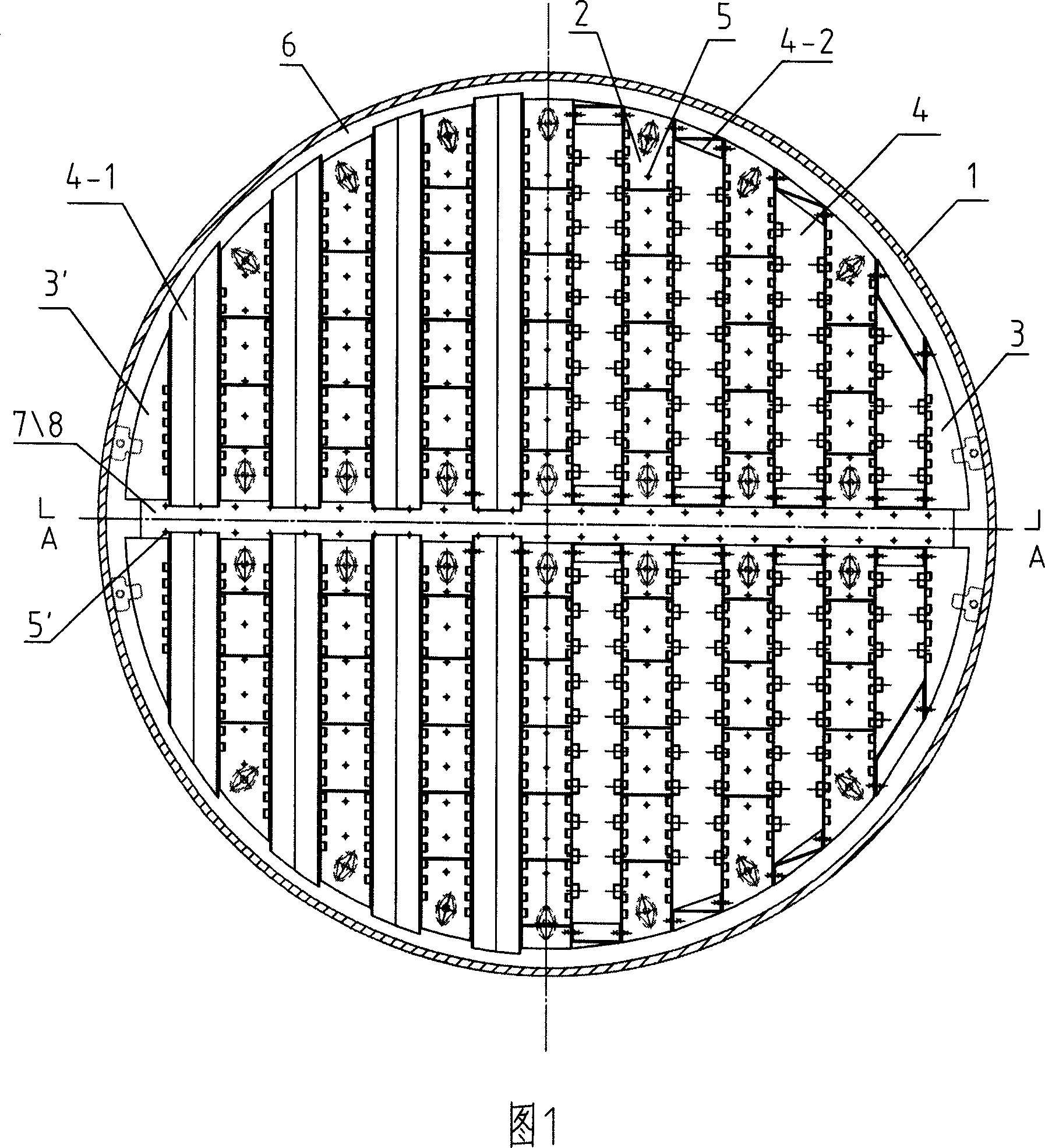

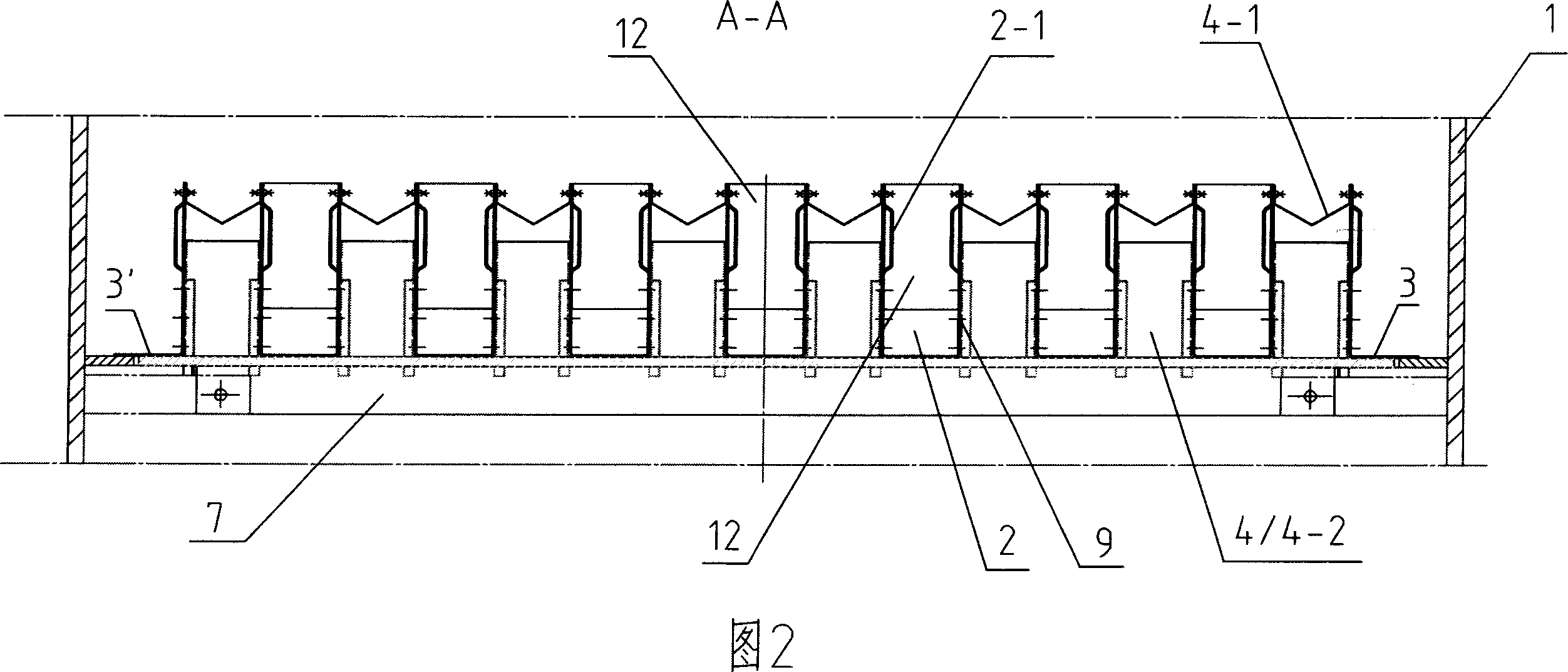

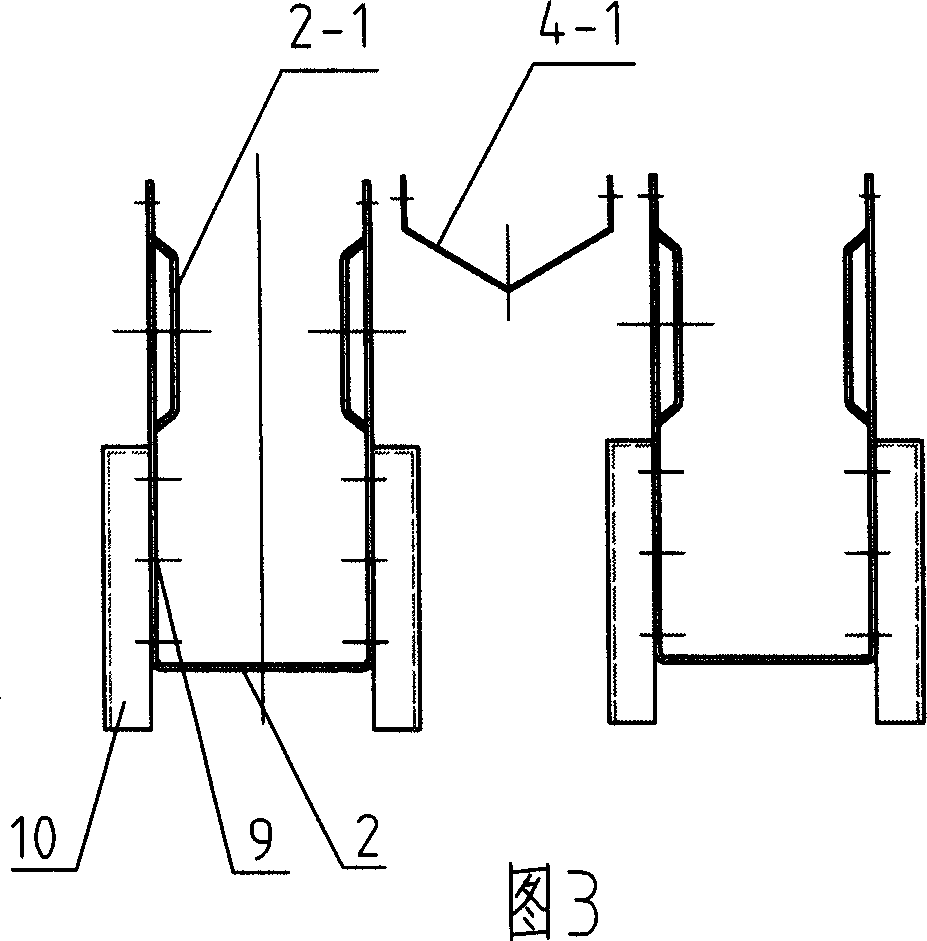

[0025] Referring to Figures 1 and 2, the distributor includes multiple liquid phase distribution tanks 2 and liquid phase distribution half tanks 3, 3', the multiple liquid phase distribution tanks 2 are arranged in parallel at intervals along the radial direction of the tower 1, and the liquid phase The distribution half tanks 3, 3' are arranged on both sides of a plurality of liquid phase distribution tanks 2, and the interval between each liquid phase distribution tank and the liquid phase distribution half tanks is a gas phase channel 4, and a groove is sealed on the upper end of the gas phase channel Type gas phase cover 4-1, the two ends of this gas phase channel are sealed with upright gas phase sealing plate 4-2, through cover 4-1 and sealing plate 4-2 a plurality of liquid phase distributing tanks 2 and liquid phase distribution The half grooves 3 and 3' are connected into one body, and the axisymmetric right half in the figure shows the structure without the gas phase...

Embodiment 2

[0030] Referring to Figures 1 and 7, this example is basically the same in structure as Embodiment 1, except that the narrow diversion groove on the side vertical plate of the liquid phase distribution tank 2 is replaced by a wide diversion groove 13, and the mass transfer hole is removed, and the wide diversion groove Line distribution of two lines of liquid can be formed at the gas phase channel, thereby eliminating the distribution blind area of the gas phase channel, and also has a good distribution effect.

[0031] The distribution process of the liquid phase and gas phase of the distributor is: see Figure 1, 2, the liquid falling from the top of the distributor enters the liquid phase distribution tank 2 and the liquid phase distribution half tank 3, 3', and the liquid that falls on the gas phase channel The liquid is collected by the grooved gas phase cover (4-1), flows out from both ends and enters the liquid crossing channel 8 and the annular liquid channel 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com