Patents

Literature

59results about How to "Eliminate local hot spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite graphene infrared radiation and heat conduction film and manufacturing method thereof

ActiveCN105514066AImprove infrared radiation performanceFast heat conductionSemiconductor/solid-state device detailsConjugated diene hydrocarbon coatingsOptoelectronicsHeat sink

The invention discloses a composite graphene infrared radiation and heat conduction film and a manufacturing method of the composite graphene infrared radiation and heat conduction film, and is characterized in that a substrate is provided with a composite graphene infrared radiation coating layer. According to the manufacturing method of the composite graphene infrared radiation and heat conduction film disclosed by the invention, a thin film manufactured by utilizing good infrared radiation capacity and good heat conduction capacity of a composite graphene infrared radiation material has the good heat conduction capacity in both directions which are parallel to and vertical to the substrate, so that heat can be rapidly transferred from a heating part to a heat sink device or an environment, the heat conduction efficiency is increased, local hot points in a device are removed, and temperature gradient in a heat conduction path is reduced; the composite graphene infrared radiation and heat conduction film disclosed by the invention has the advantages that the manufacturing is simple and convenient, and a powerful support is provided for high integration of electronic devices and rapid heat conduction of heating devices.

Owner:宿州晶禾科技有限公司

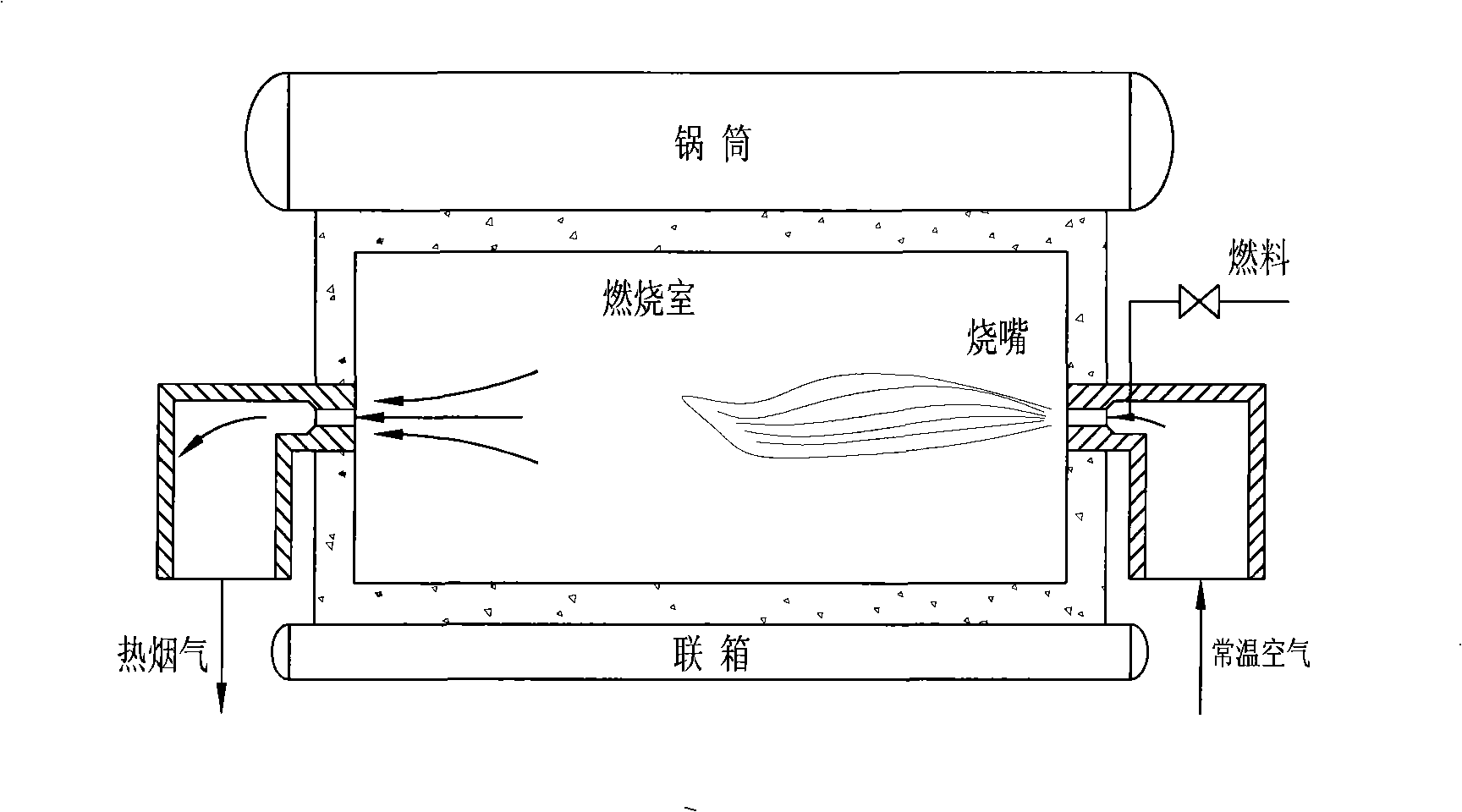

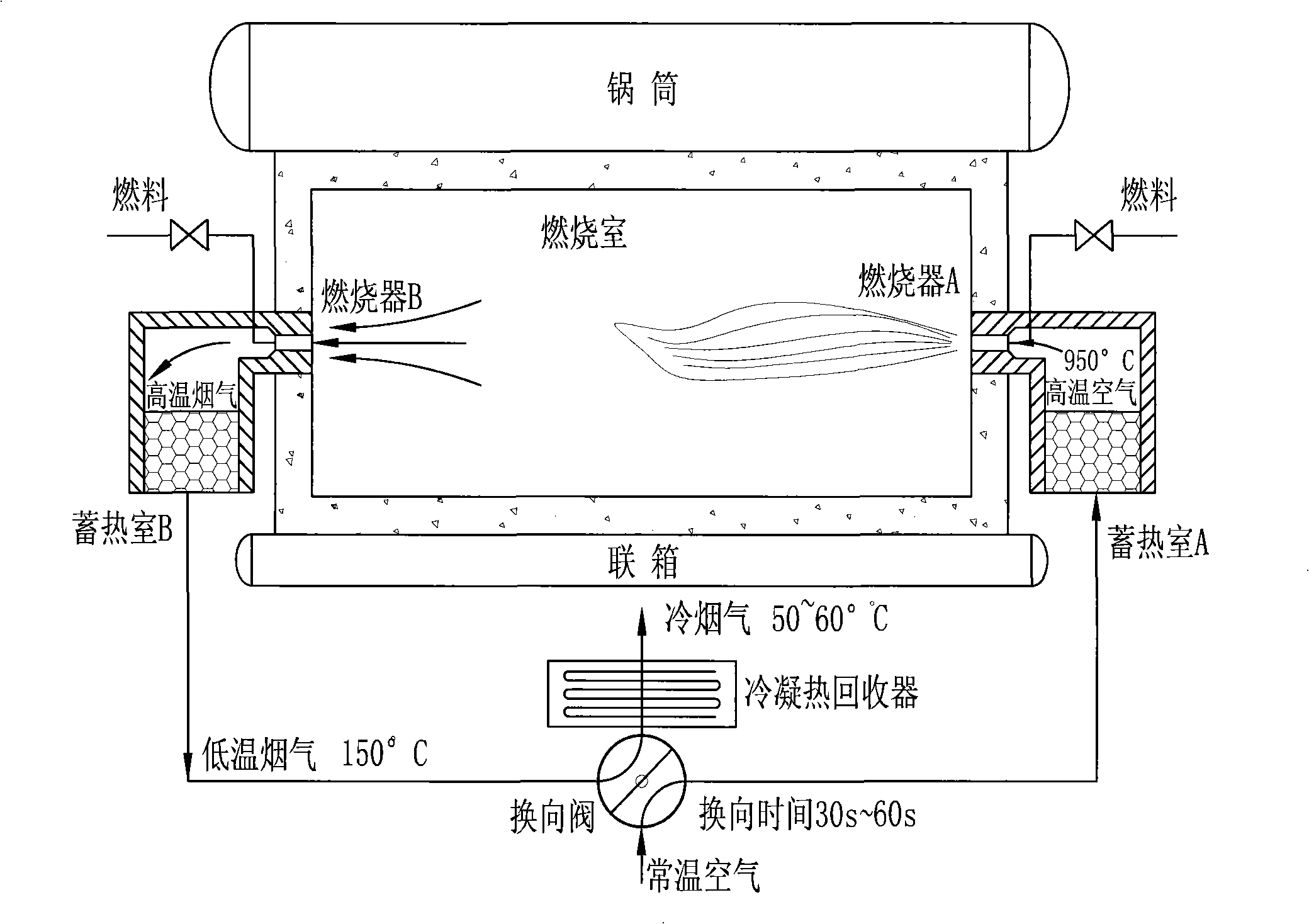

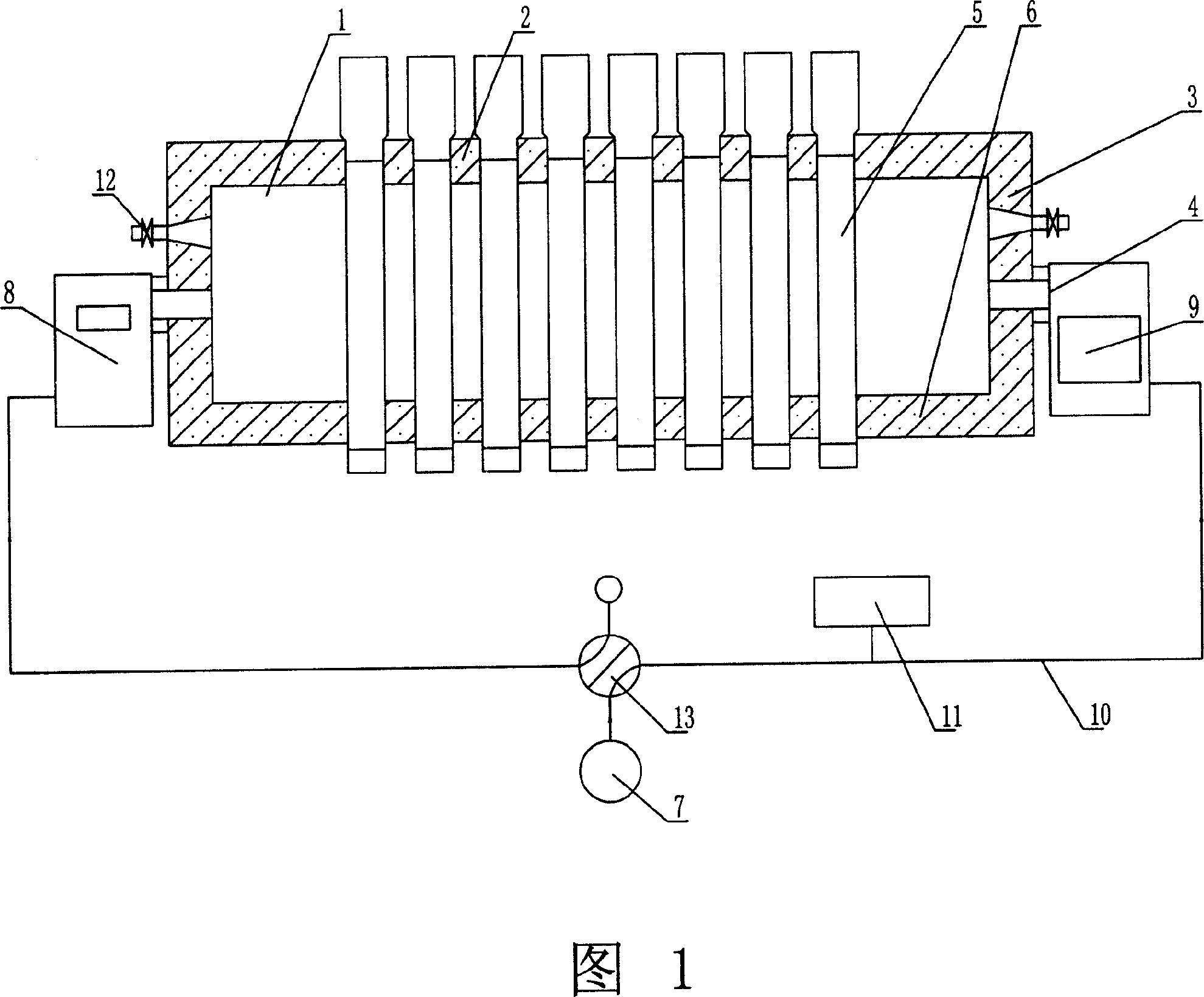

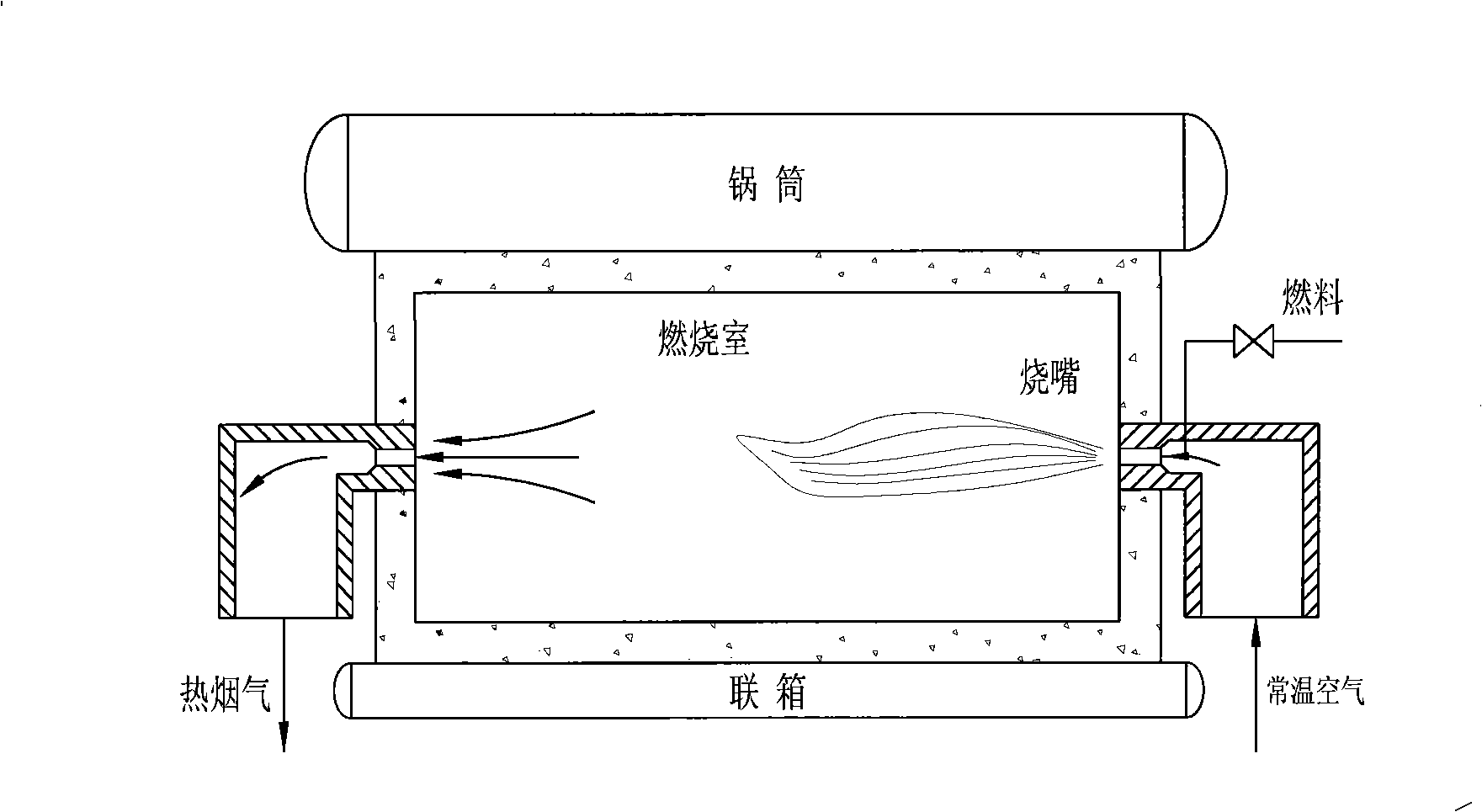

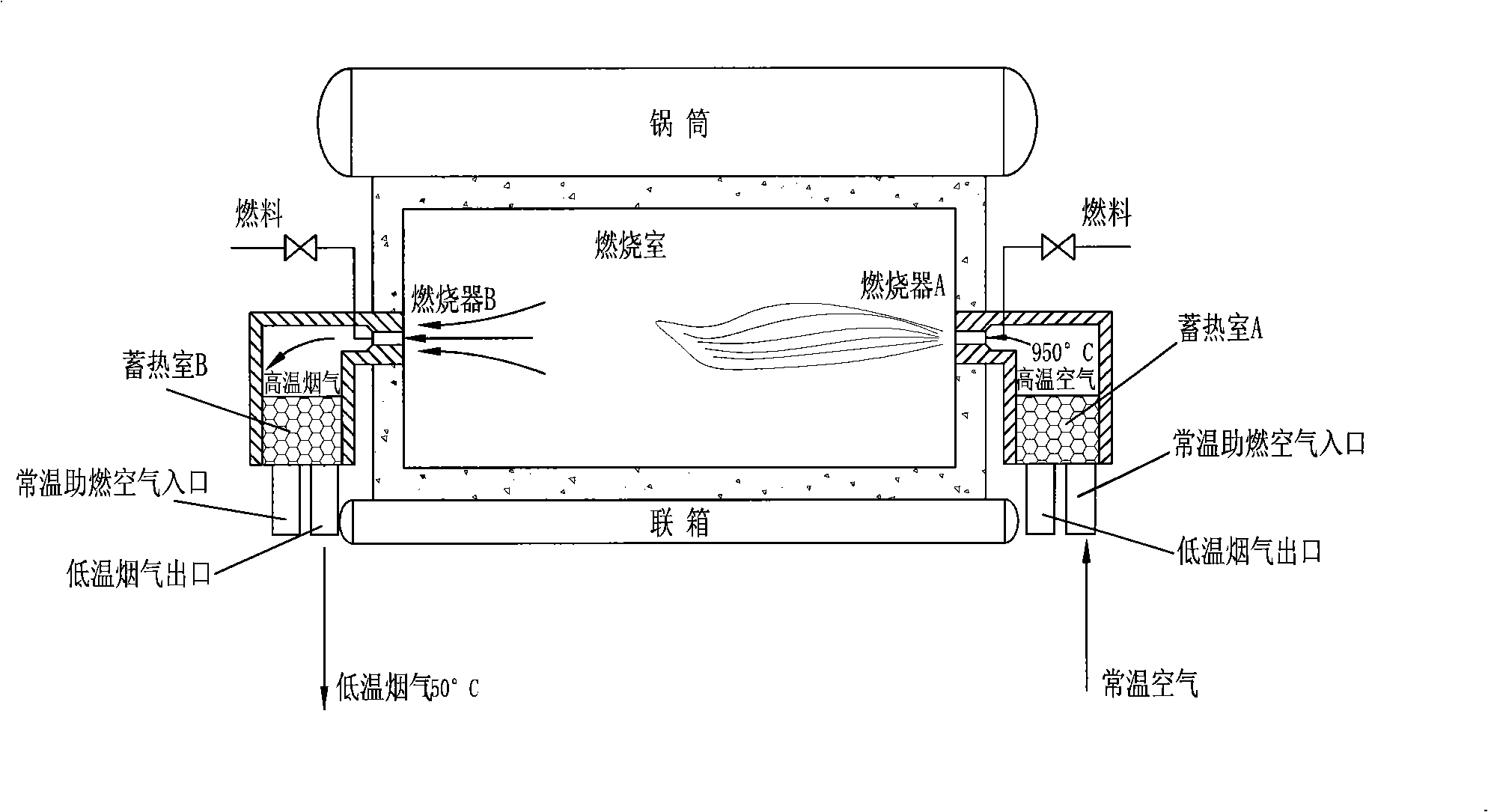

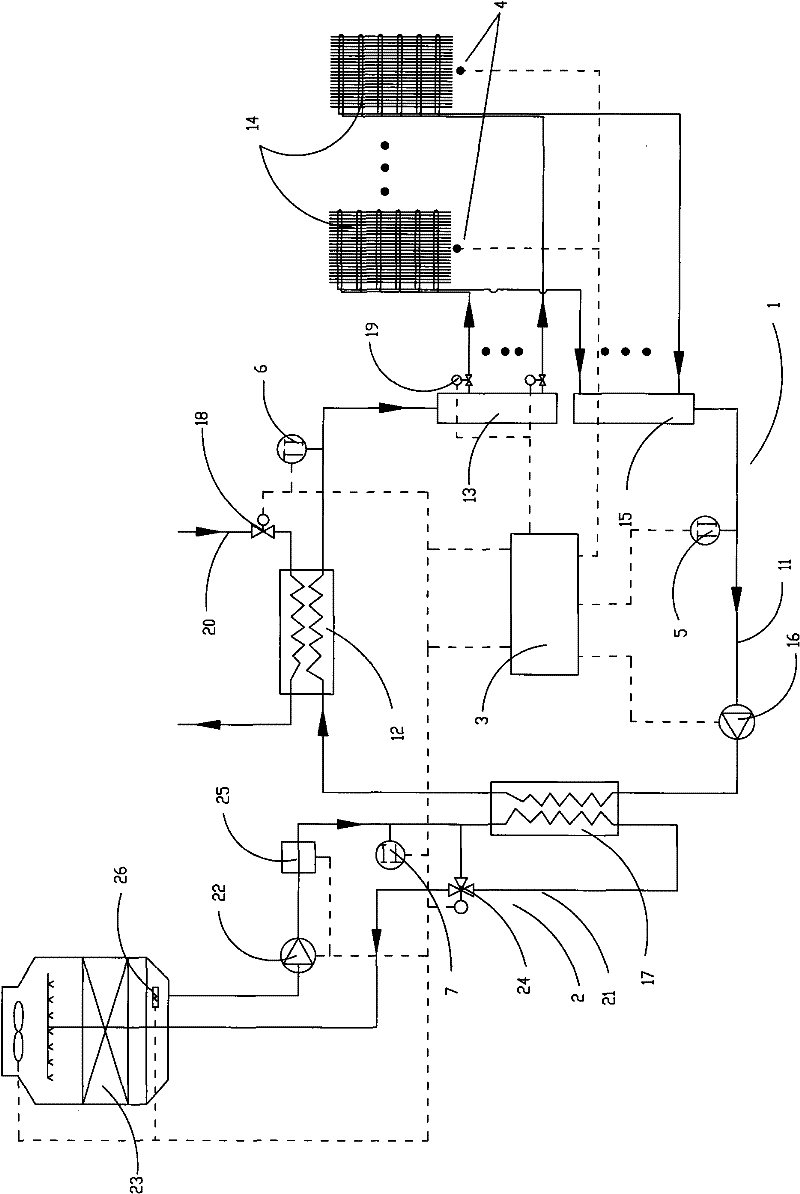

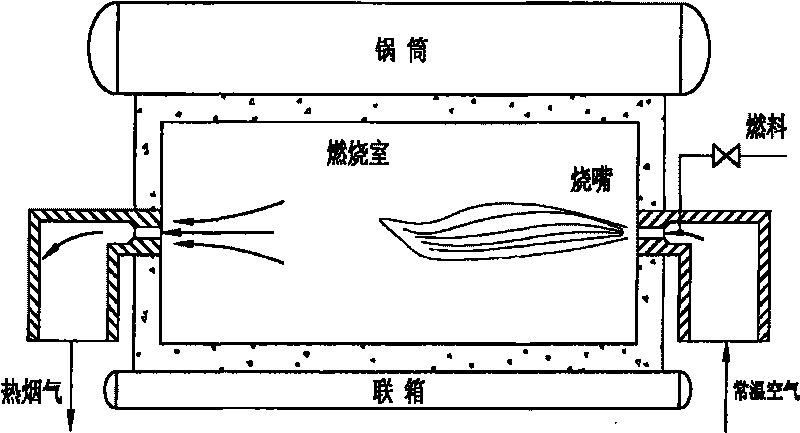

High performance fuel heat accumulation type condensation energy-saving boiler

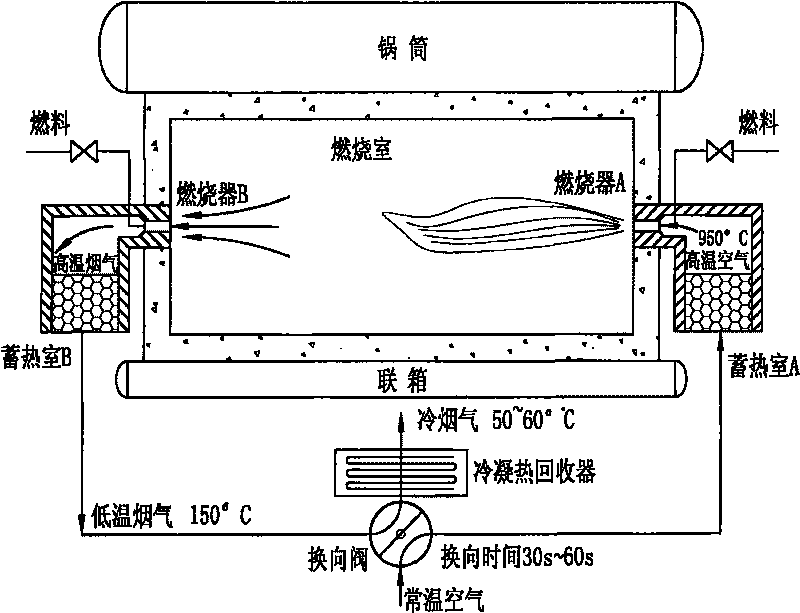

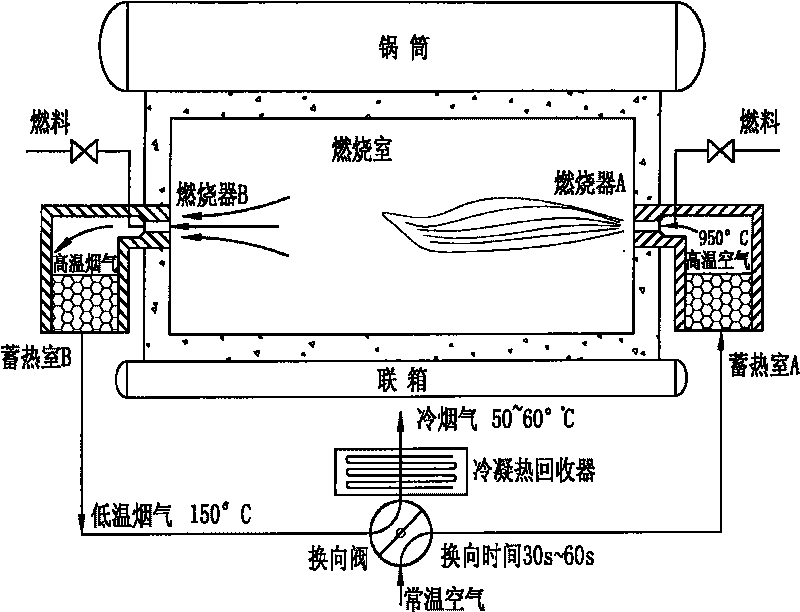

InactiveCN101319788AReduce lossesEliminate local hot spotsCombustion processDrum steam boilersCombustorHigh energy

The invention discloses a heat accumulating type condensing and energy saving boiler for high energy fuel, which comprises a boiler body. Two or more combustors are arranged in the boiler body, a high-temperature combustion-supporting air inlet opening and a fuel spraying opening are arranged on the combustor, a checker chamber is connected with the high-temperature combustion-supporting air inlet opening, a normal temperature combustion-supporting air inlet and a low-temperature flue gas outlet are connected with the checker chamber, a direction change device is arranged between the normal temperature combustion-supporting air inlet and the low-temperature flue gas outlet, and a condensing heat recoverer is connected with the low-temperature flue gas outlet. On one hand, when the fuel gas is discharged, the waste heat of the fuel gas is recovered through the checker chamber and the condensing heat recoverer, thereby the heat energy loss is reduced, and the combustion efficiency is enhanced; on the other hand, after passing through the checker chamber, the normal temperature combustion-supporting air assists in combustion supporting, and thereby the combustion temperature can be increased; thirdly, a plurality of combustors adopts periodic reversing combustion, thereby the partial high temperature zones in the combustors are avoided, and the internal temperature distribution of the combustors is more uniform. The boiler is applied to various gas fired boilers.

Owner:SHENWU TECH GRP CO LTD

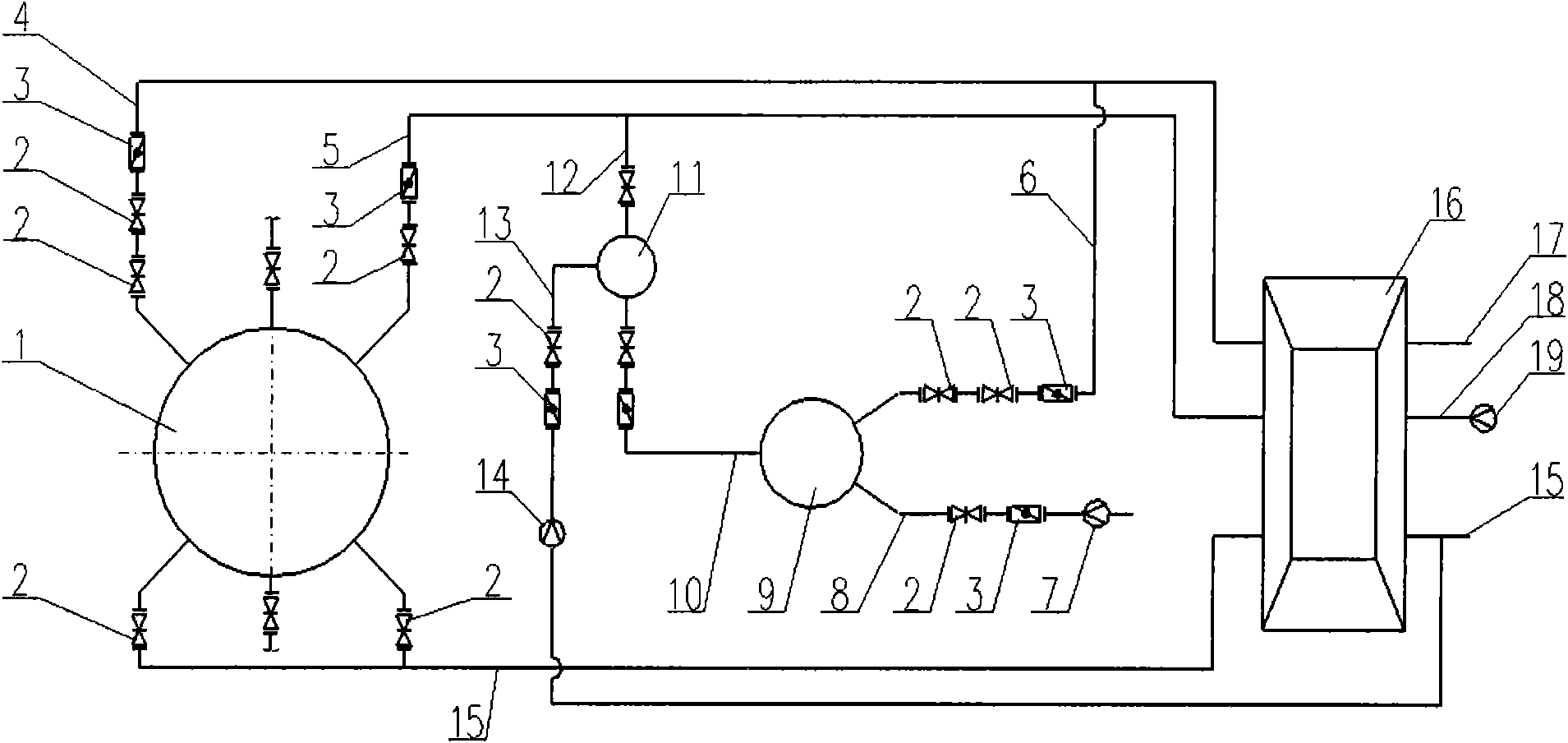

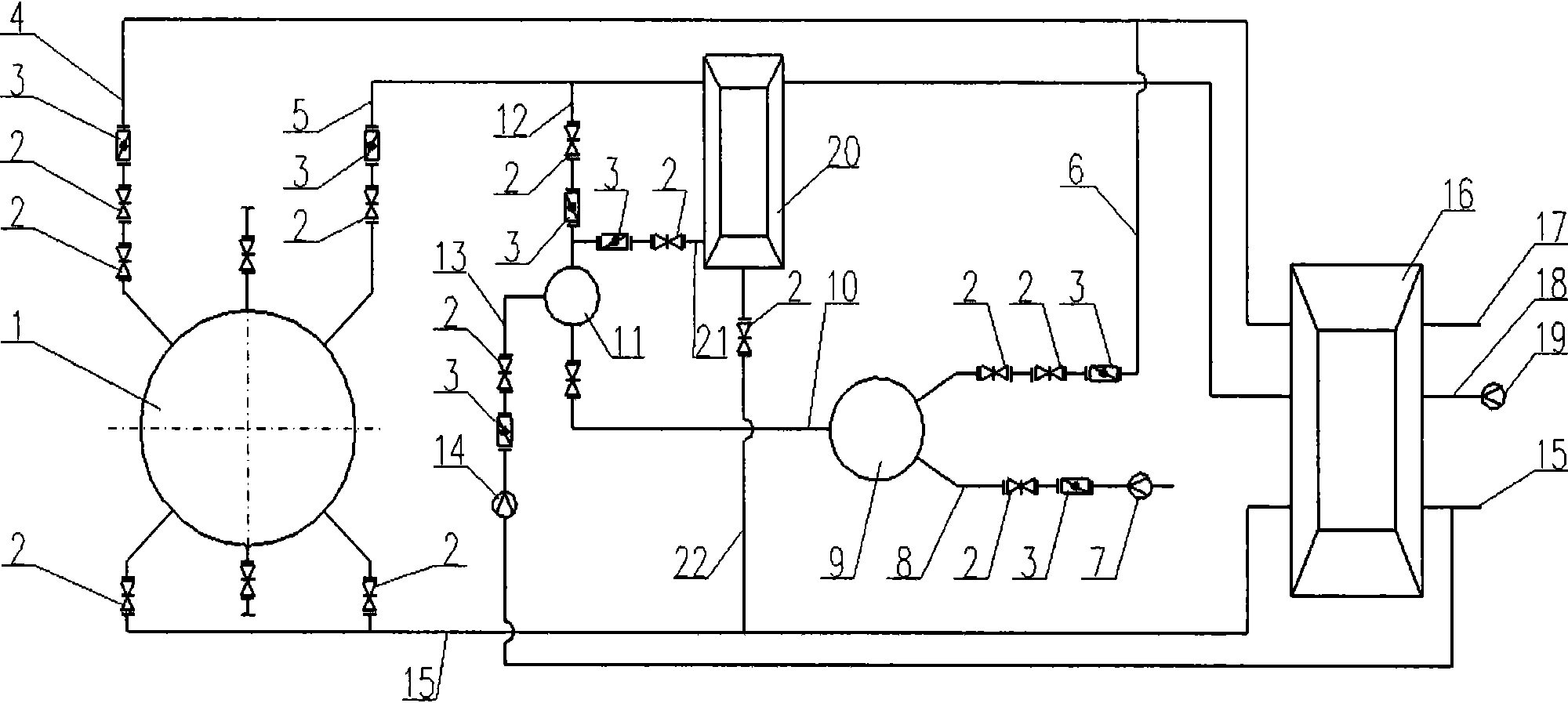

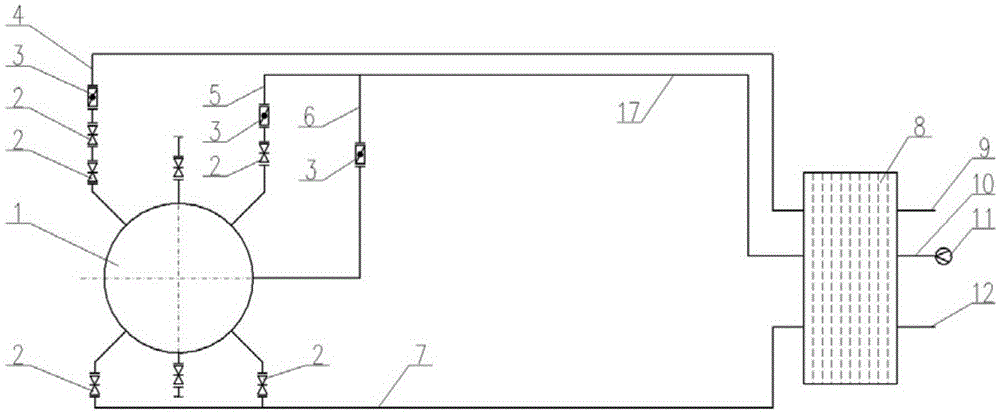

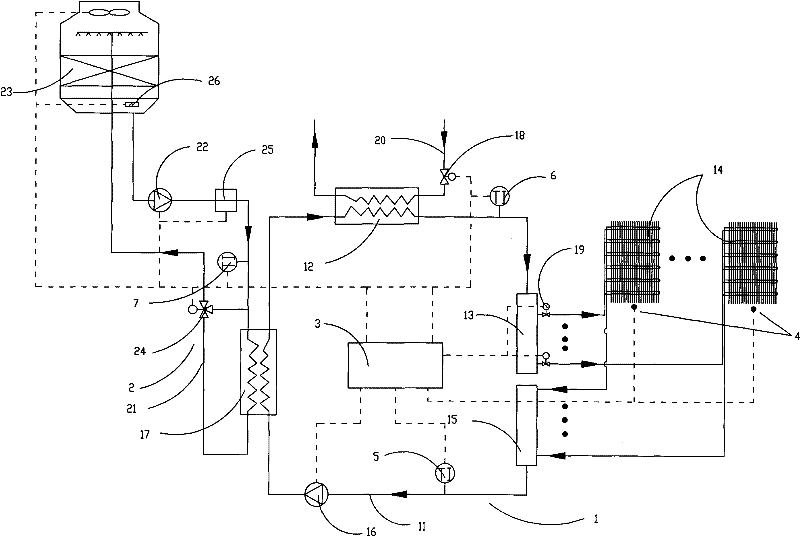

Environment-friendly high temperature low oxygen hot blast furnace

ActiveCN101792839AFlexible adaptation to smelting intensityFlexible process adaptationBlast furnace detailsHeating stovesHot blastFlue

An environment-friendly high temperature low oxygen hot blast furnace belongs to the technical field of hot blast furnaces in the metallurgy industry. The invention comprises a hot blast furnace, shut-off valves, regulating valves, a gas flue for the hot blast furnace, a combustion air pipeline for the hot blast furnace, a gas flue for a combustion furnace, a combustion air fan for the combustion furnace, a combustion air pipeline for the combustion furnace, the combustion furnace, a high temperature flue for the combustion furnace, a gas mixing furnace, a gas mixing pipeline, a low temperature flue, a flue gas pressing machine, flues for the hot blast furnace, a low temperature preheating system, a gas main from a pipe network, a combustion air main and a combustion air fan for the hot blast furnace. The hot blast furnace has the following advantages: the hot blast furnace is suitable for different metallurgical technological processes, can be used in combination with various combustion air and gas low temperature preheating devices, fully recover the flue gas waste heat and further improve the heat efficiency, and realizes high blast temperature, high efficiency, environment friendliness and long life.

Owner:BEIJING SHOUGANG INT ENG TECH

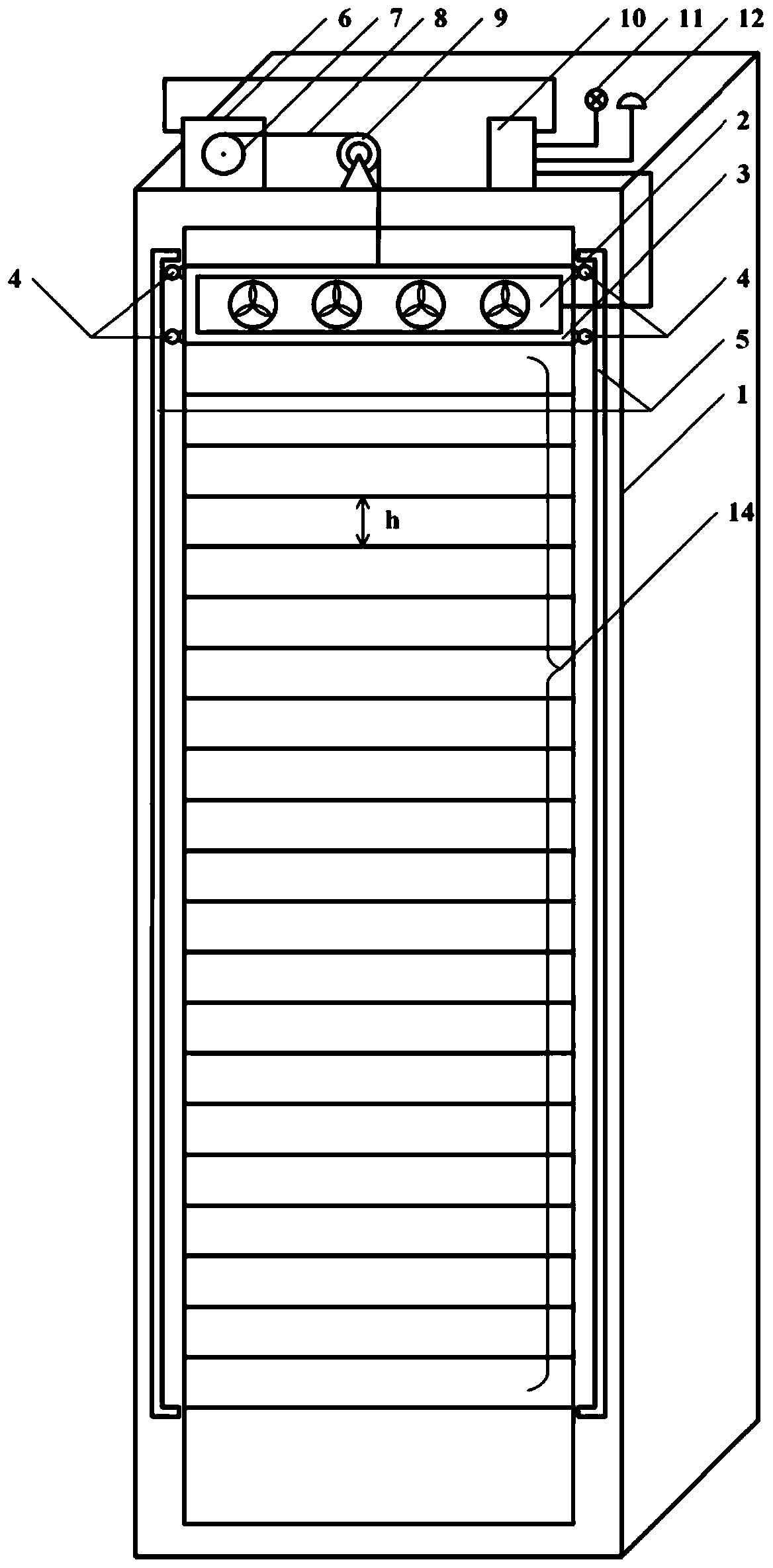

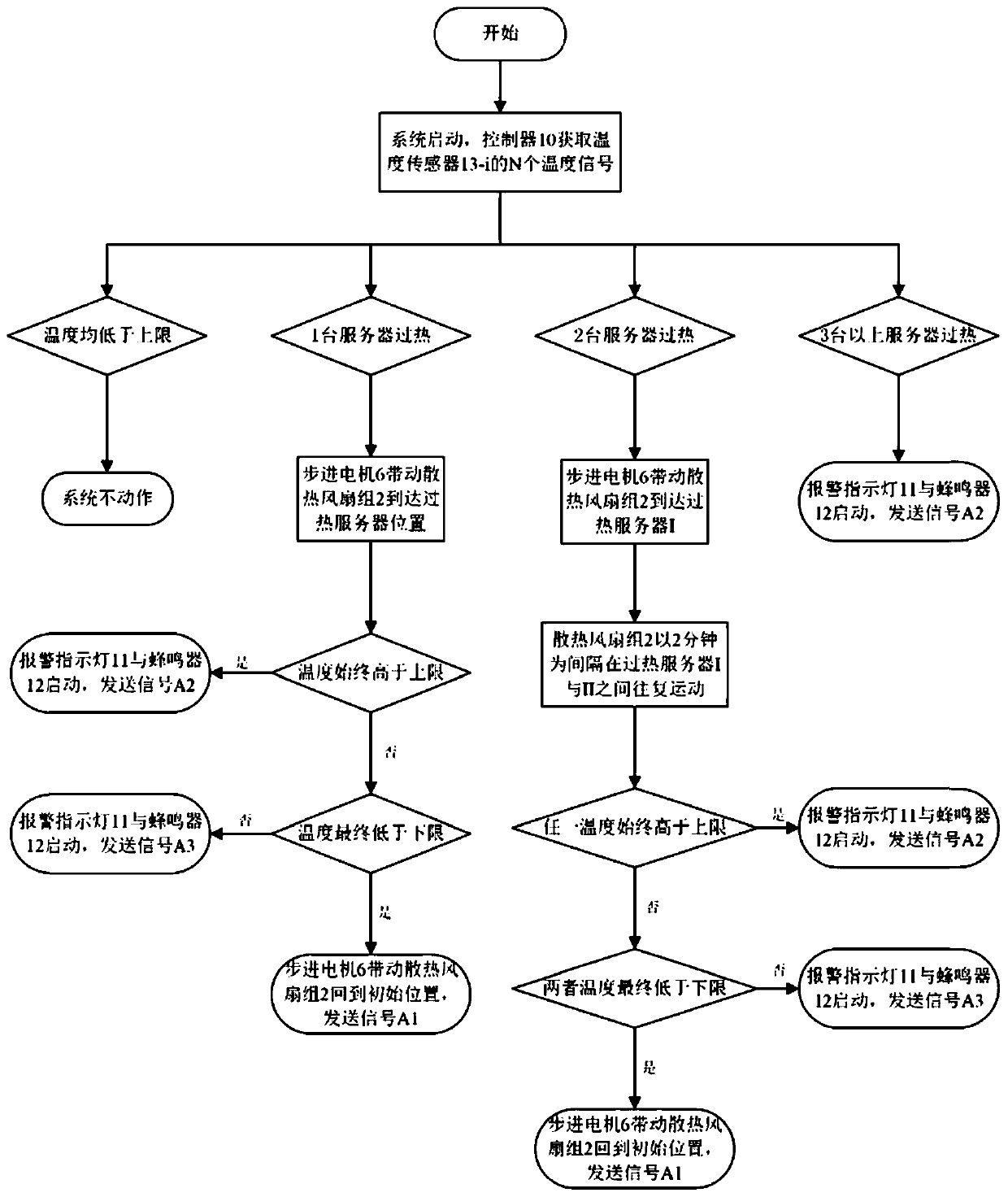

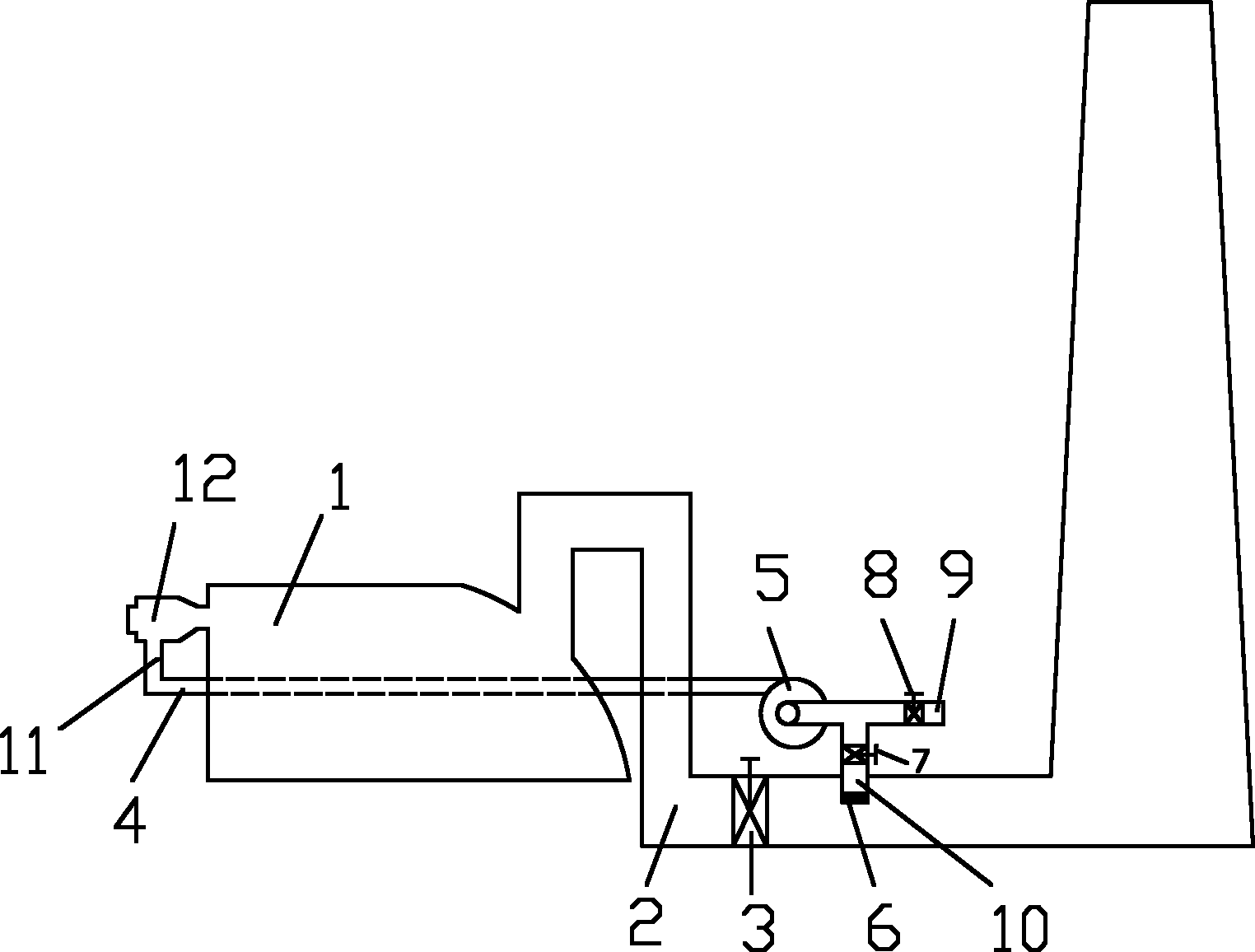

System and method for eliminating local hot spots of server cabinet at data center

ActiveCN110099546AGuaranteed uptimeExtended service lifeModifications using gaseous coolantsEngineeringEnergy consumption

The invention discloses a system and method for eliminating local hot spots of a server cabinet at a data center. The system comprises a server cabinet, a cooling fan group, a fan bracket, a guide rail, a stepping motor, a traction rope, a fixed pulley, a controller and temperature sensors, wherein the stepping motor is connected with the cooling fan group through the traction rope and can drive the cooling fan group to move up and down along the guide rail; and the controller detects local hot spots of the cabinet through the temperature sensors, so that the stepping motor is driven to rotatefor a certain number of turns, the cooling fan group is enabled to reach the air inlet position of an overheated server to increase the air supply volume at the position, enhance heat dissipation andeliminate the local shot spots. The system can automatically carry out accurate air supply on the overheated server, thereby lowering the temperature, ensuring the stable operation of the server, andprolonging the service life. Meanwhile, the air conditioner temperature is avoided from being lowered, and the energy consumption of the data center is reduced.

Owner:SOUTHEAST UNIV +1

Method and device for smelting recycled copper in reverberator

InactiveCN102061396AReduce oxygen contentFacilitate control of burning rateReverberatory furnaceCombustorCombustion

The invention discloses a method and device for smelting recycled copper in a reverberator. With the method, partial high-temperature fumes of the reverberator are directly mixed with combustion-supporting air to form a combustion-supporting gas with high temperature and low oxygen concentration, thereby improving the uniformity of temperature distribution in the reverberator, reducing local high temperature and reducing the burning loss of metal. The horizontal section of a flue gate of the reverberator is connected with a fume backflow pipe, a high temperature fan and a bypass cool air pipe to transmit a part of high temperature fume exhausted from the reverberator to a burner so that high air temperature and low oxygen concentration combustion is implemented in the reverberator and the fume backflow content accounts for 30% to 50% of the total volume of the fume in the reverberator. The method provided by the invention has the advantages of high metal recovery rate and high heat efficiency, and the device has the advantages of simple structure and reliable performance.

Owner:CENT SOUTH UNIV

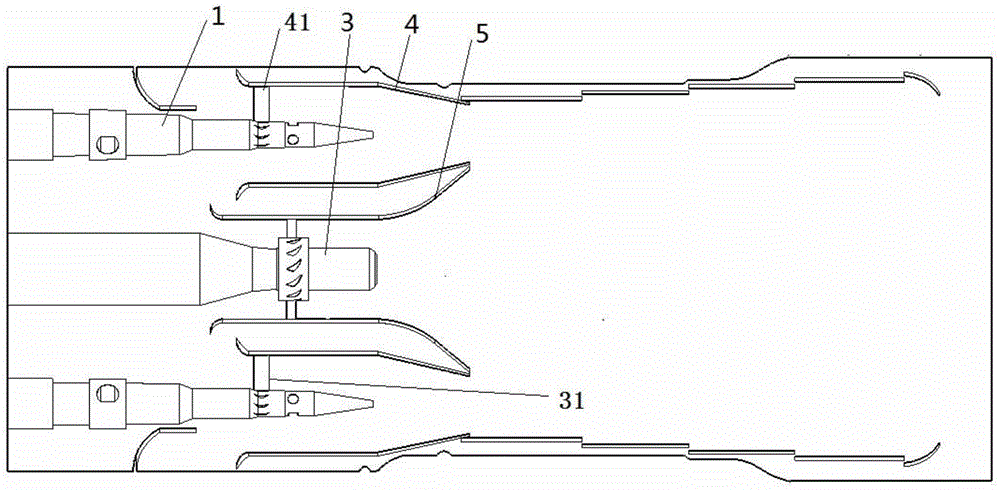

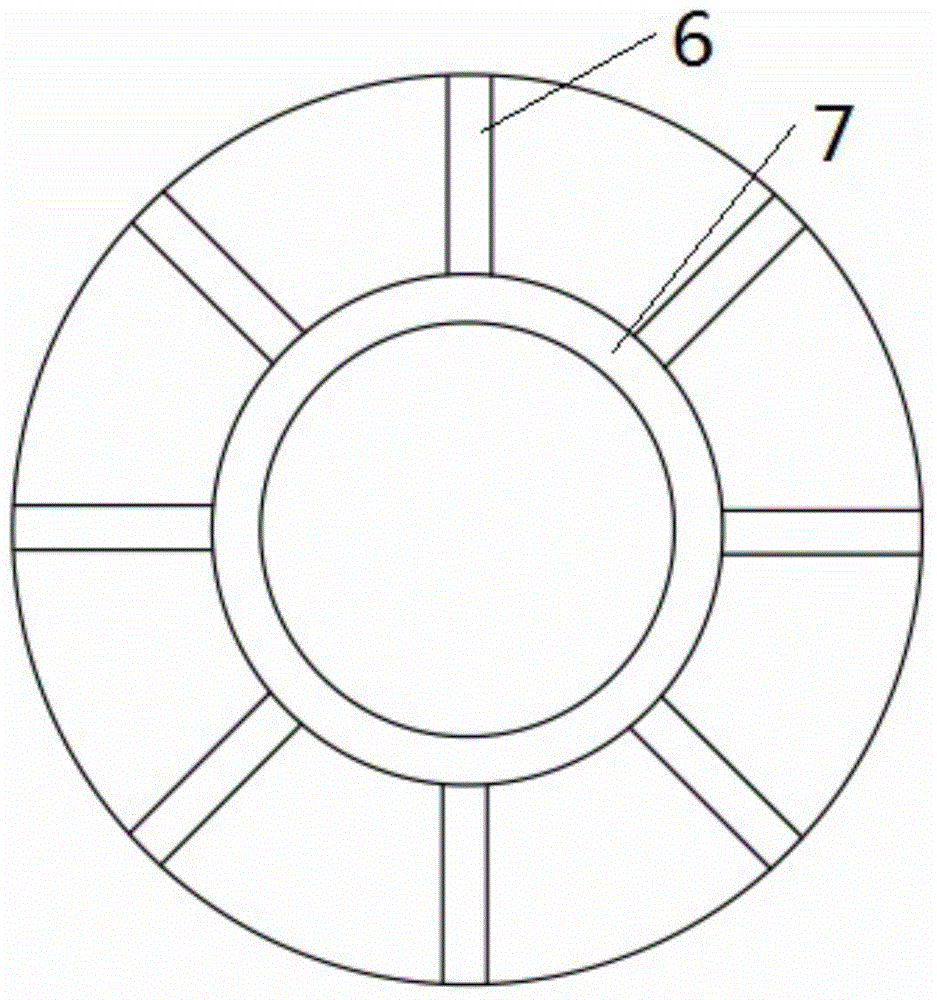

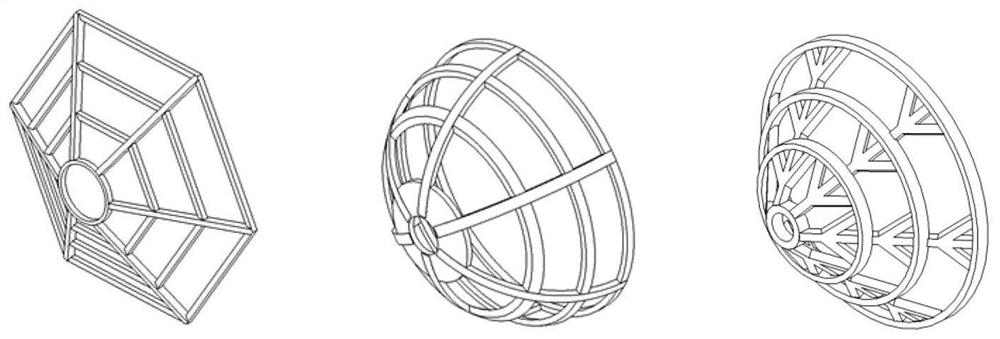

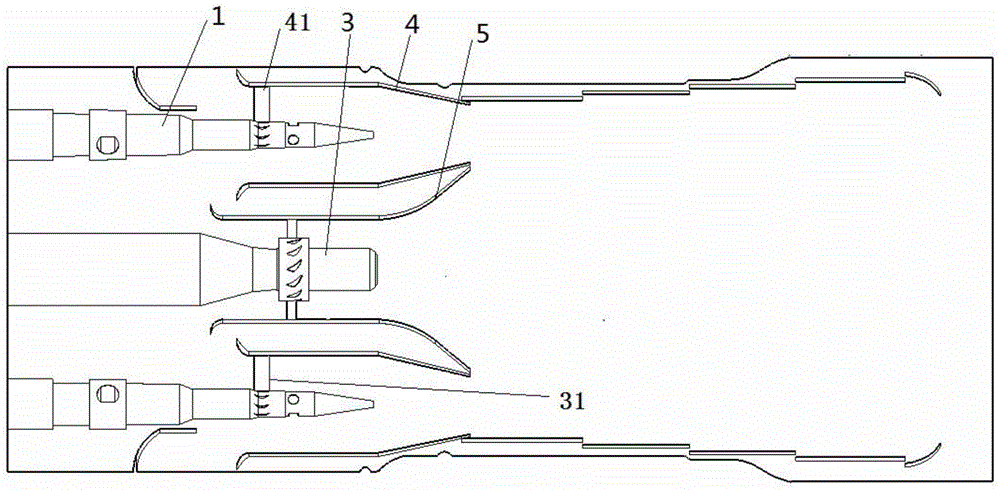

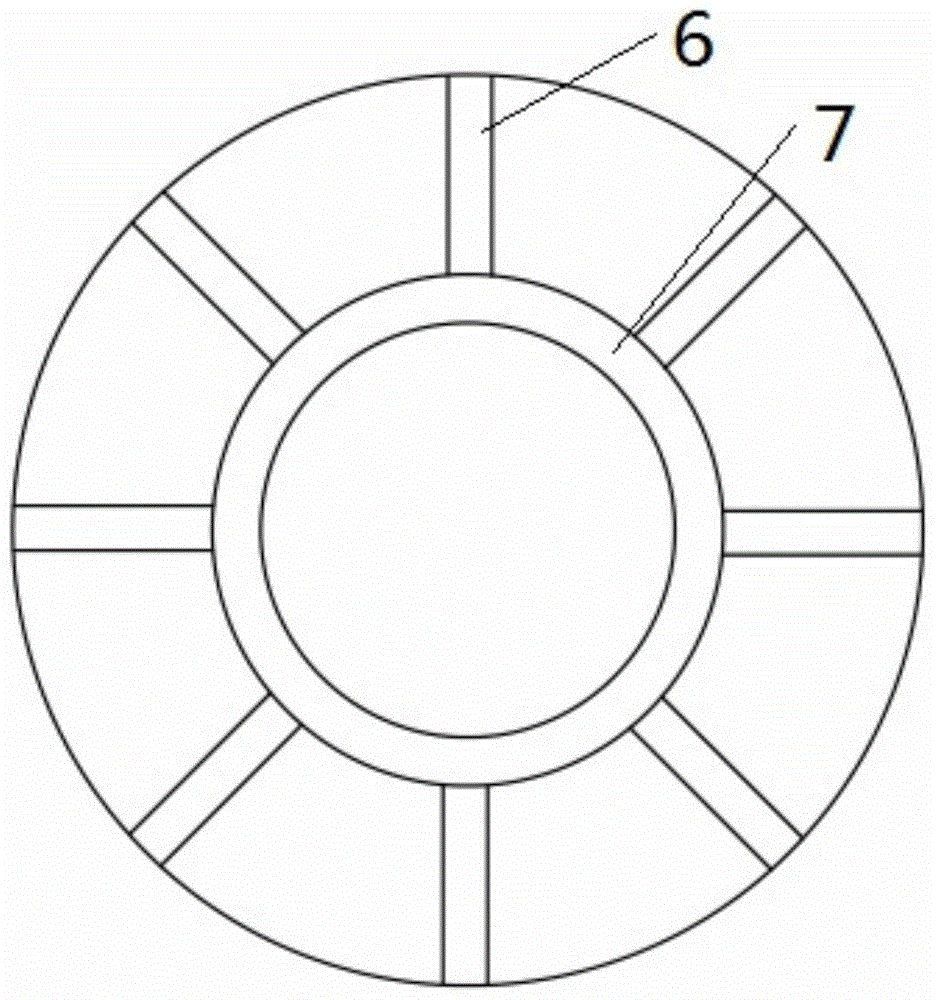

Flame holder and ground gas turbine combustion chamber with same

ActiveCN104896510AWell mixedEliminate local hot spotsContinuous combustion chamberCombustion chamberEngineering

The invention discloses a flame holder and a ground gas turbine combustion chamber with the same. The flame holder comprises a central ring and a plurality of radial struts fixed on the outer circular face of the central ring along the radial direction uniformly. A ring body of the central ring and the radial struts are formed by members in groove structures, and groove opening directions of the central ring and the radial struts are identical. Gas flow channels are formed in the members in groove structures and are communicated with the outside through a plurality of gas spray holes in the bottoms of the grooves. The gas flow channel in the central ring and the gas flow channels in the radial struts are communicated to form a gas flow cavity with the shape corresponding to the shape of the flame holder. By means of the flame holder, fuel gas can be burnt stably on the flame holder even under the impact of high-speed gas flows.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

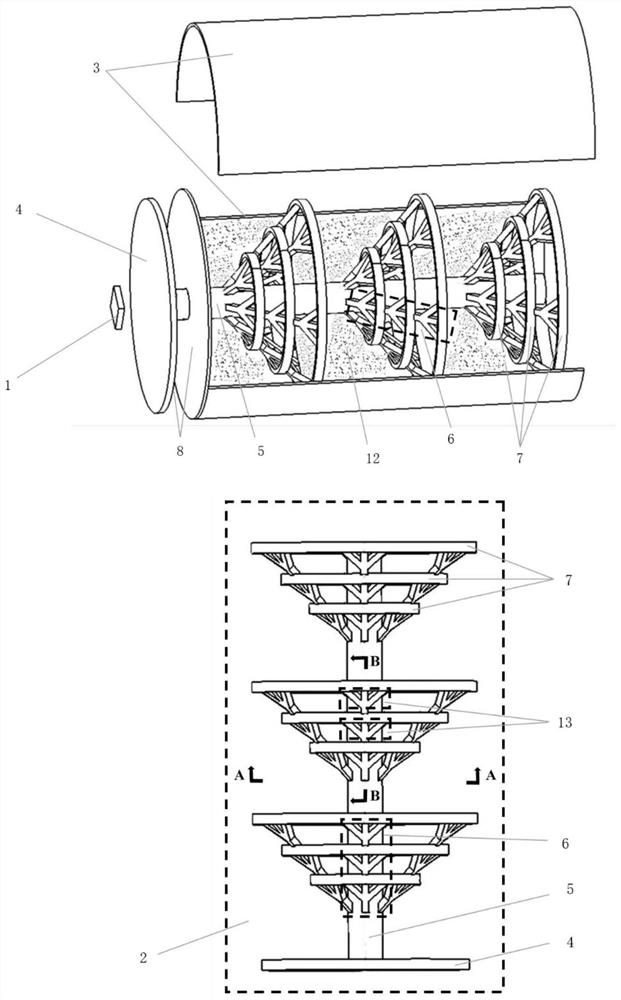

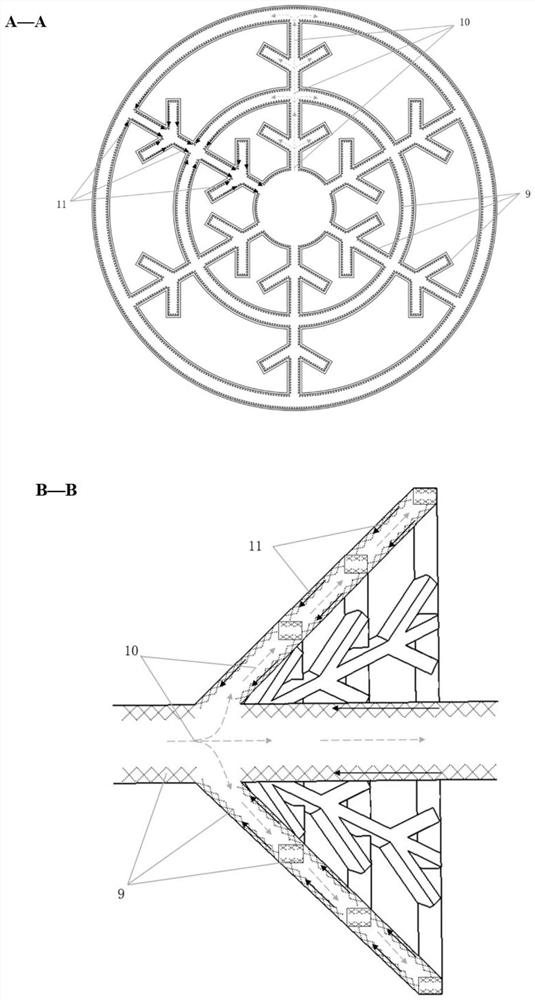

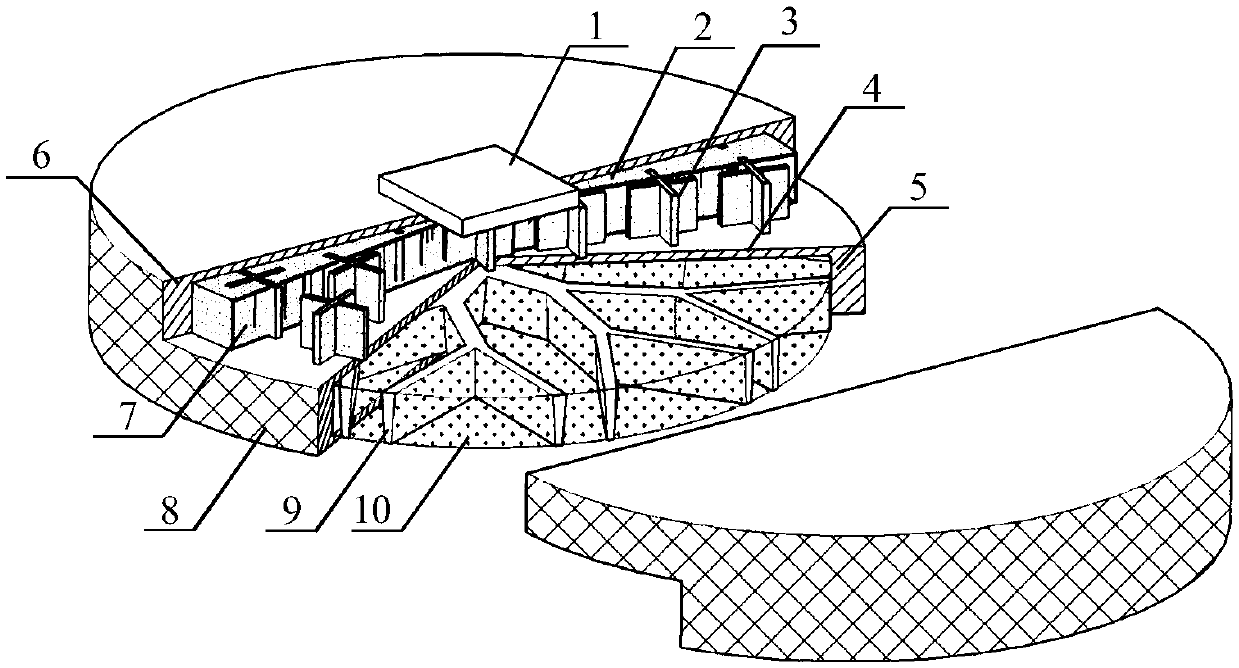

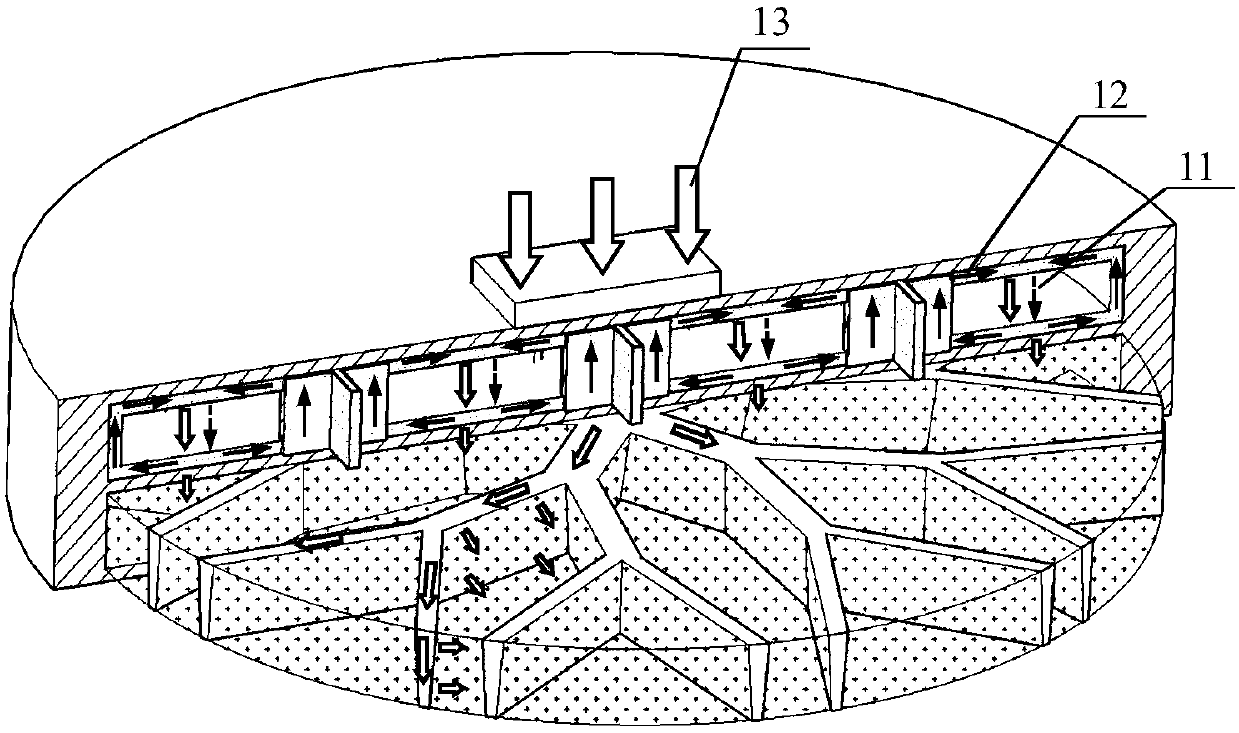

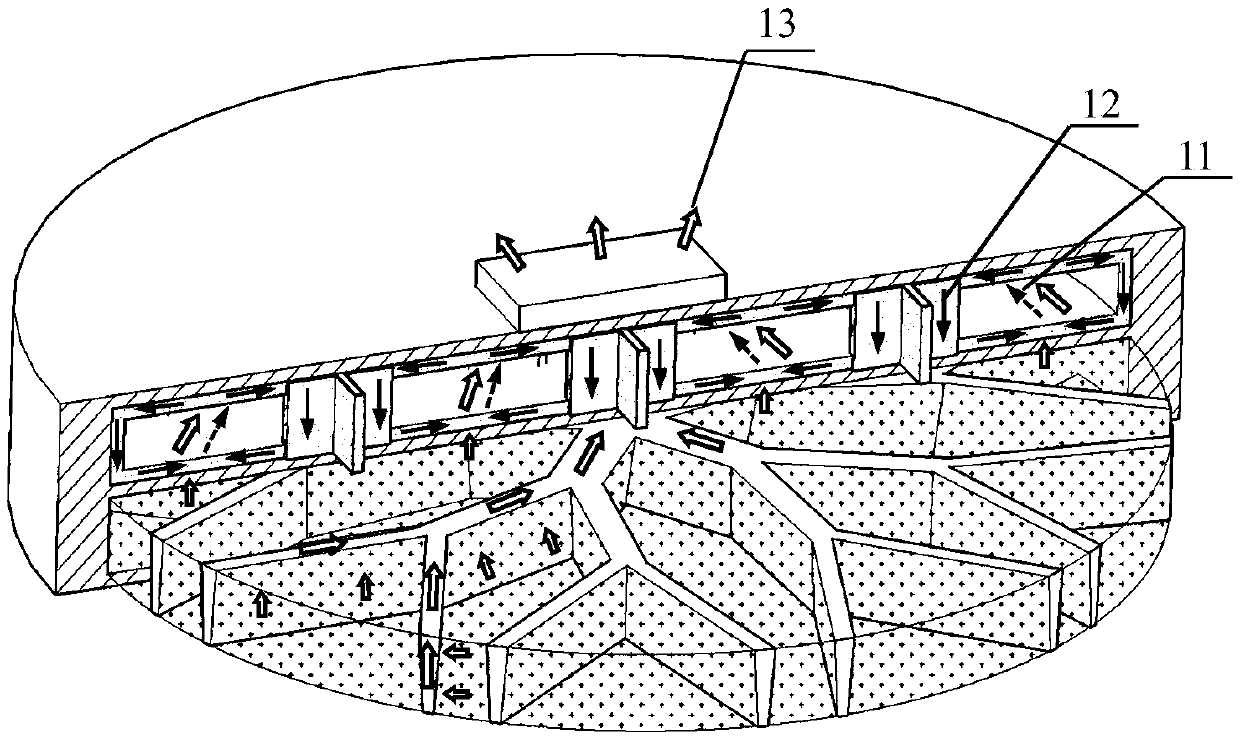

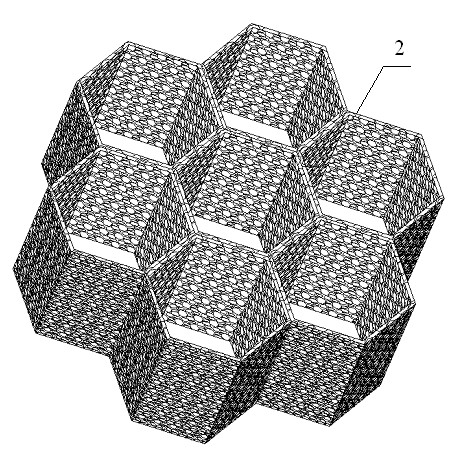

Bionic phase change energy storage steam cavity module

ActiveCN113154922AImplement storageImprove thermal conductivityIndirect heat exchangersThermodynamicsEngineering

The invention relates to a bionic phase change energy storage steam cavity module which comprises a tree-shaped steam cavity and a phase change container. The tree-shaped steam cavity comprises at least one steam cavity flat plate, a columnar steam cavity and multiple groups of branch and trunk steam cavity structures. One surface of the steam cavity flat plate is in contact with a heat source so that heat concentrated by the heat source can be uniformly diffused to the surface of the steam cavity flat plate, and the other surface of the steam cavity flat plate is packaged with the outer surface of the phase change container. The columnar steam cavity is connected with the steam cavity flat plate, and the multiple groups of branch and trunk steam cavities are arranged around the columnar steam cavity and each provided with two or more branch and trunk steam cavity branches extending towards the space. The multiple groups of branch and trunk steam cavities are connected through multiple layers of annular steam cavity ribs. Internal channels of the steam cavity flat plate, the columnar steam cavity, the branch and trunk steam cavities and the annular steam cavity ribs are communicated with one another, the internal spaces are filled with phase change working media, and the inner surfaces are provided with porous capillary structures. The tree-shaped steam cavity structure is arranged in the phase change container, and other parts in the phase change container are filled with phase change materials.

Owner:XI AN JIAOTONG UNIV

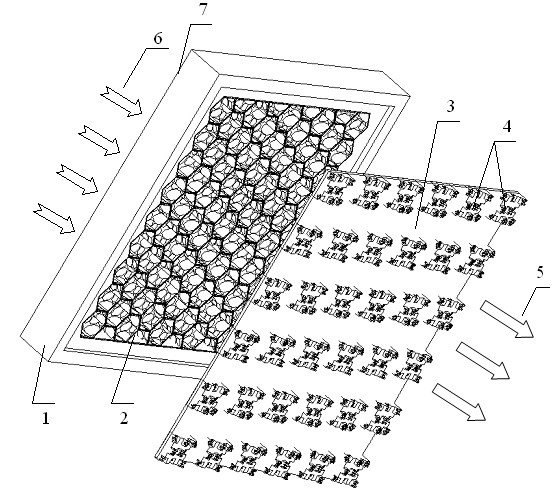

Phase change energy storage temperature controller for space

ActiveCN108662933AReduce the loop path distanceImprove cycle efficiencyIndirect heat exchangersModifications using liquid coolingThermochromismEvaporation

The invention discloses a phase change energy storage temperature controller for space. The temperature controller comprises a heat dispersion device, a heat storage device and a thermochromism paintlayer; the heat dispersion device consists of an evaporation section, a gas / liquid phase change cavity, support frames, a liquid sucking core, a condensation section, and gas / liquid phase mediums filled in the gas / liquid phase change cavity; the support frames are arranged in the gas / liquid phase change cavity in a lattice form; the heat storage device consists of a condensation section, gradual shrinkage layering ribs, a radiation section, and solid / liquid phase change storage mediums filled among gaps of the gradual shrinkage layering ribs; the widths of the gradual shrinkage layering ribs are reduced from top to bottom in the vertical direction; and the thermochromism paint layer is coated on the outer surface of the radiation section of the heat storage device. The heat dispersion device with the lattice support frames is excellent in temperature uniformity, and can eliminate local heat spots; and through the gradual shrinkage layering ribs, the heat exchange between the solid / liquid phase change storage mediums in the heat dispersion device and the heat storage device is strengthened, so that the energy storage is more efficient.

Owner:SOUTHEAST UNIV

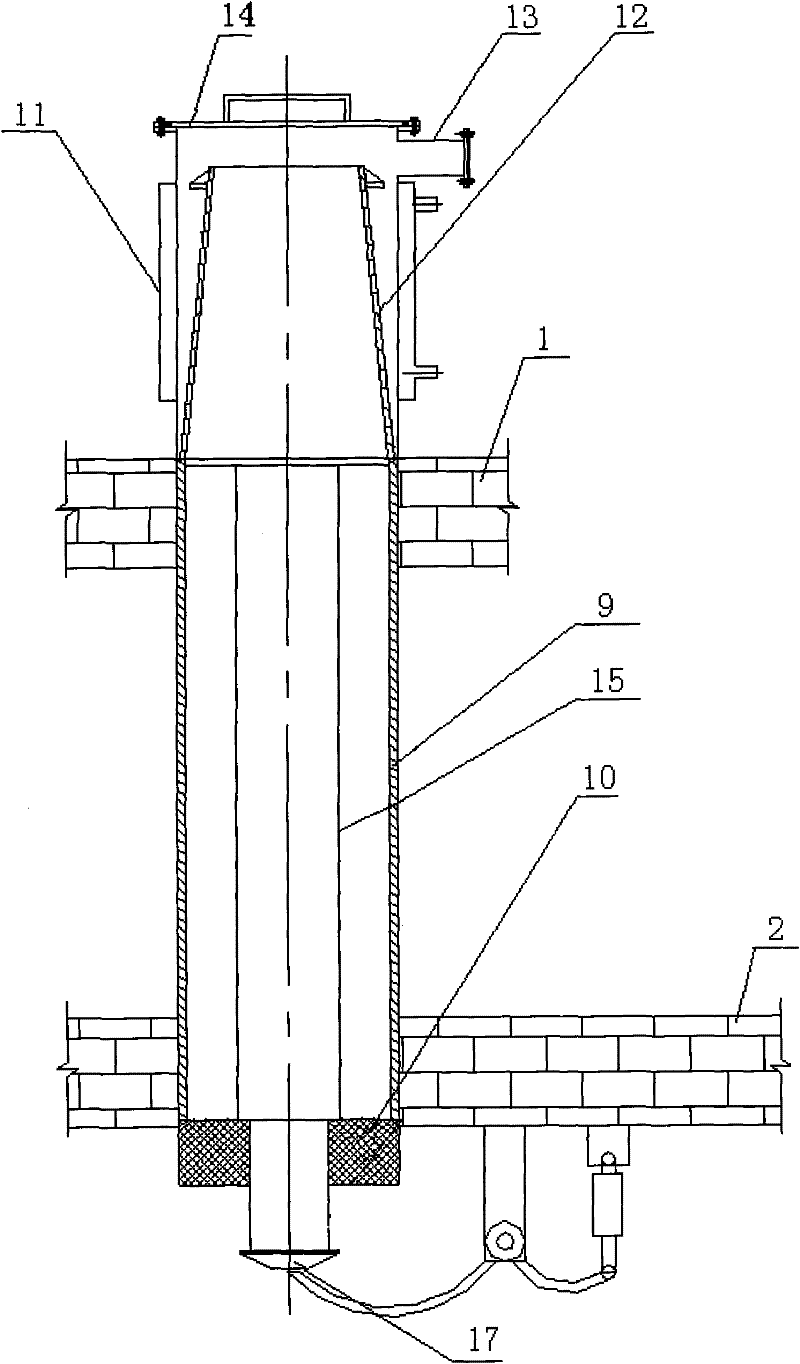

Heat storage type vertical metal magnesium reducing furnace

InactiveCN101093140AExtended service lifeUniform temperatureCrucible furnacesControl systemEngineering

This invention relates to a Mg recovery furnace with a vertical recovery tank composed of a hearth, a roof, a wall, burners, a recovery tank, bottom storage chambers and a fan charactering in arranging several pairs of double-storage burners along the bottom of two ends on the furnace width direction, forming storage chamber1 and 2 on the bottom of the two ends, installing two directional valves at either end, the directional valves, the storage chamber 1 and 2 and the fan are connected with a directional control system by exterior pipelines, applying a vertical mode to arrange the recovery tank in the hearth and feeding from the top and discharging from the bottom, which costs less energy, temperature in the furnace is the uniform and burning mode is exclusive.

Owner:宁夏华源冶金实业有限公司 +1

Low-grade fuel single prewarming and thermal storage type energy-saving boiler

InactiveCN101338907AReduce lossesExtend your lifeCombustion processEnergy efficient heating/coolingCombustorCombustion chamber

The invention discloses a single preheating and heat accumulating energy-saving boiler using low-calorie fuels, comprising a furnace body. Two or more burners are arranged on the furnace body; a high-temperature combustion-air inlet and a fuel inlet are arranged on each burner; the high-temperature combustion-air inlet is connected with a regenerator; the regenerator is connected with a constant-temperature combustion-air inlet and a low-temperature fume outlet; a switching-over unit is arranged between the constant-temperature combustion-air inlet and the low-temperature fume outlet. Firstly, the heat-energy loss is reduced and the combustion efficiency is improved by waste heat recovery at the regenerator; secondly, the constant-temperature combustion-air participates in the combustion-supporting after being preheated by the regenerator, and as a result, the combustion temperature is increased; thirdly, thirdly, a plurality of burners adopt periodical switching-over combustion, thereby, local high-temperature area inside the combustion chamber is avoided, the distribution of temperature in the combustion chamber is more even and the service life of the furnace chamber is prolonged. The single preheating and heat accumulating energy-saving boiler is applicable to various gas boilers.

Owner:SHENWU TECH GRP CO LTD

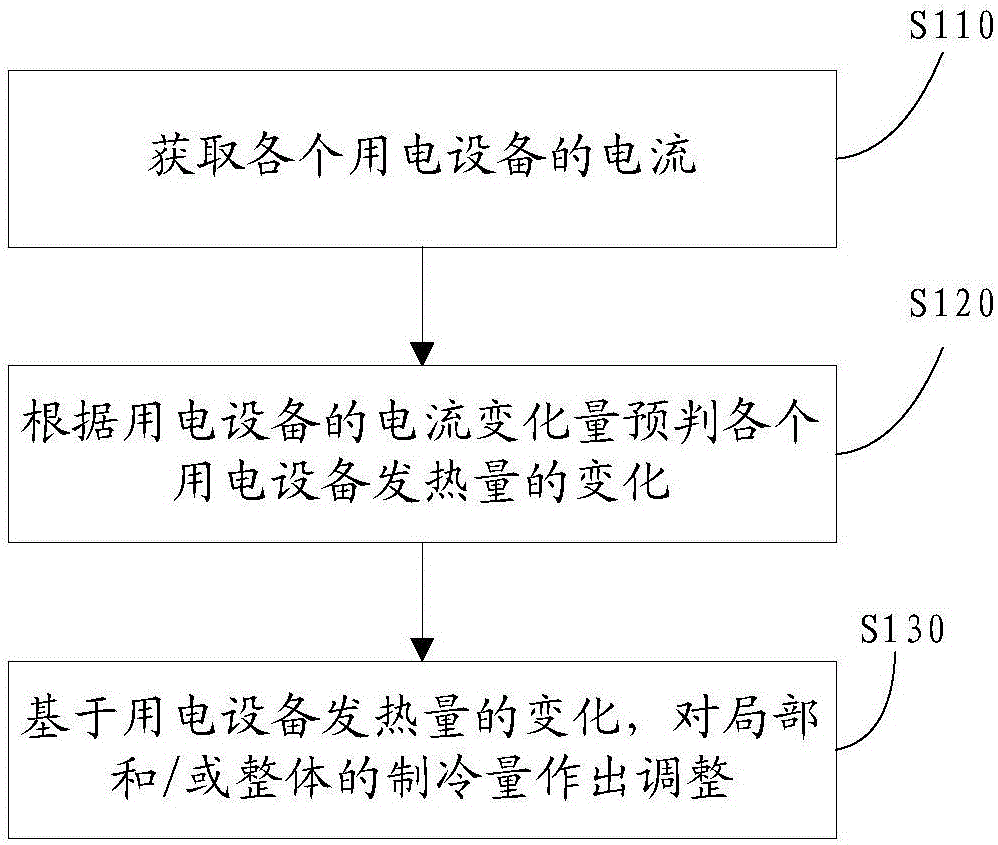

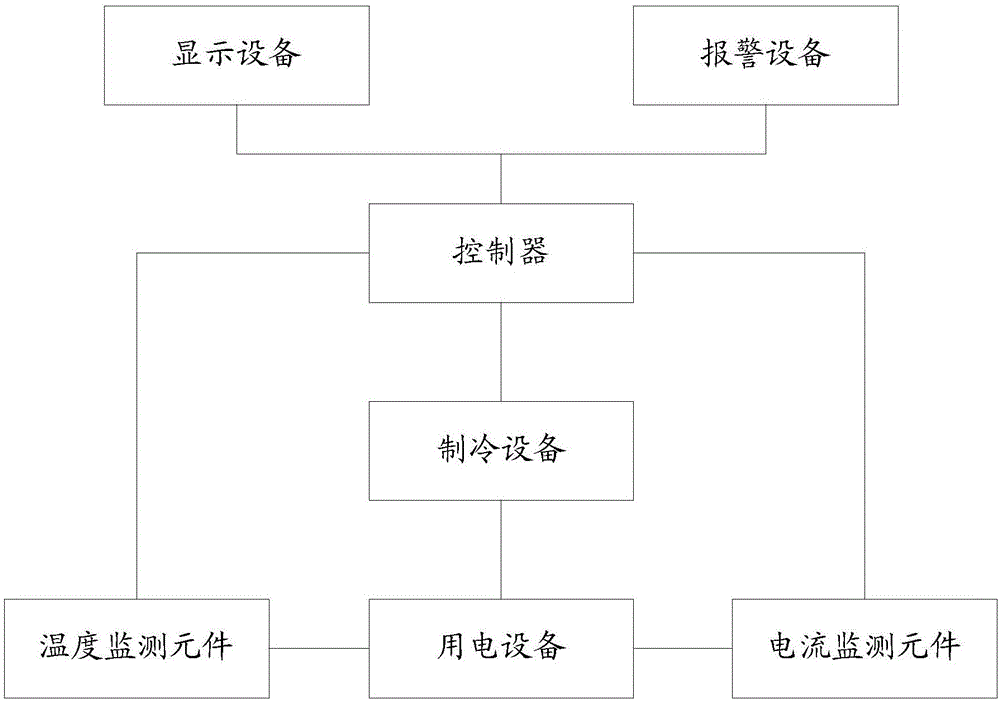

Machine room air conditioner control method and system

InactiveCN106288167AFlexible adjustmentSolve the technical problem that the cooling capacity cannot be adjusted according to the calorific value of the electrical equipmentMechanical apparatusSpace heating and ventilation safety systemsElectricityPower flow

The invention discloses a machine room air conditioner control method and system. The method at least comprises the steps of obtaining currents of all electricity devices; according to the current change amount of the electricity devices, pre-judging changes of the heating amount of all the electricity devices; on the basis of the changes of the heating amount of the electricity devices, adjusting the local and / or whole refrigeration amount; the refrigeration amount of a refrigeration device is flexibly adjusted, and distribution refrigeration adjustment of local hot points is achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Condensing and radiating heating panel

InactiveCN102056468AImprove heat dissipationLight weightCooling/ventilation/heating modificationsFlight vehicleEngineering

The invention discloses a condensing and radiating heating panel, which is composed of a hollow heat conduction panel, a capillary structure and a gas-liquid two-phase fluid; the capillary structure is composed of sintering cores and liquid-sucking cores; the sintering cores are lined at the periphery of the inner surface of the hollow heat conduction panel and the inside surface of the heating surface of the hollow heat conduction panel; the liquid-sucking cores are filled in the hollow part of the hollow heat conduction panel and closely connected with the sintering cores; the gas-liquid two-phase fluid is soaked in the pore structures of the liquid-sucking cores and the sintering cores; the inside surface of a radiating surface of the hollow heat conduction panel is provided with a drainage layer which is closely connected with the liquid-sucking cores; the external surface of a radiating condensing surface is a fractal surface which is a self-affine fractal structure surface and provided with at least two levels of concave-convex structures; and the liquid-sucking core structure is of a porous foam honeycomb structure. The heating panel can efficiently spread heat generated by airborne electric equipment of an aircraft under the condition of no-pump drive, thus ensuring efficient, safe and stable operation of the airborne equipment in the spacecraft.

Owner:SOUTHEAST UNIV

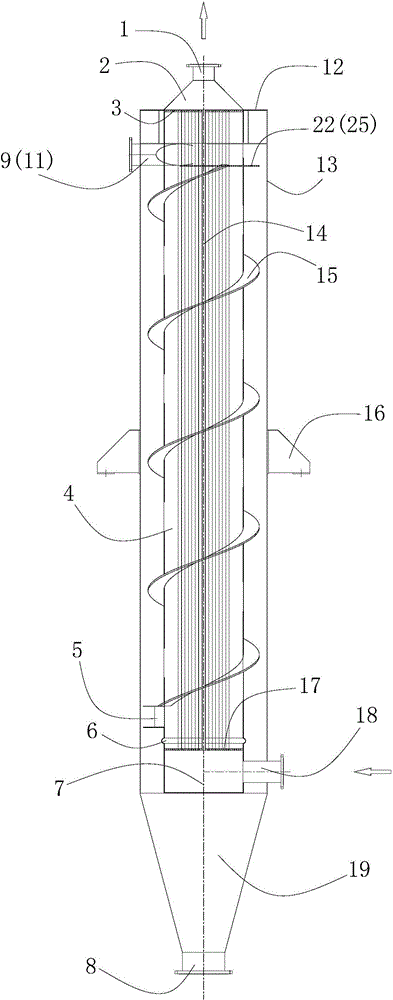

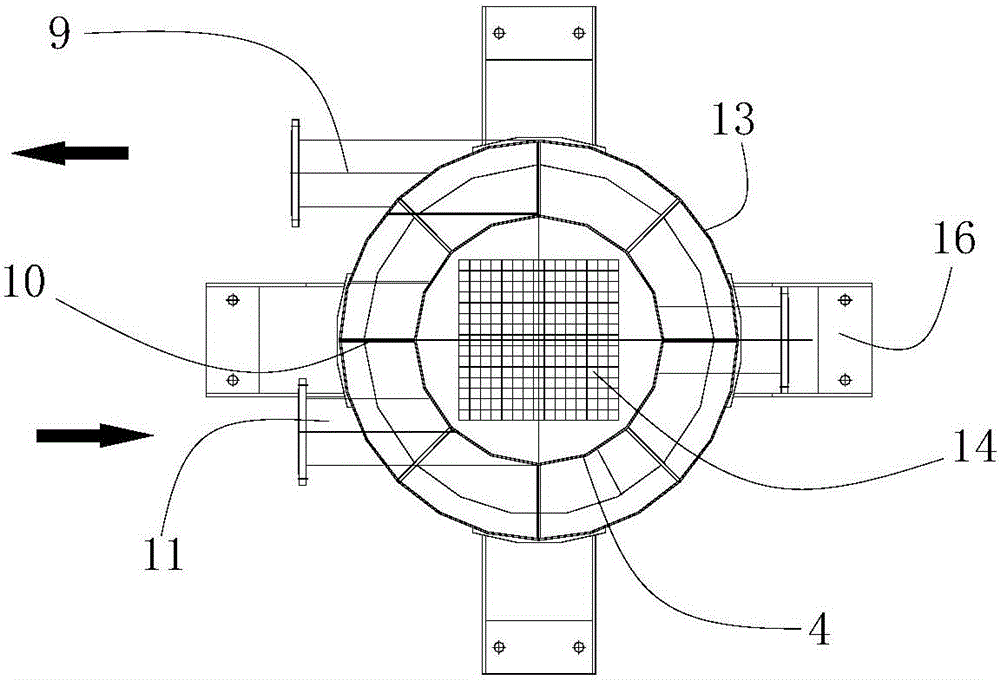

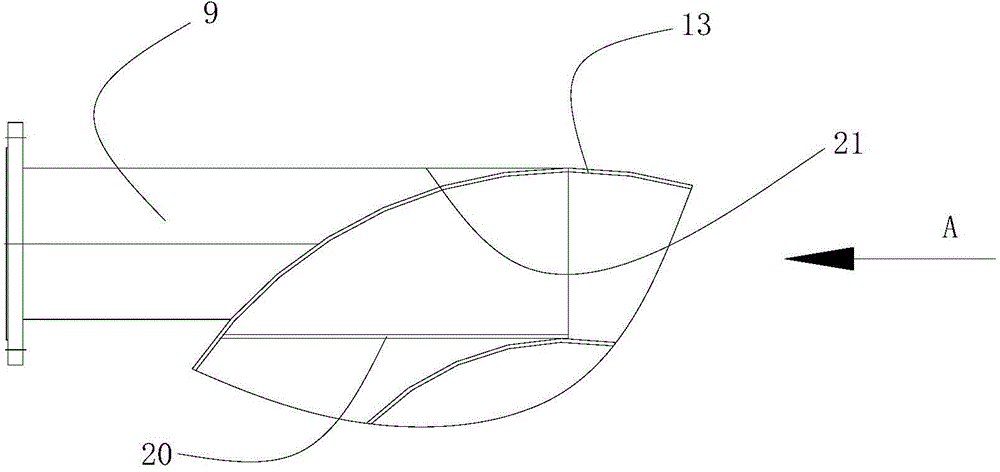

Efficient dehaze waste heat recovery energy-saving emission reduction device

InactiveCN105783013AImprove heat recovery efficiencyLower exhaust gas temperatureCorrosion preventionHeat exchanger casingsFriction lossEngineering

The invention discloses an efficient dehaze waste heat recovery energy-saving emission reduction device. The device comprises an SP heat exchange pipe, an upper tube plate, a lower tube plate, an inner barrel, a spiral plate and an outer barrel. The inner barrel is provided with a smoke inlet tube orifice and an inner barrel smoke outlet tube orifice. The lower tube plate is connected with a lower tube box provided with an air inlet tube orifice. The upper tube plate is connected with an upper tube box provided with an air outlet tube orifice. The spiral plate is spirally arranged on the outer wall of the inner barrel. The upper end of the inner barrel and the upper end of the outer barrel are connected through closure plates and reinforcing rib plates. The upper end of the outer barrel is provided with an outer barrel smoke outlet tube orifice, and the lower end of the outer barrel is connected with a dust hopper provided with a dust removing opening. The device has high heat exchange efficiency and can prolong the structure time of equipment, dust in smoke can be efficiently separated and removed, the emission amount of CO2, NOX and the like is effectively reduced, and resistance loss of the device is smaller than equipment of the same type under the same working condition. The size of the device is small, heat exchange, dust removal and dehazing are achieved, and the smoke temperature is lowered.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Graphene-based thermal conductive film preparing method

The invention provides a graphene-based thermal conductive film preparing method which includes the steps that biological materials are stirred and squeezed broken, and a solvent is added to the biological materials to dilute the materials; ultrasonic suction filtration is conducted on the obtained biological material pulp, and filter liquor of the biological material pulp is obtained and sealed for use; ultrasound is conducted on a graphite oxide solution, and oxidized graphene sol is obtained; the biological material filter liquid is mixed with the oxidized graphene sol, the mixed solution is made to react, and a reduced graphene film is obtained; the thermal annealing is conducted on the obtained film under the conditions of the inert atmosphere and low temperature, and the high-thermal-conductive graphene film is obtained. The graphene film prepared through the method has the advantages of being thermal conductive, electric conductive, good in mechanical property, controllable in thickness, wide in raw material source and capable of achieving batch production easily.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

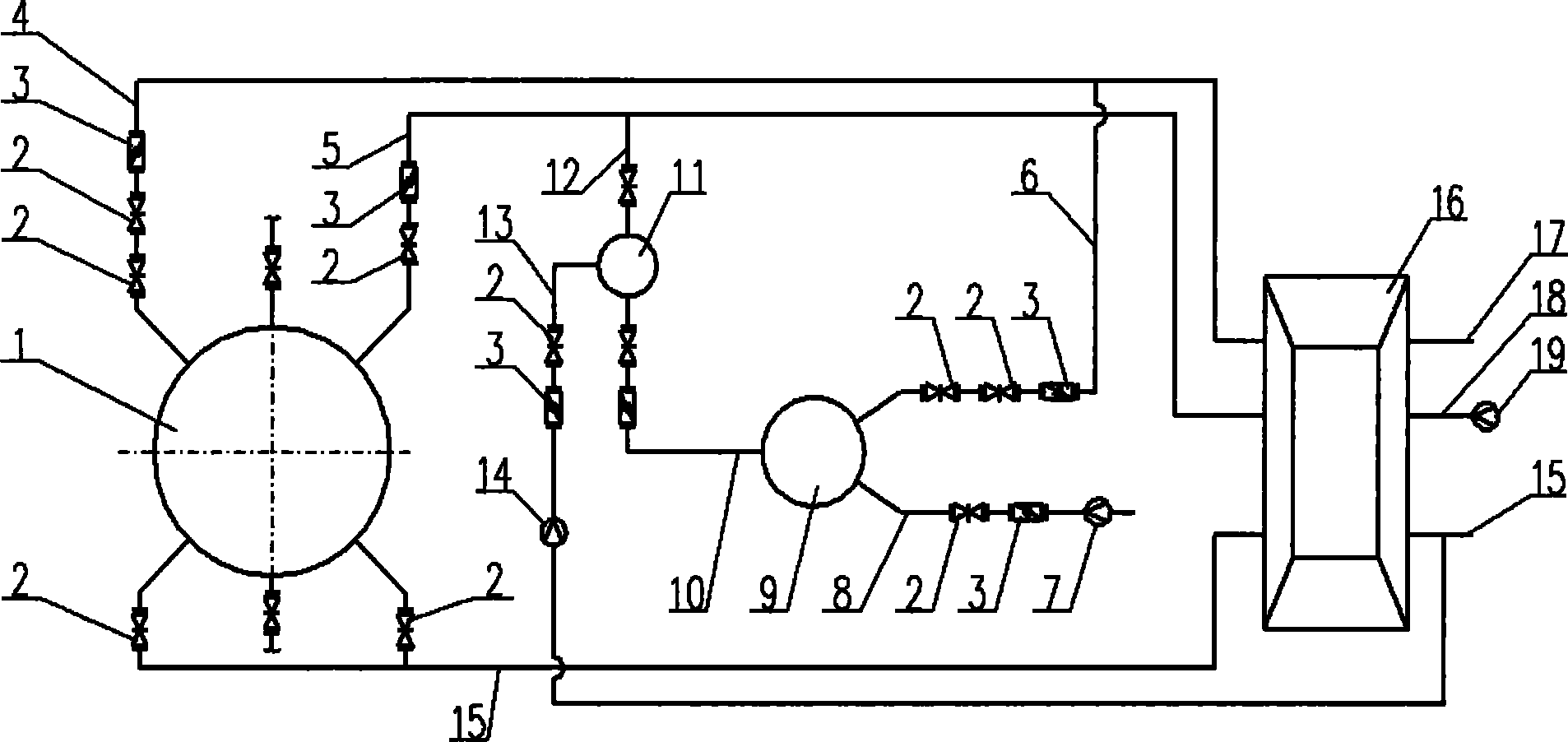

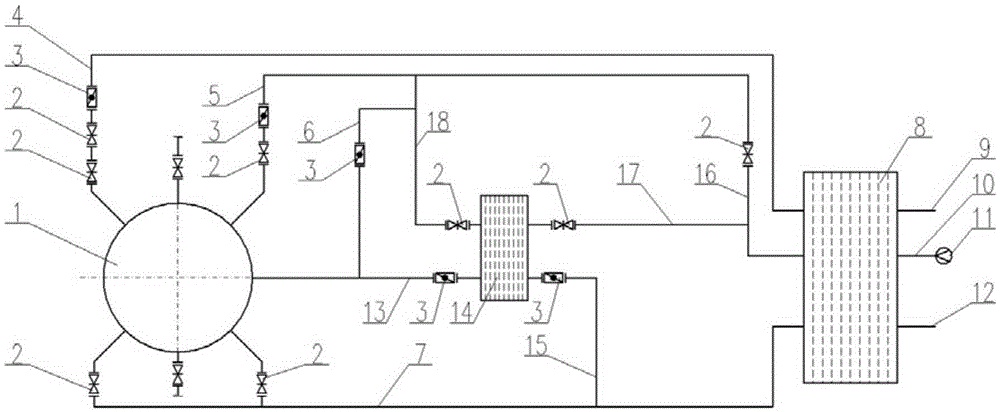

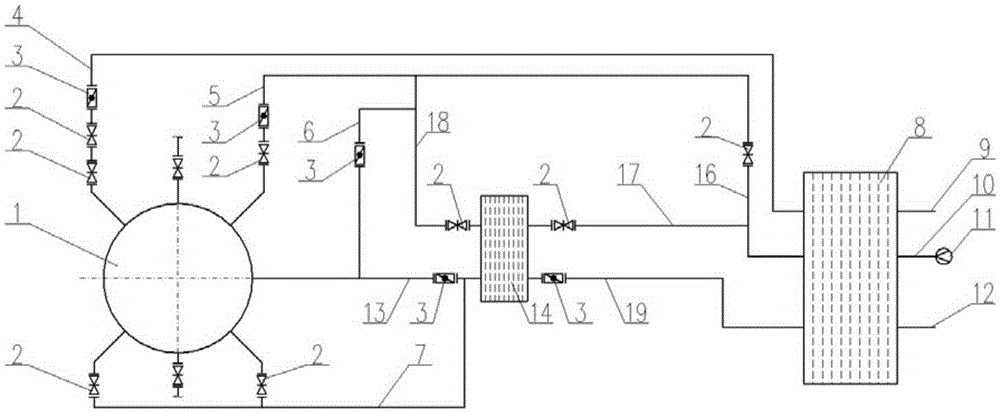

Efficient low-emission high-temperature low-oxygen hot blast stove

ActiveCN105238899AFlexible adaptation to smelting intensityFlexible process adaptationBlast furnace detailsHeating stovesHot blastLow emission

The invention discloses an efficient low-emission high-temperature low-oxygen hot blast stove and belongs to the technical field of hot blast stoves in the metallurgical industry. The efficient low-emission high-temperature low-oxygen hot blast stove comprises a hot blast stove body, a stop valve, a regulating valve, a gas pipeline for the hot blast stove body, a combustion-supporting air pipeline for the hot blast stove body, a high-temperature mixed gas flue, a low-temperature flue, a low-temperature preheating system, a gas header pipe from a pipe network, a combustion-supporting air header pipe, a combustion-supporting blower for the hot blast stove body, a heat exchanged flue, a high-temperature flue, a high-temperature preheated flue, a combustion-supporting air by-pass pipeline, a combustion-supporting air low-temperature preheating pipeline and a combustion-supporting air high-temperature preheating pipeline. The efficient low-emission high-temperature low-oxygen hot blast stove has the advantages that when only blast stove gas is burnt, high-temperature hot-blast air with the temperature being above 1250 DEG C can be stably provided for users; the generation of NOx is effectively controlled; the high-temperature low-oxygen combustion is achieved; the efficient low-emission high-temperature low-oxygen hot blast stove is suitable for different metallurgical technological processes, and capable of being flexibly combined with existing hot blast stoves, being used for new projects and overhaul modification projects, and being combined with various low-temperature preheating devices of combustion-supporting air and gases for use; the exhaust gas afterheat is fully recovered; the heat efficiency is improved; the high blast temperature, high efficiency, low consumption, low content of NOx and long service life are achieved.

Owner:BEIJING SHOUGANG INT ENG TECH

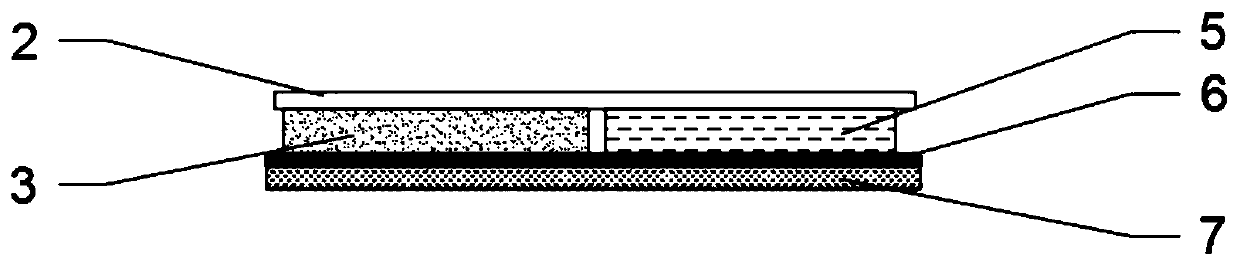

Smartwatch heat management composite

InactiveCN109743865AAchieving soakingFast heat conductionMagnetic/electric field screeningProtection against external influencesHeat managementMetal foil

The invention discloses a smartwatch heat management composite. The smartwatch heat management composite comprises a shielding layer, a heat management layer, a heat conduction layer and super glue, wherein the bottom face of the heat management layer is attached to the top face of the heat conduction layer, the bottom face of the shielding layer is attached to the top face of the heat managementlayer, and the super glue is spread on the bottom face of the heat conduction layer. According to the smartwatch heat management composite, core materials, namely metal foil, a heat insulation material layer, a heat storage material layer and a graphite layer made of a material with high heat conductivity are made into the composite which can achieve conduction shielding, a good heat conduction effect and a local hotspot elimination function, heat is transferred quickly and uniformly, the heat dissipation area is enlarged, the attachment to a bottom case of a smartwatch can be enhanced throughthe super glue on the bottom layer, and the heat conduction effect can be brought into full play.

Owner:东莞市珀信电子有限公司

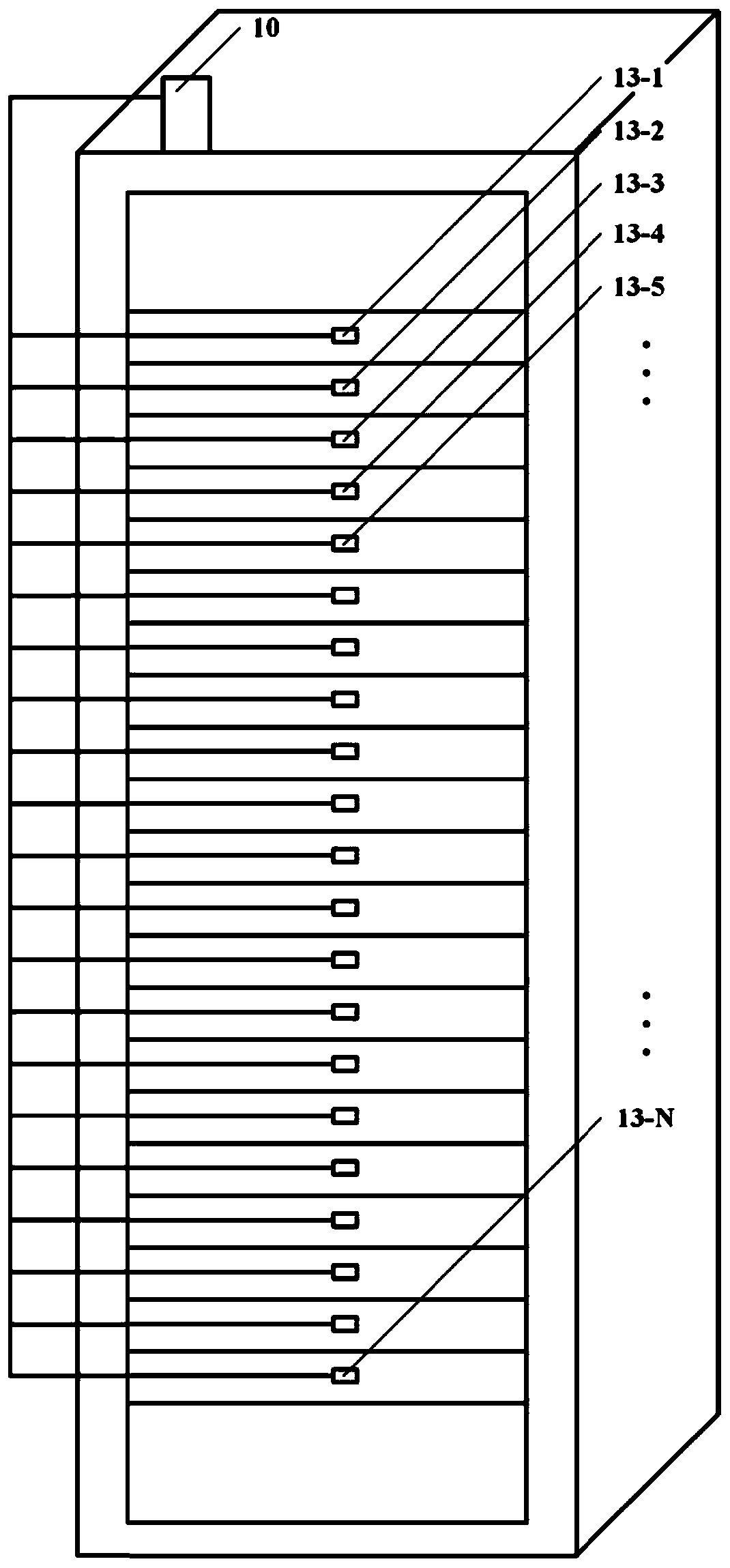

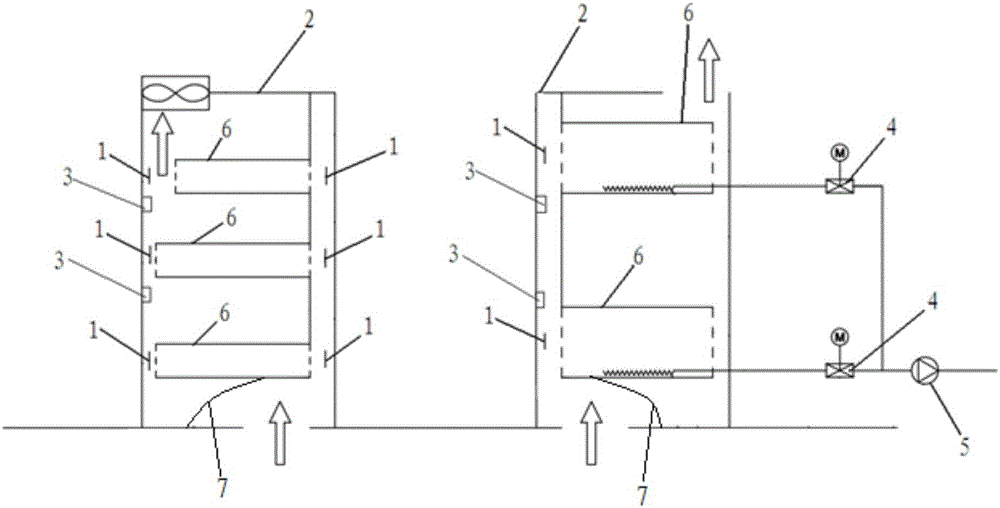

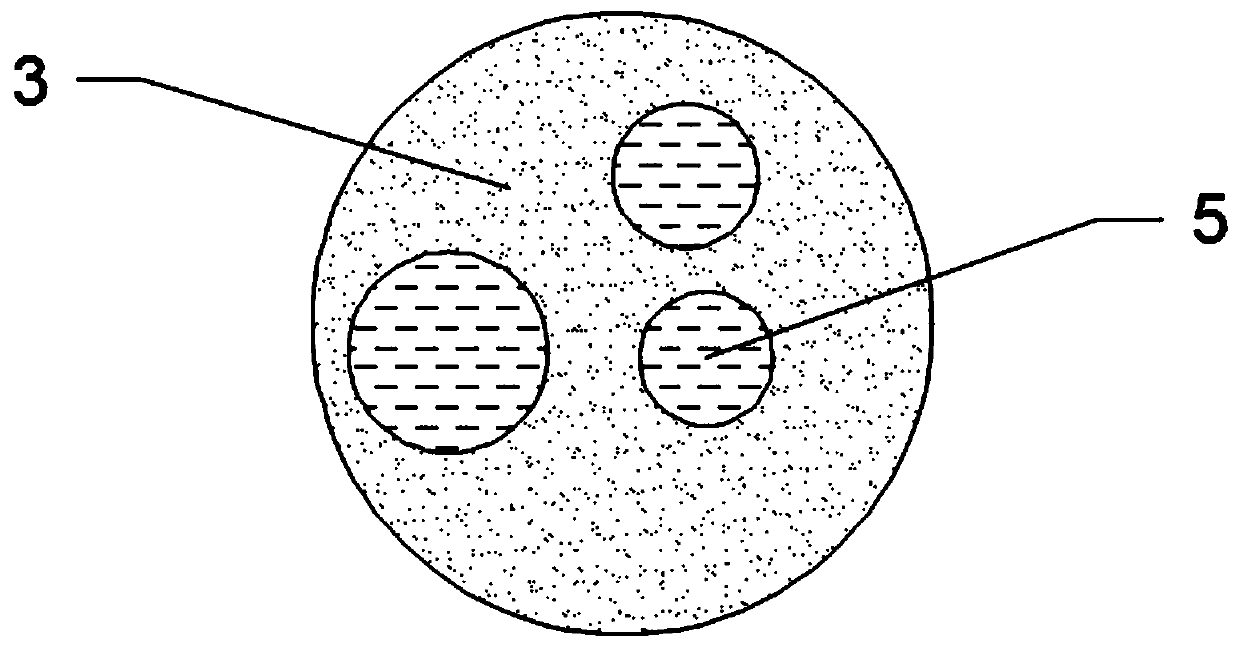

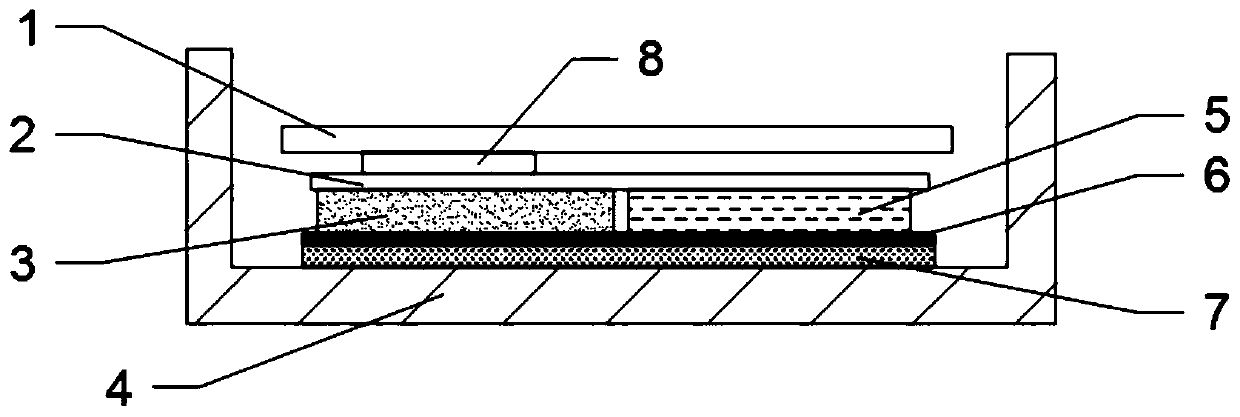

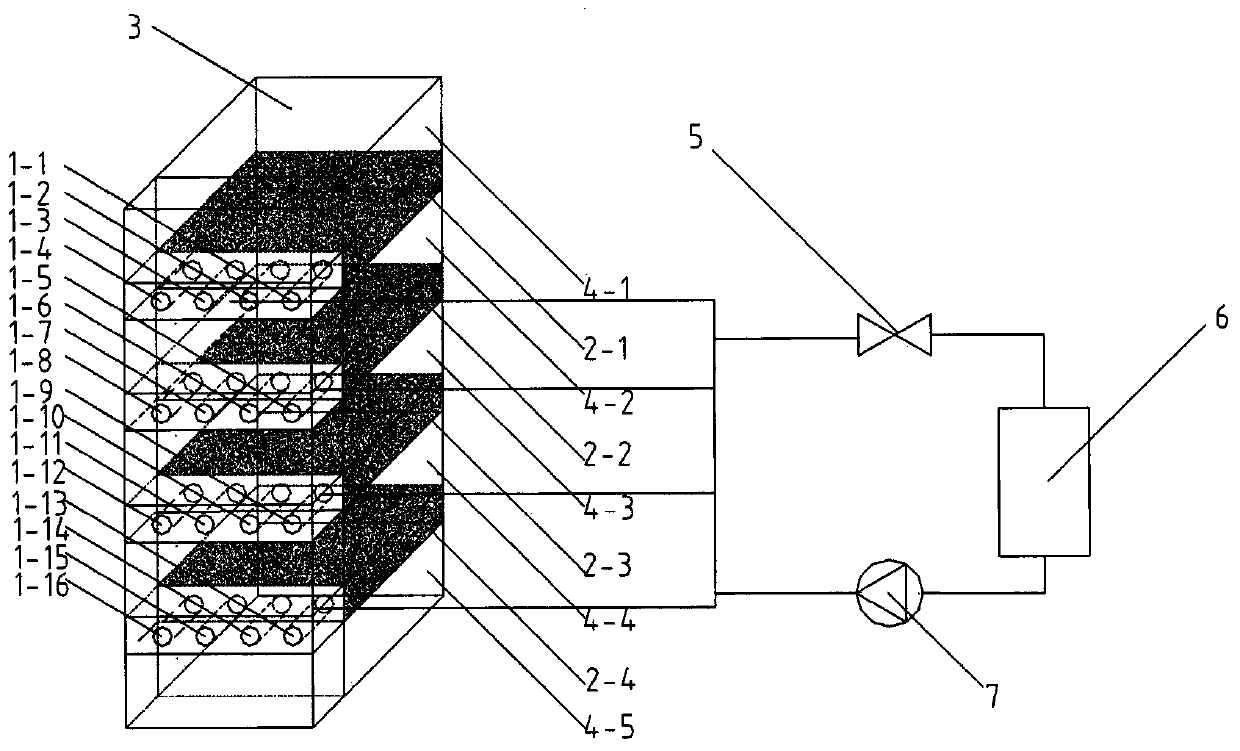

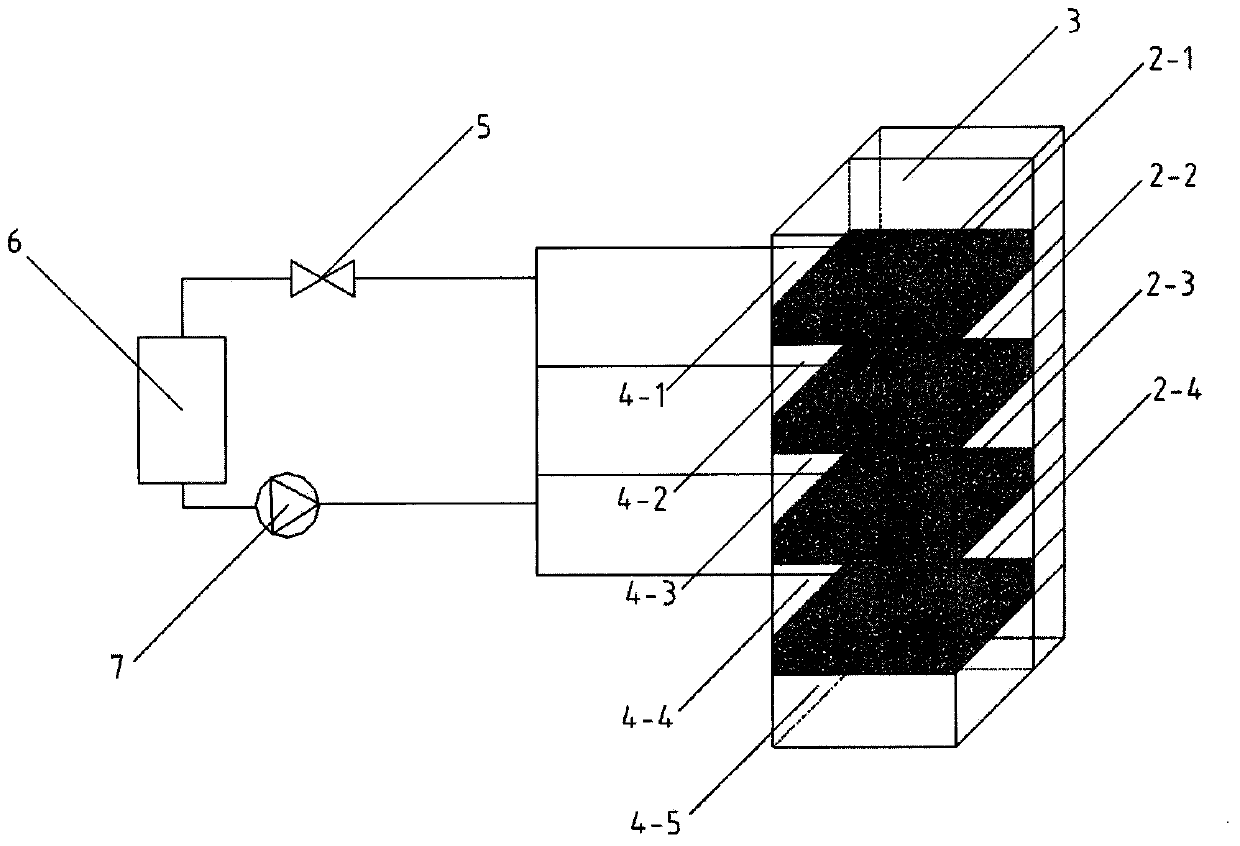

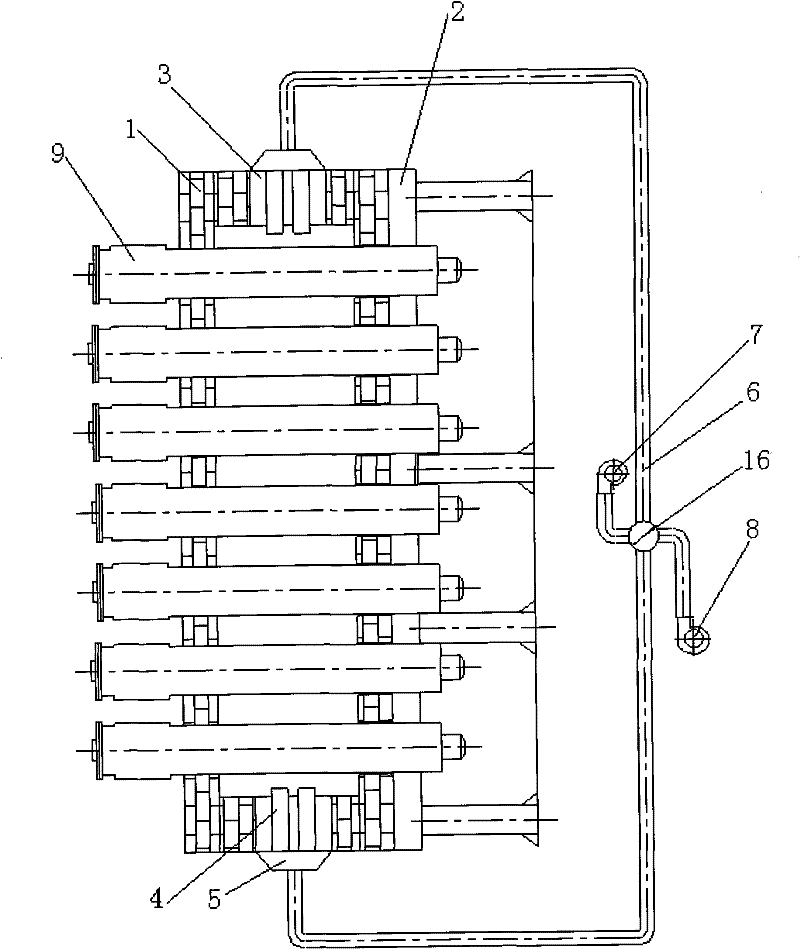

Data room server local thermal management system using phase change material and heat pipe heat exchanger

PendingCN109588026AEliminate local hot spotsImprove heat transfer effectCooling/ventilation/heating modificationsThermal management systemEngineering

The invention discloses a data room server local thermal management system using a phase change material and a heat pipe heat exchanger, belonging to the field of a data room heat pipe air conditioning system and an efficient heat dissipation method. The invention solves the problem of local hot spot heat accumulation in a machine room. The data room server local thermal management system using the phase change material and the heat pipe heat exchanger mainly comprises a first heat pipe module (1-1), a second heat pipe module (1-2), a third heat pipe module (1-3), a fourth heat pipe module (1-4), a first phase change module (2-1), a second phase change module (2-2), a third phase change module (2-3), a fourth phase change module (2-4), a server cabinet (3), a first server (4-1), a second server (4-2), a third server (4-3), a fourth server (4-4), a fifth server (4-5), a valve (5), a water tank (6), and a water pump (7) and so on. The invention utilizes the phase change material combinedwith the heat pipe heat exchanger to cool the server and replace the traditional air cooling, thereby enhancing the heat exchange performance and improving the thermal efficiency of the device.

Owner:NANJING UNIV OF TECH

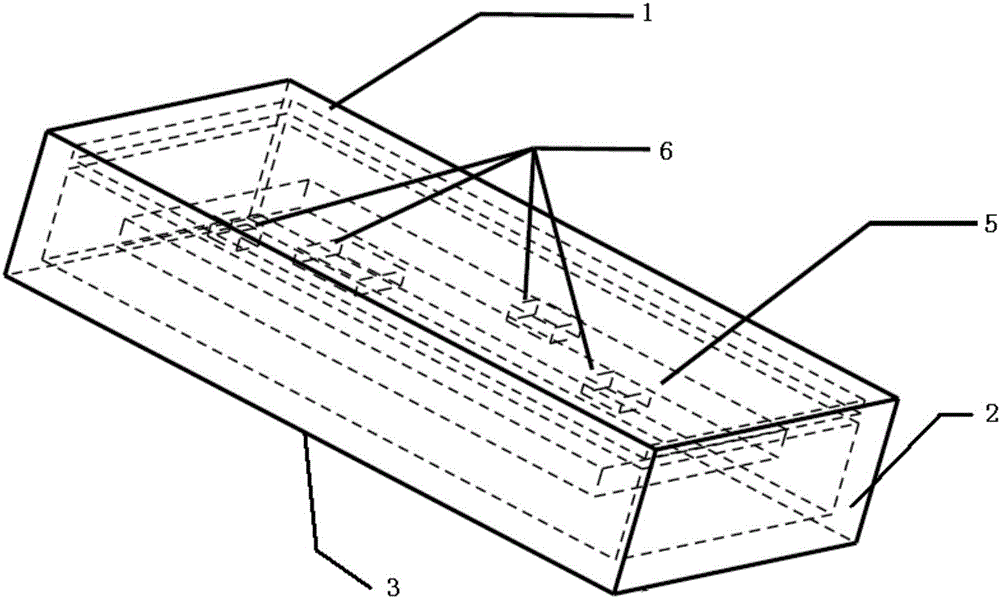

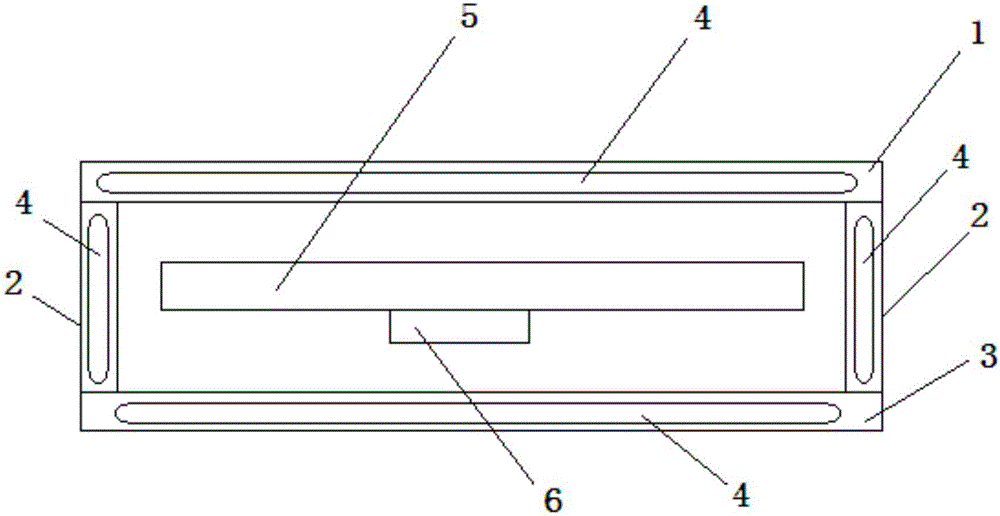

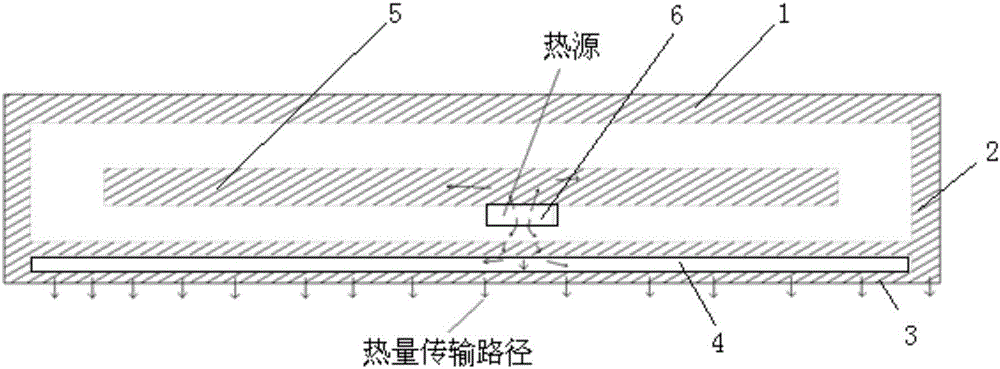

Efficient temperature control device for handheld terminal device

ActiveCN106455441ALower surface temperature levelsUniform temperatureModifications using liquid coolingModifications by conduction heat transferTemperature controlTerminal equipment

The invention discloses an efficient temperature control device for a handheld terminal device. The device comprises an upper structural plate, middle connection plates, a lower structural plate and a single board. The periphery of the upper structural plate and the periphery of the lower structural plate are connected to form a cavity structure through the four middle connection plates, the single board is arranged in the cavity between the upper structural plate and the lower structural plate, the single board is provided with a heating chip, the lower structural plate is of a cavity structure, and a phase change material is arranged in the cavity. The temperature of the outer surface of equipment and the temperature of the inner chip can be effectively controlled, characteristics of the phase change material are effectively used, and precise control over the temperature of the outer surface is implemented; the temperature of the single board and the device can be reduced, the temperature of the outer surface of the equipment can be reduced, so the temperature of the outer surface is made uniform, and the problem that the equipment is hot is solved; local hotspots possibly generated by multiple local high-heat-density hot source points can be effectively eliminated, temperature uniformity of a heated face is improved, the surface temperate level of the electronic equipment is lowered, and accordingly safe, stable and efficient work of an electronic equipment system is guaranteed.

Owner:南京中新赛克科技有限责任公司

Vertical heat accumulating type reduction furnace

The invention discloses a vertical heat accumulating type reduction furnace, relating to metal magnesium and metal calcium melting, in particular to a vertical metal magnesium and metal calcium reduction furnace. The vertical heat accumulating type reduction furnace is characterized by comprising a reduction furnace body, a heating device, a fuel and combustion supporting gas introducing-in device and a reducing reaction tank in a vertical pipe shape, wherein the center of the reducing tank body between a reducing-tank sealing member and a taper-shaped crystallizer is coaxially provided with a vertical through pipe of which the side wall is provided with a through hole. The vertical heat accumulating type reduction furnace disclosed by the invention has the advantages of short construction period and high speed of becoming effective. The vertical heat accumulating type reduction furnace body is supported by a concrete or steel structure bracket; the furnace structure is not complex and is convenient to build and install. The steps of loading, taking the crystallizer and deslagging can be mechanically and quickly operated to save labor force cost. Hot airflow rises in the hearth, which is favorable for carrying out a reduction reaction and ensures that a reduction period is shortened. Compared with a lateral tank reduction furnace, the vertical heat accumulating type reduction furnace has the advantage of saving more energy.

Owner:于思静 +1

Communication machine room cooling system

InactiveCN101902897BSmall footprintReduce heat dissipation thermal resistanceCooling/ventilation/heating modificationsAuto regulationTemperature control

The invention discloses a communication machine room cooling system which comprises an internal circulation cooling medium providing loop, a medium natural cooling loop and a central temperature control unit, wherein the internal circulation cooling medium providing loop comprises an internal circulation duct, a chilled water cooling heat exchanger, more than one partial hot position gas-liquid heat exchanger, an internal circulation water pump and a natural cooling heat exchanger; the chilled water cooling heat exchanger is connected with a chilled water duct and exchanges heat through an automatic regulating valve; the partial hot position gas-liquid heat exchanger is arranged at the hot air outlet of each electronic device; the internal circulation cooling medium providing loop exchanges heat with the medium natural cooling loop through the natural cooling heat exchanger; the medium natural cooling loop comprises an external circulation duct, an external natural cooling device, an external circulation water pump and an automatic regulating valve; and the central temperature control unit is connected with temperature sensors and regulating valves.

Owner:中兴新通讯有限公司

High performance fuel heat accumulation type condensation energy-saving boiler

InactiveCN101319788BReduce lossesEliminate local hot spotsCombustion processDrum steam boilersCombustorFlue gas

The invention discloses a heat accumulating type condensing and energy saving boiler for high energy fuel, which comprises a boiler body. Two or more combustors are arranged in the boiler body, a high-temperature combustion-supporting air inlet opening and a fuel spraying opening are arranged on the combustor, a checker chamber is connected with the high-temperature combustion-supporting air inletopening, a normal temperature combustion-supporting air inlet and a low-temperature flue gas outlet are connected with the checker chamber, a direction change device is arranged between the normal temperature combustion-supporting air inlet and the low-temperature flue gas outlet, and a condensing heat recoverer is connected with the low-temperature flue gas outlet. On one hand, when the fuel gasis discharged, the waste heat of the fuel gas is recovered through the checker chamber and the condensing heat recoverer, thereby the heat energy loss is reduced, and the combustion efficiency is enhanced; on the other hand, after passing through the checker chamber, the normal temperature combustion-supporting air assists in combustion supporting, and thereby the combustion temperature can be increased; thirdly, a plurality of combustors adopts periodic reversing combustion, thereby the partial high temperature zones in the combustors are avoided, and the internal temperature distribution ofthe combustors is more uniform. The boiler is applied to various gas fired boilers.

Owner:SHENWU TECH GRP CO LTD

Flame holder and ground gas turbine combustor with the flame holder

ActiveCN104896510BWell mixedEliminate local hot spotsContinuous combustion chamberThermodynamicsCombustor

The invention discloses a flame holder and a ground gas turbine combustion chamber with the same. The flame holder comprises a central ring and a plurality of radial struts fixed on the outer circular face of the central ring along the radial direction uniformly. A ring body of the central ring and the radial struts are formed by members in groove structures, and groove opening directions of the central ring and the radial struts are identical. Gas flow channels are formed in the members in groove structures and are communicated with the outside through a plurality of gas spray holes in the bottoms of the grooves. The gas flow channel in the central ring and the gas flow channels in the radial struts are communicated to form a gas flow cavity with the shape corresponding to the shape of the flame holder. By means of the flame holder, fuel gas can be burnt stably on the flame holder even under the impact of high-speed gas flows.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

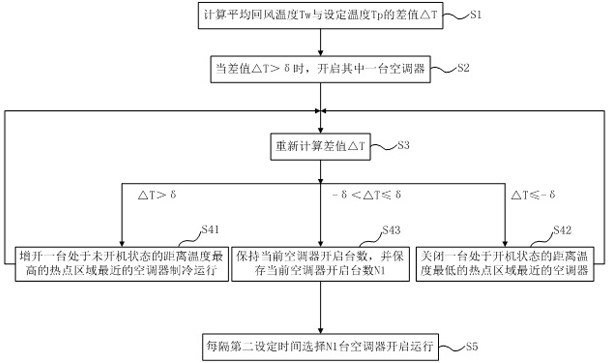

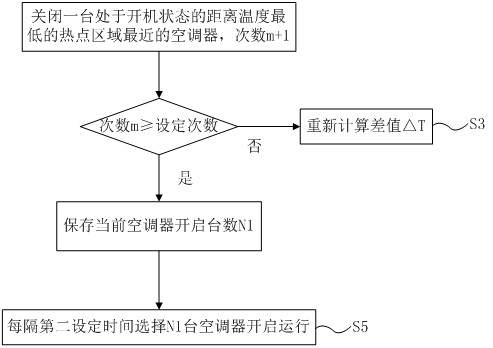

Machine room air conditioning system control method and machine room air conditioning system

ActiveCN114353283AQuick response to temperatureUniform temperatureMechanical apparatusCooling/ventilation/heating modificationsProcess engineeringAir conditioning

The invention discloses a machine room air conditioning system control method and a machine room air conditioning system. The method comprises the steps that the difference value T between the average return air temperature Tw and the set temperature Tp is calculated; when the difference value T is larger than delta, an air conditioner which is in a non-starting state and is closest to the hot spot area with the highest temperature is additionally started for refrigeration operation; when the difference value T is smaller than or equal to-delta, the air conditioner which is in the starting state and is closest to the hot spot area with the lowest temperature is turned off; when delta is larger than-delta and smaller than or equal to delta, the number of the current started air conditioners is kept, and the number N1 of the current started air conditioners is stored; n1 air conditioners are selected to be started every second set time; according to the machine room air conditioning system control method and the machine room air conditioning system, the temperature in the machine room is quickly responded, local hot spots in the machine room are eliminated, temperature balance of the machine room is quickly achieved, and the problem that hot spot areas in the machine room cannot be effectively cooled is solved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +2

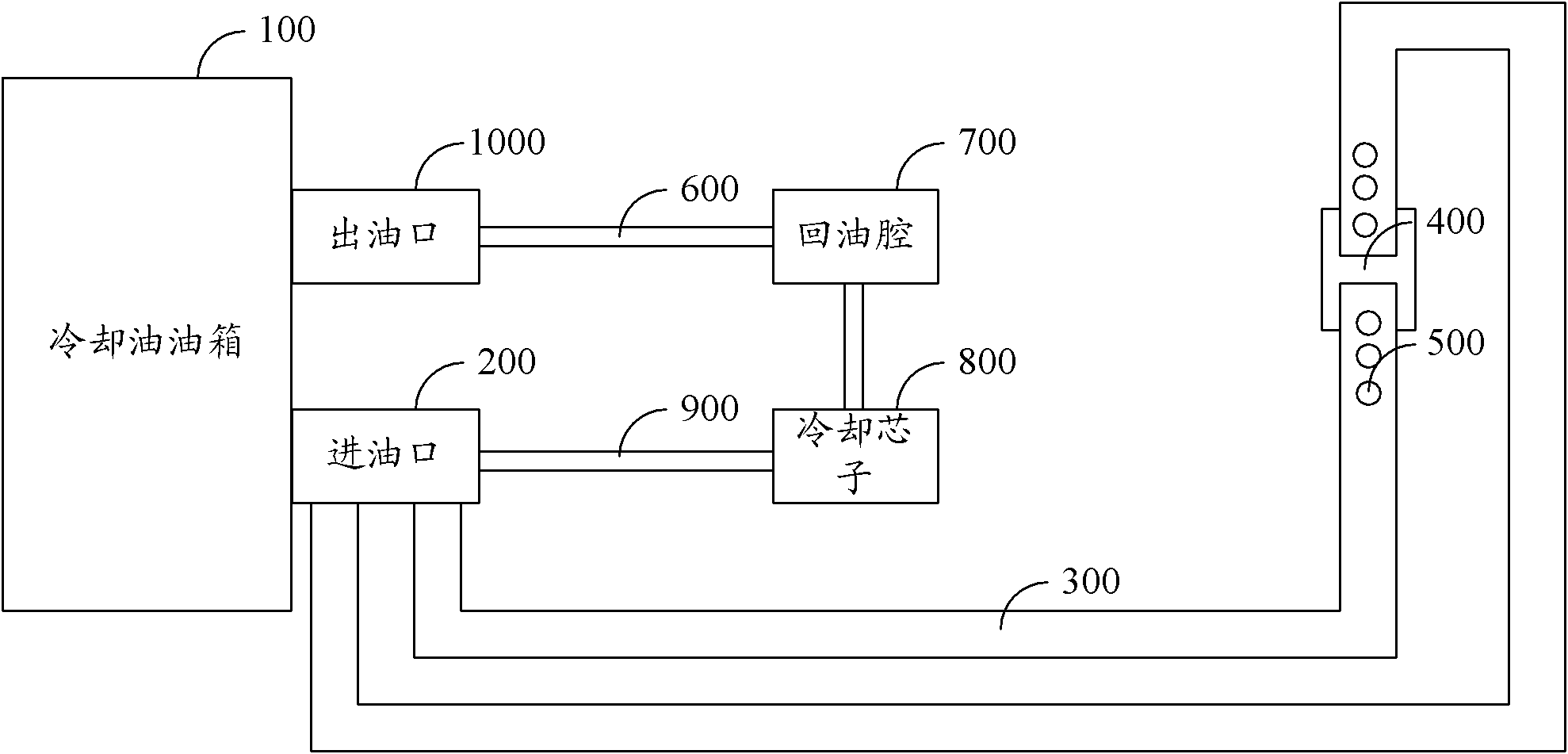

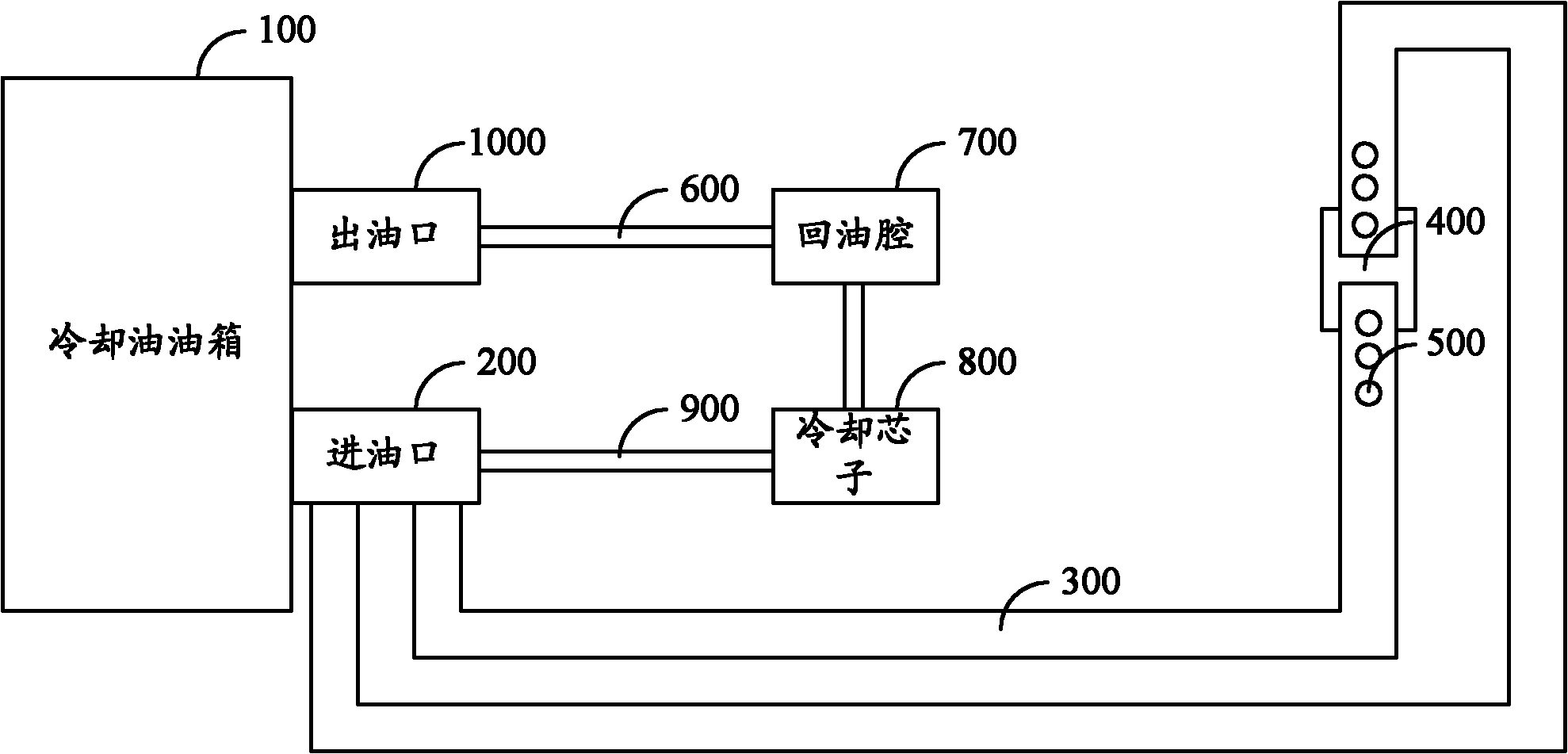

Oil cooling system of large transformer for nuclear power station

ActiveCN102468039AGuaranteed service lifeExtended service lifeTransformers/inductances coolingTransformers/inductances coils/windings/connectionsNuclear powerSludge

The invention is suitable for the field of electromechanical technologies and provides an oil cooling system of a large transformer for a nuclear power station. In an embodiment of the invention, an oil inlet of an oil cooler at a high-voltage side of the transformer is connected with an oil conduit extending to a region of a bus copper bar at a low-voltage side of the transformer, a plurality of shunting holes are formed in the extending end part of the oil conduit, working oil introduced from the oil inlet flows through the surface of the bus copper bar through the oil conduit and the shunting holes so as to circularly cool the bus copper bar, therefore, local hot spots existing inside the transformer are eliminated and the quality of insulating oil is increased; in addition, the surface of the bus copper bar is prevented from the accumulation of a large amount of black oil sludge and the phenomenon of oxide layer shedding, so that the service life of the transformer is ensured and even can be prolonged, and giant economic benefits are brought.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

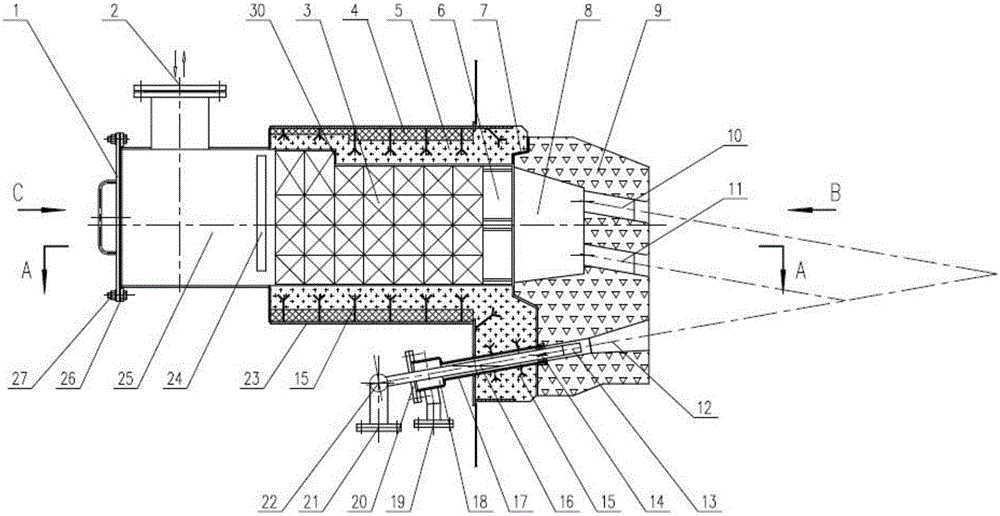

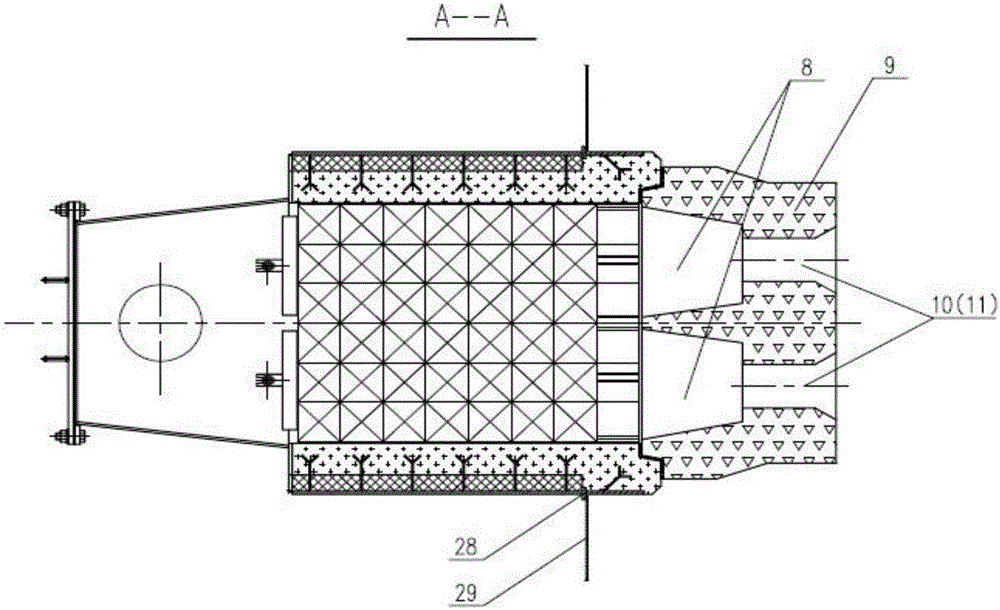

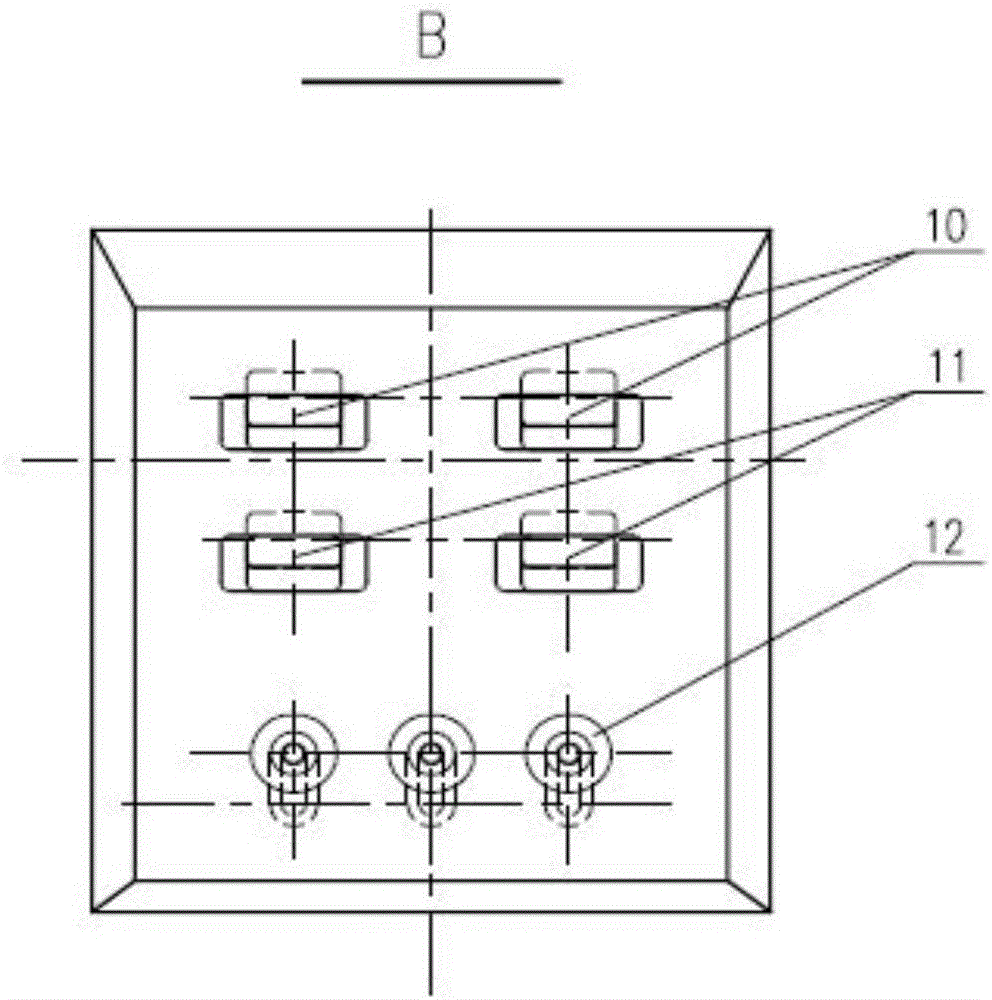

Multi-stage combustion energy-saving environment-friendly burner

PendingCN107435925AIncrease overall volumeReduce the temperatureGaseous fuel burnerThermodynamicsNitrogen oxides

The invention discloses a multi-stage combustion energy-saving environment-friendly burner, and belongs to the technical field of energy conservation and environmental protection. The burner comprises a burner overhaul cover plate, a combustion air inlet, a heat accumulator, a heat insulation material, a fire-resistant pouring material, a large-hole baffle brick, a high-temperature gas distribution chamber, a natural gas sprayer, a primary air spinning disk, an anchoring nail, a primary air inlet, a first connecting flange, a natural gas inlet, a grille plate, a second connecting flange, a bolt connector and a burner installation positioning plate, the burner overhaul cover plate is fixed on a low-temperature gas distribution chamber through the second connecting flange and the bolt connector, a steel pipe of the combustion air inlet is welded on the low-temperature gas distribution chamber, and the heat accumulator is mounted in a heat accumulation burner box. According to the burner, the advantages of air classifying combustion technique are sufficiently played, NOx generation is effectively restrained by the aid of oxygen-deficient combustion mechanism, and the discharge amount of pollutants such as nitrogen oxide is greatly reduced.

Owner:安徽皓沣环保科技有限公司

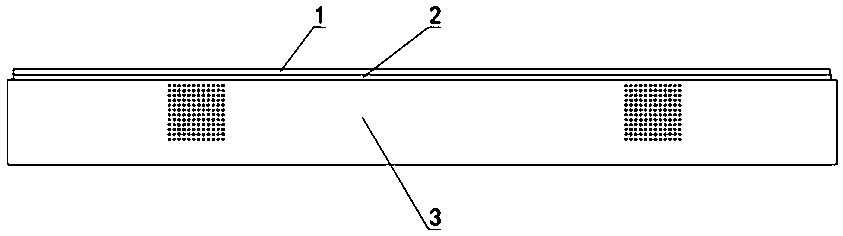

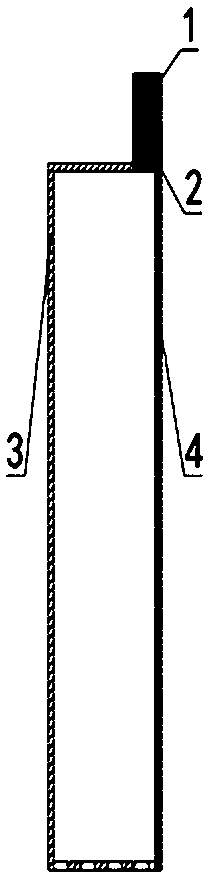

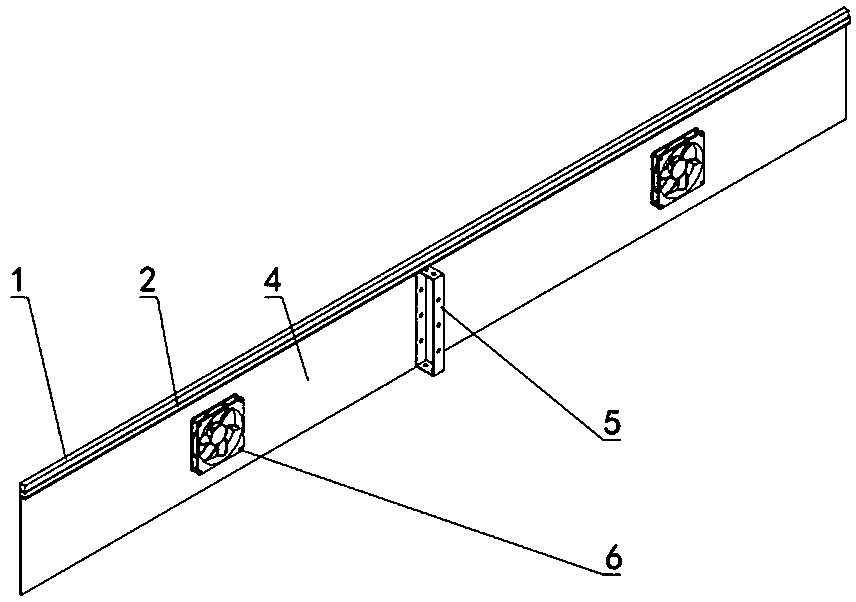

Efficient heat dissipation structure of large-size high-power ultra-thin liquid crystal display (LCD) television

PendingCN108234913AAvoid interactionEasy to installTelevision system detailsColor television detailsLiquid-crystal displayEngineering

The invention discloses an efficient heat dissipation structure of a large-size high-power ultra-thin liquid crystal display (LCD) television. The structure comprises a bar-shaped hollow heat dissipation frame, at least one axial fan, and a bar-shaped heat tube temperature equalizing bar, wherein the hollow heat dissipation frame is mainly formed by a casing 3 and a heat dissipation aluminum platein an enclosing manner; the heat tube temperature equalizing bar is fixed at the top end of the heat dissipation aluminum plate in the length direction of the hollow heat dissipation frame; the axialfan is fixed on the inner side surface of the casing and is arranged right opposite to the inner side surface at a certain interval; and a plurality of vent holes are uniformly formed in positions ofthe bottom and the side surfaces of the casing where the axial fan is mounted. The structure provided by the invention has the advantages that space partition plates and the axial fan are combined for partitioned heat dissipation, so that an LED light bar can achieve good cooling effect even under the conditions of a small space, a small air volume and low noises, temperatures of light beads on the LED light bar tend to be identical through the temperature equalization effect of the heat tube temperature equalizing bar, and the overall heat dissipation effect is improved.

Owner:SOUTH CHINA UNIV OF TECH +1

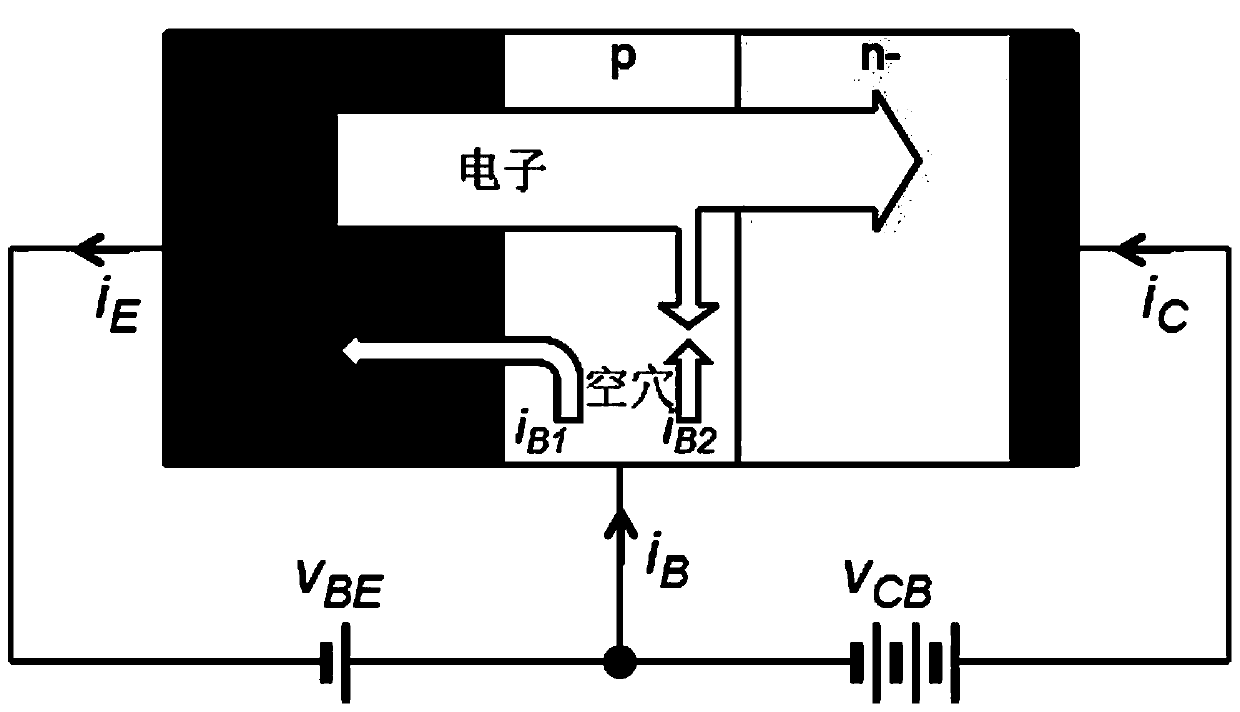

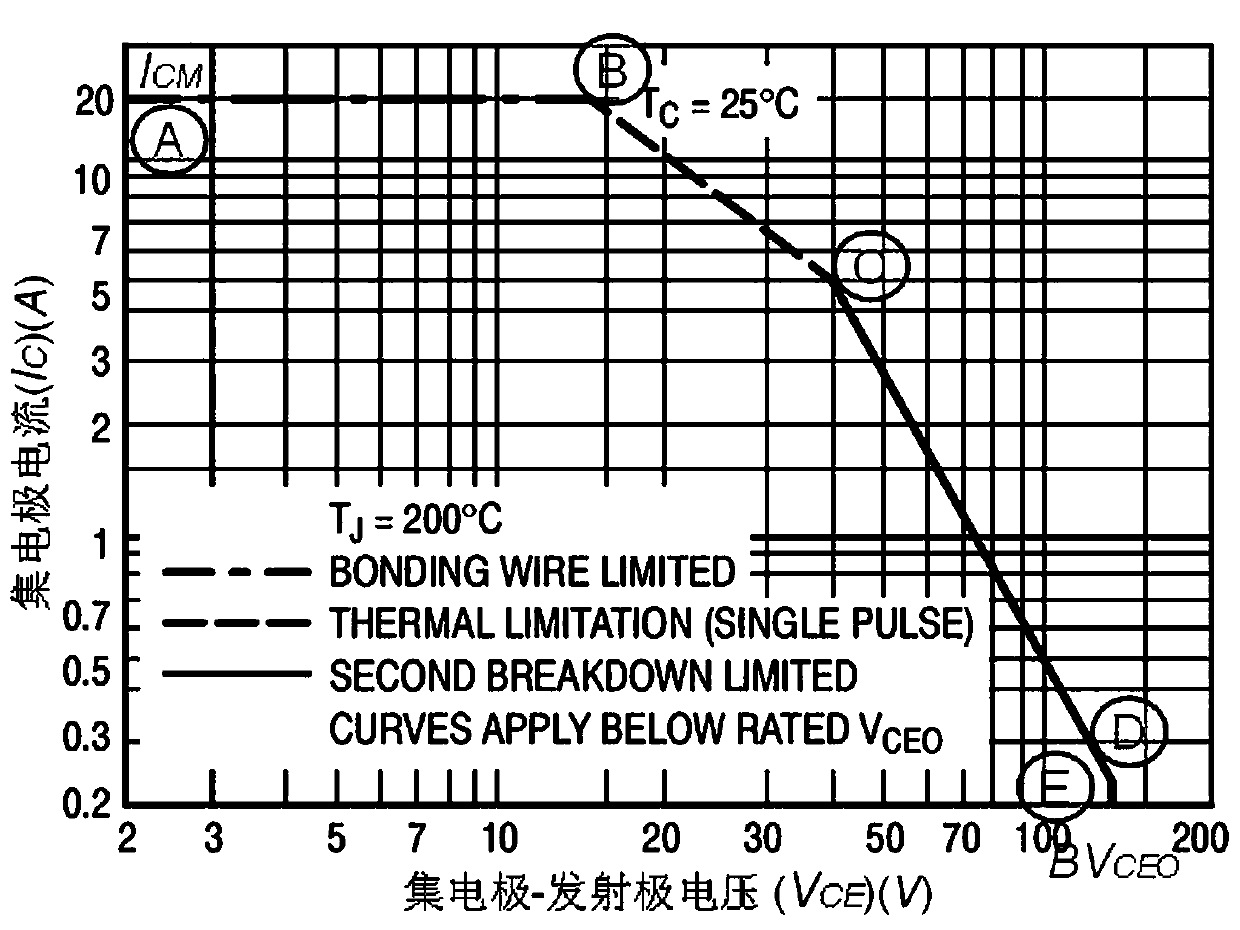

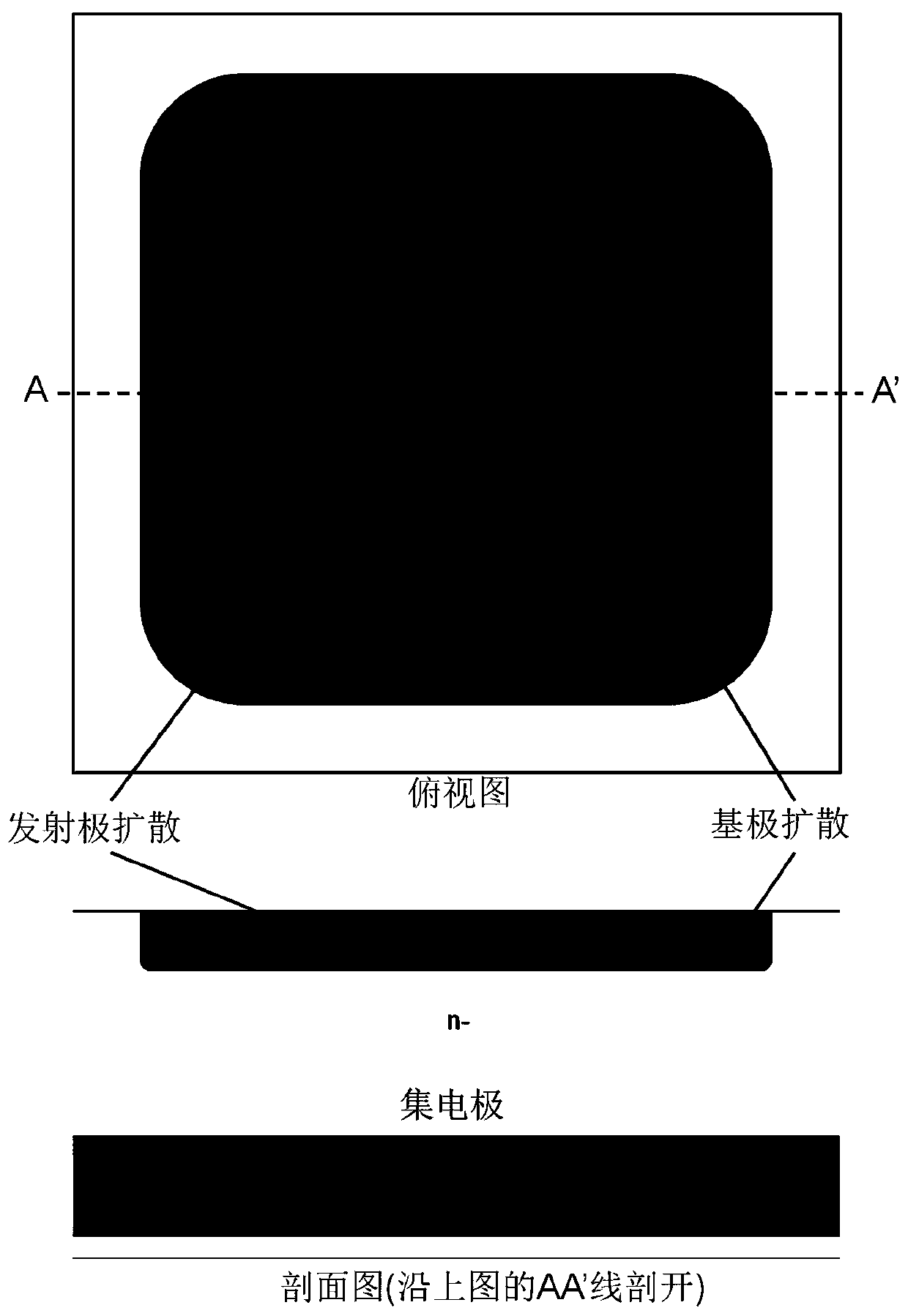

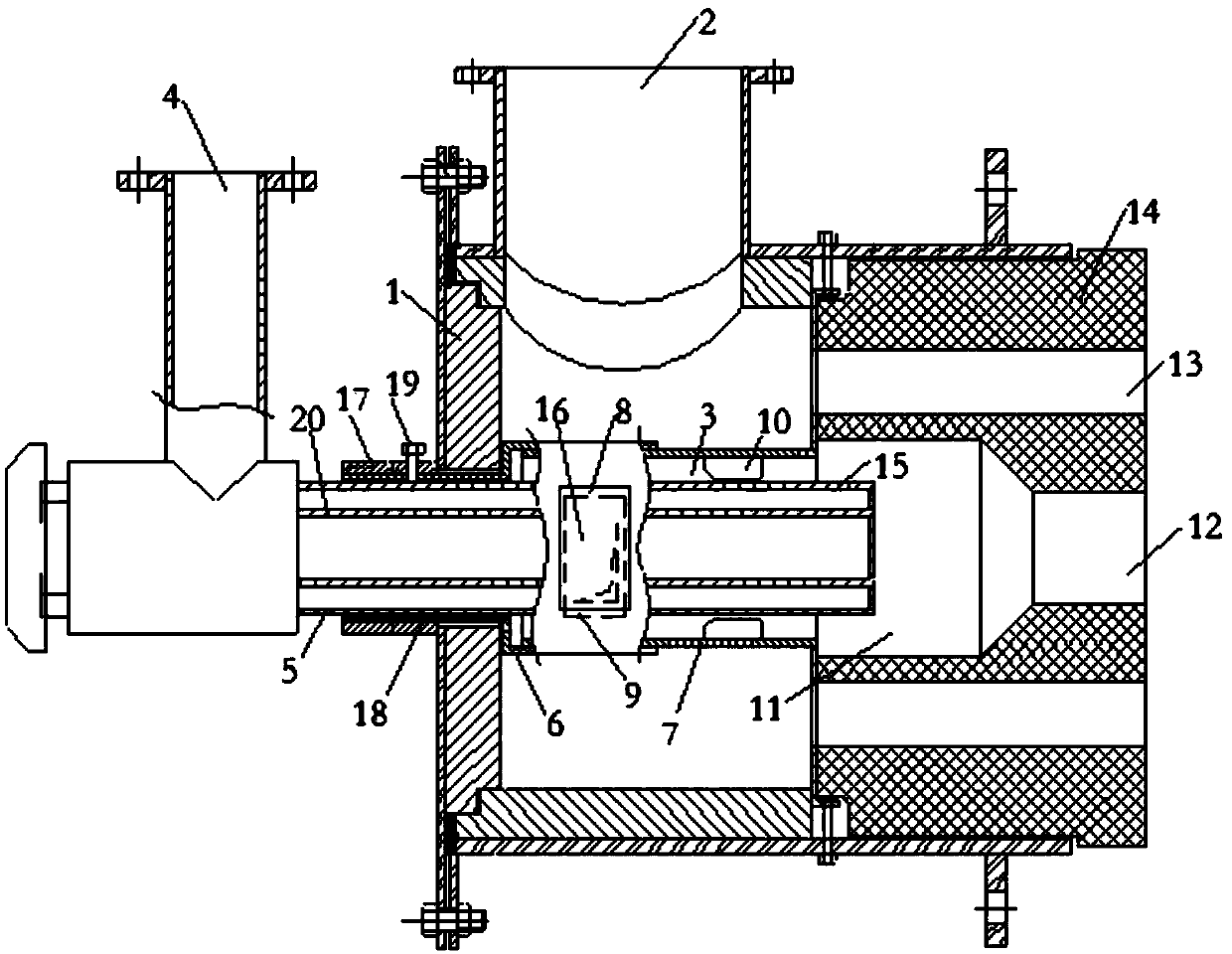

Transistor with high performance, wide safety operation area and high reliability

InactiveCN110600544AIncrease the effective chip areaImprove current magnificationTransistorSolid-state devicesPower flowLocal current

The invention discloses a transistor with high performance, wide safety operation area and high reliability. The transistor comprises multiple mutually independent sub-transistors, and the sub-transistors are formed by entirely segmenting and spacing the original big transistor; the segmentation of the total current of the entire transistor is realized at each sub-transistor, so that the temperatures at multiple parts of the entire transistor are uniform, the excessive increasing of the local current of the transistor is effectively inhibited, and multiple sub-transistors are arranged on one monocrystalline silicon wafer. The transistor disclosed by the invention has the advantages of improving the secondary breakdown tolerance of the power transistor, broadening the safety operation arearange, reinforcing the reliability of the device and the electronic product, prolonging the service life of the transistor and the complete machine, and expanding the application field of the power transistor.

Owner:SHANDONG AOTIAN ELECTRONICS & TECH CO LTD

Method for melting copper through line frequency furnace

ActiveCN105274354AImprove airtightnessImprove energy savingProcess efficiency improvementIngotShaft furnace

The invention discloses a method for melting copper through a line frequency furnace. The method comprises the following steps that 1, a waste copper piece and waste are subjected to primary treatment; 2, screening is carried out; 3, classification is carried out; 4, accessories are fed into furnaces, wherein the accessory I, the accessory II and the accessory III are fed into the shaft furnace, the open-hearth furnace and the line frequency cored copper melting copper to be refined, and a product I, a product II and a product III are obtained; 5, the product I and the product II are transported to a copper continuous casting and rolling unit for casting treatment, a steel rod is obtained, and the product III is placed in a pig casting machine to be machined and treated, and a copper ingot is obtained; and 6, the steel rod in the step 5 is drawn, and a qualified copper piece is obtained. The method for melting copper through the line frequency furnace achieves energy saving and is environmentally friendly, and manufactured steel is good in quality.

Owner:NINGXIA RUIYIN NONFERROUS METAL TECH CO LTD

Biomass gas burner with adjustable flame length and using method thereof

InactiveCN109611843AAdvantages of the burnerEasy to operateAir/fuel supply for combustionNon-combustible gases/liquids supplyEngineeringFuel gas

The invention discloses a biomass gas burner with adjustable flame lengths. A mixing chamber is arranged in the center of inner burner blocks, a fuel gas source communicates with the left end of a fuel gas effuser through a fuel gas inlet pipe; the right end of the fuel gas effuser penetrates through a burner outer shell and extends into the mixing chamber; a fixed air cover sleeves the outer sideof the fuel gas effuser; a primary air channel is formed between the outer wall of the fuel gas effuser and the inner wall of the fixed air cover; a movable air cover is rotatably assembled on the outer side of the fixed air cover; a first air port and a second air port are correspondingly formed in overlapping parts of the fixed air cover and the movable air cover; the size of a opening formed by the first air port and the second air port is adjusted by a rotary movable air cover; one end of the primary air channel communicates with an air inlet pipe through the opening; the other end of theprimary air channel communicates with the mixing chamber; a secondary air channel is further arranged on the inner burner blocks; and the air inlet pipe communicates with a furnace chamber through the secondary air channel. According to the biomass gas burner with the adjustable flame lengths, air covers are used for adjusting a primary air flow rate, so the ratio of primary and secondary combustion air can be adjusted without disassembling a burner, and the operation is very convenient and simple.

Owner:NORTHEASTERN UNIV

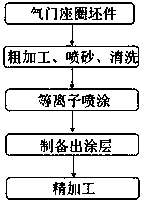

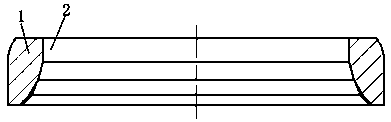

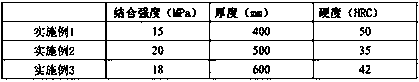

Thermal spraying engine valve seat ring wear-resistant coating and preparation method and use thereof

InactiveCN111118433AImprove thermal conductivityImprove wear resistanceMolten spray coatingMachines/enginesEngine valveMetal powder

The invention discloses a thermal spraying engine valve seat ring wear-resistant coating and a preparation method and use thereof. The purpose is to provide the thermal spraying engine valve seat ringwear-resistant coating with a simple process and the preparation method and use thereof. The wear-resistant coating is prepared from the following components in percentage by mass: 60-99% of metal powder and 1-40% of ceramic powder. The wear-resistant coating has high hardness and good adhesion performance, and can operate under high-temperature, high-scouring and high-pressure environments for along time without failure, falling off and other phenomena, and the wear-resistant performance is good.

Owner:云南云内动力机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com