Phase change energy storage temperature controller for space

A phase change energy storage and temperature controller technology, which is applied in indirect heat exchangers, modification with liquid cooling, cooling/ventilation/heating modification, etc., can solve the problem of uneven temperature distribution, low heat transfer coefficient, energy storage, The heat release performance needs to be optimized to achieve the effect of eliminating local hot spots, efficient heat transfer, and eliminating local high heat flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing this description is further described:

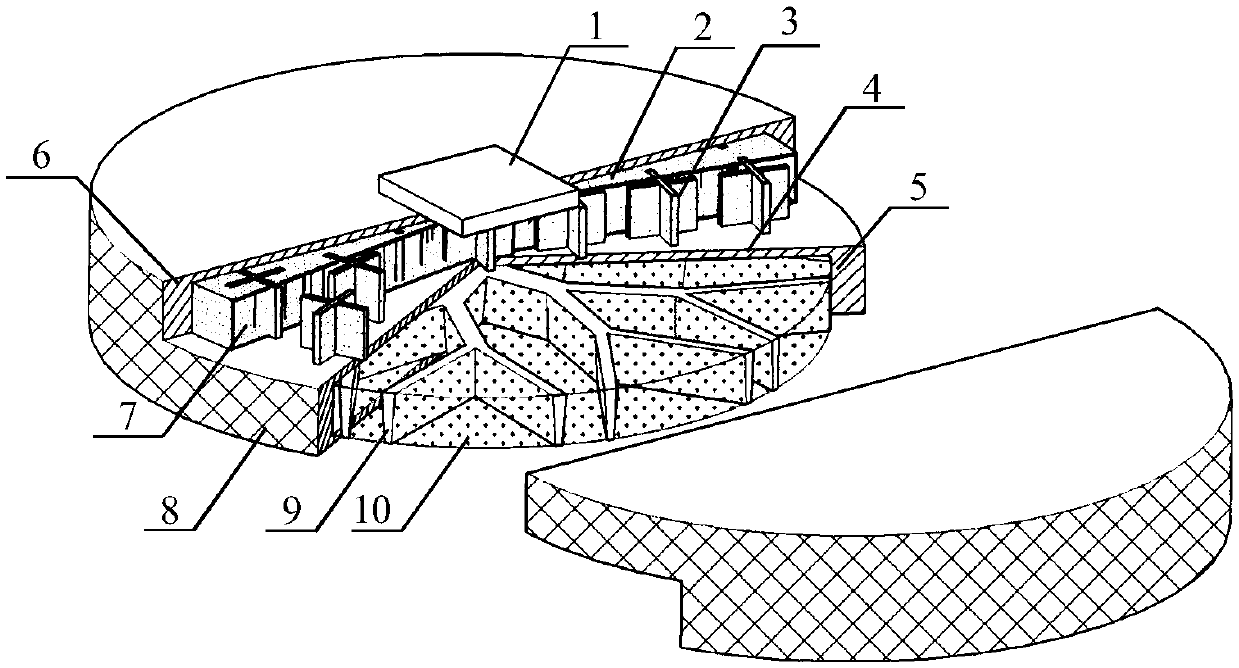

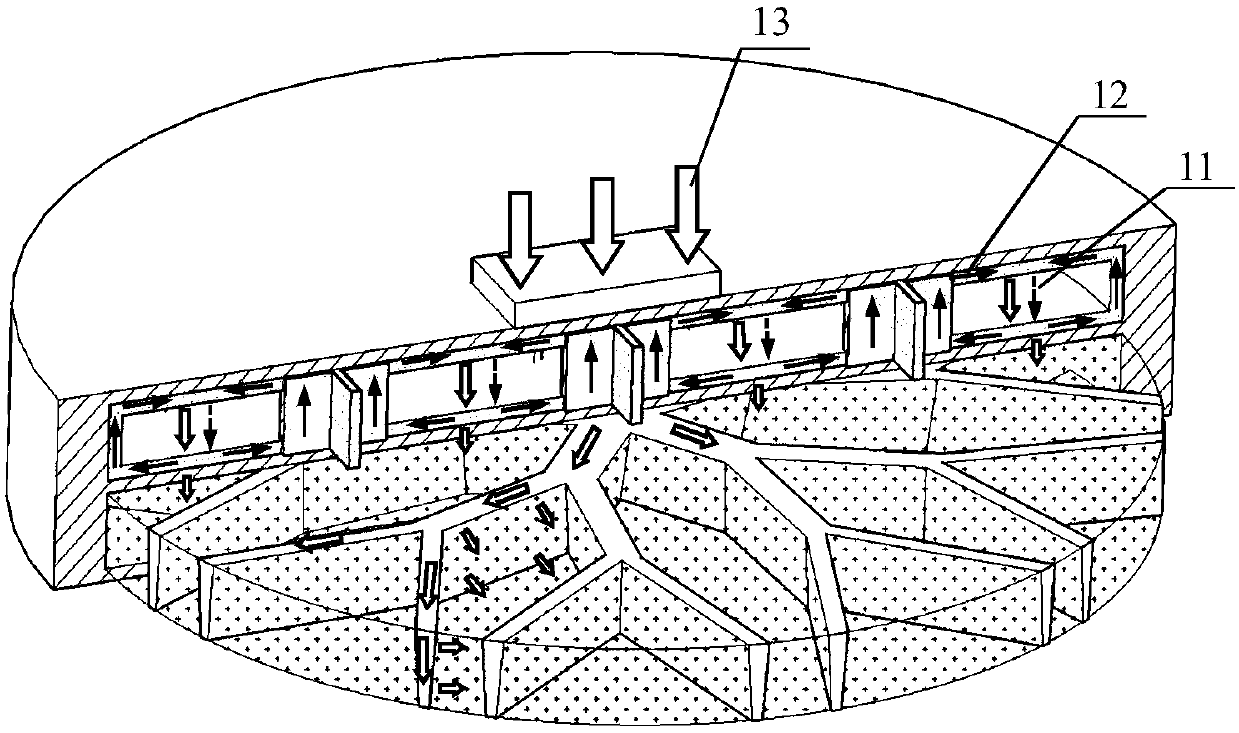

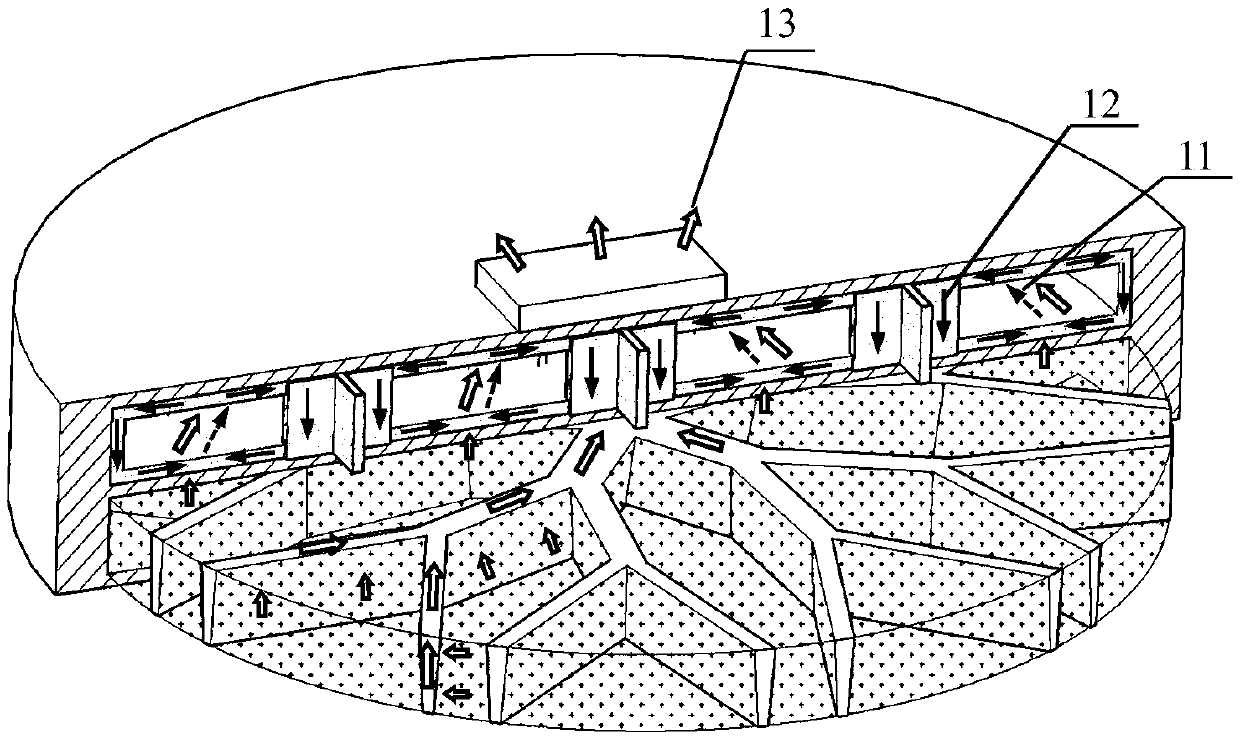

[0025] figure 1 A schematic diagram of the structure of the present invention is given, a thermal diffusion device based on the gas-liquid phase transition process and a heat storage device based on the solid-liquid phase transition process are combined, and the tapered and layered fins are used to enhance the space of the heat transfer device A phase-change energy storage thermostat is used, and the specific structure includes: electronic device 1, liquid-absorbing core 2, support frame 3, high thermal conductivity spacer 4, condensation section 5, evaporation section 6, gas-liquid phase change chamber 7, Radiation section 8, tapered and layered fins 9, solid-liquid phase change storage medium 10 and other main parts. The electronic device 1 is located on the outer surface of the upper wall of the gas-liquid phase change cavity 7, the liquid-absorbing core 2 is closely attached to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com