Flame holder and ground gas turbine combustion chamber with same

A flame stabilizer and combustion chamber technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of wasting combustion chamber space, increasing pollutants, increasing gas residence time, etc., achieving full combustion and reducing residence time. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

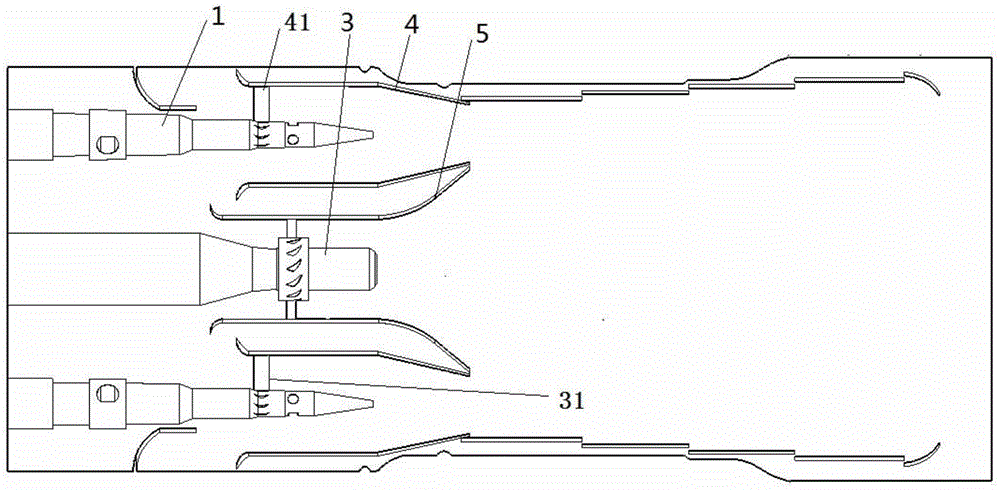

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

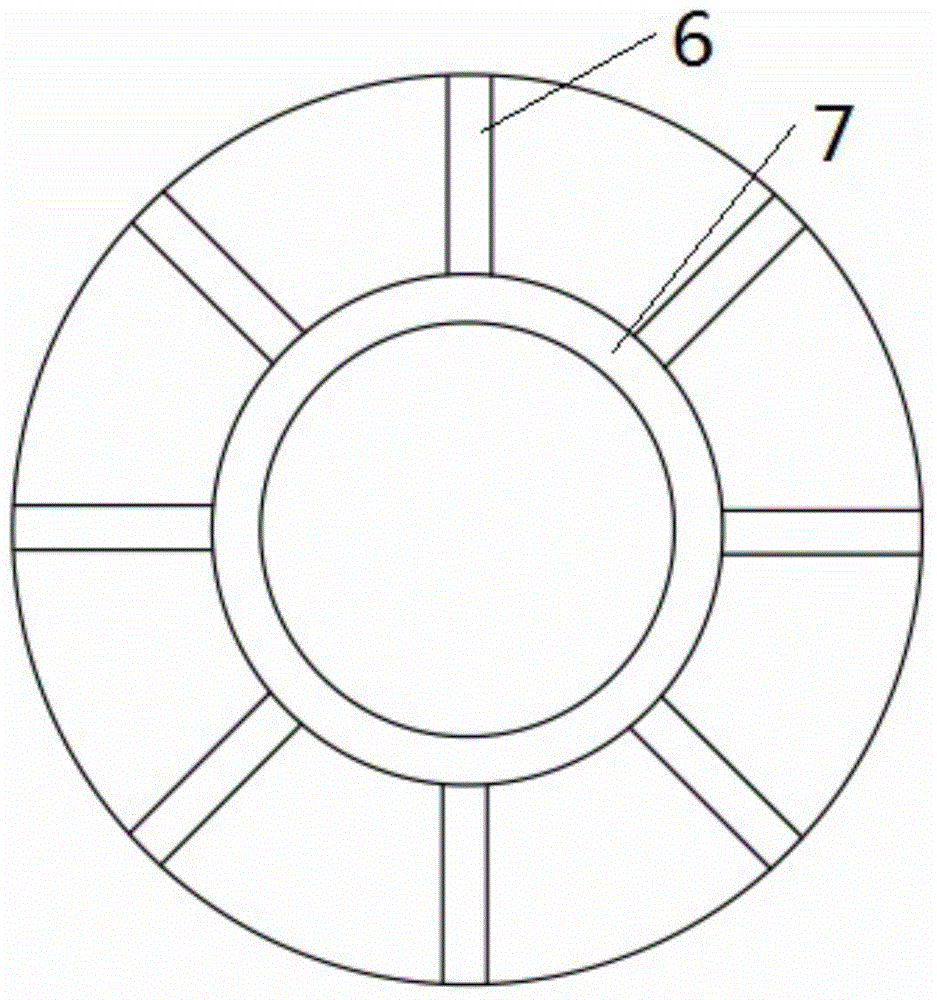

[0025] Such as Figure 2~4 As shown, the flame stabilizer of this embodiment includes a central ring 7, eight radial struts 6 (the number of radial struts corresponds to the number of main swirlers in the combustion chamber) and a connecting ring. The central ring 7 is arranged in the middle of the connecting ring in parallel, and eight radial struts 6 are evenly fixed on the outer ring surface of the central ring 7 along the radial direction, and the free ends are connected with the inner ring surface of the connecting ring.

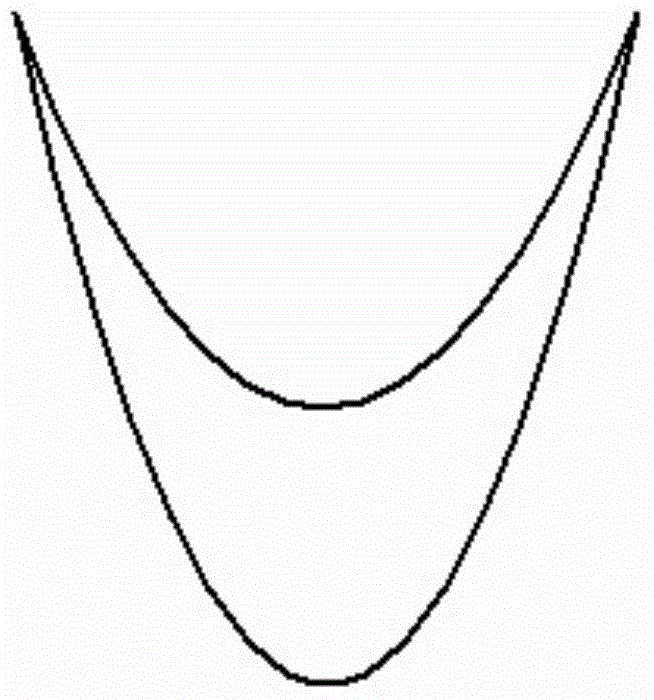

[0026] Both the ring body of the central ring 7 and the radial struts 6 are formed by components of a groove-like structure. Such as image 3 As shown, the member of the trough structure is composed of two upper and lower arc-shaped surfaces, the two sides of the two arc-shaped surfaces are overlapped together, and a cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com