Thermal spraying engine valve seat ring wear-resistant coating and preparation method and use thereof

A technology of engine valves and wear-resistant coatings, which is applied in the direction of engine components, machines/engines, coatings, etc., can solve the problem that the wear resistance of the workpiece surface lubrication cannot meet the working conditions, etc., to eliminate local hot spots and improve Thermal conductivity, wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

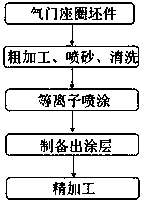

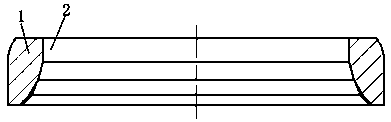

[0026] A preparation method of a thermally sprayed engine valve seat ring wear-resistant coating, comprising the following steps:

[0027] (1) Carry out the pretreatment of machining, sandblasting and cleaning on the valve seat to be sprayed, so that the surface roughness of the valve seat can reach Ra>6.4; The surface of the seat ring is clean, so that the surface roughness of the valve seat ring reaches Ra>6.4, which improves the bonding performance of the coating.

[0028] (2) Use the plasma spraying system to spray the wear-resistant coating one or more times to obtain a metal-ceramic composite wear-resistant coating with a uniform thickness, with a thickness of 300um~700μm;

[0029] (3) Perform honing and finishing on the valve seat ring coating obtained in step (2), and the thickness of the wear-resistant coating reaches 200um~500um.

[0030] Before spraying the wear-resistant coating, the metal powder and the ceramic powder are uniformly mixed and ball-milled to a part...

Embodiment 1

[0033] (1) Select 100g of metal and ceramic powder, and the preparation ratio of ceramic powder and metal powder is (mass fraction ratio): 40%, 60%. Among them, the metal powder is 5% Mo, 10% Co, 1% Cu, 9% W, 7% Ni, and the rest is Fe alloy powder, and the ceramic powder is silicon carbide (SiC);

[0034] (2) Mix the well-proportioned metal powder and ceramic powder evenly and ball-mill to a particle size of 20 μm;

[0035] (3) Machining, sandblasting and cleaning the surface of the valve seat, using ordinary quartz sand for sandblasting, so that the surface roughness of the valve seat can reach Ra>6.4;

[0036] (4) Adjust the plasma spraying process parameters and write the robot arm program;

[0037] (5) Without changing the above parameters, spray the valve seat ring to make the coating uniform;

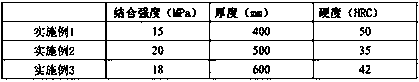

[0038] (6) Finish the sprayed coating, and use a grinding machine to process the surface of the coating. The bonding strength of the coating prepared in this example is 15 MPa, ...

Embodiment 2

[0040] (1) Select 100g of metal and ceramic powder, and the preparation ratio of ceramic powder and metal powder is (mass fraction ratio): 1%, 99%. Among them, the metal powder is 1%Mo, 1%Co, 0.5%Cu, 7%W, 5%Ni, the rest is Fe alloy powder, and the ceramic powder is boron nitride (BN);

[0041] (2) Mix the well-proportioned metal powder and ceramic powder evenly and ball-mill to a particle size of 45 μm;

[0042] (3) The valve seat ring shall be machined, sandblasted, and pre-cleaned, and the sandblasted quartz sand shall be ordinary quartz sand, so that the surface roughness of the valve seat ring can reach Ra>6.4.

[0043] (4) Adjust the plasma spraying process parameters and write the robot arm program;

[0044] (5) Without changing the above parameters, rotate and spray the valve seat ring to make the coating uniform.

[0045] (6) Finish the sprayed coating, and use a grinding machine to process the surface of the coating. The bonding strength of the coating prepared in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com