Method and device for smelting recycled copper in reverberator

A technology of reverberatory furnace and regenerated copper, which is applied in the direction of reverberatory furnace, furnace, furnace type, etc., which can solve the problems of high flue gas temperature and limited use of heat exchangers, and achieve improved metal recovery rate, simple structure, and engineering transformation Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

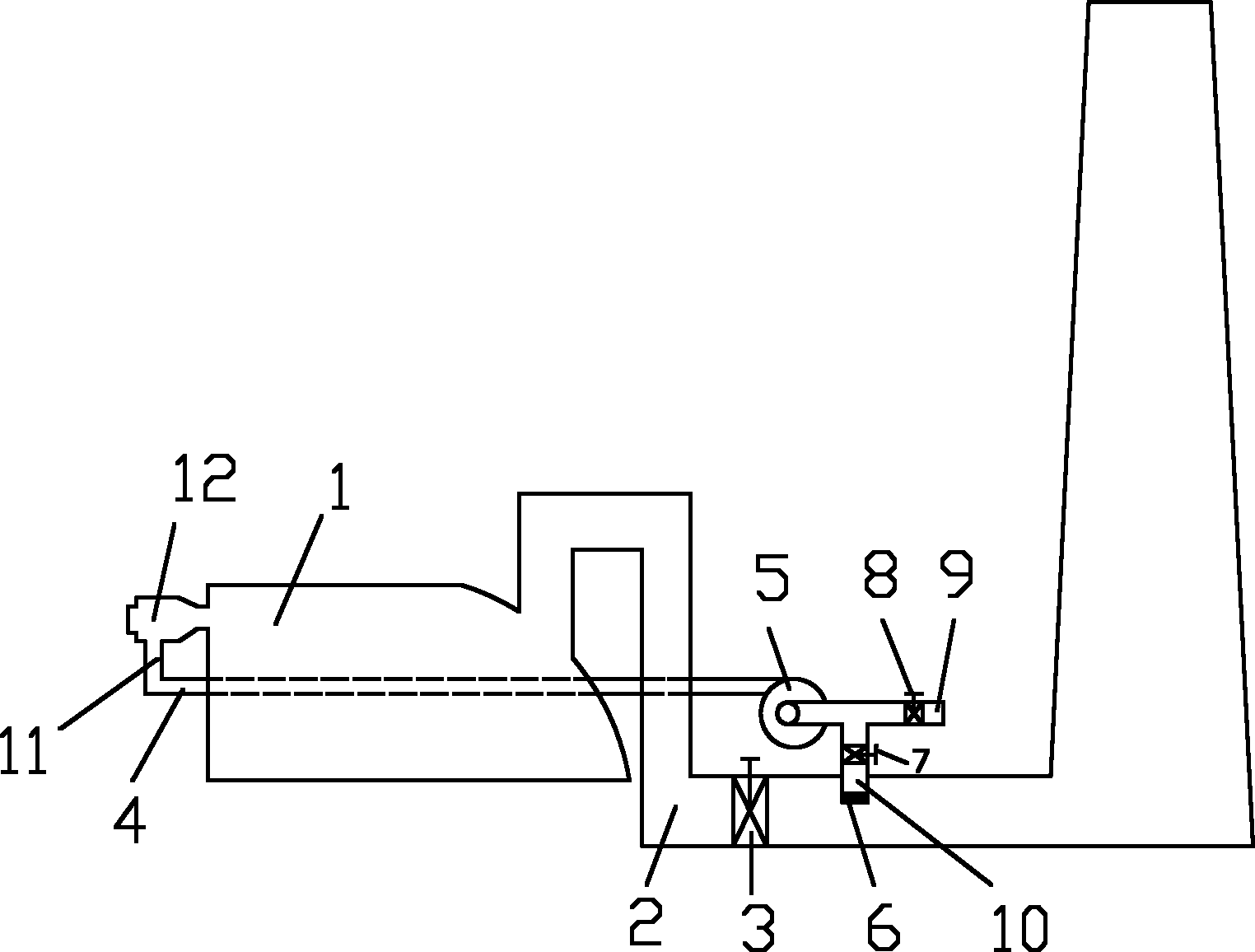

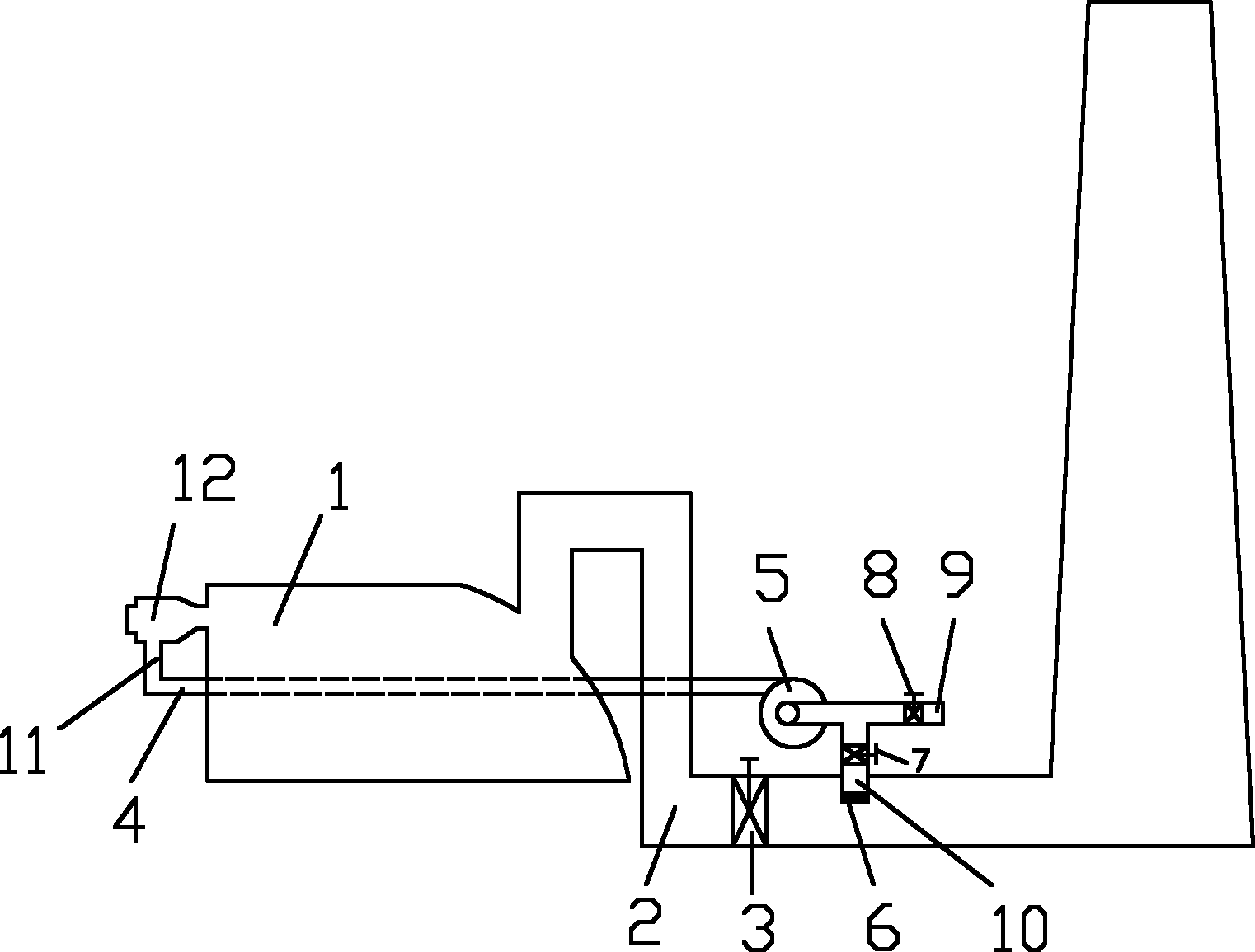

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] The reverberatory furnace smelting regenerated copper method adopted in the present invention directly mixes part of the high-temperature flue gas of the reverberatory furnace 1 with the combustion-supporting air to form a combustion-supporting gas with a higher temperature and a lower oxygen concentration, so as to improve the uniformity of temperature distribution in the reverberatory furnace 1 , reduce the local high temperature, realize high wind temperature, low oxygen concentration combustion in the reverberatory furnace 1, thereby reducing the burning loss of metal, and the amount of returned smoke accounts for 30-50% of the total flue gas volume of the reverberatory furnace 1. The negative pressure in the horizontal flue 2 is strictly controlled, and the negative pressure of the horizontal flue 2 behind the gate 3 is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com