Patents

Literature

44results about How to "Thermally matched well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

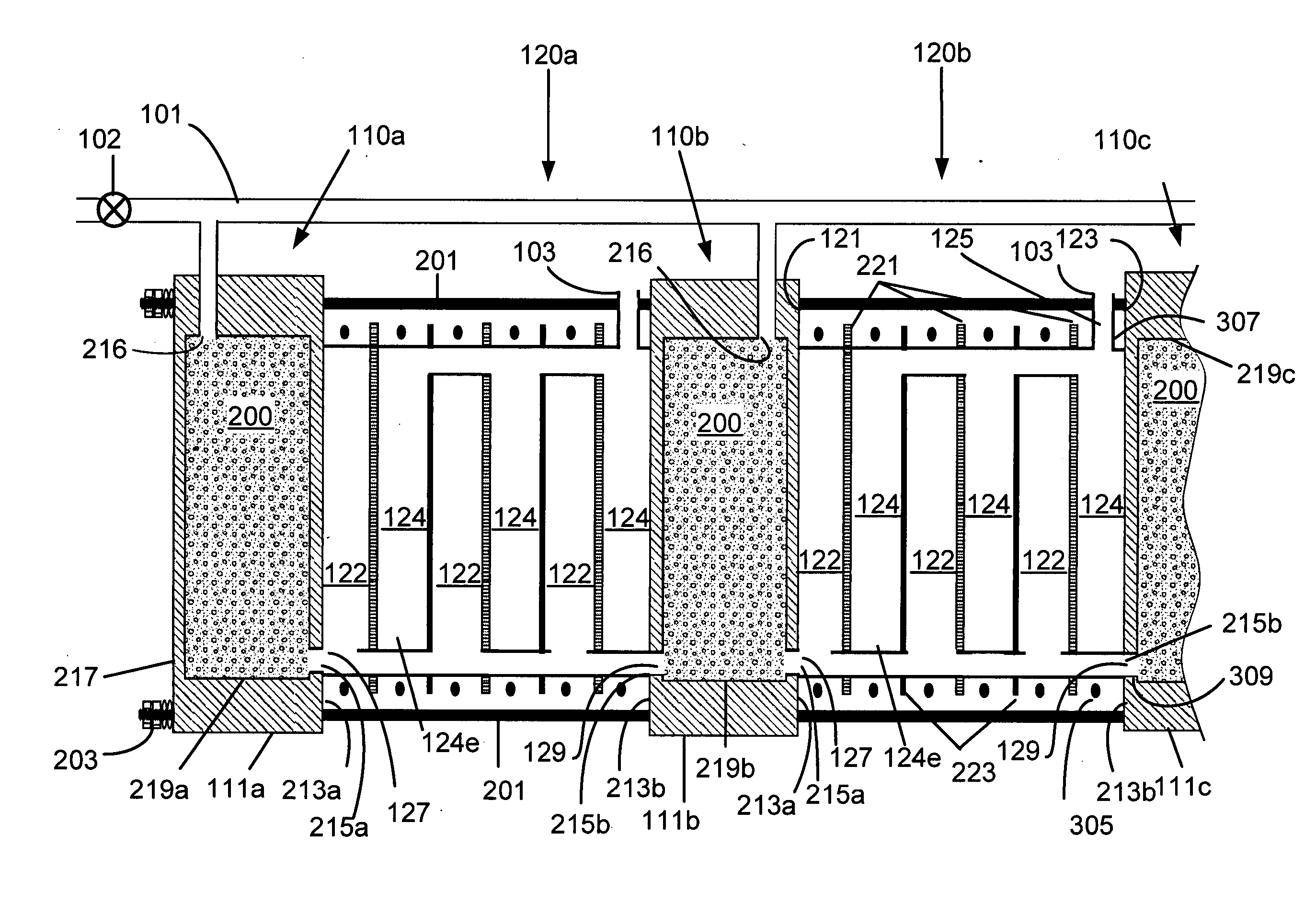

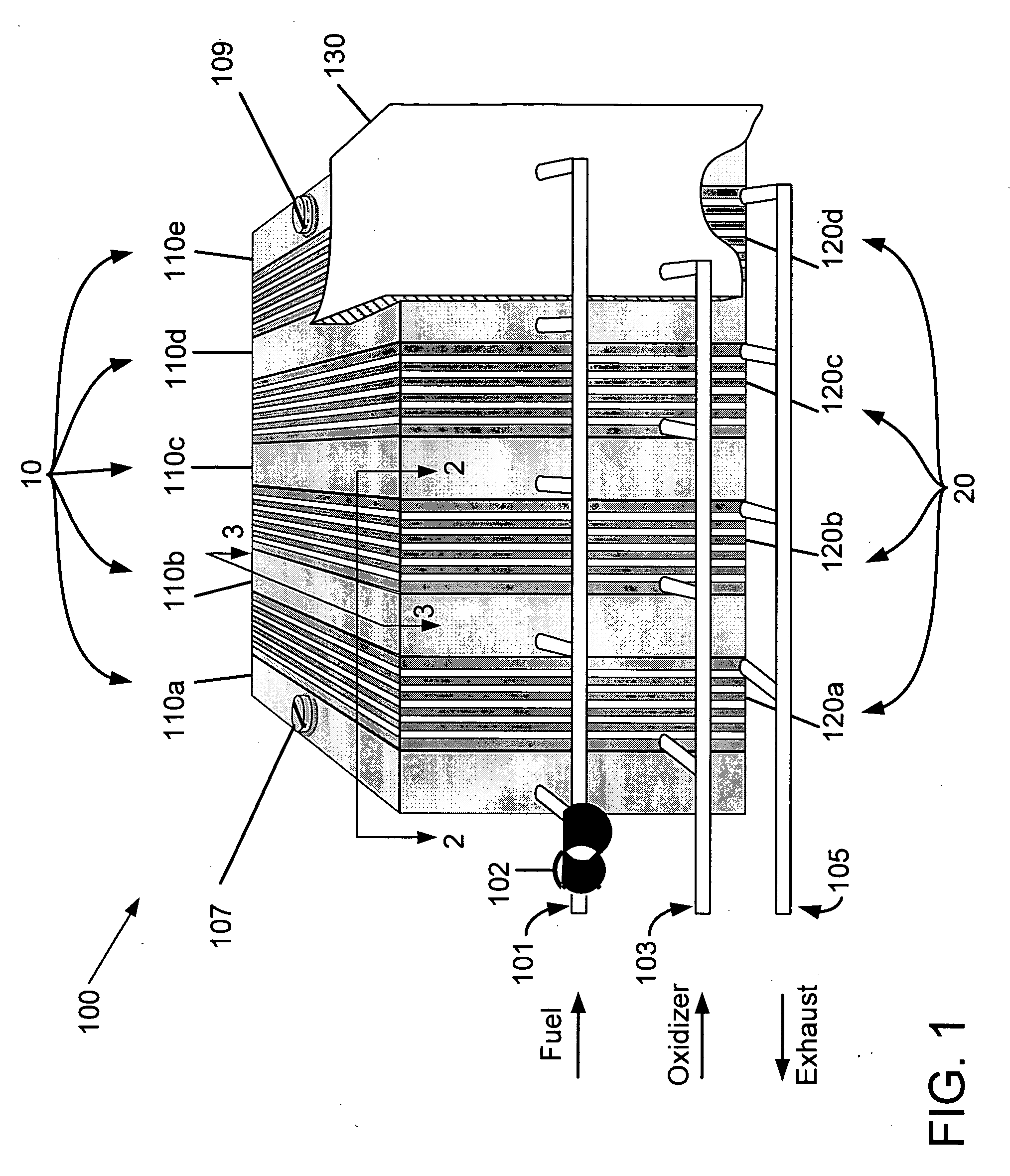

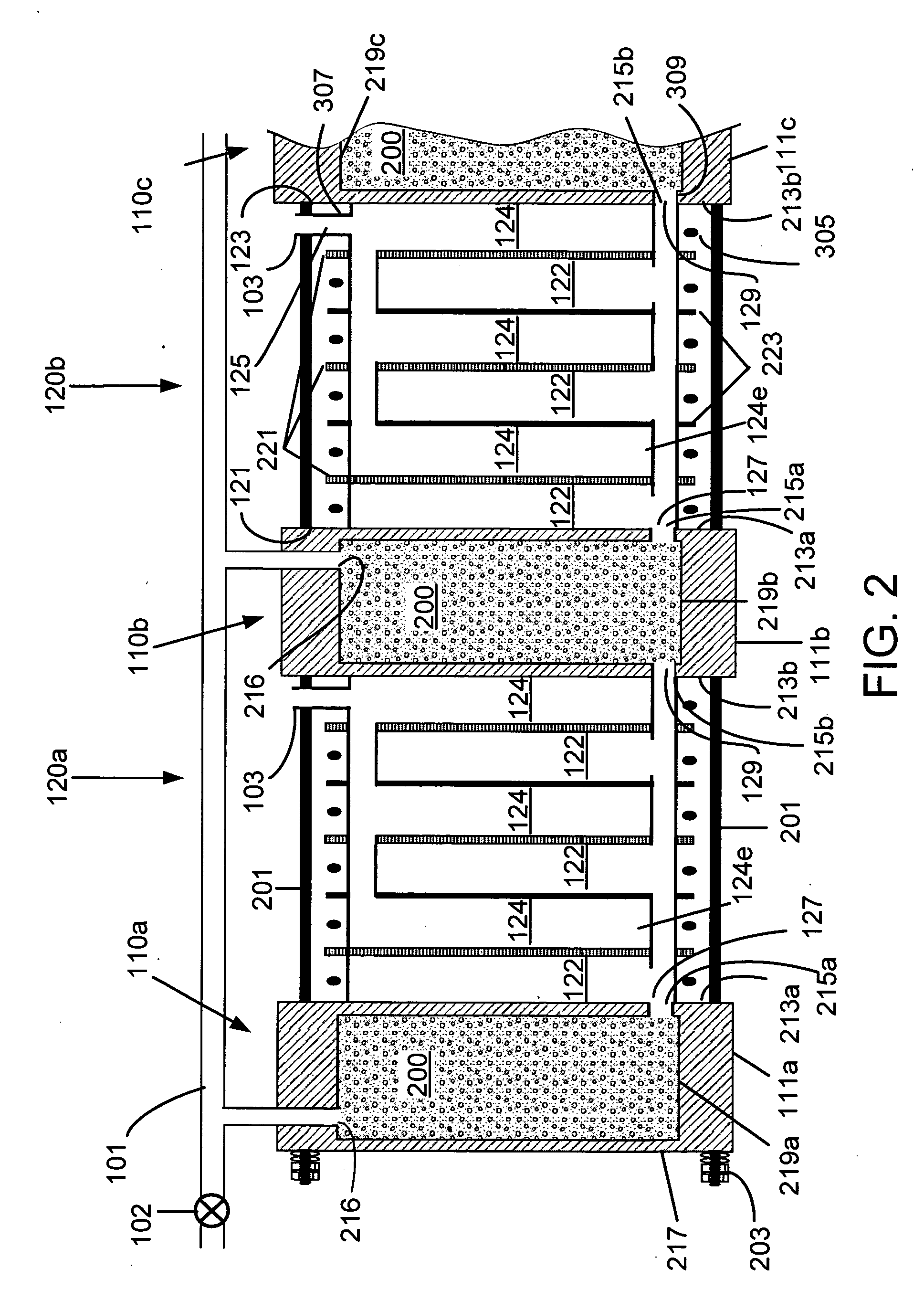

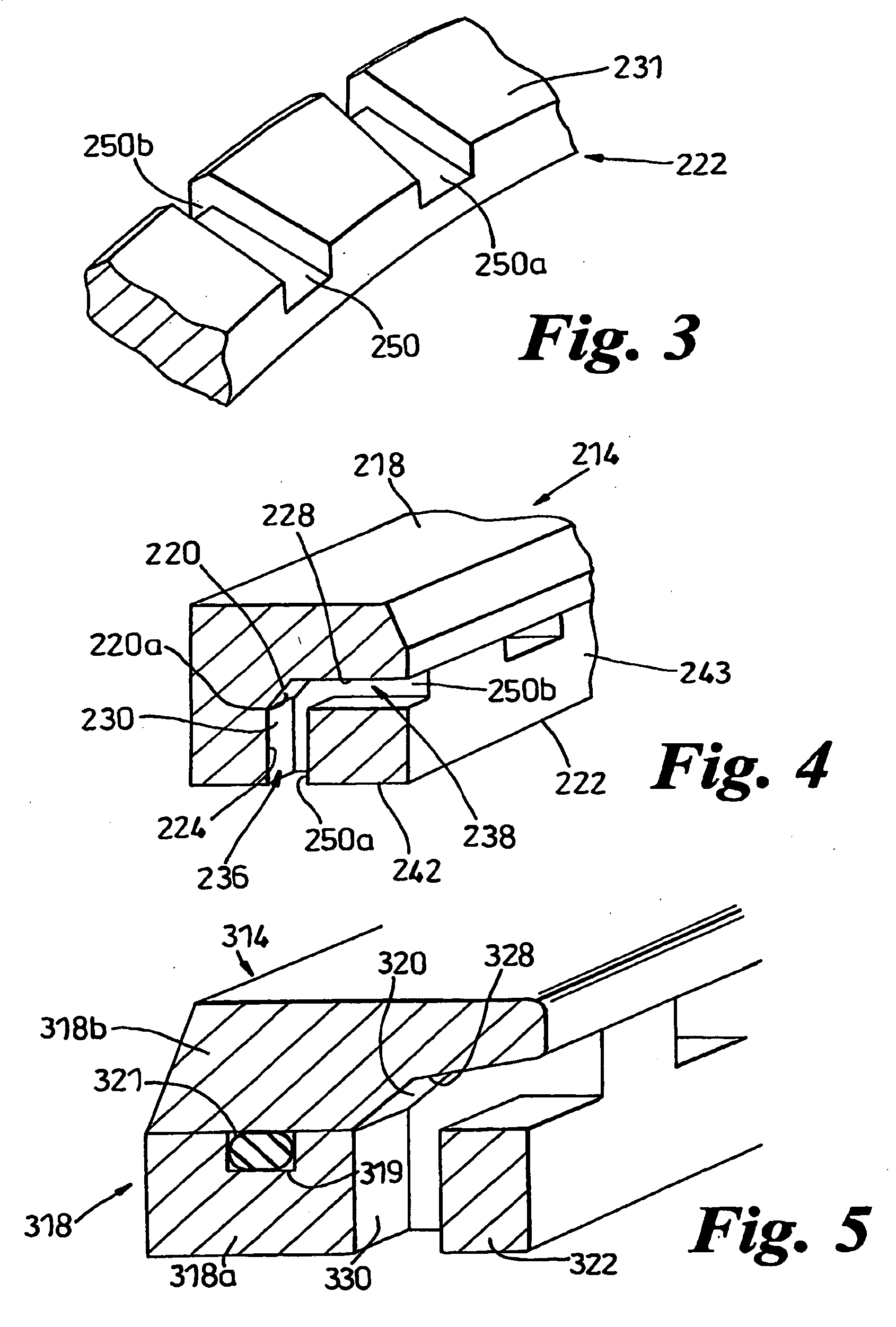

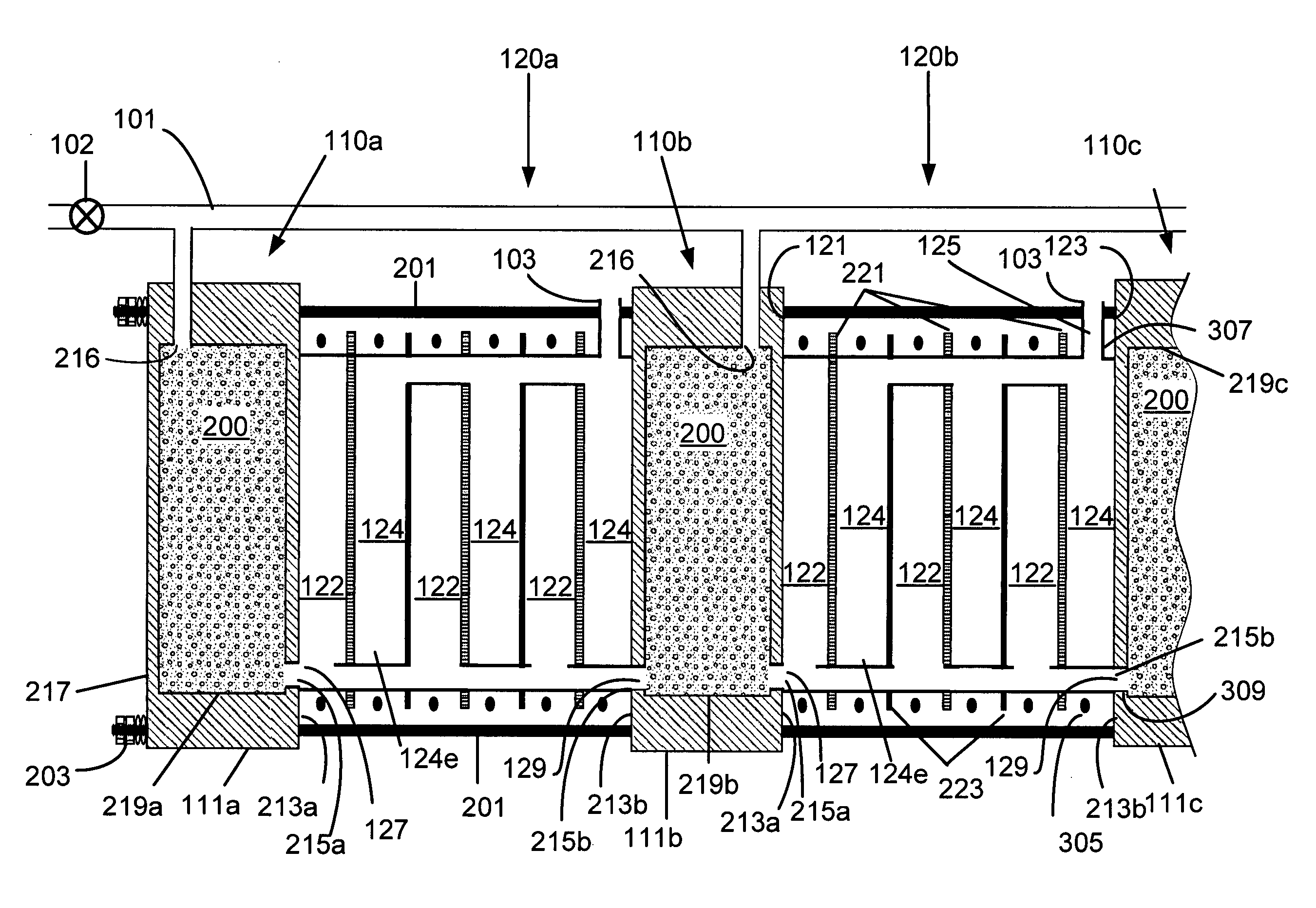

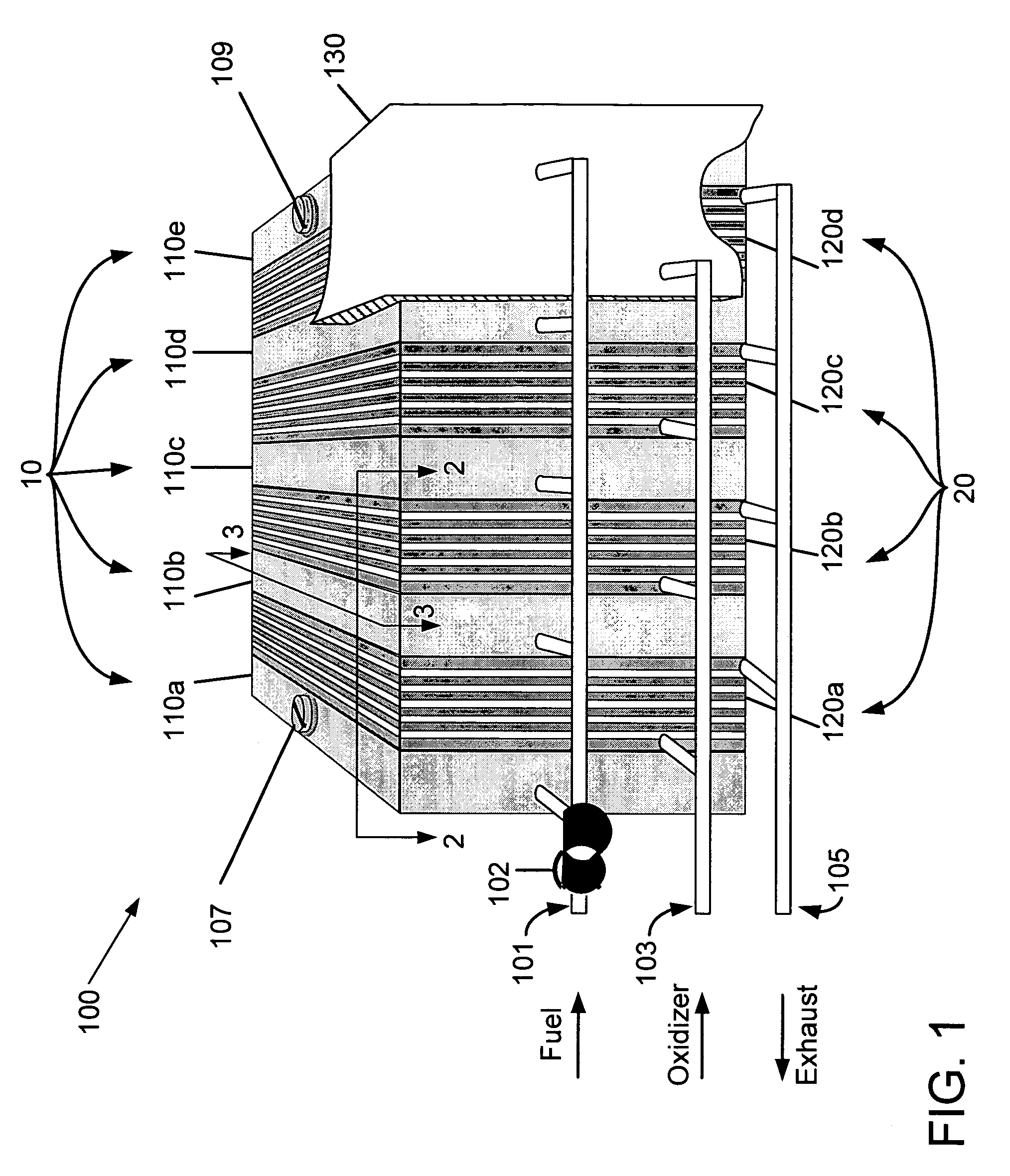

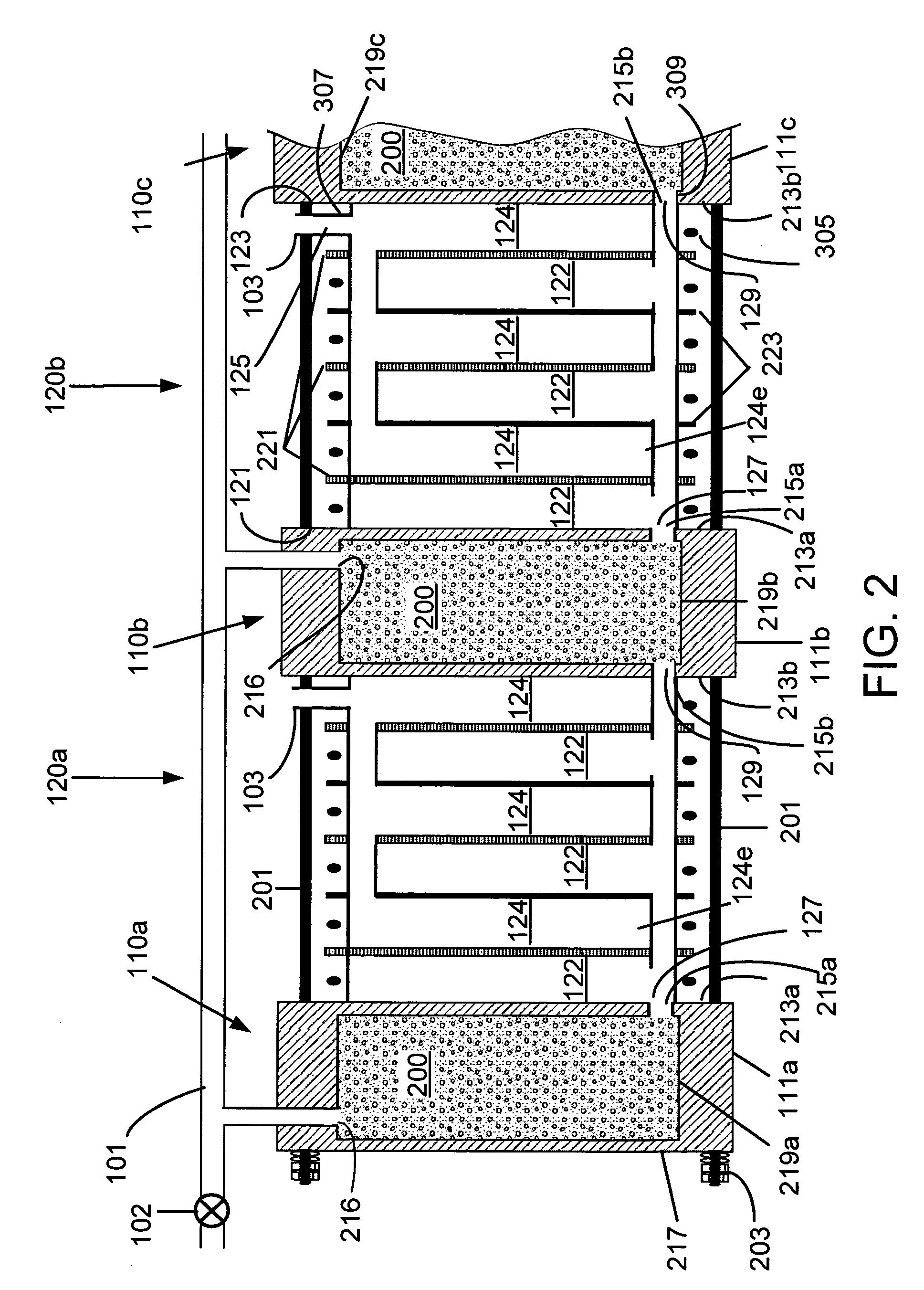

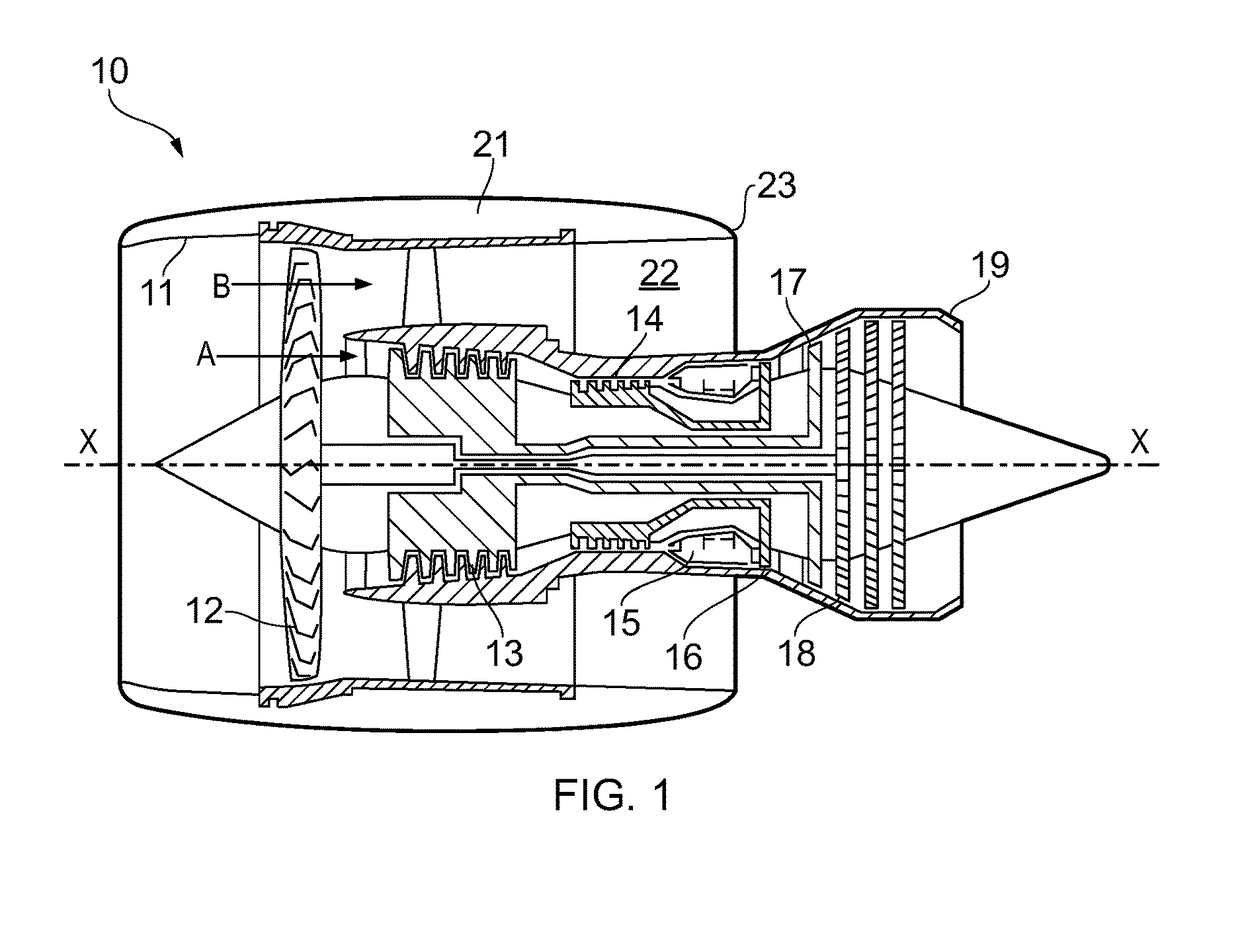

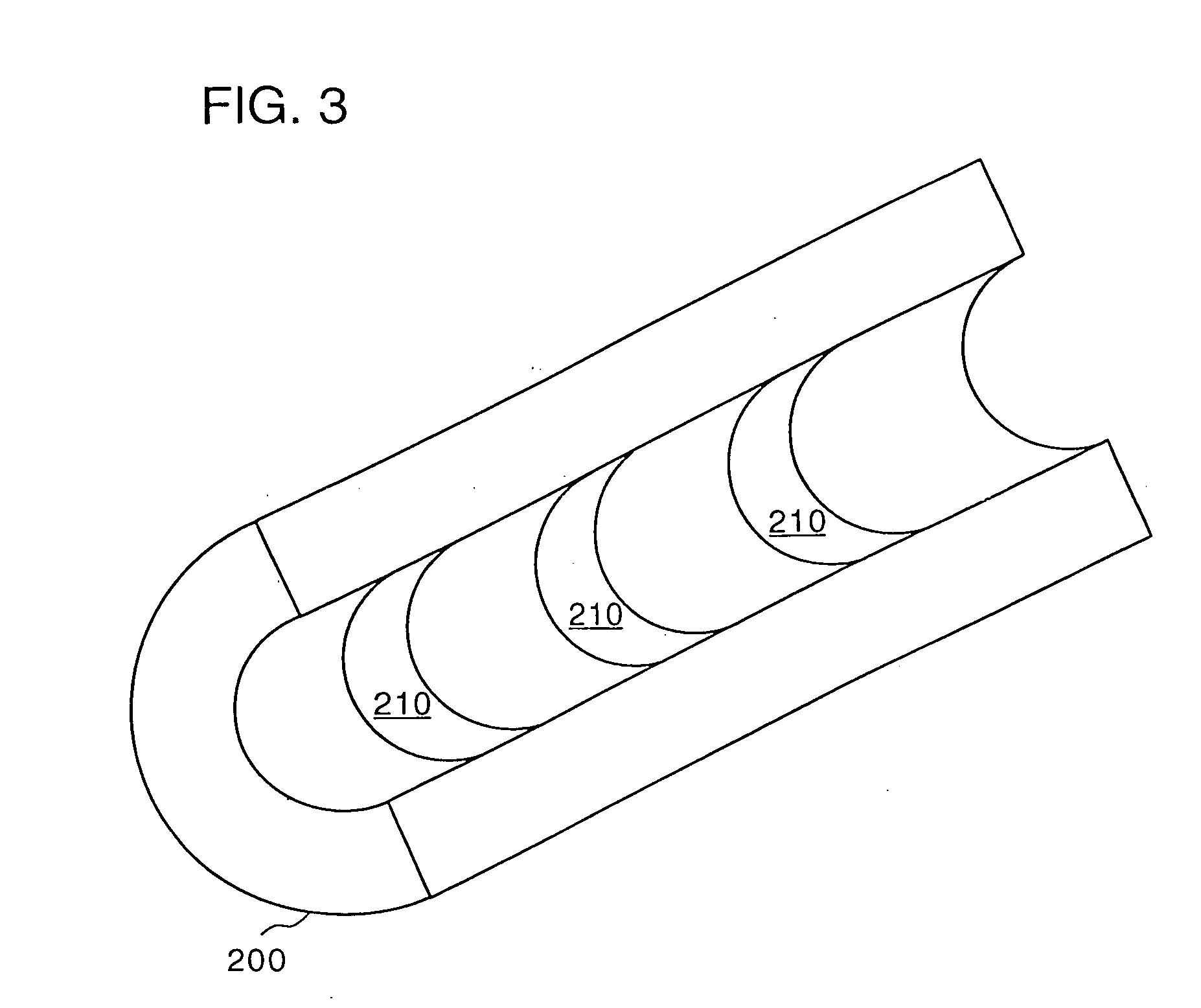

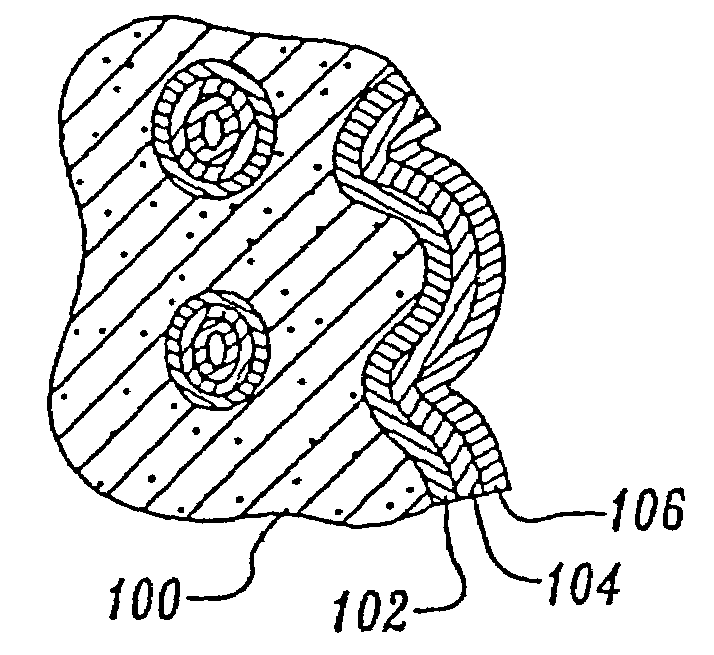

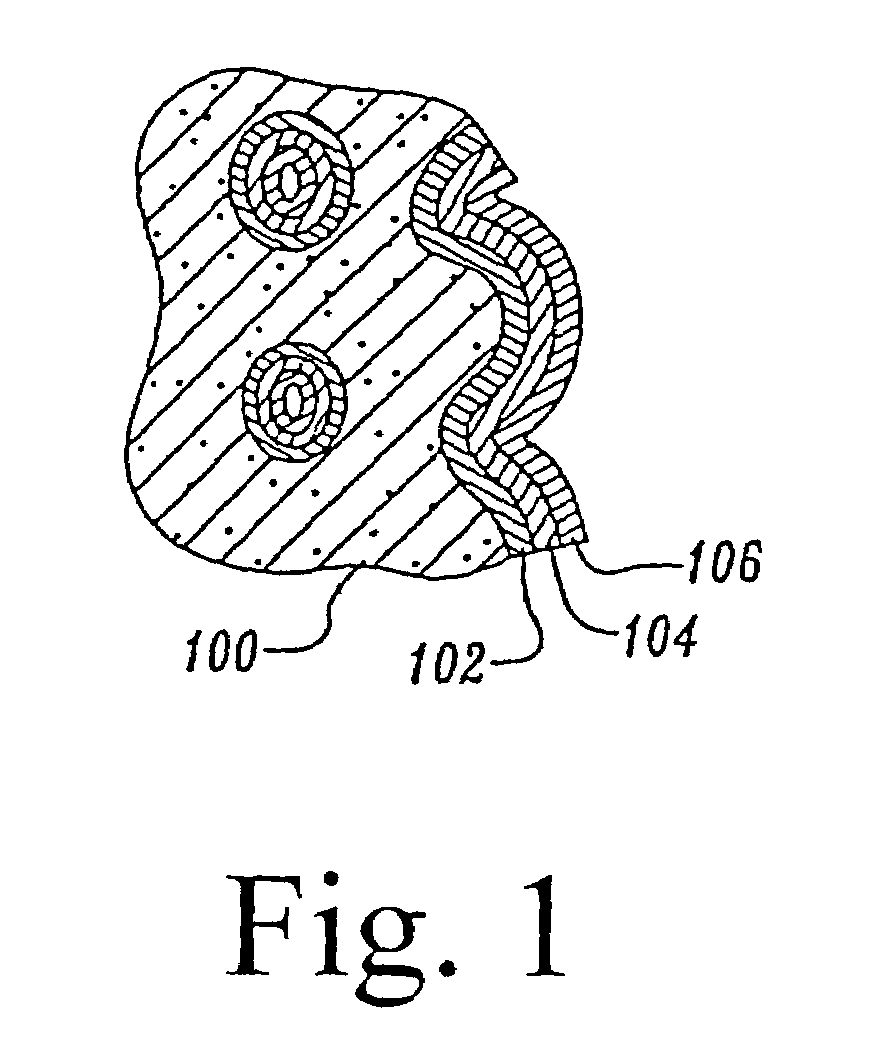

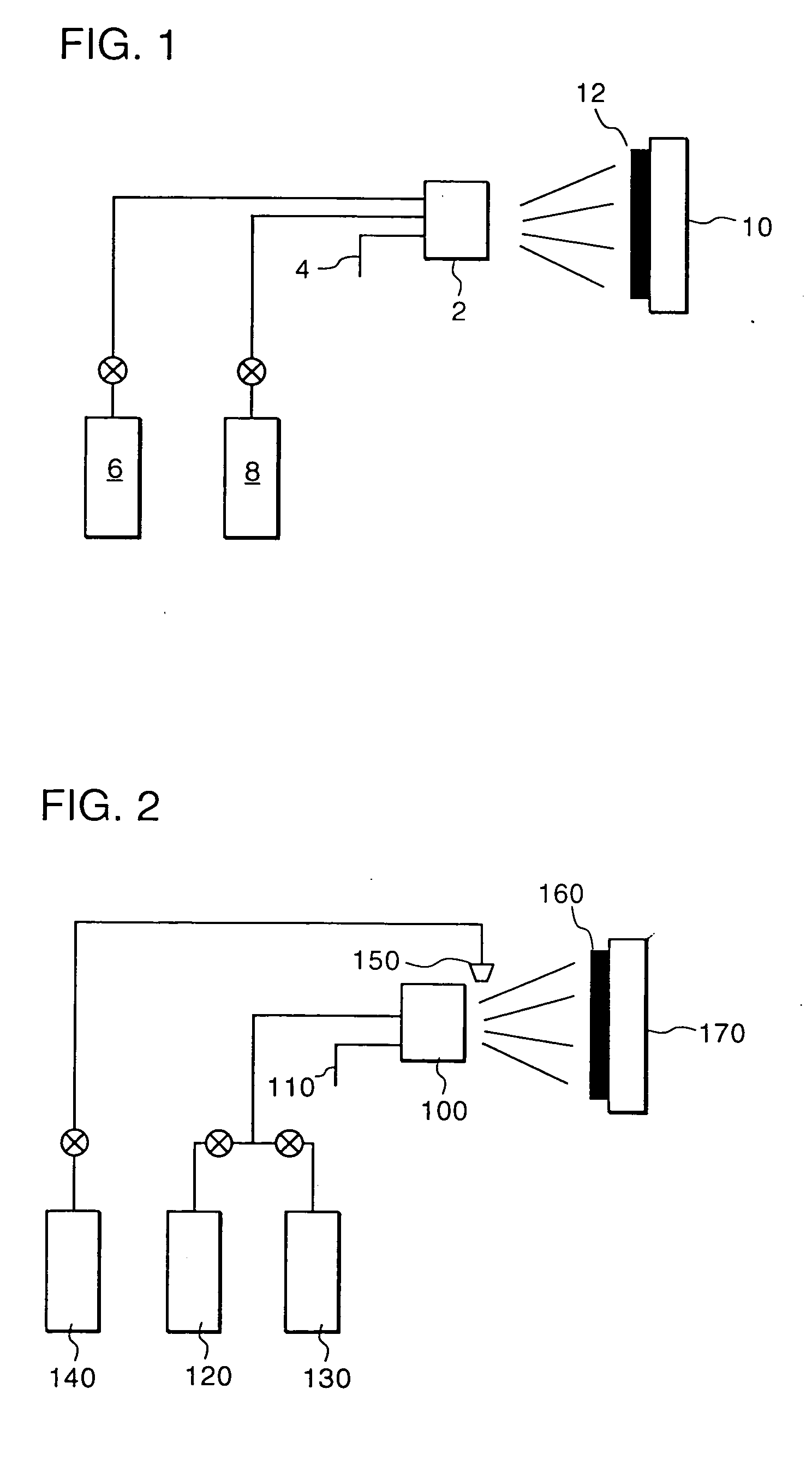

Hydrogen storage and integrated fuel cell assembly

InactiveUS20060051638A1Easy to replaceImprove heat transfer performanceFuel cell heat exchangeReactant parameters controlFuel cellsThermal insulation

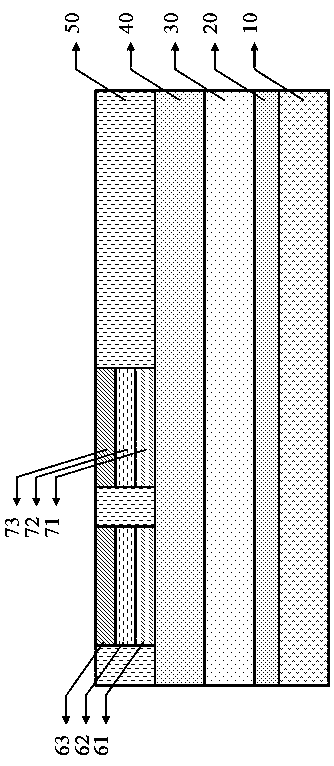

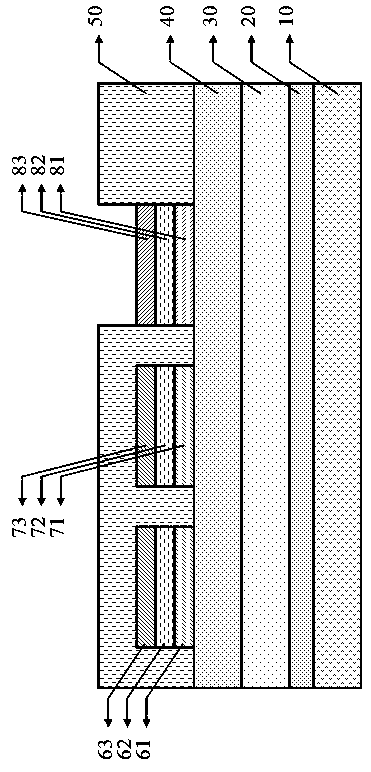

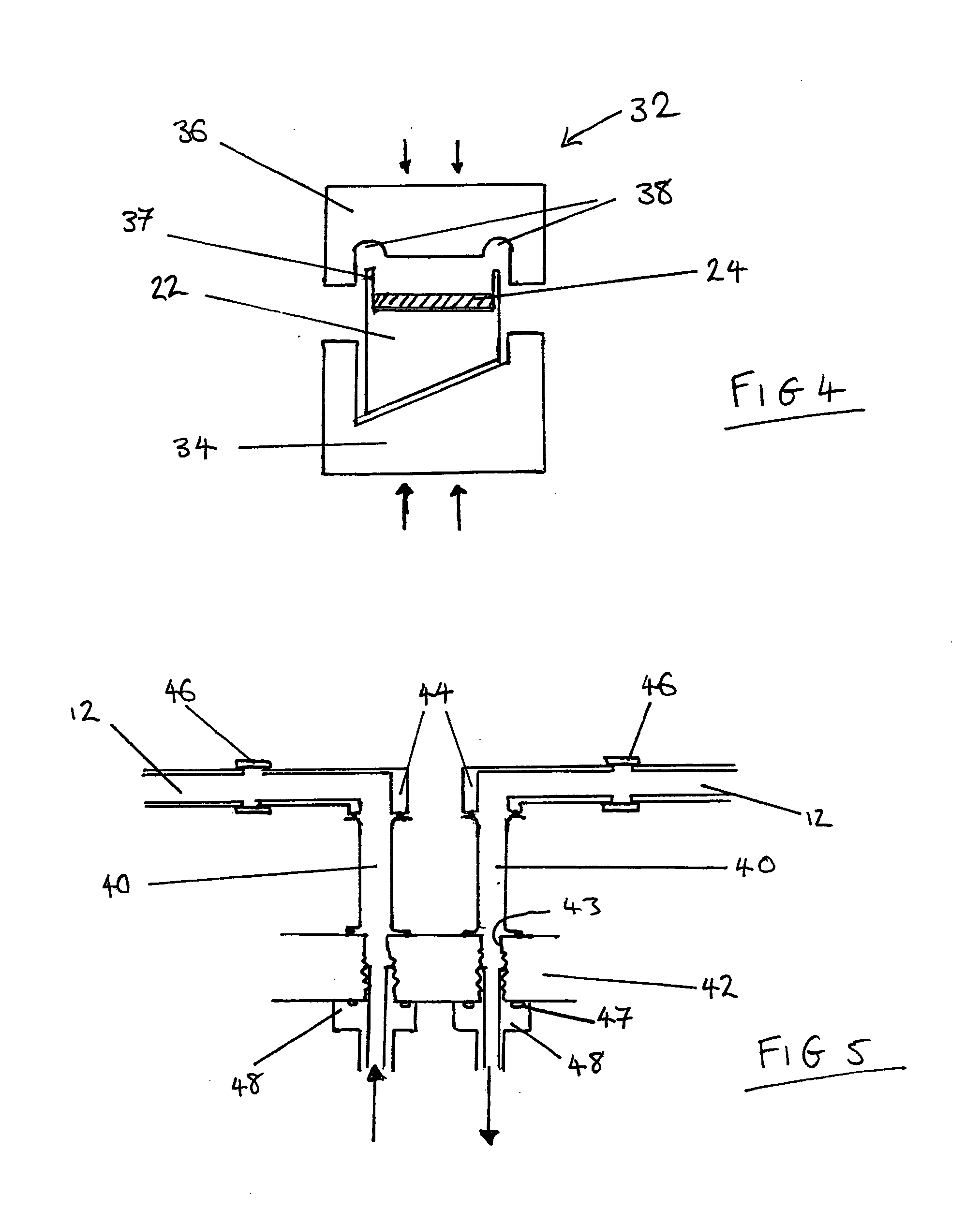

Hydrogen is stored in materials that absorb and desorb hydrogen with temperature dependent rates. A housing is provided that allows for the storage of one or more types of hydrogen-storage materials in close thermal proximity to a fuel cell stack. This arrangement, which includes alternating fuel cell stack and hydrogen-storage units, allows for close thermal matching of the hydrogen storage material and the fuel cell stack. Also, the present invention allows for tailoring of the hydrogen delivery by mixing different materials in one unit. Thermal insulation alternatively allows for a highly efficient unit. Individual power modules including one fuel cell stack surrounded by a pair of hydrogen-storage units allows for distribution of power throughout a vehicle or other electric power consuming devices.

Owner:GROSS KARL J

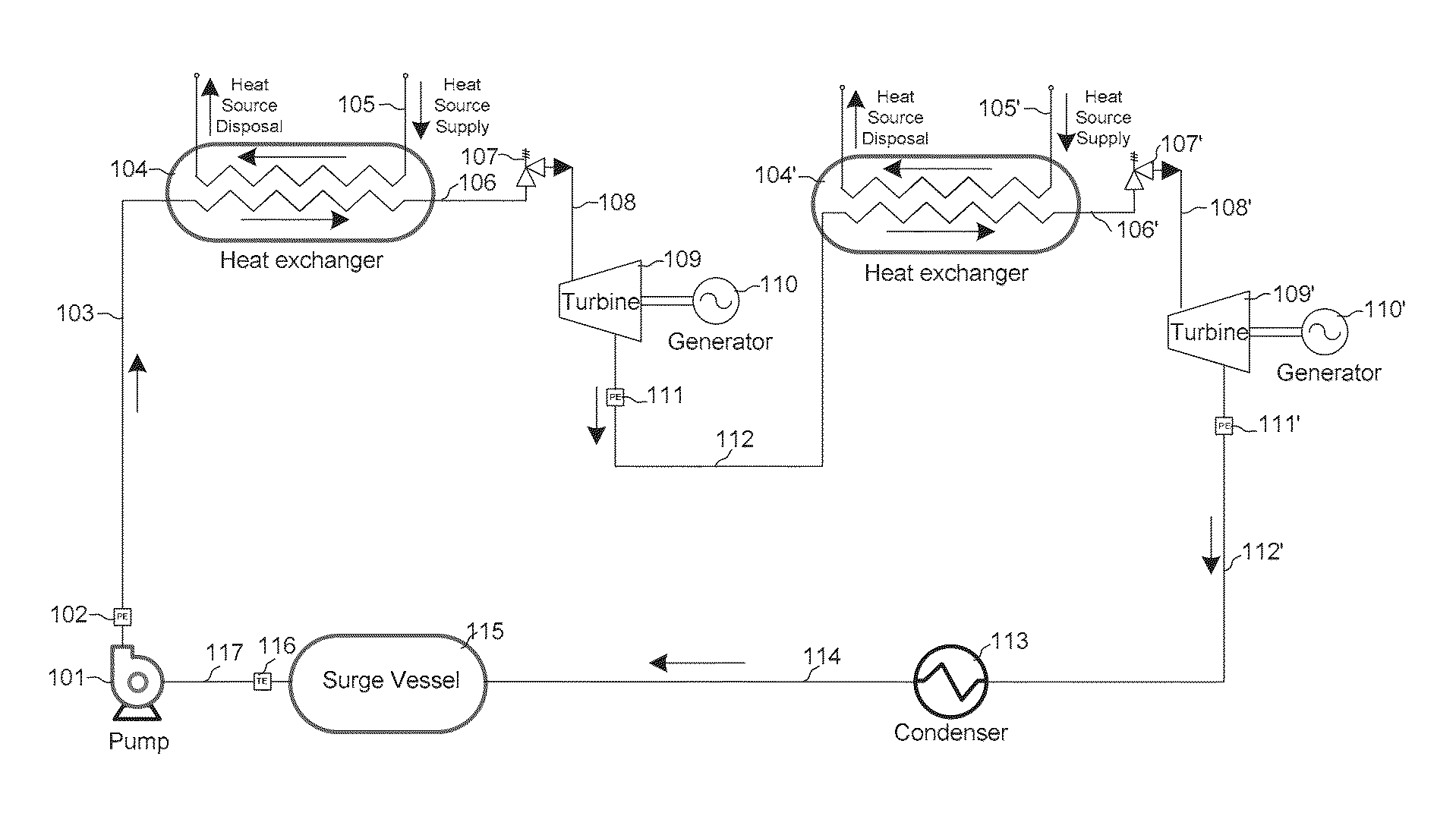

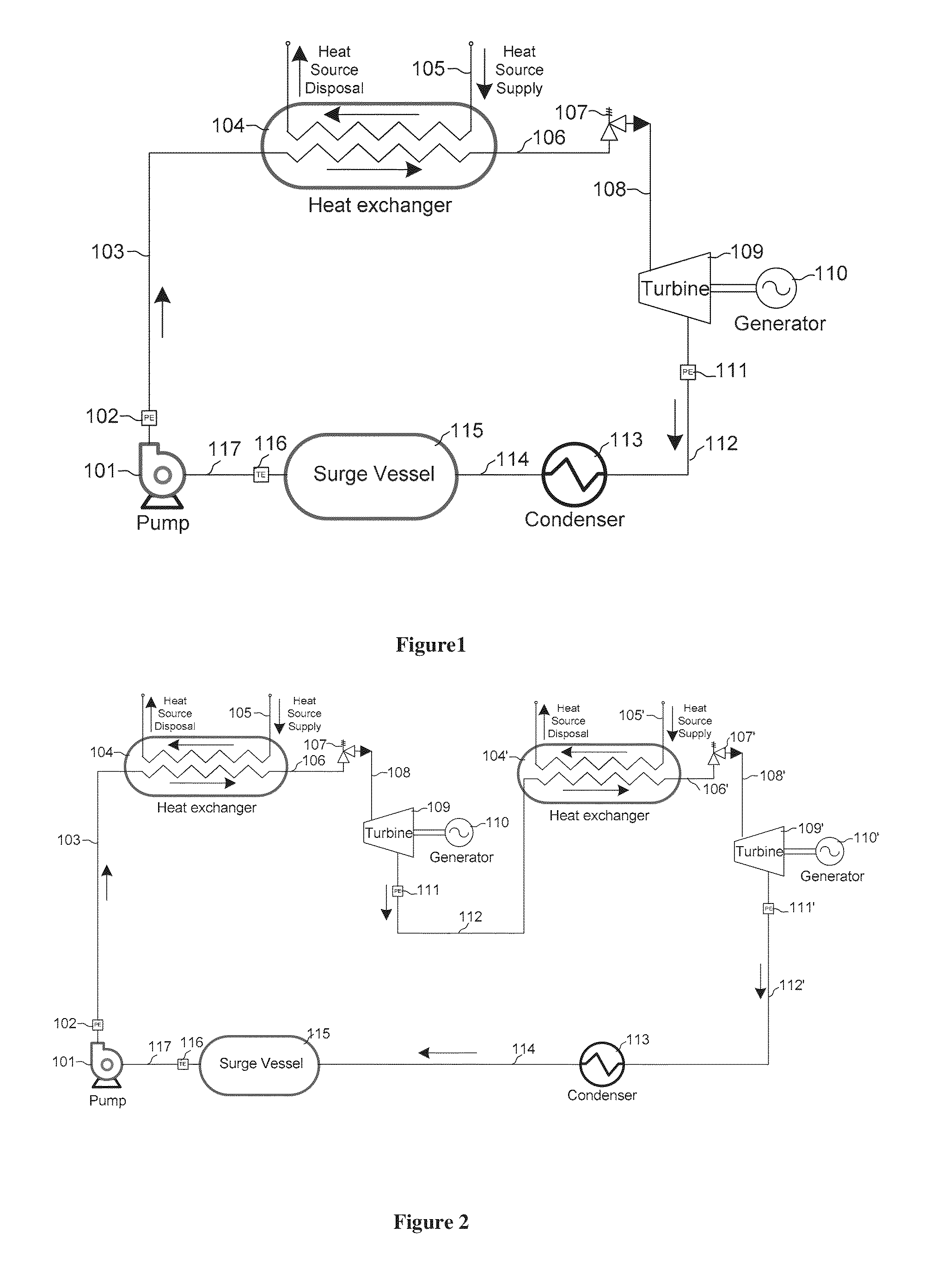

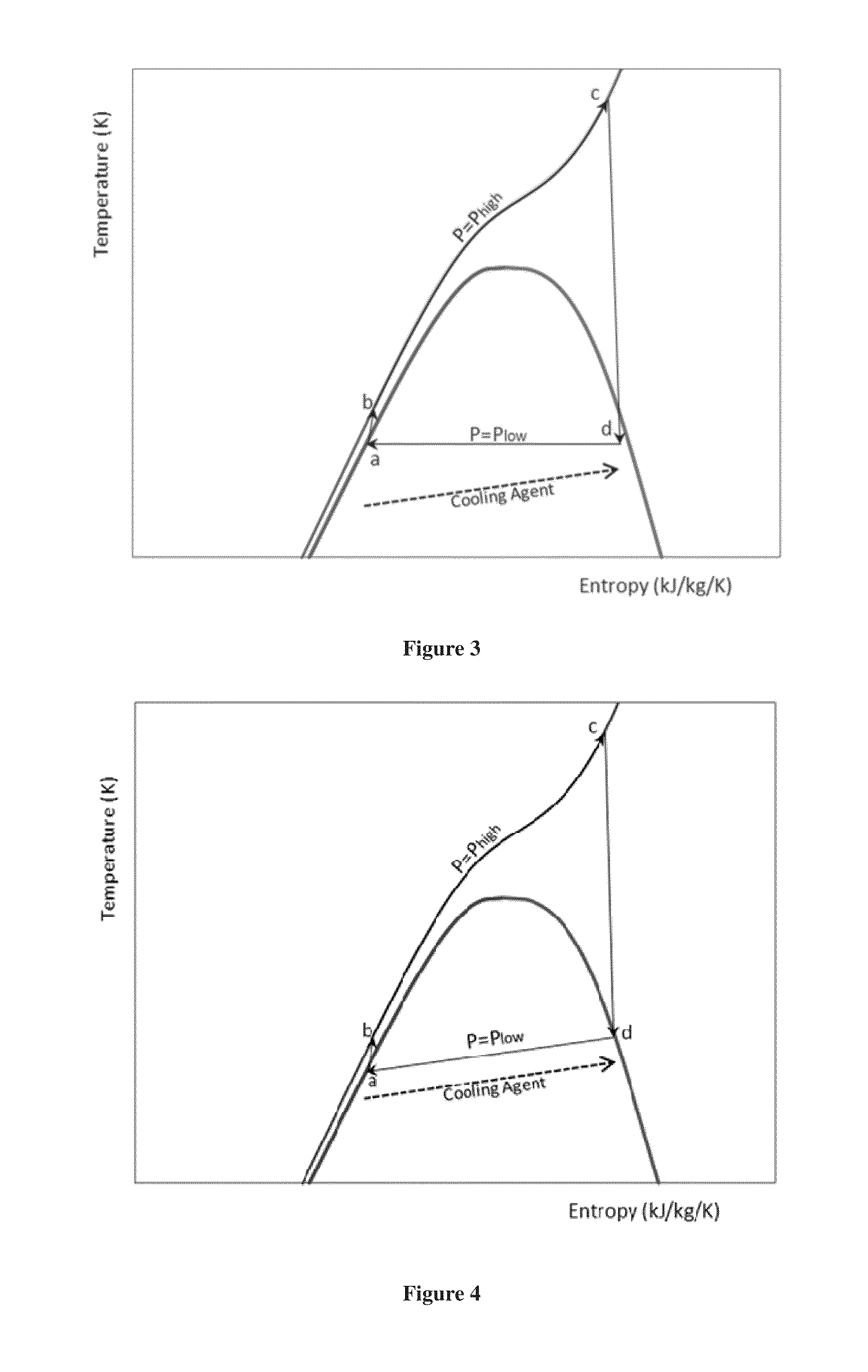

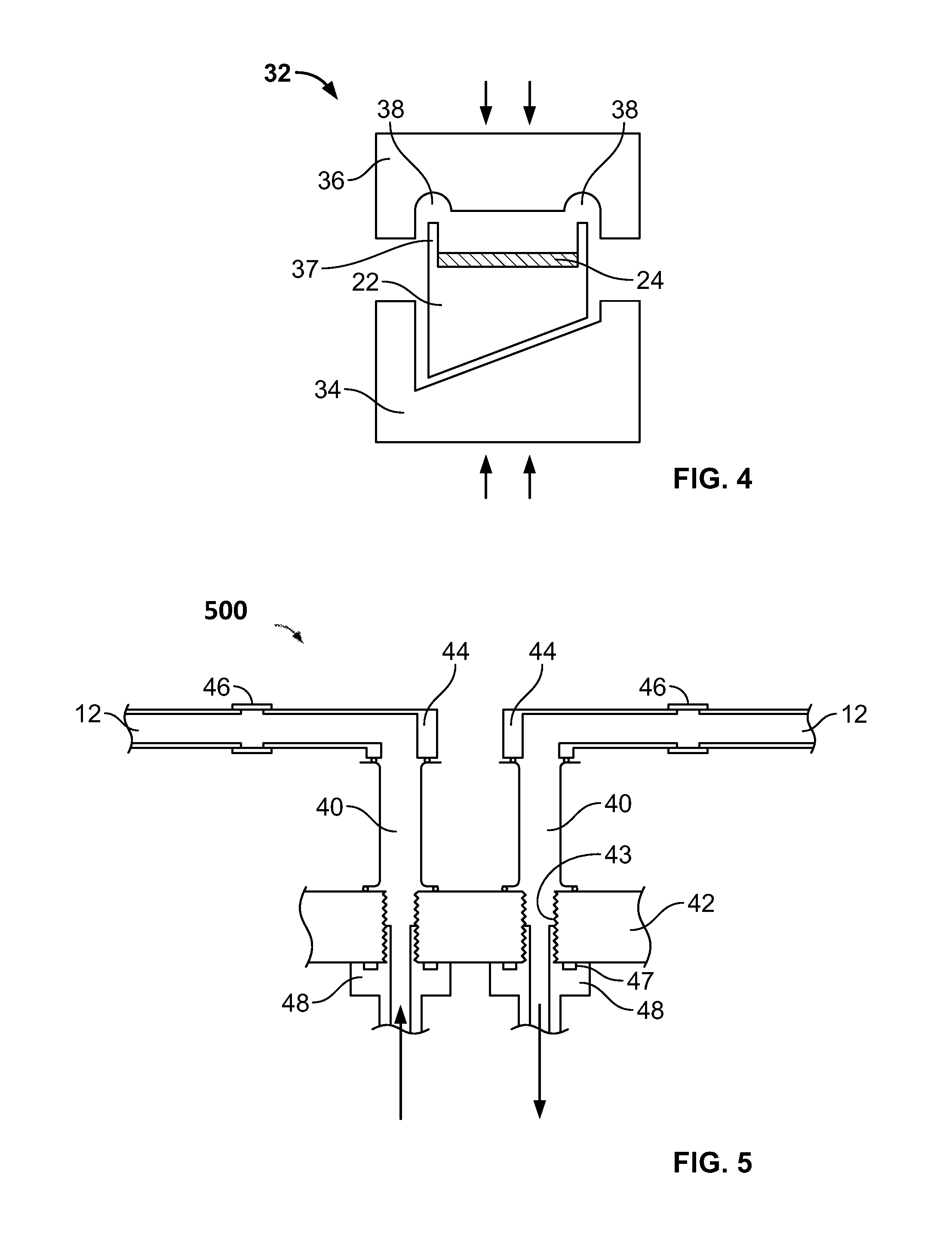

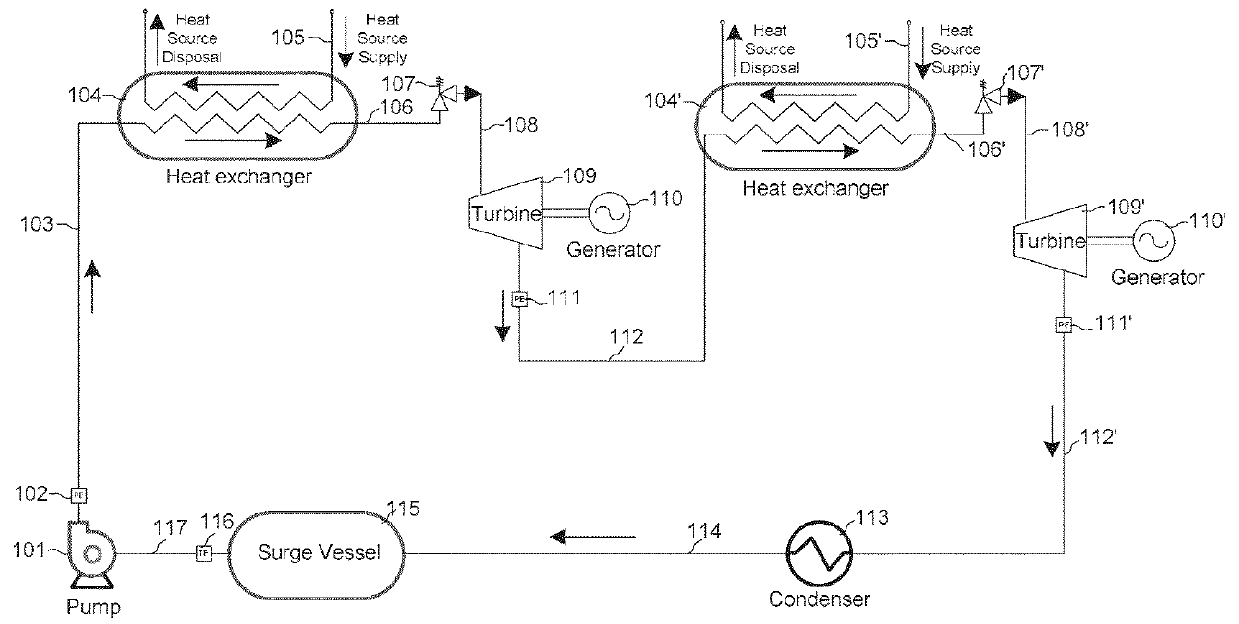

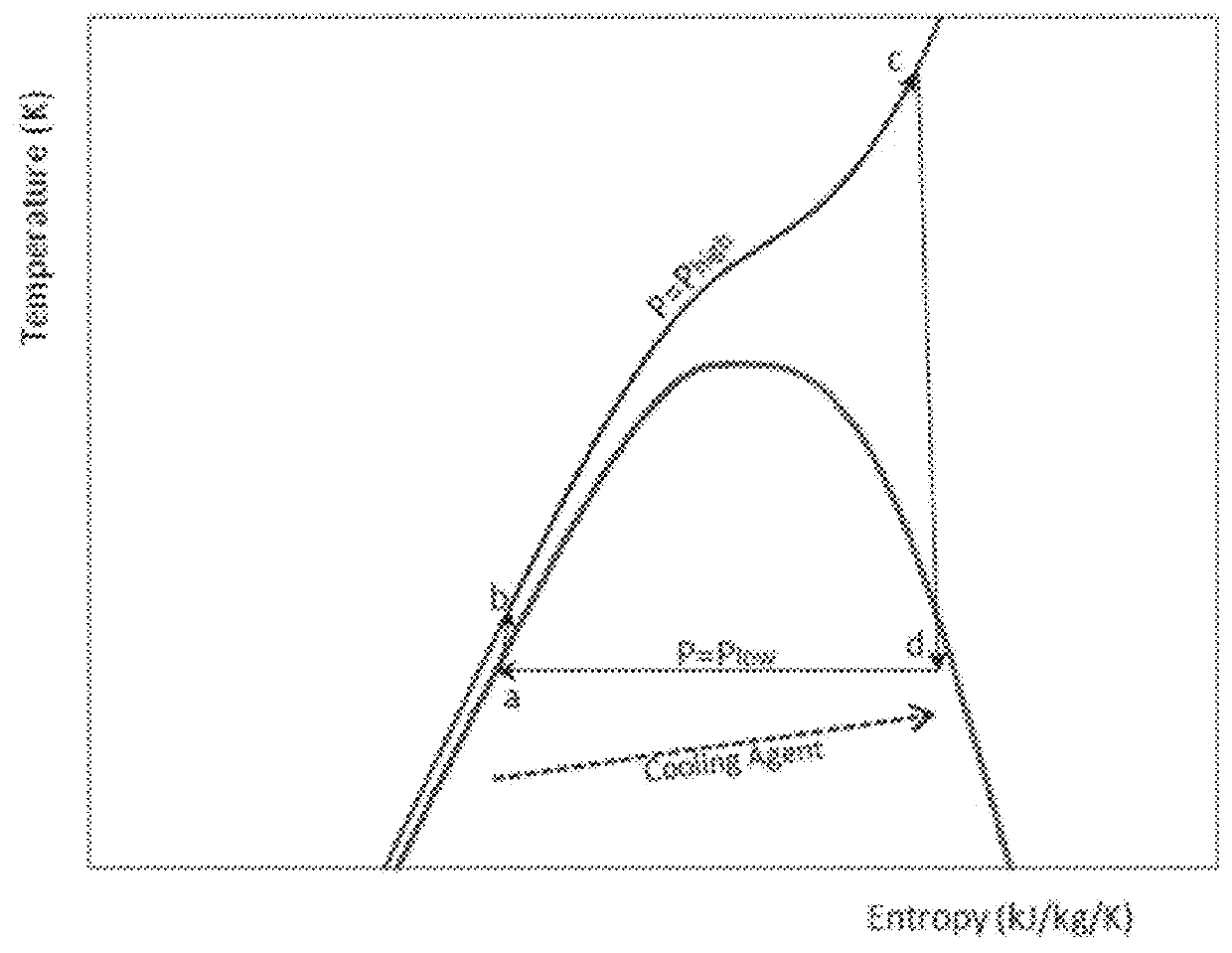

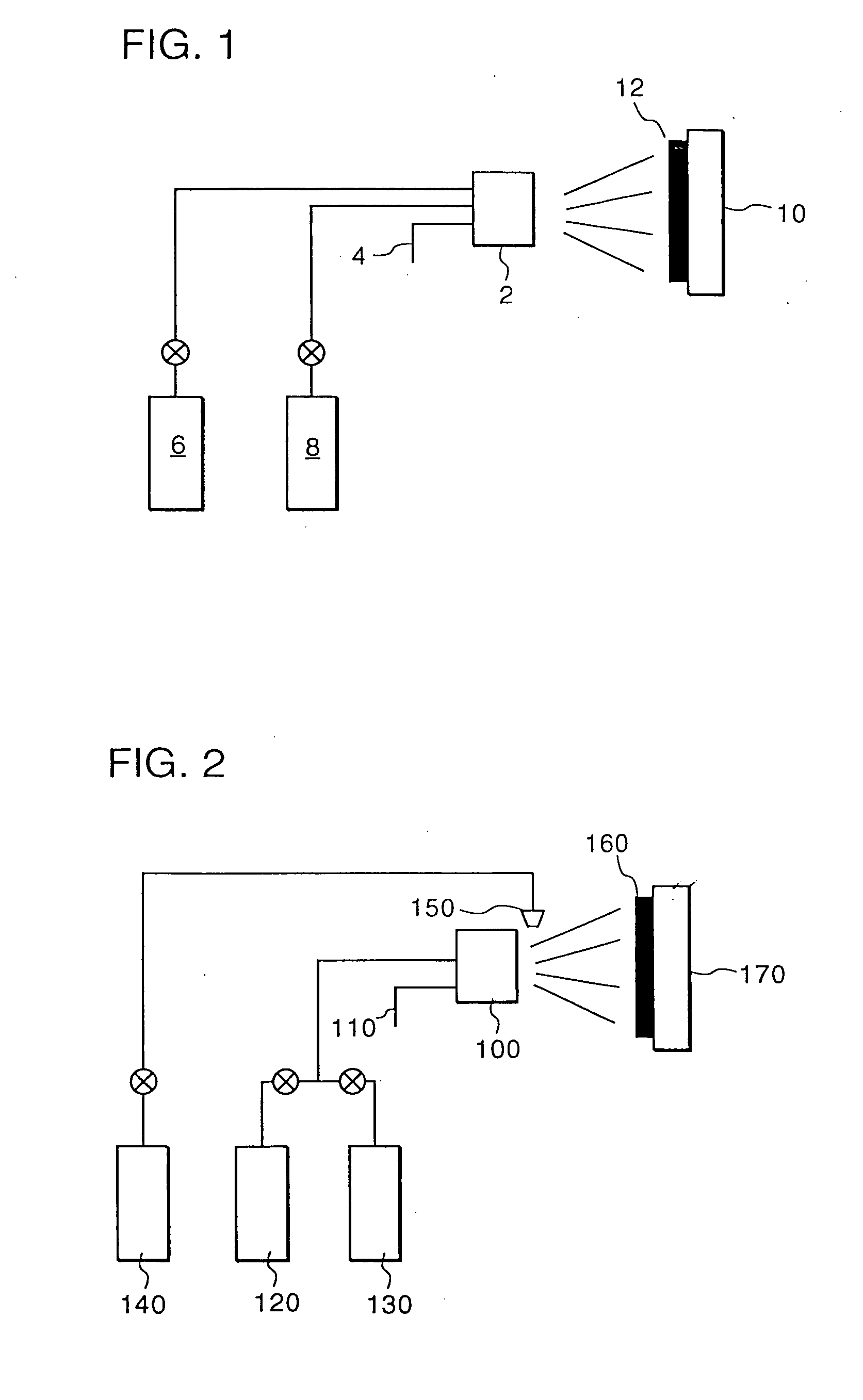

Method and system for generating power from low- and mid- temperature heat sources

ActiveUS20130213040A1Minimal human interventionValid conversionReciprocating combination enginesCombination enginesWorking fluidZeotropic mixture

A method and system for generating power from low- and mid-temperature heat sources using a zeotropic mixture as a working fluid. The zeotropic mixture working fluid is compressed to pressures above critical and heated to a supercritical state. The zeotropic mixture working fluid is then expanded to extract power. The zeotropic mixture working fluid is then condensed, subcooled, and collected for recirculation and recompression.

Owner:UNIV OF SOUTH FLORIDA

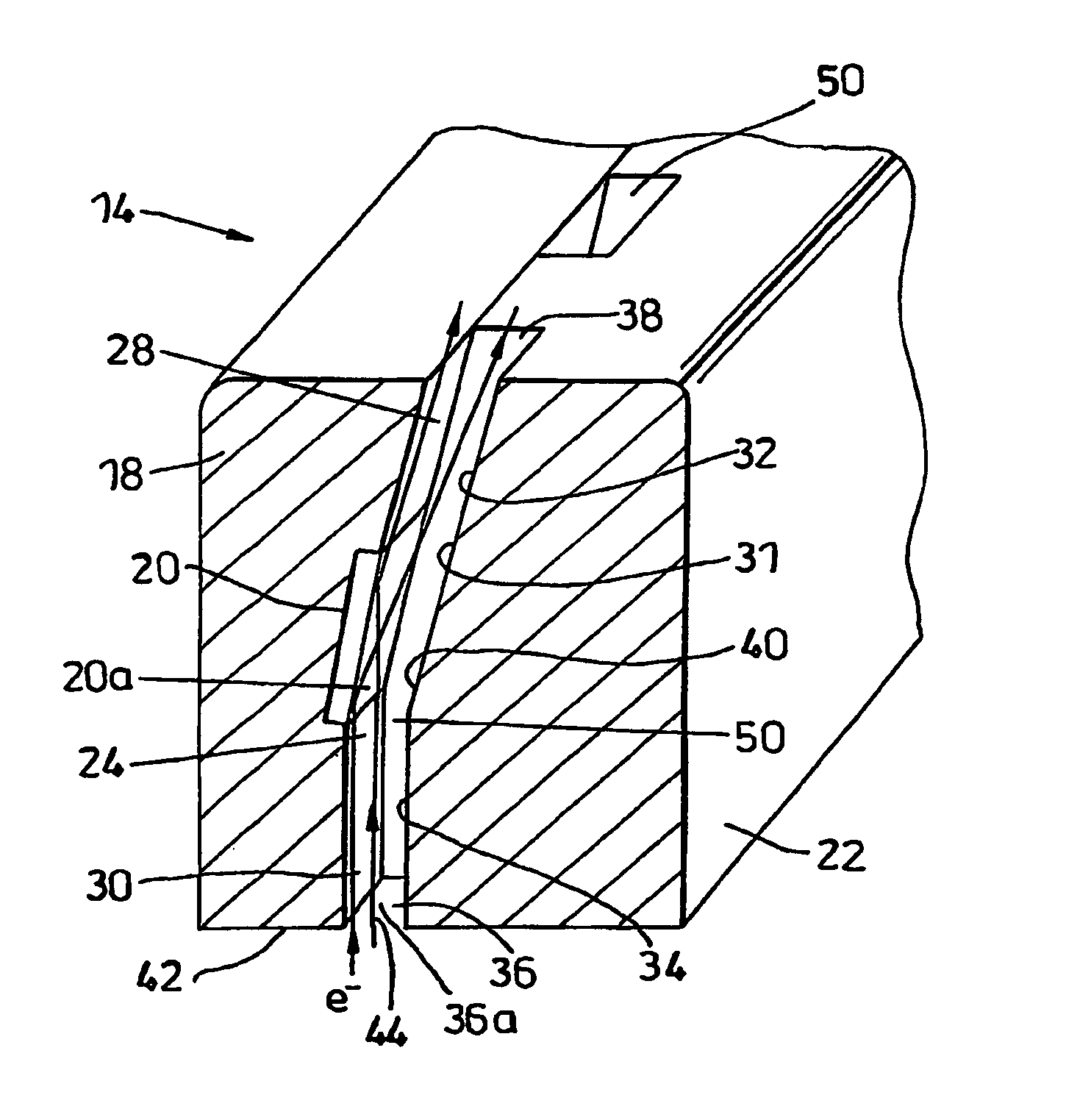

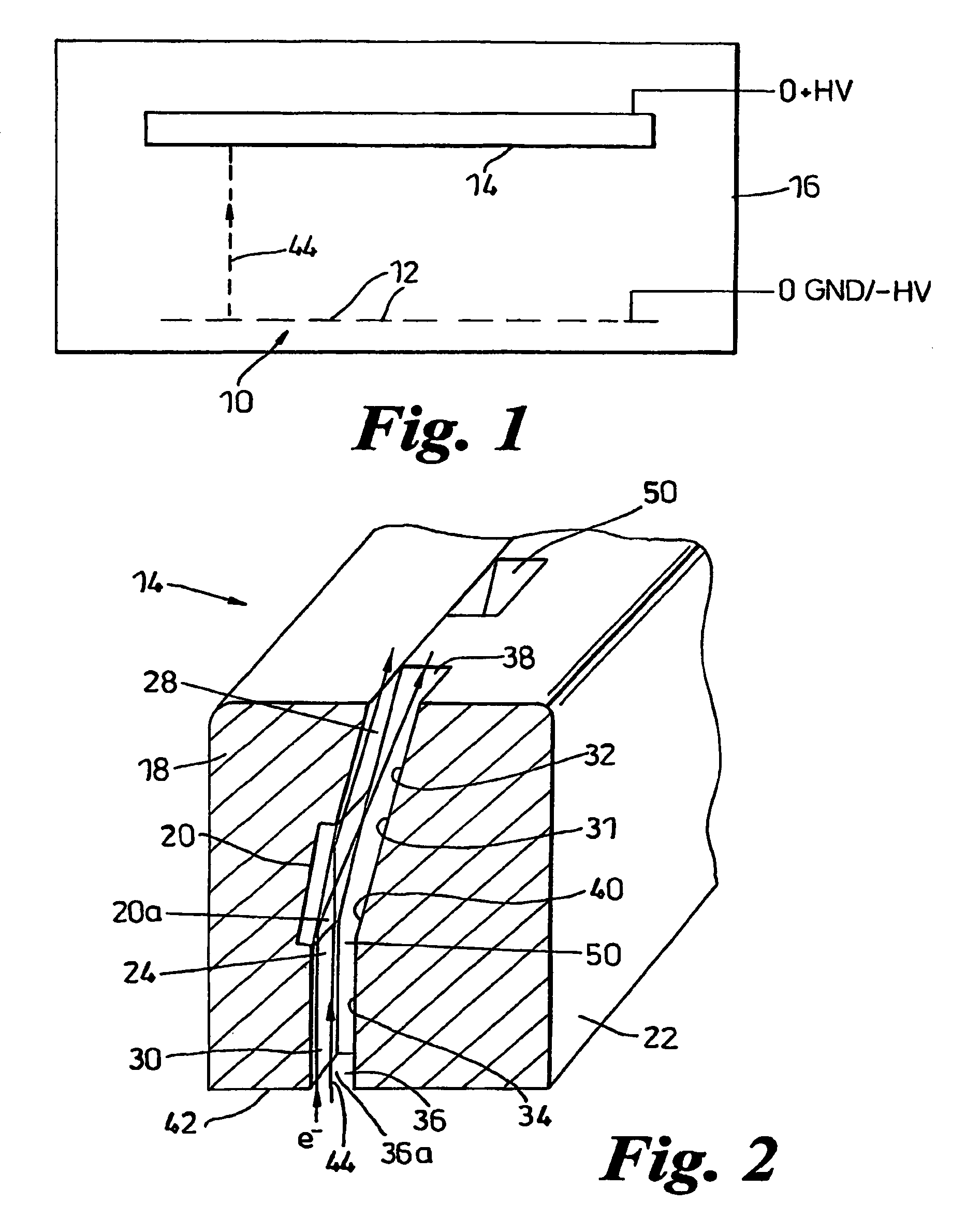

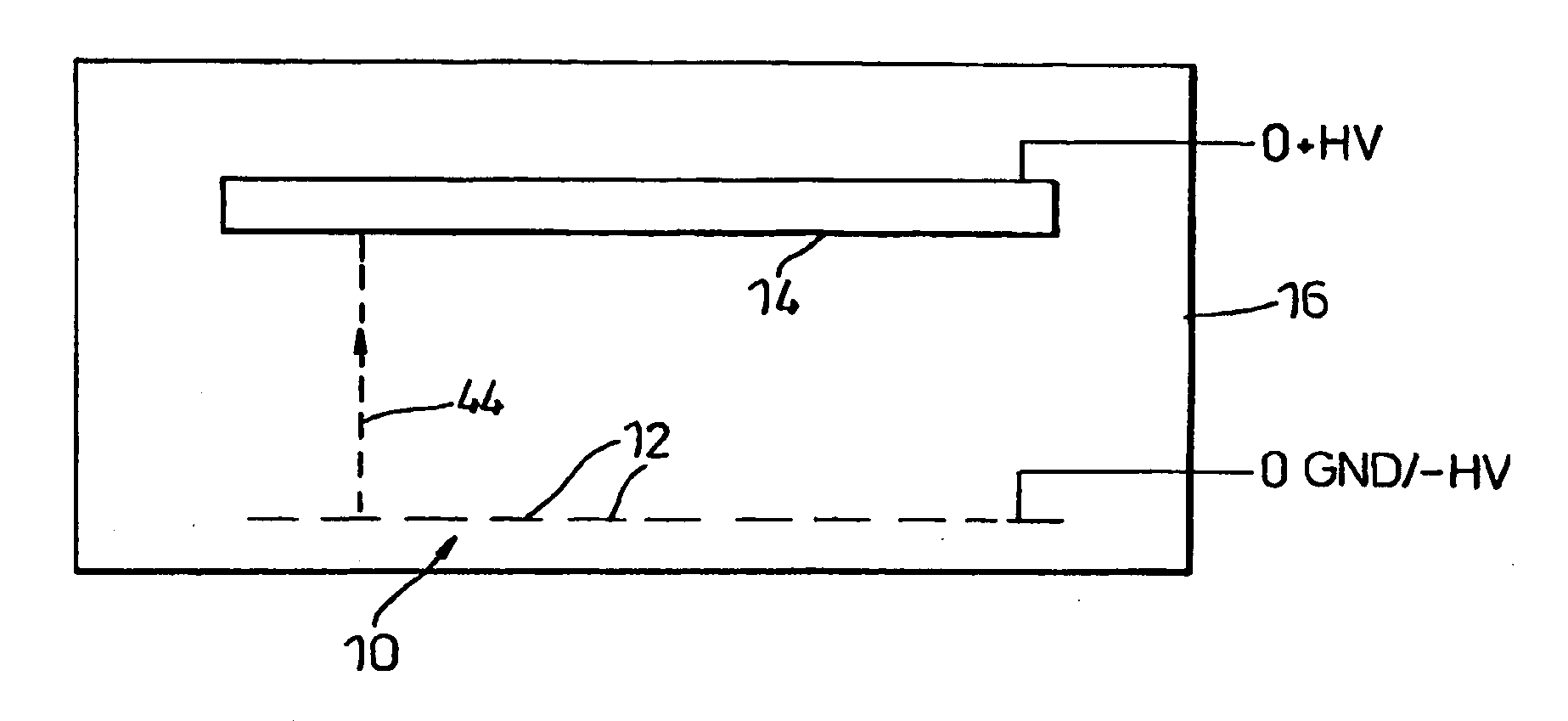

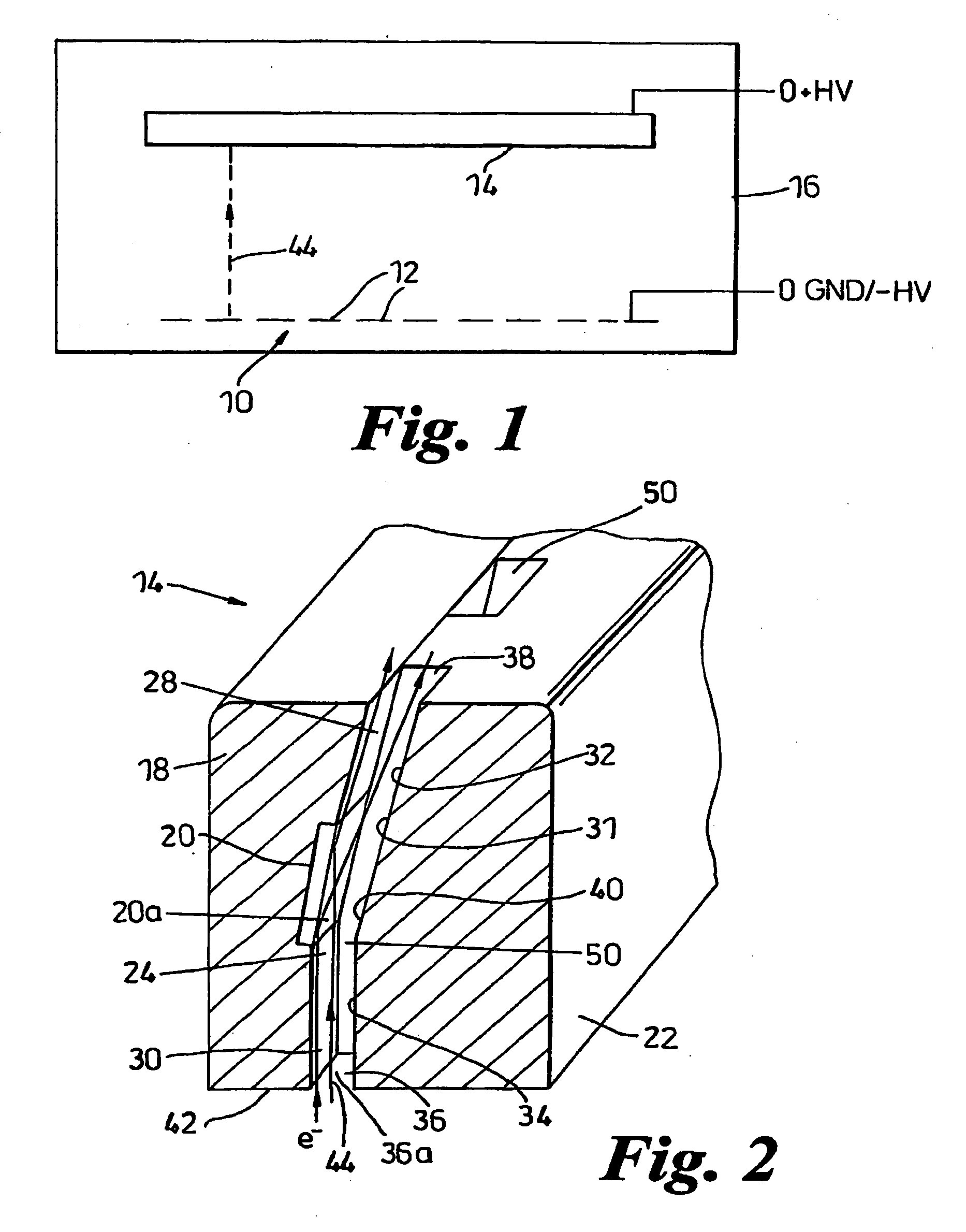

X-ray sources

ActiveUS8094784B2Easy to manufactureThermally matched wellX-ray tube anode coolingX-ray tube electrodesElectron sourceX-ray

Owner:RAPISCAN SYST INC (US)

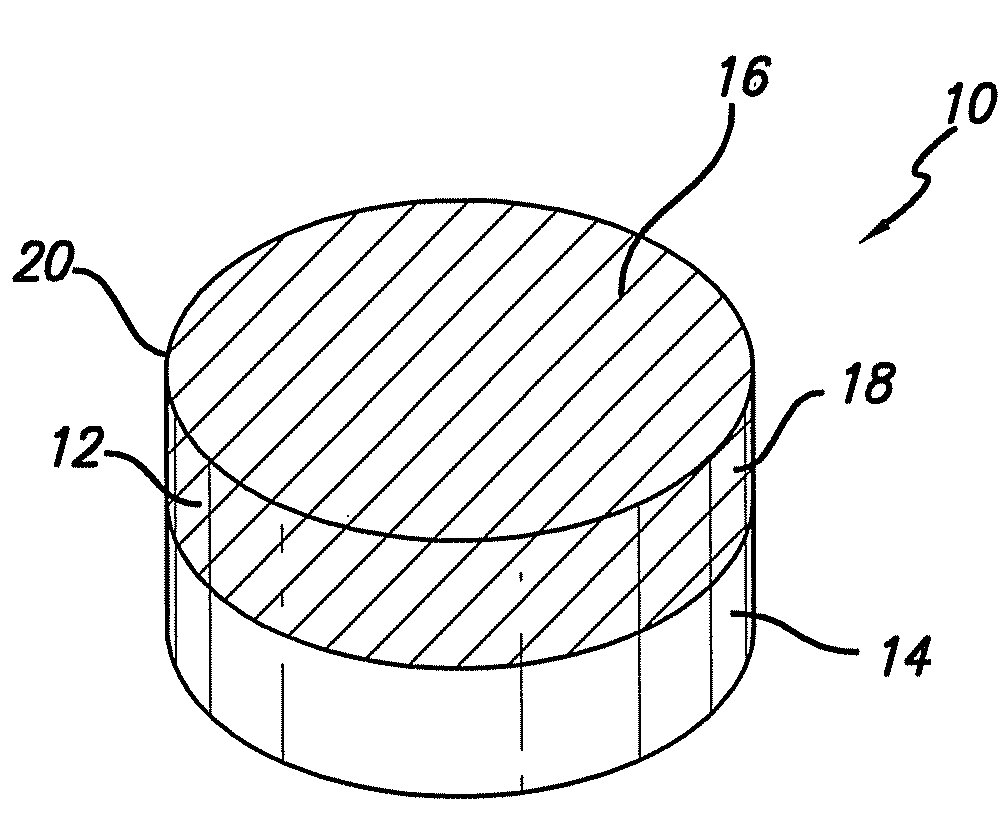

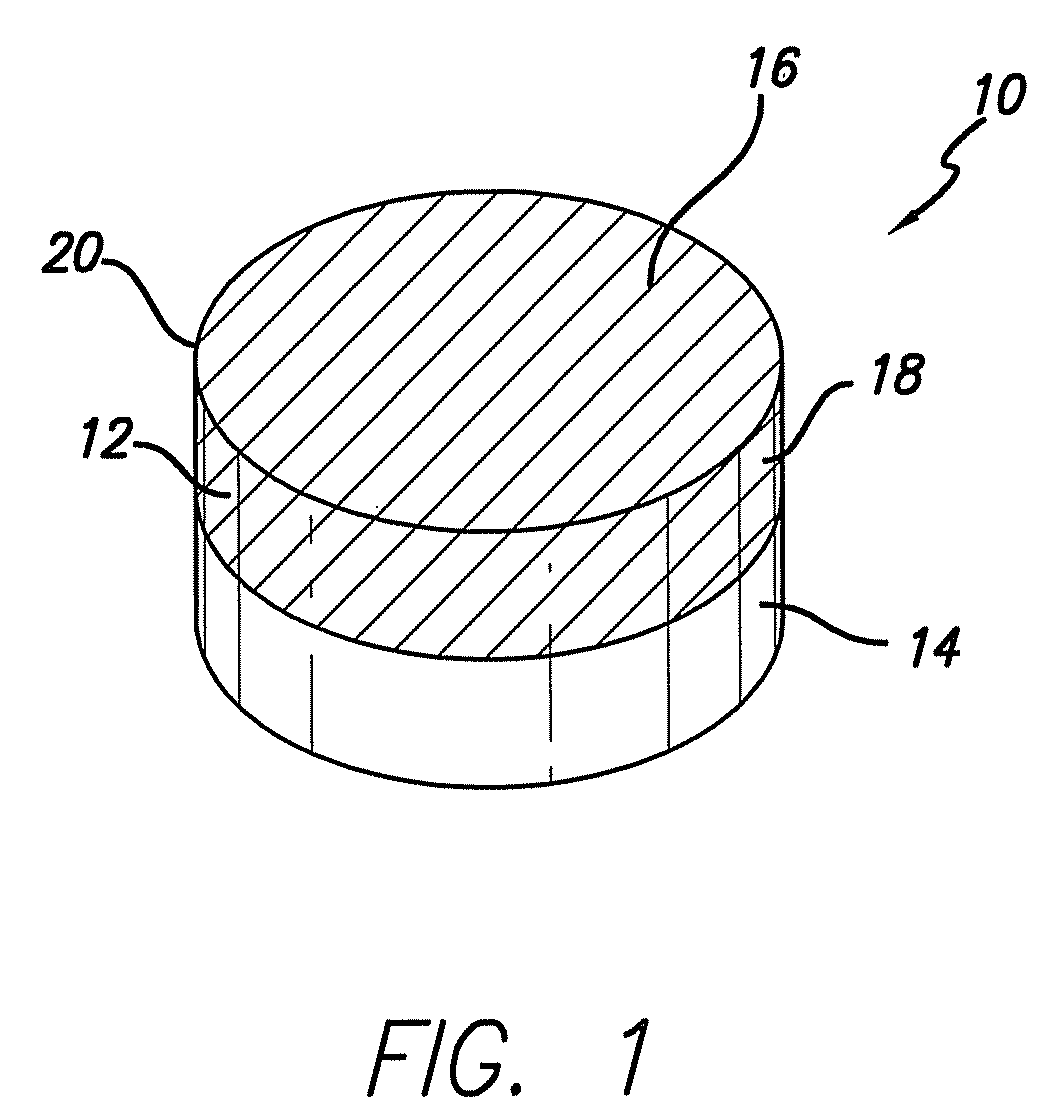

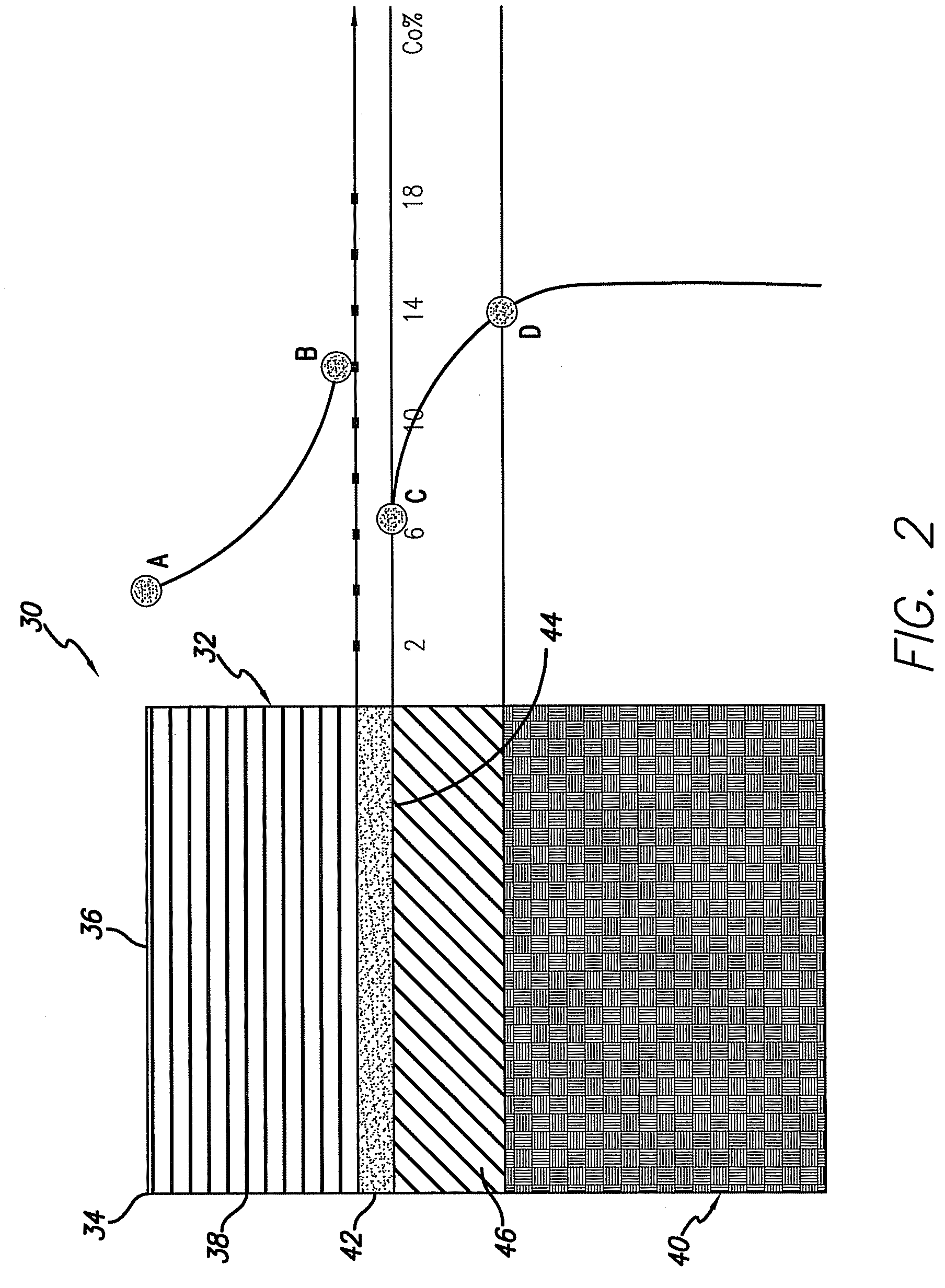

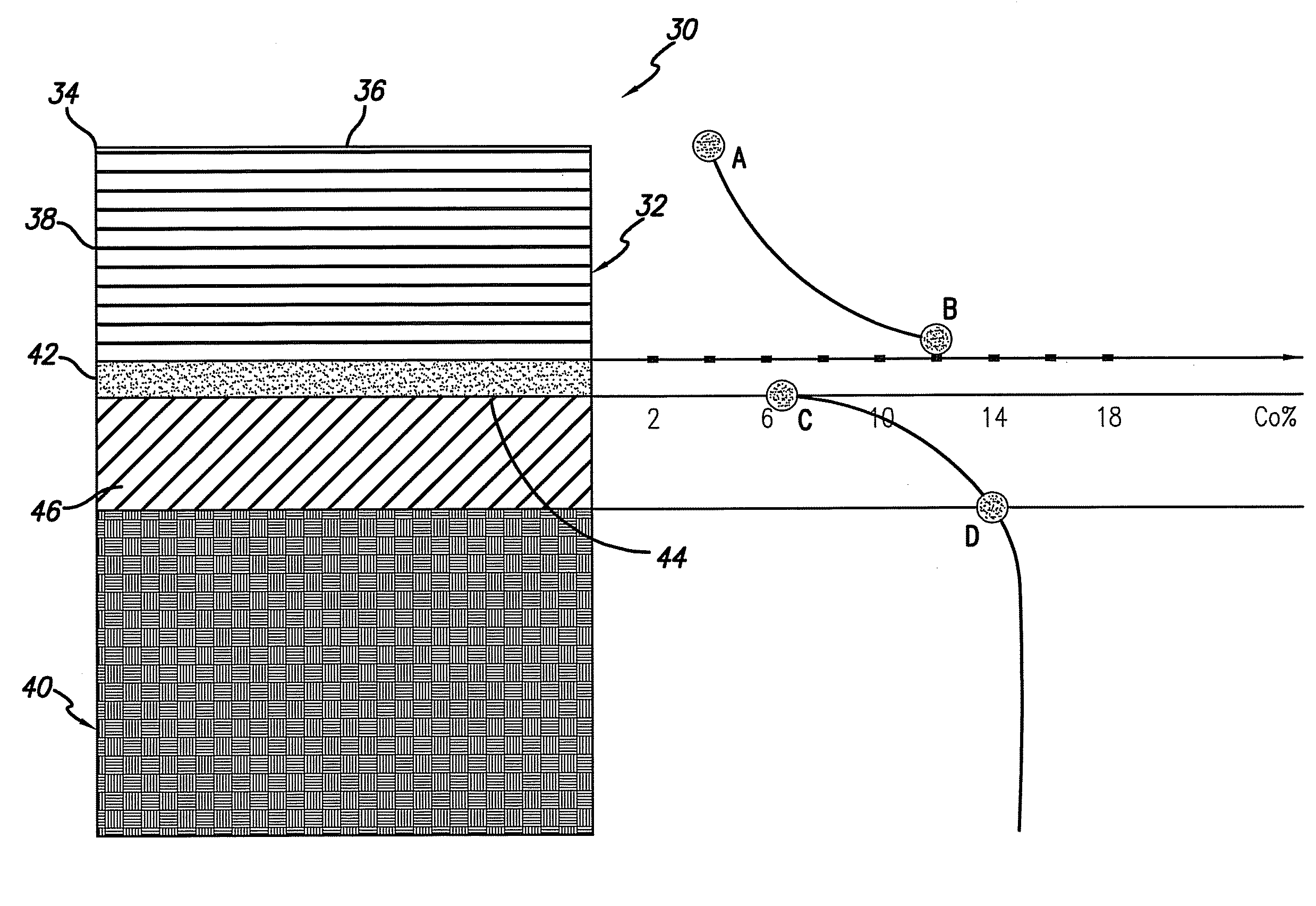

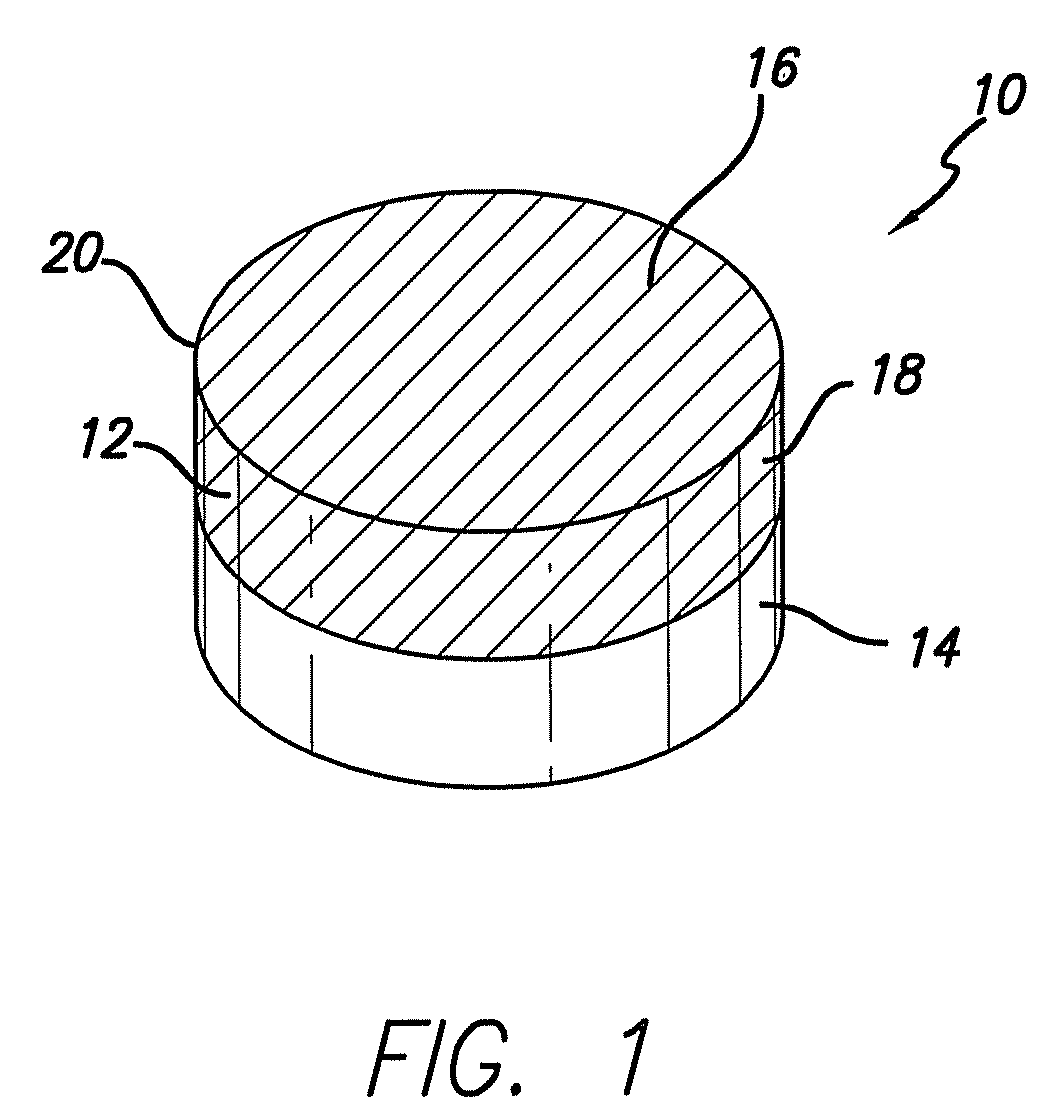

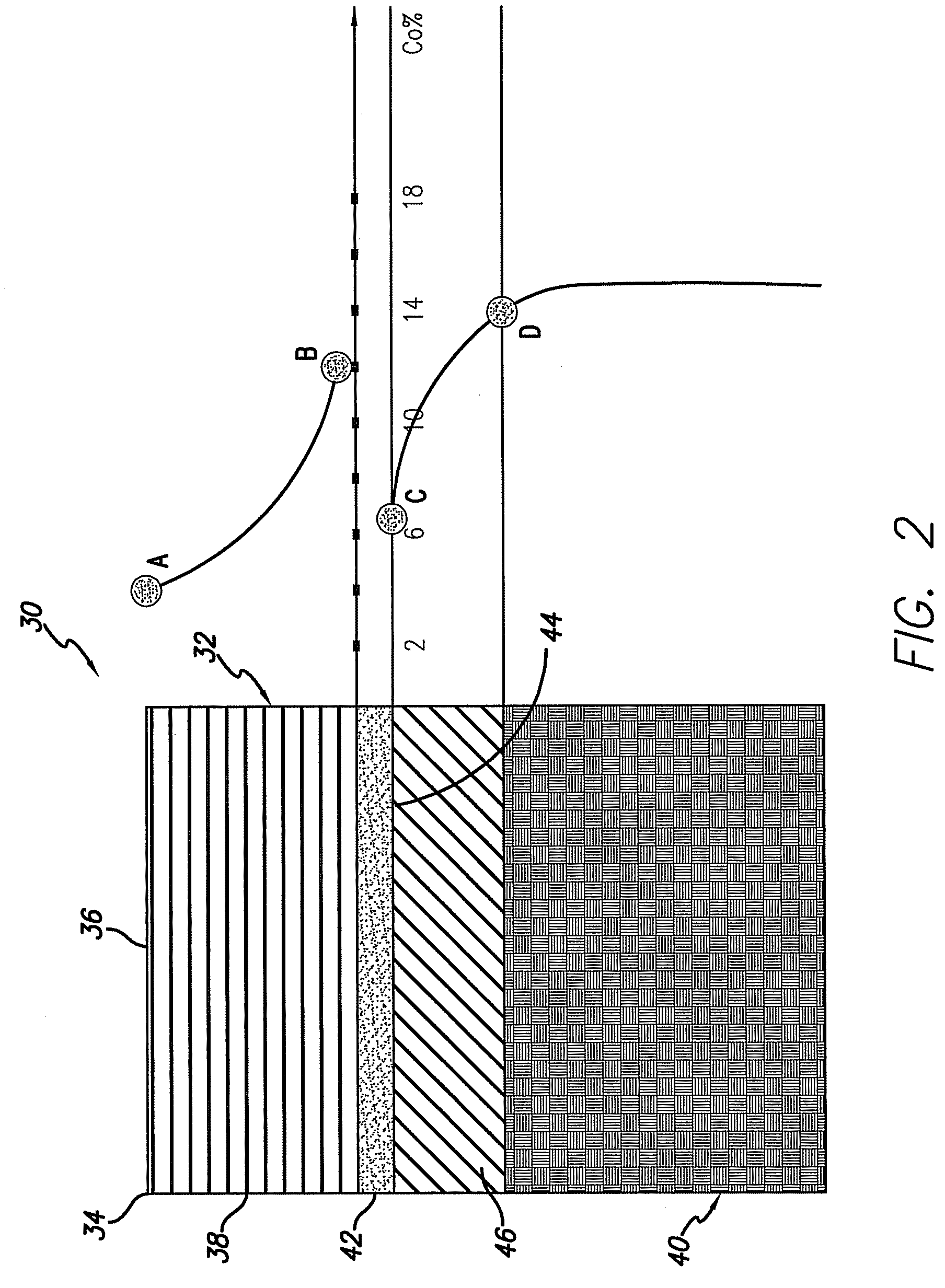

Polycrystalline diamond construction with controlled gradient metal content

ActiveUS20090152017A1Hardness resistanceResistance to stabilityDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Polycrystalline diamond constructions comprises a diamond body attached to a metallic substrate, and having an engineered metal content. The body comprises bonded together diamond crystals with a metal material disposed interstitially between the crystals. A body working surface has metal content of 2 to 8 percent that increases moving away therefrom. A transition region between the body and substrate includes metal rich and metal depleted regions having controlled metal content that provides improved thermal expansion matching / reduced residual stress. A point in the body adjacent the metal rich zone has a metal content that is at least about 3 percent by weight greater than that at a body / substrate interface. The metal depleted zone metal content increases gradually moving from the body, and has a thickness greater than 1.25 mm. Metal depleted zone metal content changes less about 4 percent per millimeter moving along the substrate.

Owner:SMITH INT INC

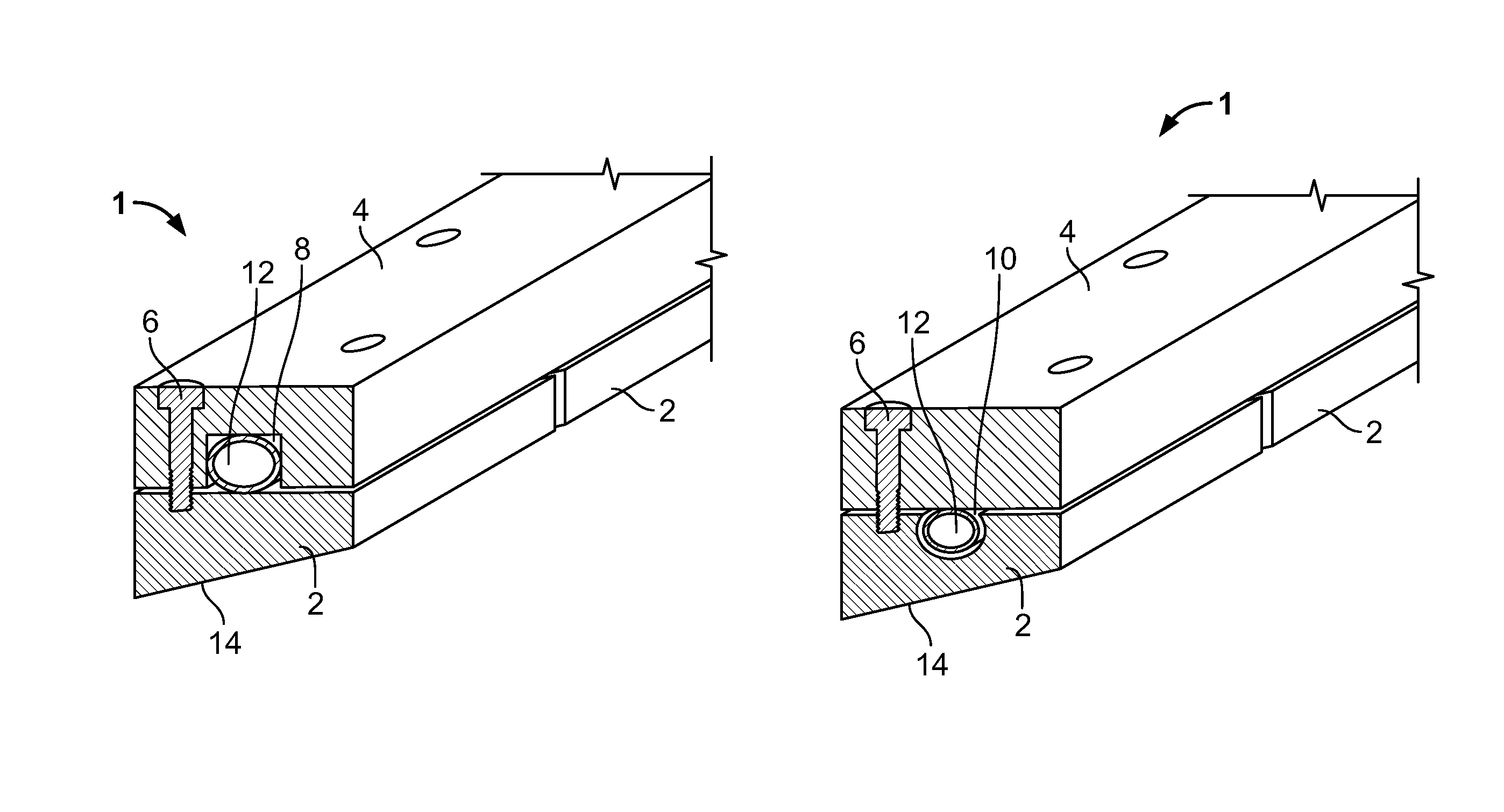

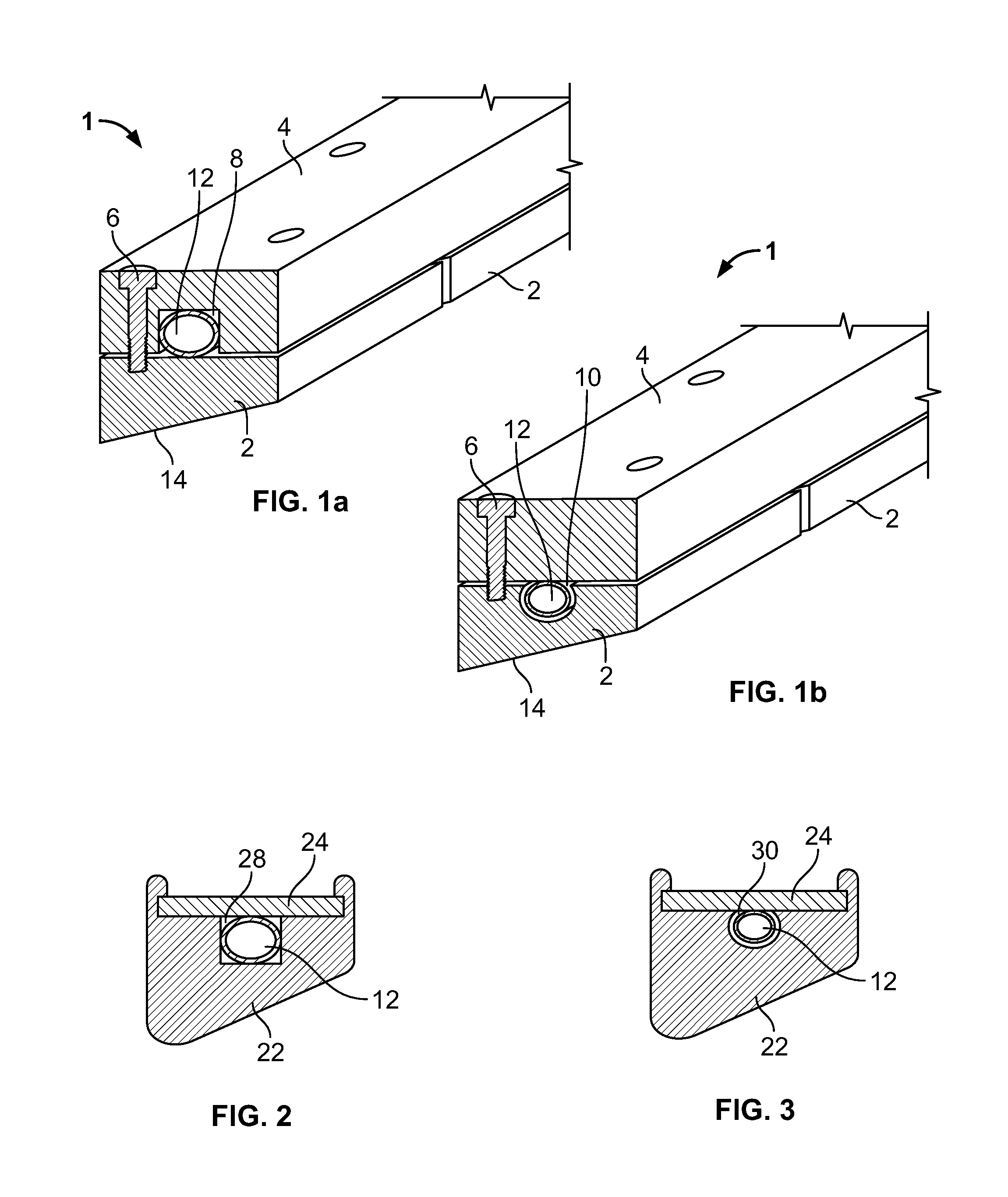

X-ray tube anode comprising a coolant tube

ActiveUS9263225B2Thermally matched wellImprove thermal conductivityX-ray tube anode coolingX-ray tube electrodesX-rayCoolant

Owner:RAPISCAN SYST INC (US)

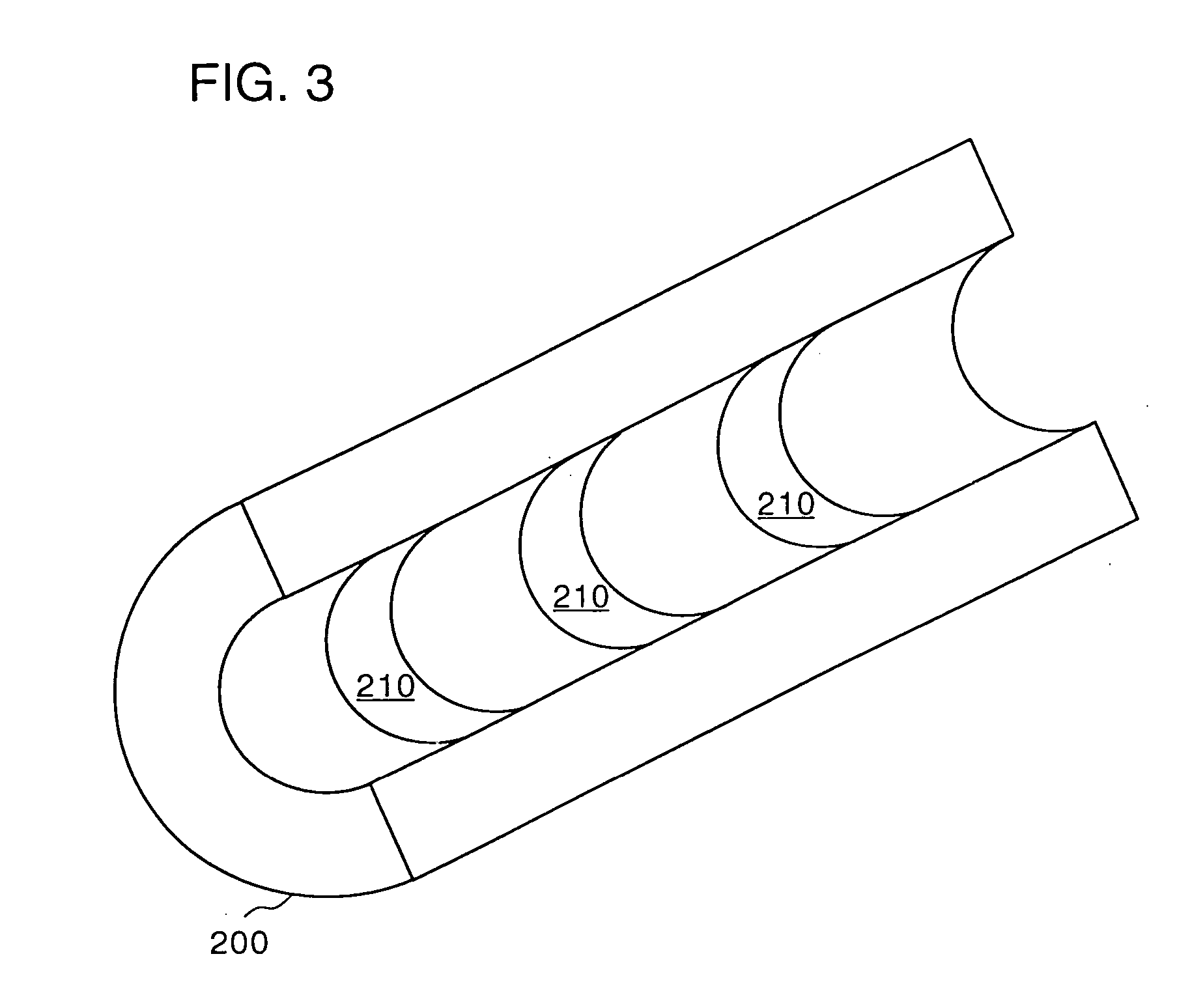

Method and system for generating power from low- and mid- temperature heat sources using supercritical rankine cycles with zeotropic mixtures

ActiveUS9376937B2Thermally matched wellSimple configurationReciprocating combination enginesCombination enginesWorking fluidZeotropic mixture

A method and system for generating power from low- and mid-temperature heat sources using a zeotropic mixture as a working fluid. The zeotropic mixture working fluid is compressed to pressures above critical and heated to a supercritical state. The zeotropic mixture working fluid is then expanded to extract power. The zeotropic mixture working fluid is then condensed, subcooled, and collected for recirculation and recompression.

Owner:UNIV OF SOUTH FLORIDA

X-Ray Sources

ActiveUS20100008471A1Easy to manufactureThermally matched wellX-ray tube anode coolingX-ray tube electrodesElectron sourceNuclear engineering

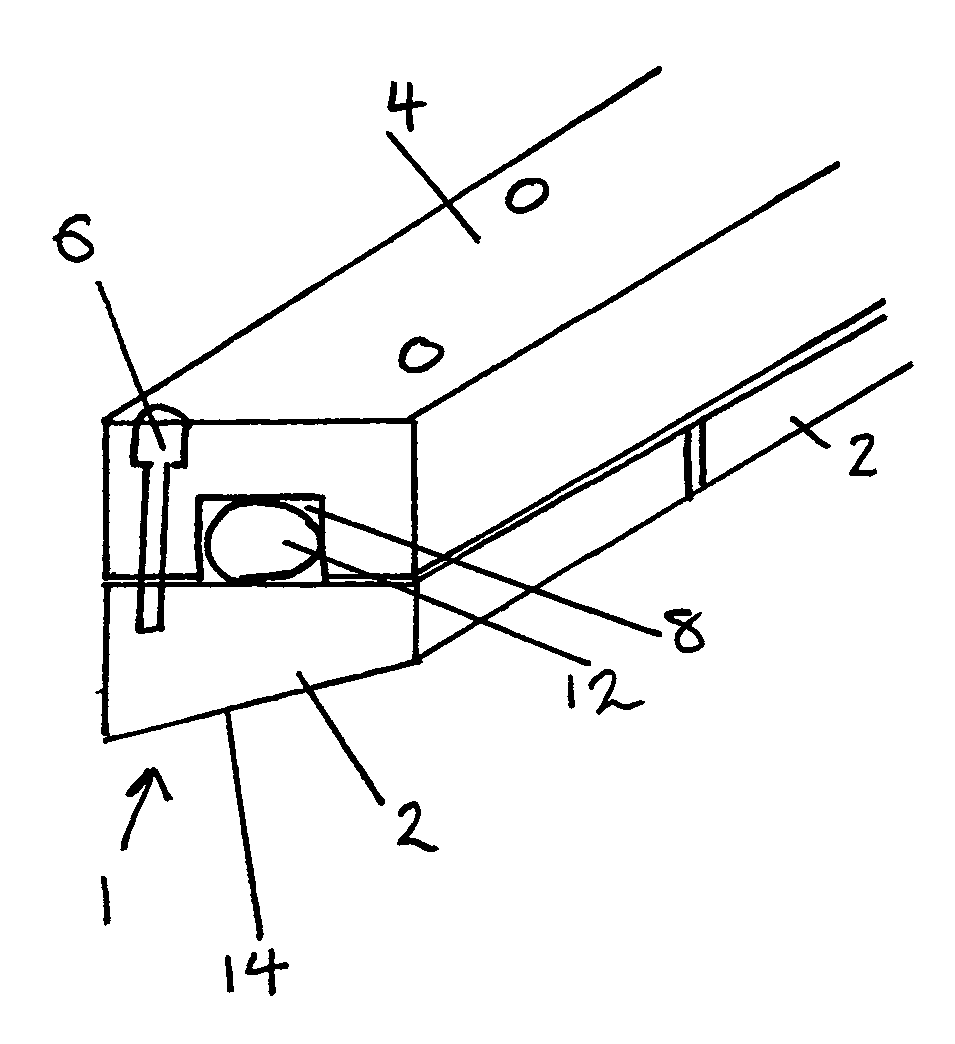

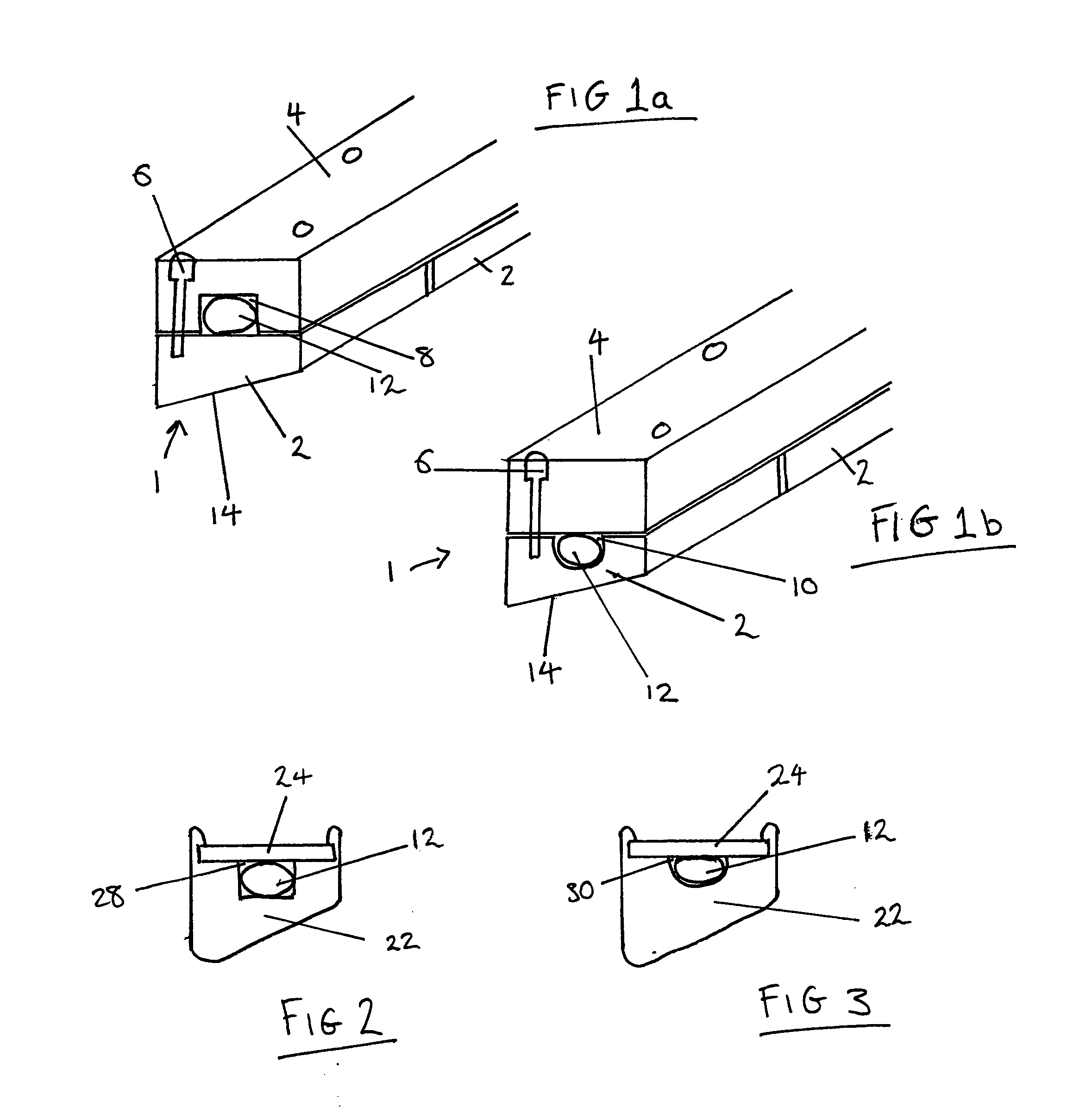

The present invention is directed to an anode for an X-ray tube. The X-ray tube has an electron aperture through which electrons emitted from an electron source travel subject to substantially no electrical field and a target in a non-parallel relationship to the electron aperture and arranged to produce X-rays when electrons are incident upon a first side of the target, wherein the target further comprises a cooling channel located on a second side of the target. The cooling channel comprises a conduit having coolant contained therein. The coolant is at least one of water, oil, or refrigerant.

Owner:RAPISCAN SYST INC (US)

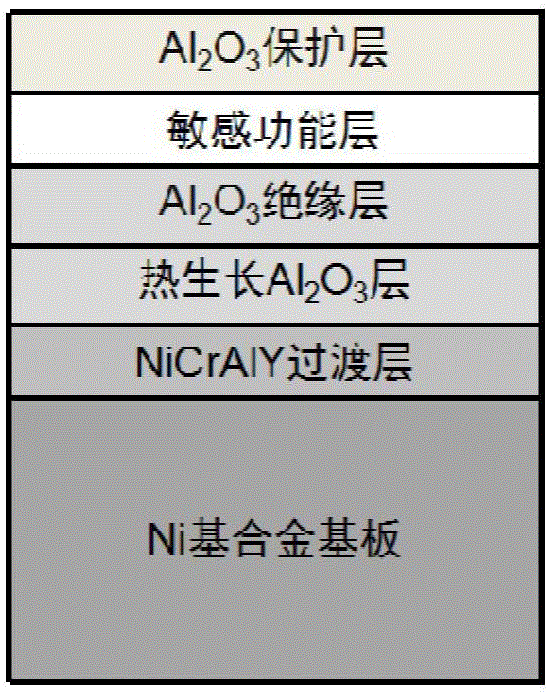

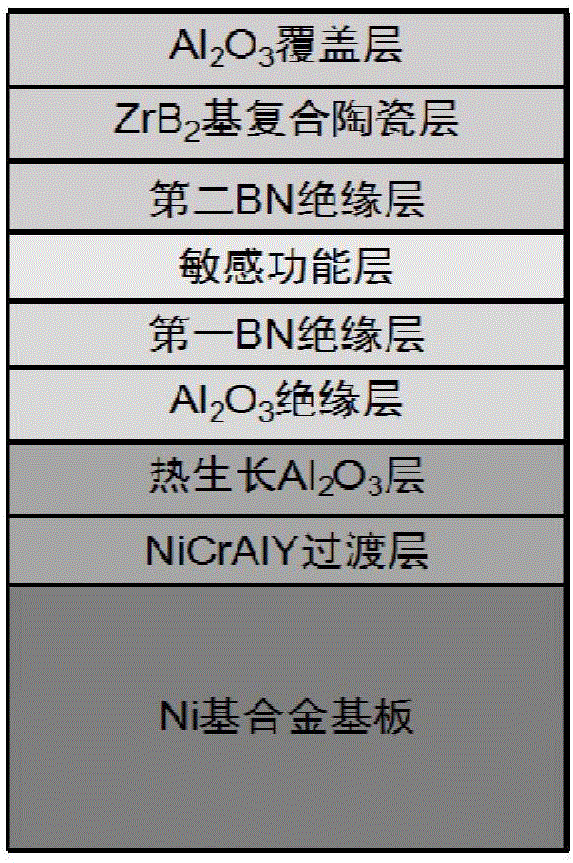

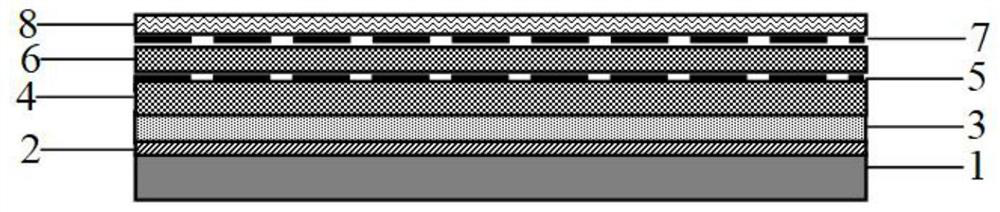

Antioxidant composite protective layer for high-temperature film sensor and manufacturing method of antioxidant composite protective layer

InactiveCN106498355AStrong covalent bond propertiesExcellent high temperature insulation performanceVacuum evaporation coatingSputtering coatingThin film sensorSputtering

The invention discloses an antioxidant composite protective layer for a high-temperature film sensor and a manufacturing method of the antioxidant composite protective layer, and belongs to the technical field of film sensors. The antioxidant composite protective layer sequentially comprises a BN insulation layer, a ZrB2-based composite ceramic layer and a Al2O3 covering layer from bottom to top, wherein the BN insulation layer, the ZrB2-based composite ceramic layer and the Al2O3 covering layer are sequentially deposited on a sensitive function layer of the film sensor in the way of evaporation or sputtering or the like. By means of the antioxidant composite protective layer for the high-temperature film sensor, the antioxidant protective requirements of the aero-engine high-temperature film sensor at the high temperature of 1000-1700 DEG C can be met, the stability and reliability of the film sensor in high-temperature high-pressure severe environment are effectively improved, and the service life of the film sensor in high-temperature high-pressure severe environment is effectively prolonged.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

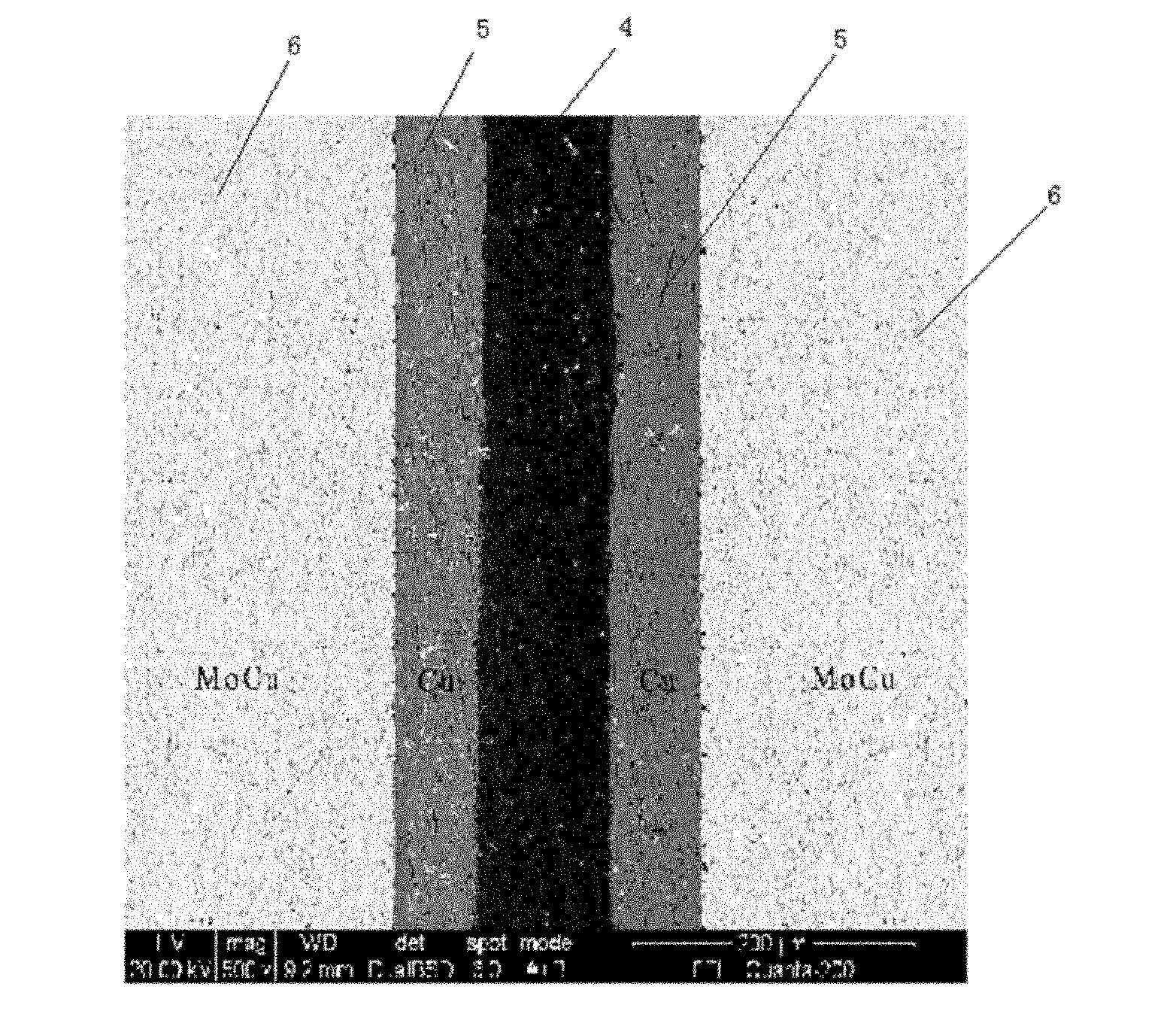

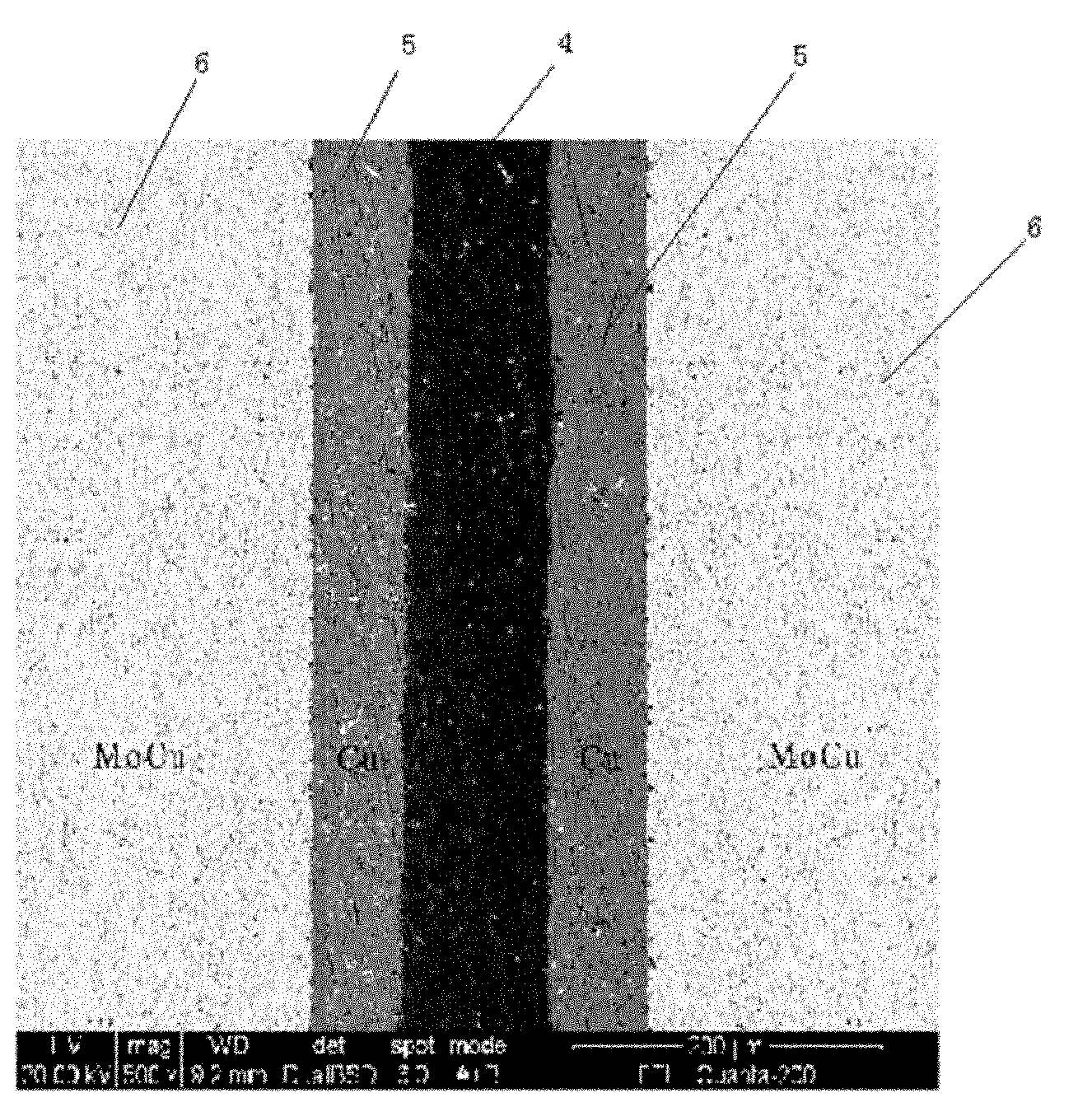

Preparation method of electromagnetic shielding multi-layer composite material in electric vacuum device

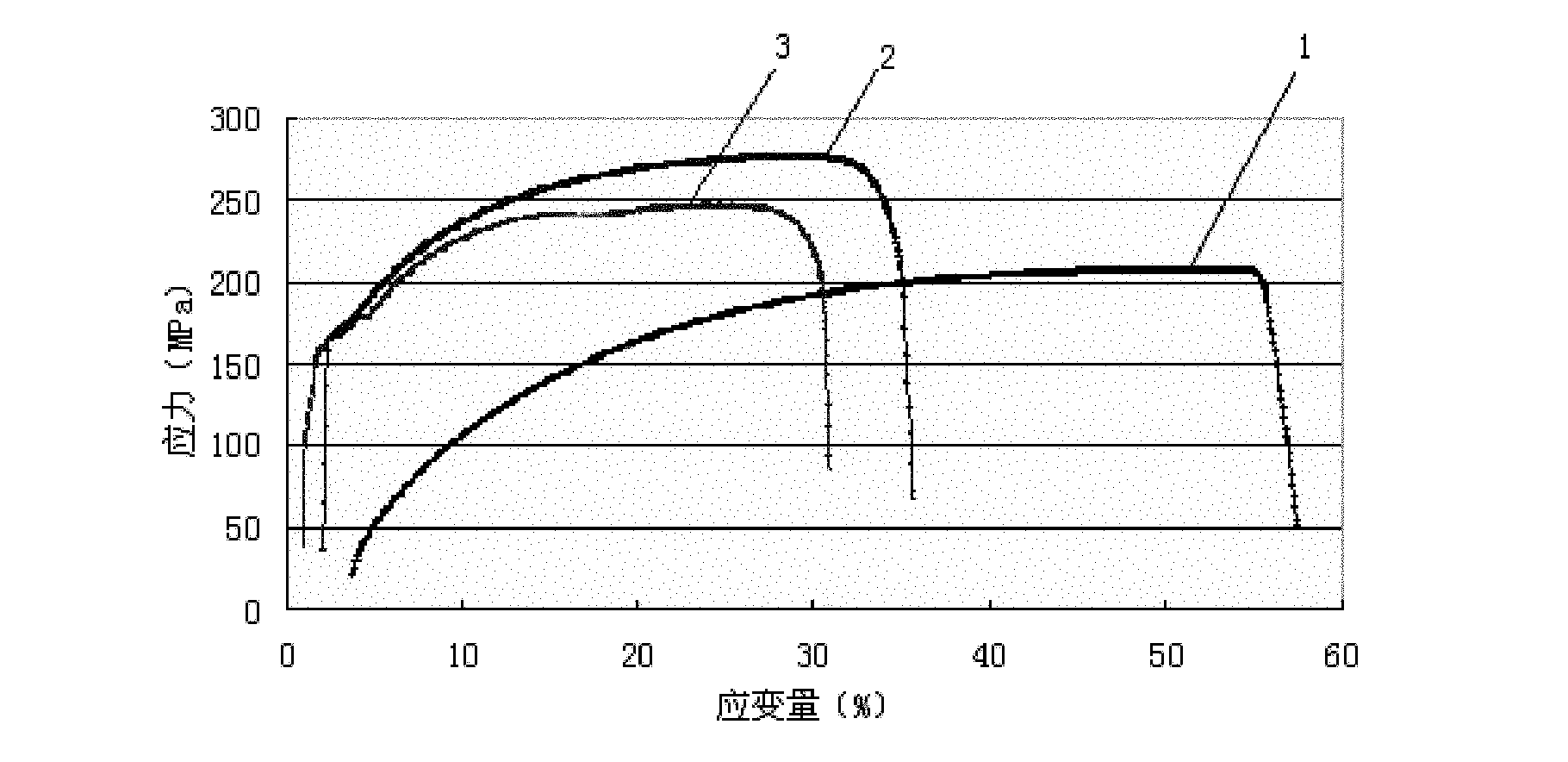

InactiveCN102126112AHigh material strengthHigh magnetic screen effectMetal layered productsThermal expansionHigh dimensional

The invention relates to a preparation method of an electromagnetic shielding multi-layer composite material in an electric vacuum device, which belongs to the field of preparation of layered composite materials. The preparation process comprises the following steps: firstly performing large-deformation rolling bonding on oxygen-free copper after surface treatment and an electrical pure iron thin plate, and getting a Cu / Fe / Cu composite foil with higher parallelism and mechanical properties; and then combining and stacking the Cu / Fe / Cu foil with a molybdenum sheet and other low thermal expansion refractory metals, placing in a diffusion welding furnace to perform diffusion welding at a certain temperature and pressure, and further preparing the multi-layer composite material with good magnetic shielding effect, high dimensional precision, strong mechanical properties and good thermal matching. By adopting the new preparation process, not only the problem that the low thermal expansion metals are difficult to compound is solved, but also the advantages of rolling bonding and the diffusion welding process can be fully played, thereby realizing good parallelism among laminated layers, high dimensional precision and excellent mechanical properties of the material, simultaneously having relatively low cost and high production efficiency, and being easy to realize large-scale and industrialized production.

Owner:CENT SOUTH UNIV

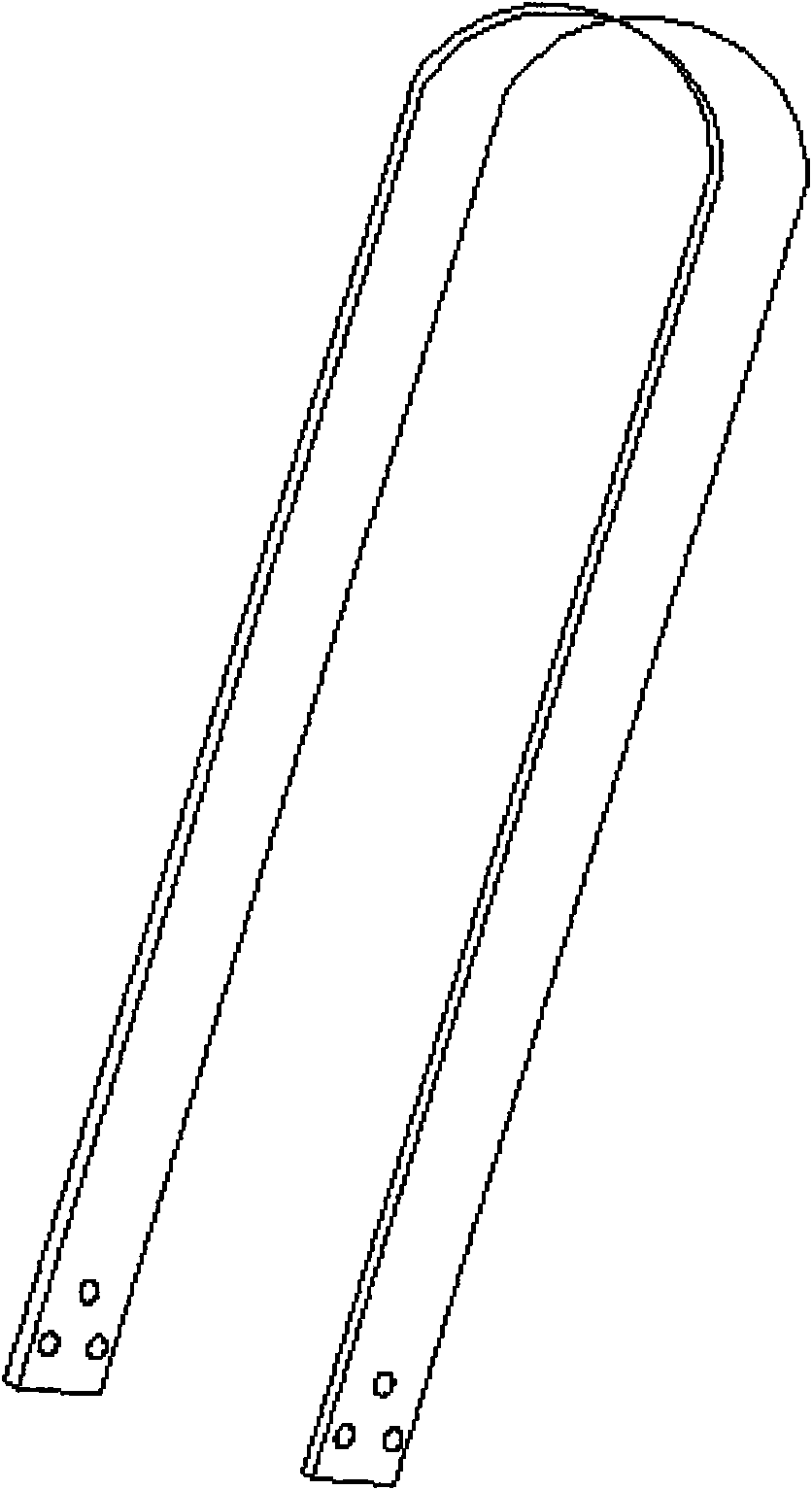

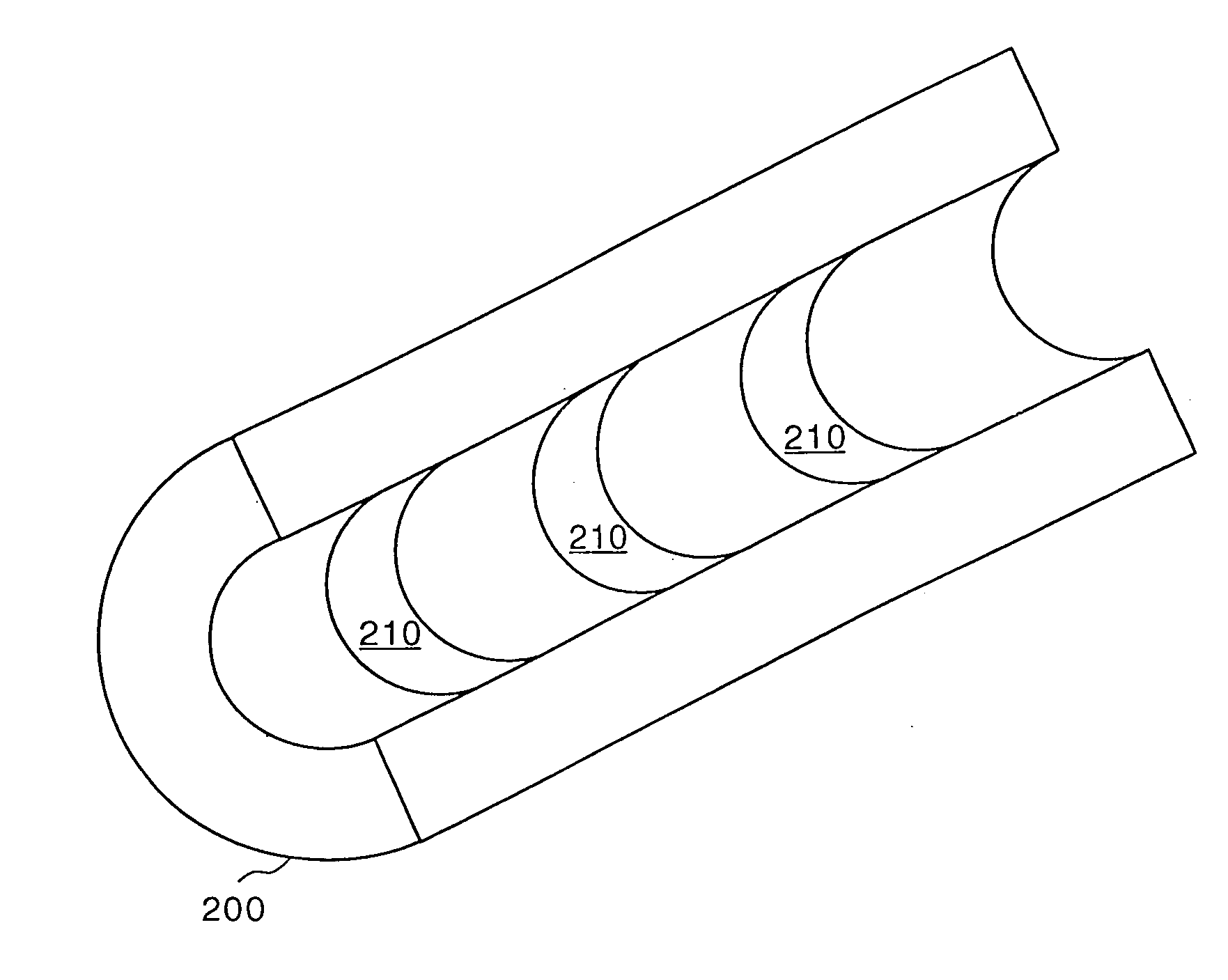

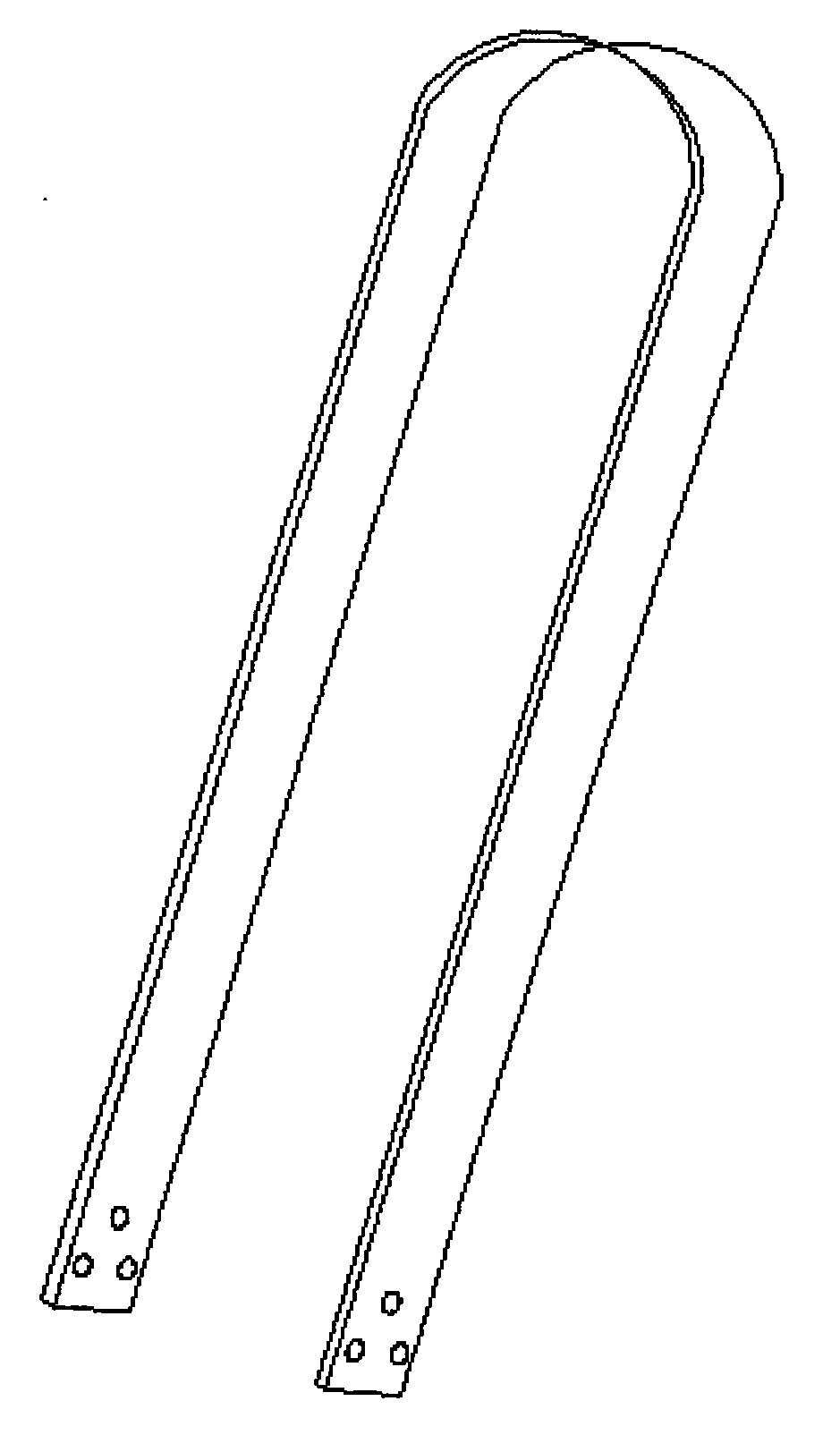

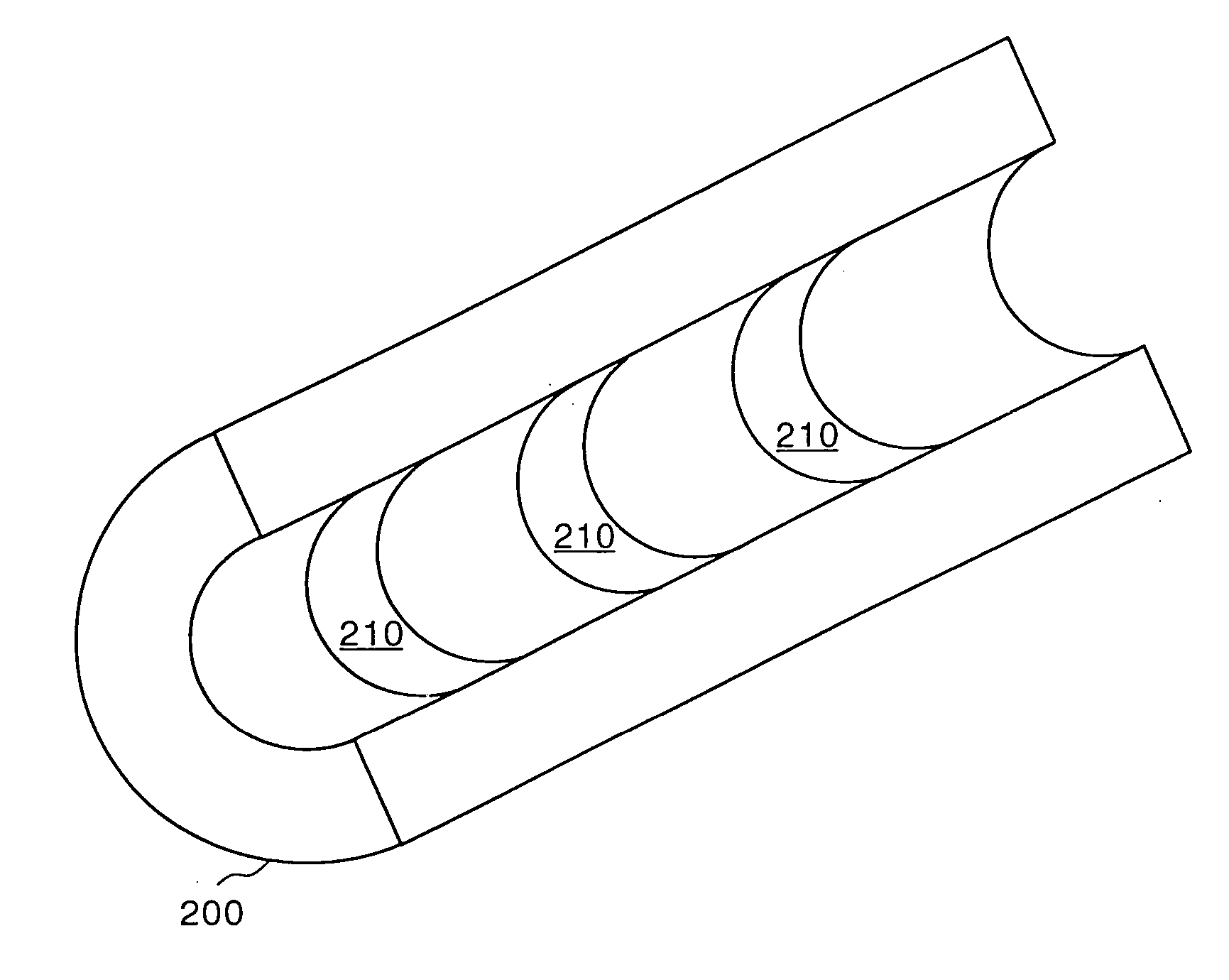

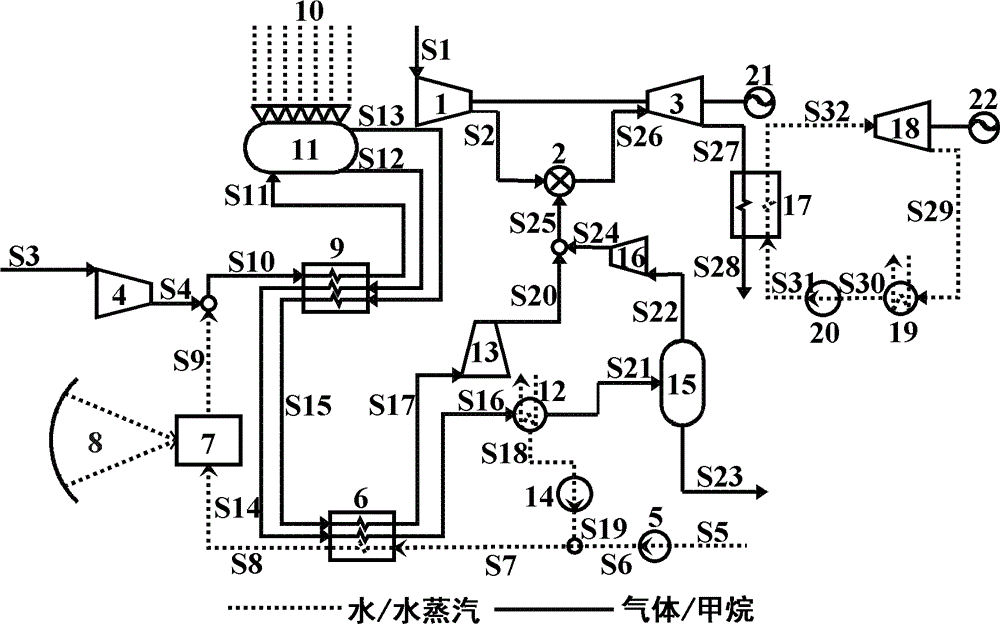

U-shaped heating element of silicon tetrachloride hydrogenation furnace and manufacturing process thereof

InactiveCN101541111AHigh in fiberThermally matched wellLiquid surface applicatorsFurnace heating elementsCorrosionHeating element

The invention provides a U-shaped heating element of a silicon tetrachloride hydrogenation furnace and a manufacturing process thereof. The U-shaped heating element of the silicon tetrachloride hydrogenation furnace consists of a green body, a matrix and a silicon carbide surface coating, wherein, the green body is prepared from 2D (two-dimensional) carbon fiber laminated fabric or quasi-3D (three-dimensional) carbon fiber needle felt with the weight not less than 50% of the total weight of the product; the matrix is composed of impregnated carbon and CVD-based (chemical vapor deposition) carbon, wherein, the content of the CVD-based carbon is not more than 30% of the total weight of the green body and the matrix; the material density of the heating element is higher than or equal to 1.3g / cm3; and the thickness of the silicon carbide surface coating is 10 to 100 mum. The U-shaped heating element of the silicon tetrachloride hydrogenation furnace has the advantages of high corrosion and erosion resistance, long service life and high reliability.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Hydrogen storage and integrated fuel cell assembly

InactiveUS7781109B2Easy to replaceImprove heat transfer performanceFuel cell heat exchangeReversible hydrogen uptakeFuel cellsThermal insulation

Hydrogen is stored in materials that absorb and desorb hydrogen with temperature dependent rates. A housing is provided that allows for the storage of one or more types of hydrogen-storage materials in close thermal proximity to a fuel cell stack. This arrangement, which includes alternating fuel cell stack and hydrogen-storage units, allows for close thermal matching of the hydrogen storage material and the fuel cell stack. Also, the present invention allows for tailoring of the hydrogen delivery by mixing different materials in one unit. Thermal insulation alternatively allows for a highly efficient unit. Individual power modules including one fuel cell stack surrounded by a pair of hydrogen-storage units allows for distribution of power throughout a vehicle or other electric power consuming devices.

Owner:GROSS KARL J

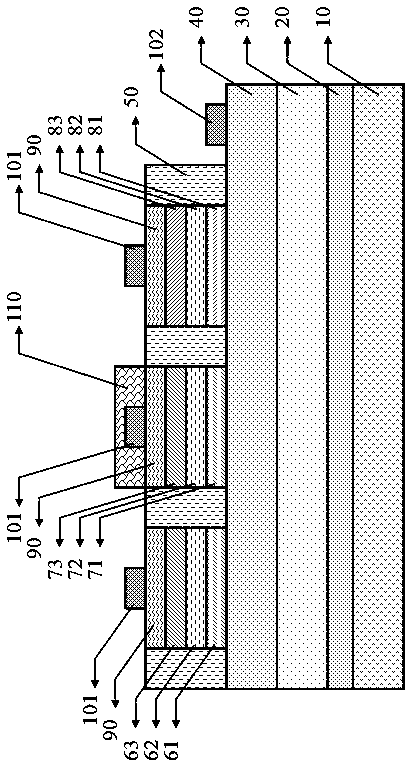

Integrated light-emitting Micro LED chip and manufacturing method thereof

PendingCN110534542AImprove luminous efficiencySmall temperature driftSolid-state devicesSemiconductor devicesPhotoluminescenceGreen-light

The invention provides an integrated light-emitting Micro LED chip and a manufacturing method thereof, which belong to the field of semiconductor optoelectronic technologies. A buffer layer, an unintentionally doped GaN layer and an n-type doped GaN layer epitaxially grow on the same side of a substrate. First and second blue light electroluminescence structure layers and a green light electroluminescence structure layer are etched laterally at intervals by depositing an insulating dielectric mask layer twice, and corresponding light-emitting structure layers are manufactured in correspondingly formed etching areas. Blue light emitted by the second blue light electroluminescence structure layer is converted into red light by a red light photoluminescence conversion layer. According to theinvention, GaN-based blue and green electroluminescence and red light photoluminescence technologies are integrated to produce red, green and blue three-primary-colour MicroLED LED light-emitting units; red, green and blue three-primary-colour light-emitting units are laterally deposited on the n-type doped GaN layer at intervals and are connected through the n-type doped GaN layer.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

AlN-particle-reinforced copper composite heat sink material and preparation method thereof

ActiveCN102433481AHigh sintering activityEnhanced interface bindingSemiconductor/solid-state device detailsSolid-state devicesElectrolysisRare earth

The invention relates to a heat sink material and a preparation method thereof, and in particular relates to an AlN-particle-reinforced copper composite heat sink material and a preparation method thereof. The invention aims to solve the technical problems that the existing AlN-particle-reinforced copper composite heat sink material has complex preparation process and high cost. The composite heat sink material is prepared from a rare earth compound, AlN particles and electrolytic copper, wherein the rare earth compound is Y2O3 powder. The method comprises the following steps: performing ball milling to the rare earth compound, AlN particles, electrolytic copper and stearic acid, then prepressing to obtain a preform, preburning the preform, and then roasting at 900-1300 DEG C to obtain the AlN-particle-reinforced copper composite heat sink material. The heat conductivity of the material is more than 200w / mK, the compactness is more than 98% and the thermal expansion coefficient is no more than 14ppm / K; and the heat sink material can be used in electronic packaging.

Owner:HEILONGJIANG HEIKE TECH CO LTD +1

X-Ray Tube Anodes

ActiveUS20120014510A1Improve thermal conductivityThermally matched wellX-ray tube anode coolingX-ray tube electrodesPhysicsX-ray tube

Owner:RAPISCAN SYST INC (US)

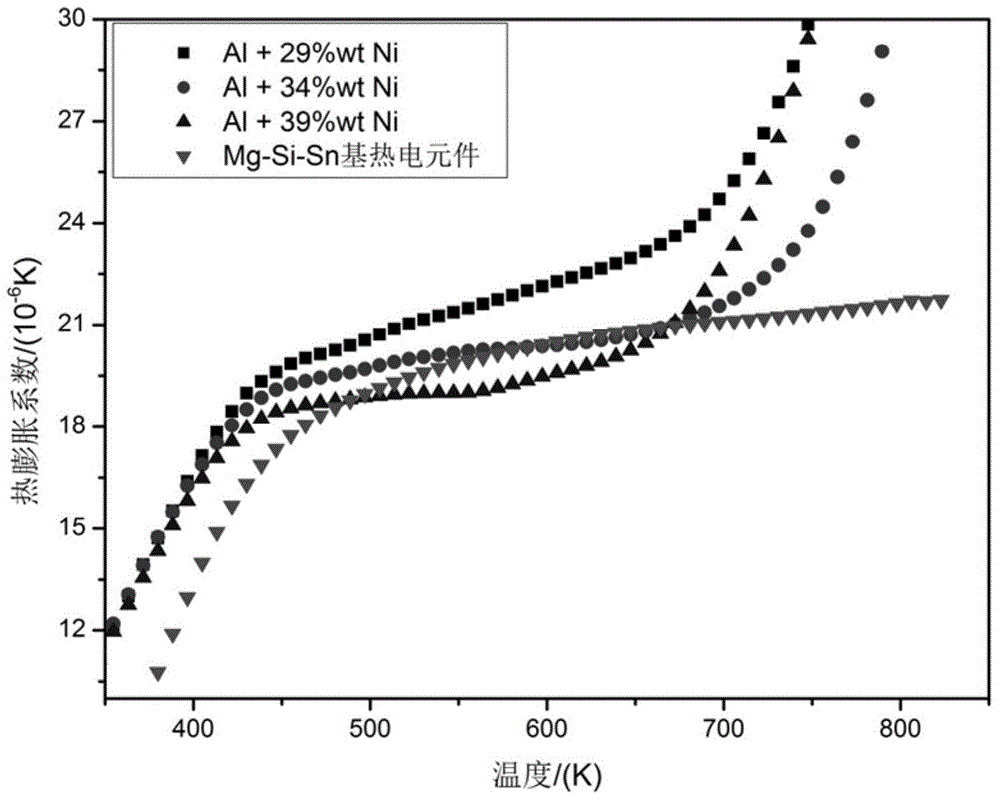

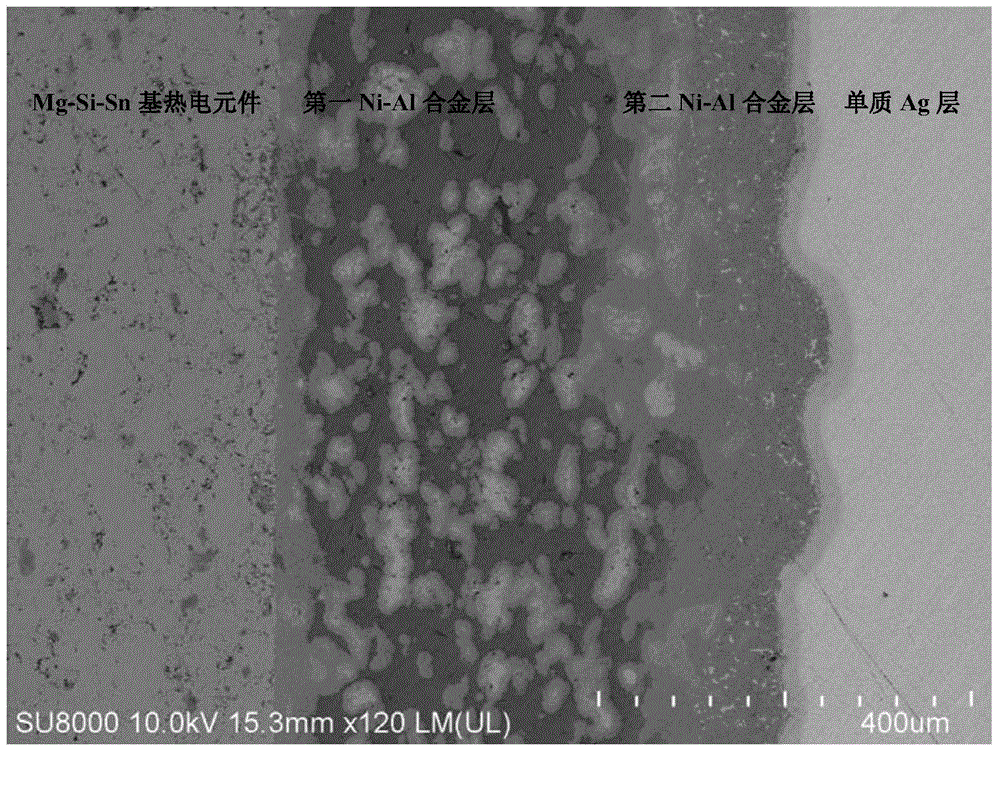

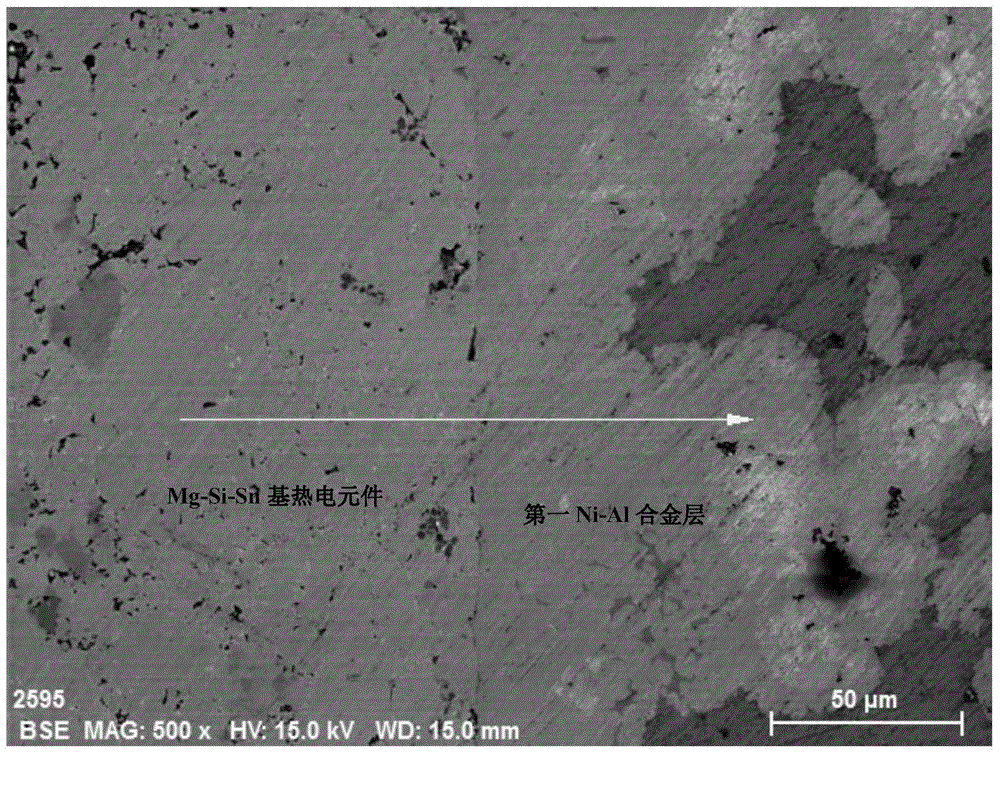

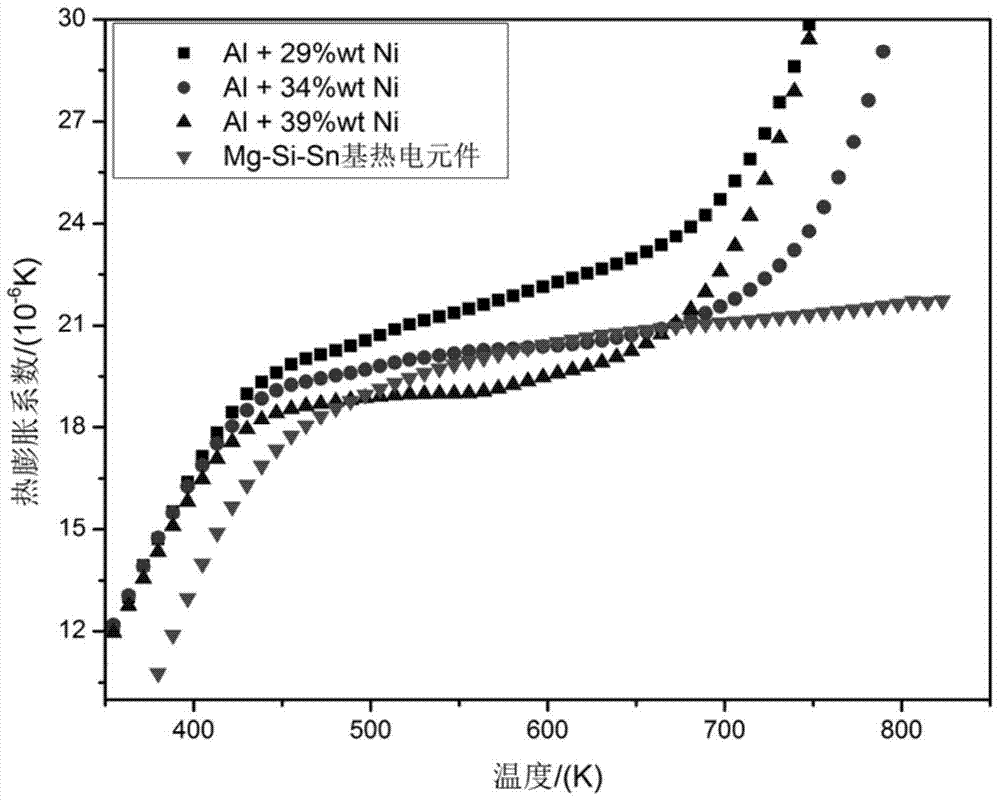

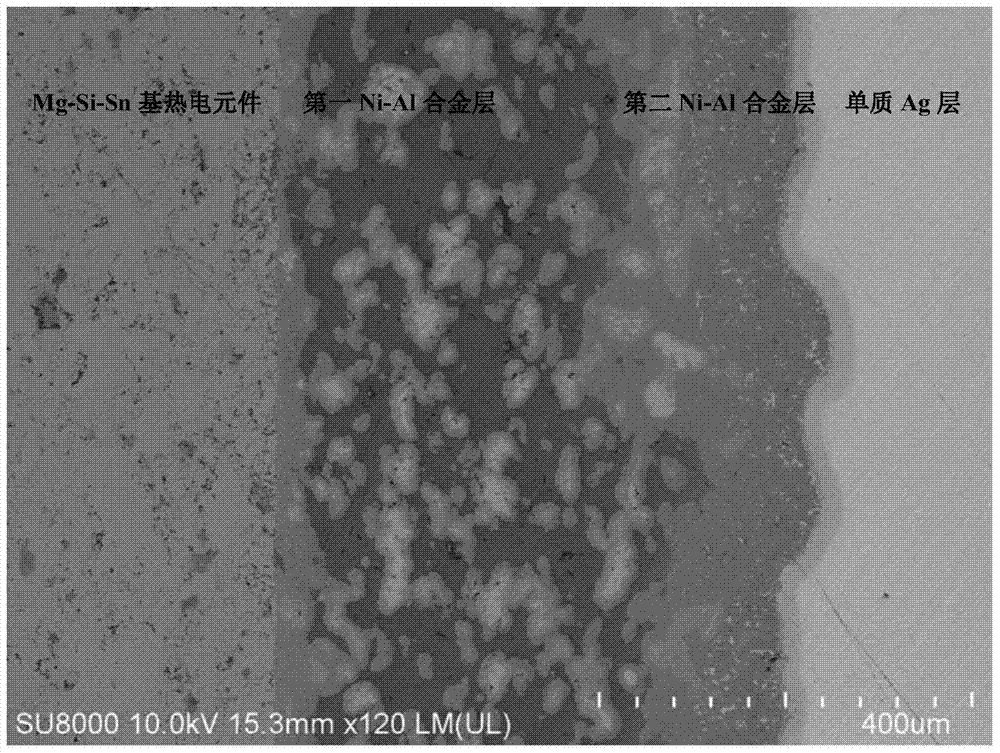

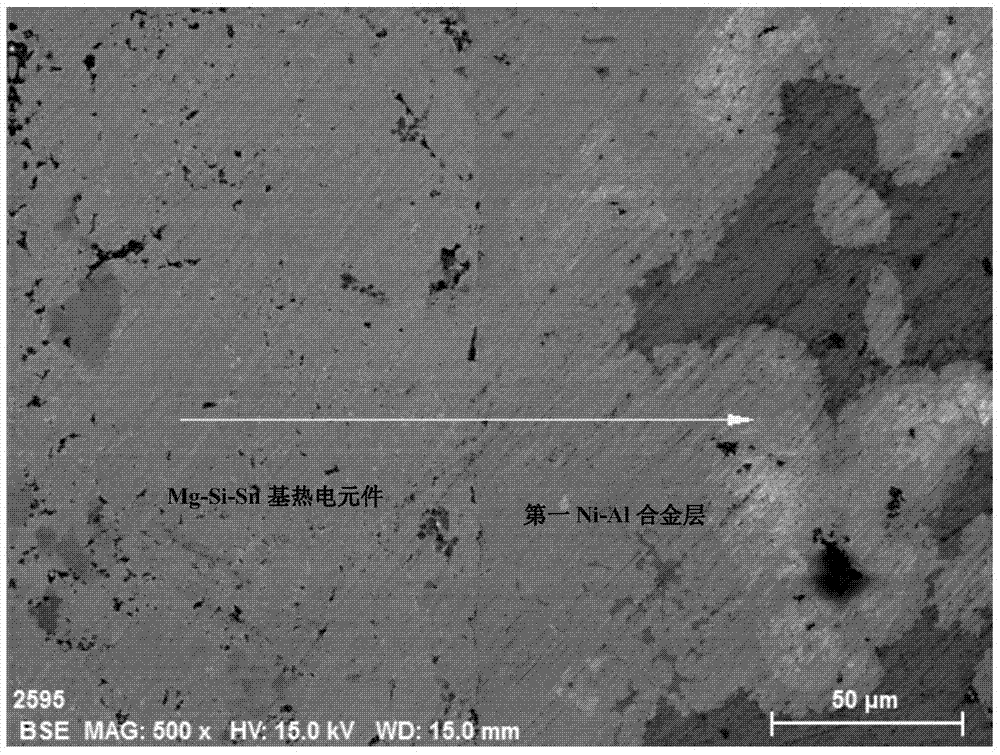

Layered electrode matched with Mg-Si-Sn-based thermoelectric element and connecting technology thereof

ActiveCN104362249AThermally matched wellAvoid it happening againThermoelectric device manufacture/treatmentThermoelectric device junction materialsElectrical resistance and conductanceInternal resistance

The invention relates to a layered electrode matched with a Mg-Si-Sn-based thermoelectric element and a connecting technology of the layered electrode. The electrode is of a three-layer structure, and sequentially comprises a first Ni-Al alloy layer, a second Ni-Al alloy layer and a simple substance Ag layer. Good heat matching between the multi-layer electrode and the Mg-Si-Sn-based thermoelectric element is achieved, interface heat stress can be reduced, and the service life can be prolonged. A small wetting angle is achieved, and the electrode can be directly welded to a current guide sheet. Good electrical property transition is achieved, contact resistance is smaller than five percent of internal resistance of the Mg-Si-Sn-based thermoelectric element, and the technology for connecting the Mg-Si-Sn-based thermoelectric element and the multi-layer electrode is simple and reliable.

Owner:WUHAN UNIV OF TECH

Polycrystalline diamond construction with controlled gradient metal content

ActiveUS9297211B2Hardness resistanceResistance to stabilityDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Polycrystalline diamond constructions comprises a diamond body attached to a metallic substrate, and having an engineered metal content. The body comprises bonded together diamond crystals with a metal material disposed interstitially between the crystals. A body working surface has metal content of 2 to 8 percent that increases moving away therefrom. A transition region between the body and substrate includes metal rich and metal depleted regions having controlled metal content that provides improved thermal expansion matching / reduced residual stress. A point in the body adjacent the metal rich zone has a metal content that is at least about 3 percent by weight greater than that at a body / substrate interface. The metal depleted zone metal content increases gradually moving from the body, and has a thickness greater than 1.25 mm. Metal depleted zone metal content changes less about 4 percent per millimeter moving along the substrate.

Owner:SMITH INT INC

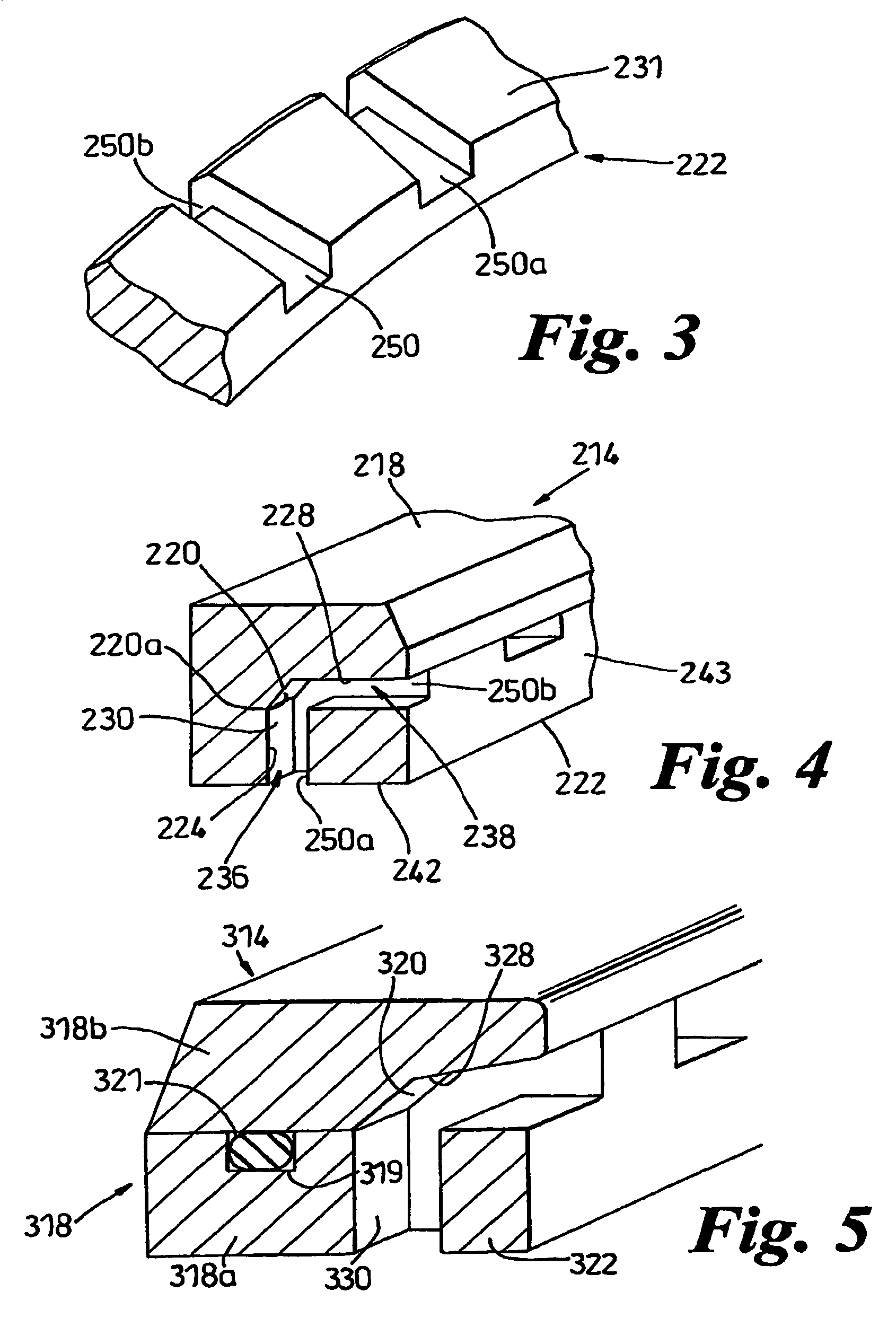

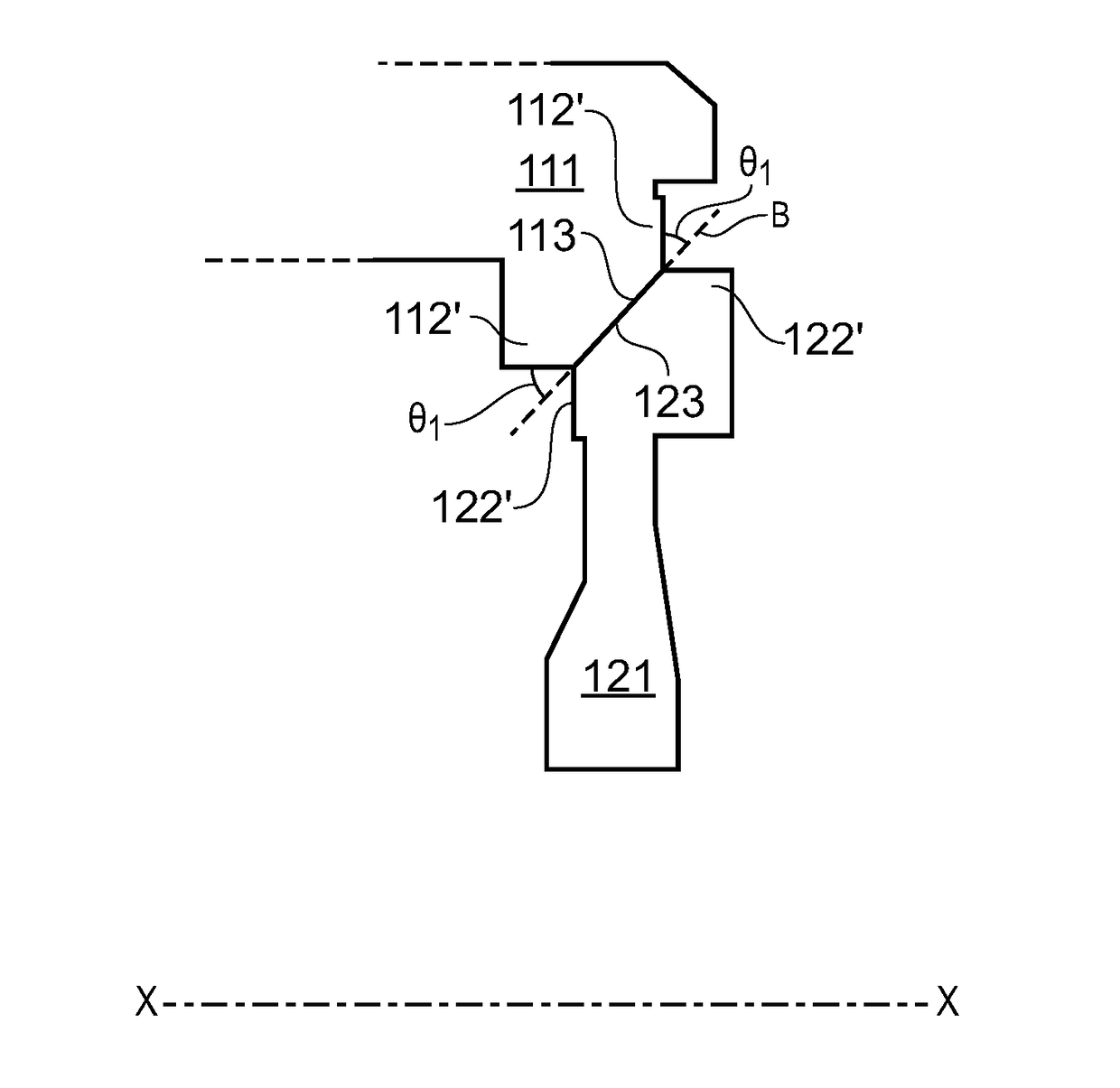

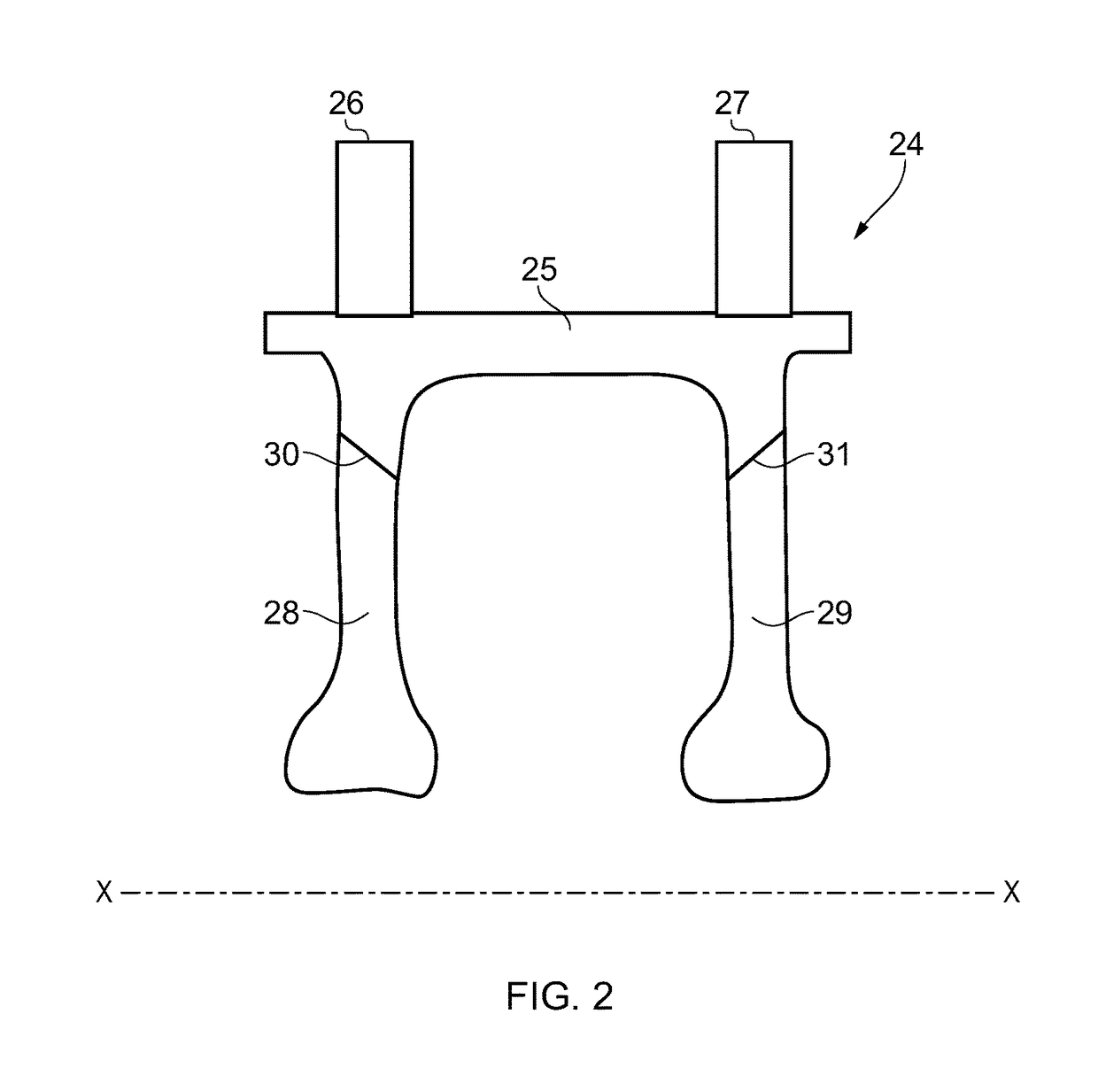

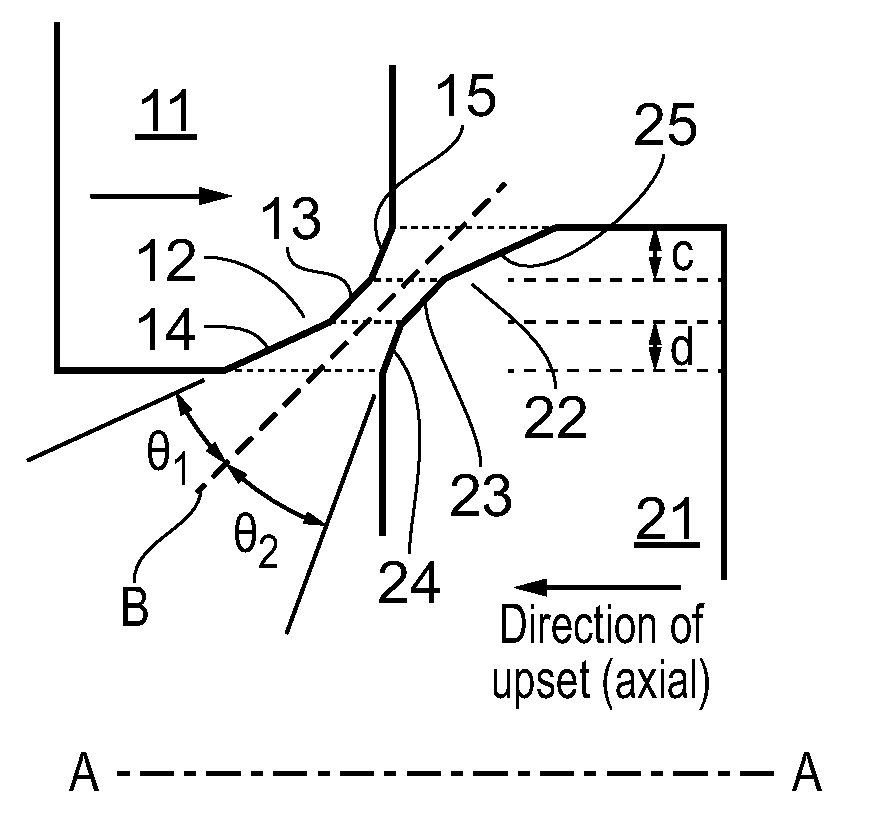

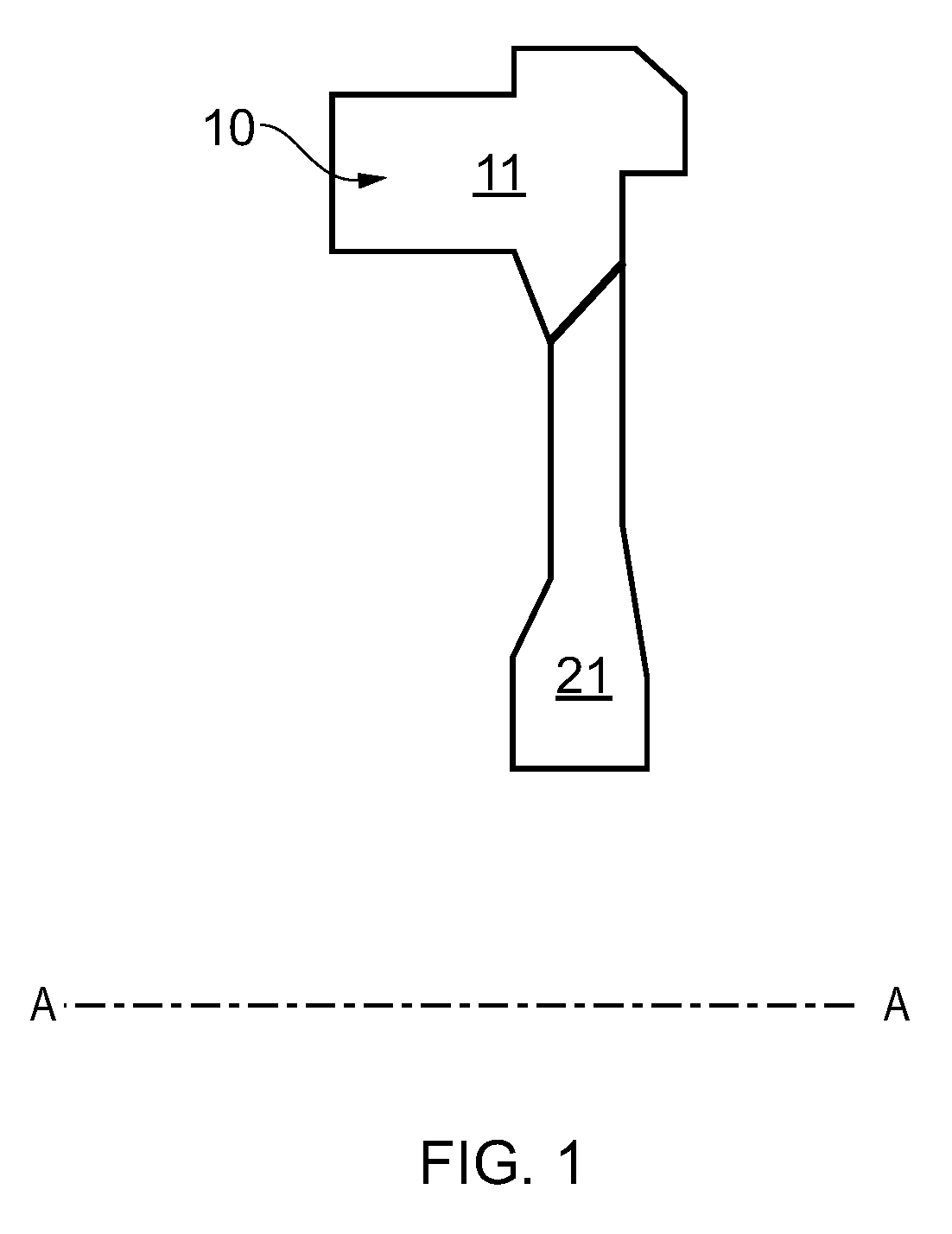

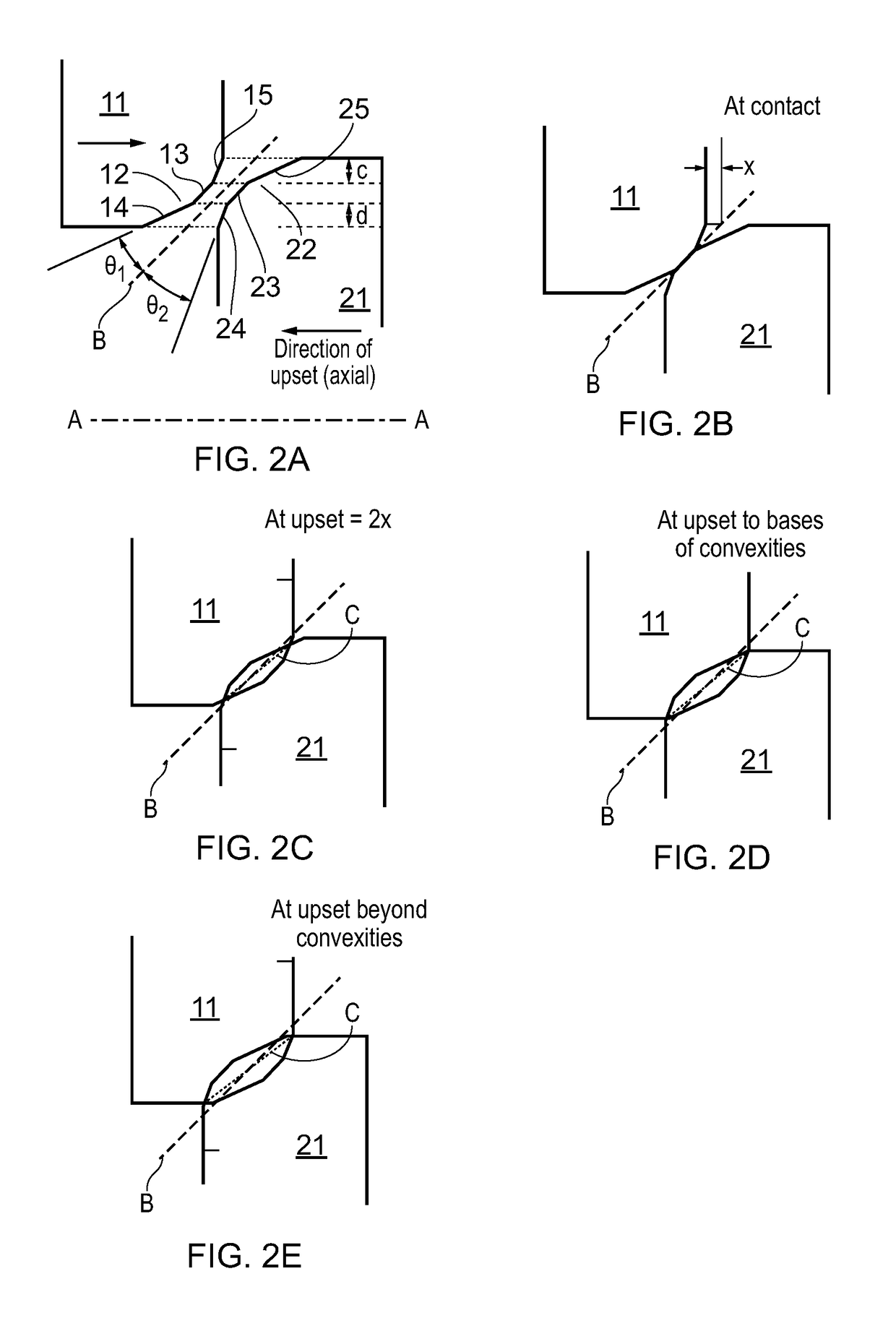

Rotary friction welding

ActiveUS20180029157A1Reduce flow deviationThermally matched wellTurbinesPump componentsEngineeringFriction welding

The present disclosure provides a rotary friction welding process including: providing an outer axisymmetric workpiece having a front first annular weld surface at a radially inward extent and a rear first annular weld surface at a radially inward extent; providing a front inner axisymmetric workpiece, the front inner workpiece having a front second annular weld surface at a radially outward extent of the front inner workpiece; providing a rear inner axisymmetric workpiece, the rear inner workpiece having a rear second annular weld surface at a radially outward extent of the rear inner workpiece; and rotary welding the workpieces together.

Owner:ROLLS ROYCE PLC

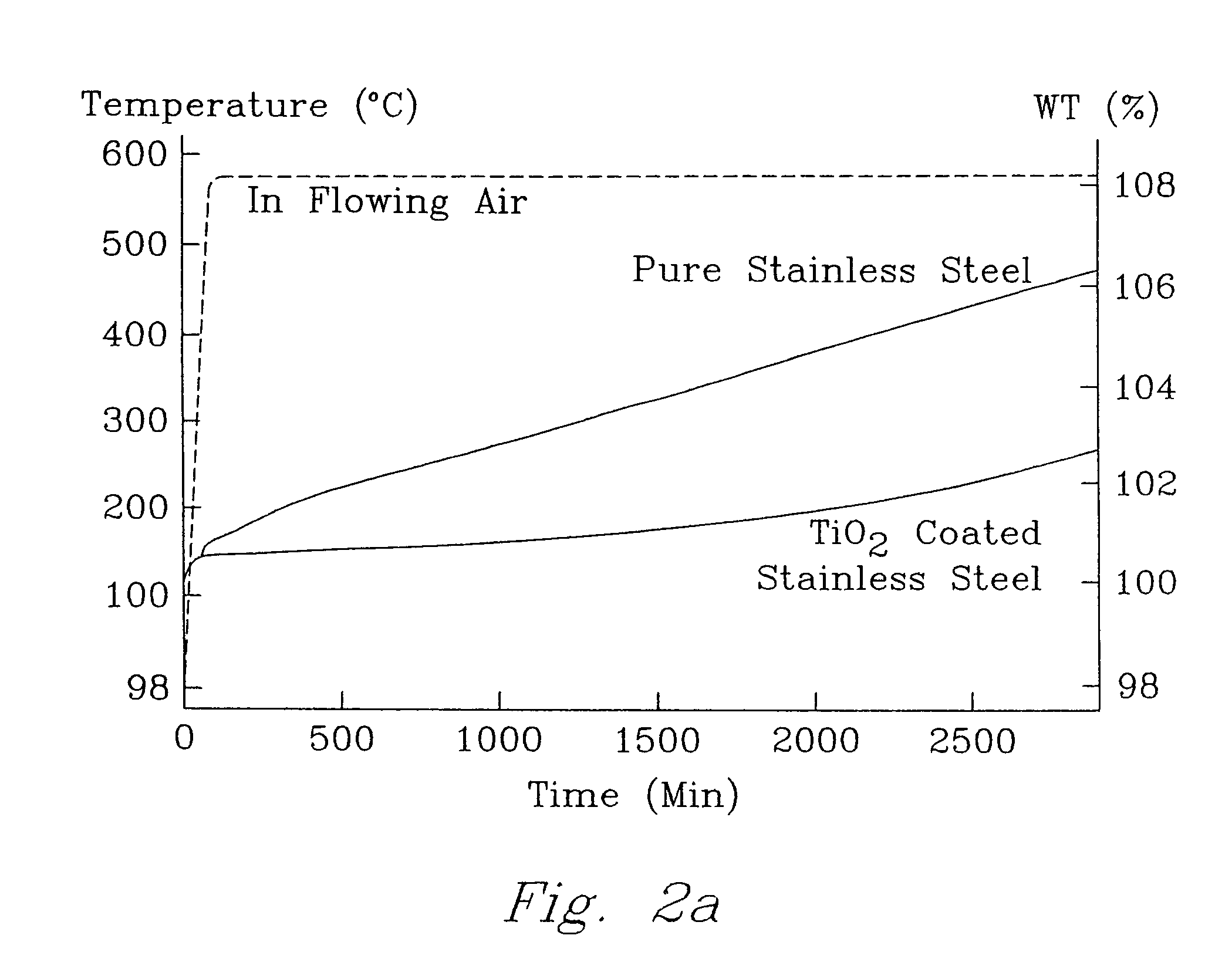

Resistive heaters and uses thereof

InactiveUS20050230378A1Prevent bending and fractureImprove adhesionMolten spray coatingLinings repairBorideElectrical resistance and conductance

The present invention features a metallic resistive heater and uses thereof. The resistive heater includes a metallic component that is electrically conductive (i.e., has low resistivity) and an oxide, nitride, carbide, and / or boride derivative of the metallic component that is electrically insulating (i.e., has high resistivity). The resistivity is controlled in part by controlling the amount of oxide, nitride, carbide, and boride formation during the deposition of the metallic component and the derivative.

Owner:REGAL WARE

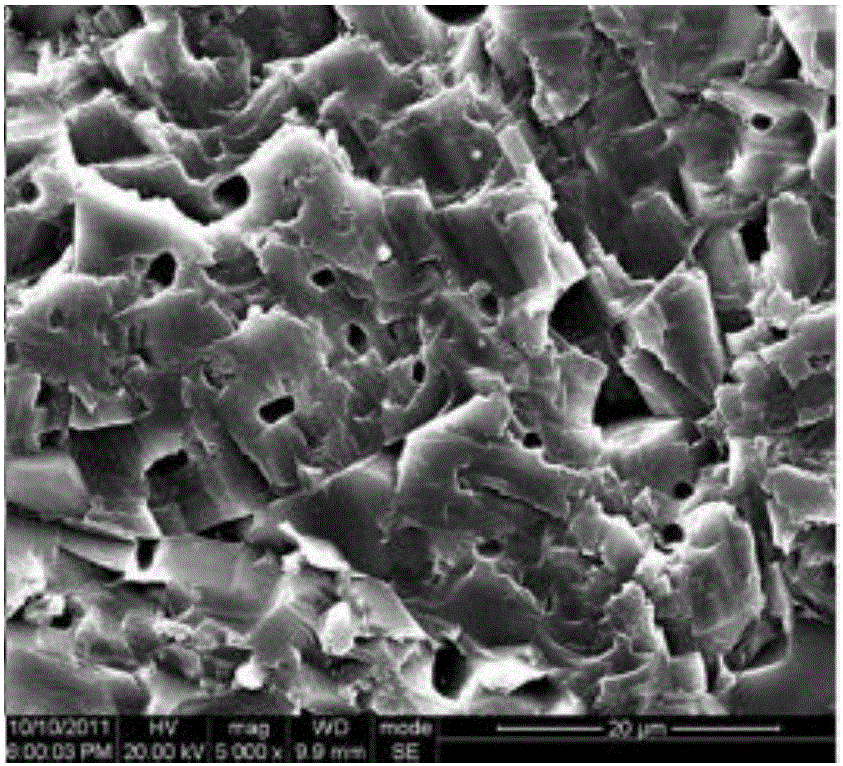

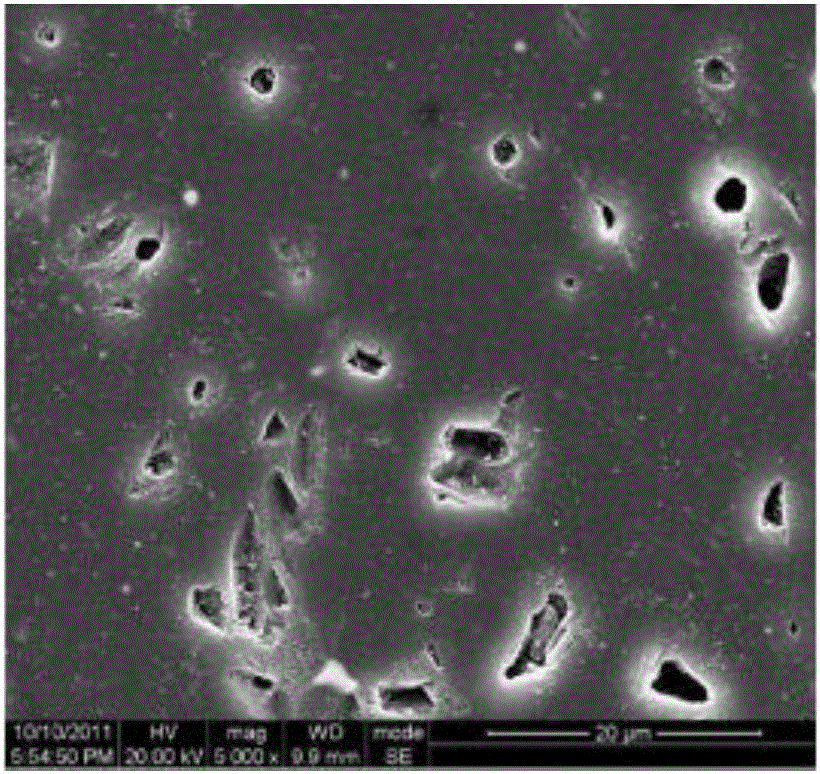

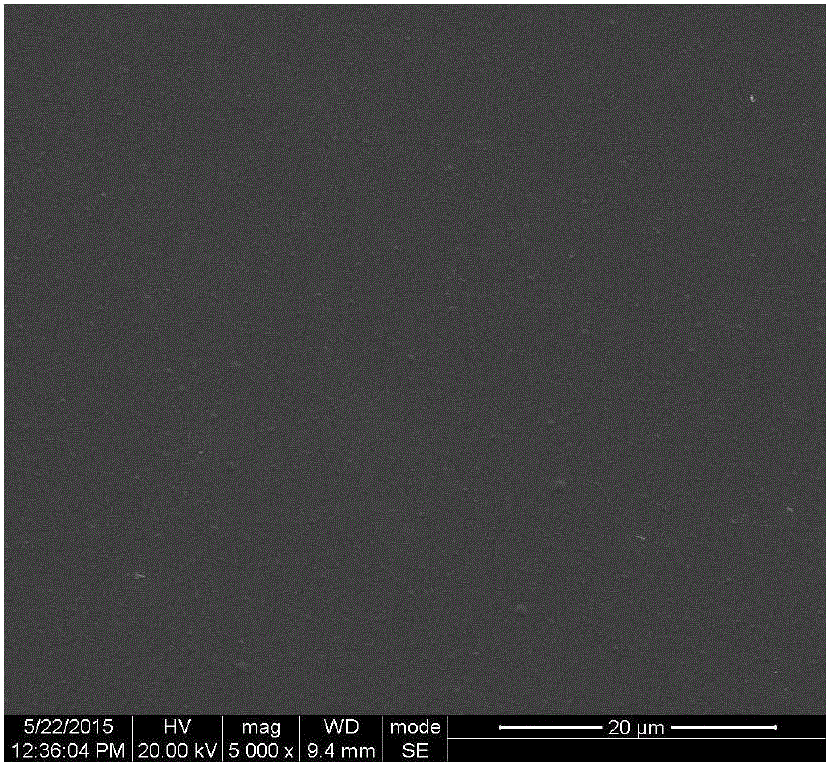

Ceramic substrate planarization manufacturing method

The invention belongs to the technical field of ceramic substrate production, and in particular relates to a ceramic substrate planarization manufacturing method for a film circuit. High-temperature glaze matched with the ceramic substrate is applied to the field of the film circuit substrate planarization. The ceramic substrate planarization manufacturing method is characterized in that a thin high-temperature glass glaze layer which has a thermal expansion coefficient similar with that of a substrate is coated on the surface of the substrate. The glass glaze takes following Ca / Al / Si-series glass in percentage by mass as the main components: 41-65% of SiO2, 9-13% of Al2O3, 10-17% of CaO, additives comprising 1-4% of MgO, 4-10% of BaO, 1-9% of Na2O, and 1-9% of K2O. A planarization substrate product manufactured by the ceramic substrate planarization manufacturing method does not have cracks on surface, does not generate wrinkles, has surface roughness Ra of 0.2 nm-0.5 nm within a range of 20*20 mum<2>, has surface roughness Ra of 0.5 nm-0.62 nm within a range of 100*100 mum<2>, and has surface roughness Ra of 0. 5nm-31.68 nm within a range of 2000*2000 mum<2>.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

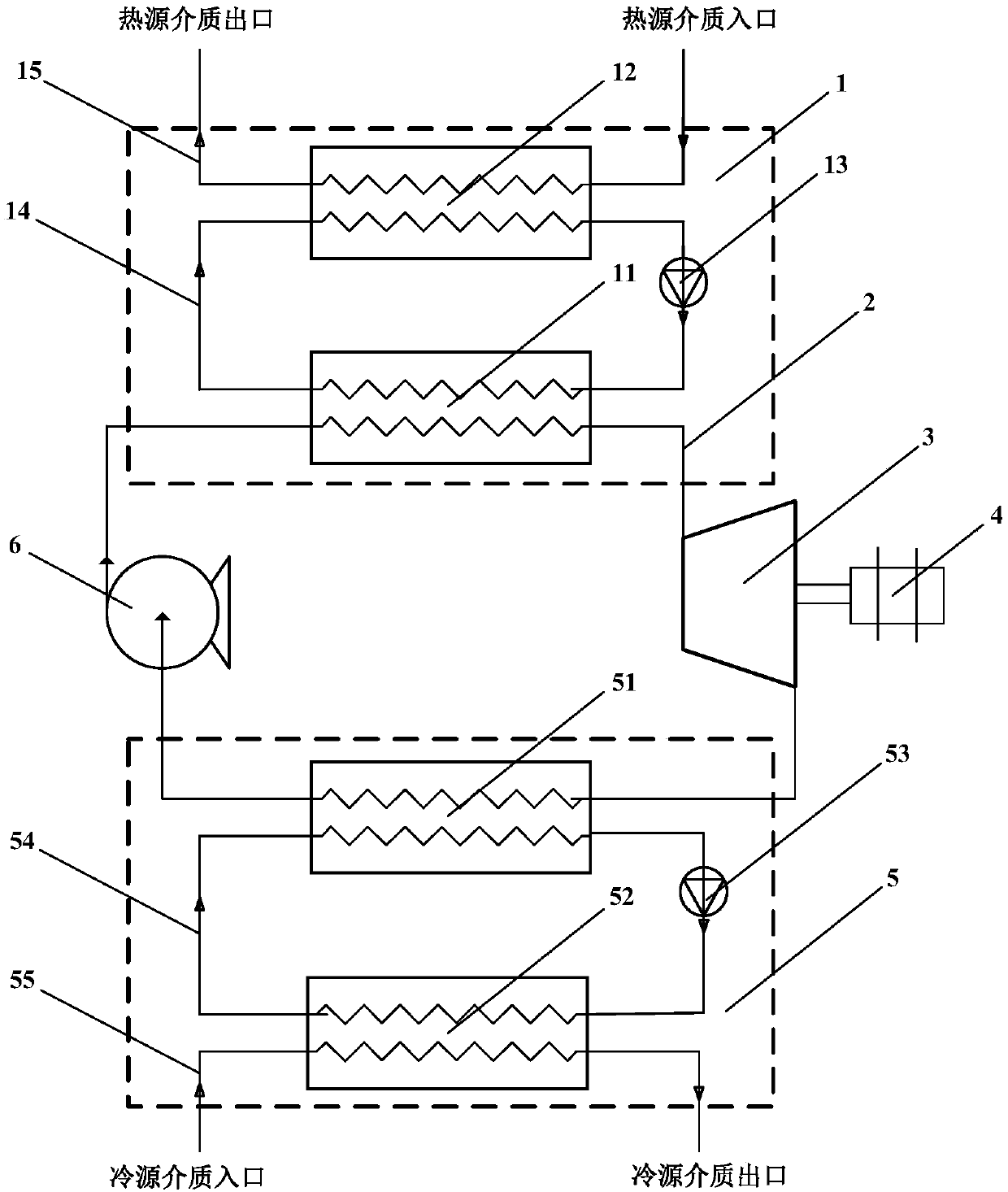

Organic rankine cycle power generation system

ActiveCN107605557ADiffusion fastEfficient deliveryStationary tubular conduit assembliesSteam engine plantsOrganic Rankine cycleHeat transmission

The invention provides an organic rankine cycle power generation system. An evaporation device is internally provided with a first heat exchanger and a second heat exchanger which are connected through a first circulating pipeline, and the first circulating pipeline is internally provided with a first duplex fluid working medium which contains first liquid metal and a first organic working medium.Meanwhile, a condensing device is provided with a third heat exchanger and a fourth heat exchanger which are connected through a second circulating pipeline, and the second circulating pipeline is internally provided with a second duplex fluid working medium which contains second liquid metal and a second organic working medium. Due to the high heat conductivity of the liquid metal in the two duplex fluid working media, heat can be rapidly dispersed, the heat releasing efficiency of a heat source medium, the heat absorbing efficiency of a cold source medium and the heat absorbing efficiency and the heat releasing efficiency of the organic working media in an organic rankine cycle pipeline are improved, meanwhile, by means of latent heat of phase change of the organic working media contained in the duplex fluid working media, much heat can be stored, higher efficient heat transmission and better heat matching of the working media on the two sides of the heat exchanger are achieved, andtherefore the power generation system efficiency is improved as a whole.

Owner:空间液态金属科技发展江苏有限公司

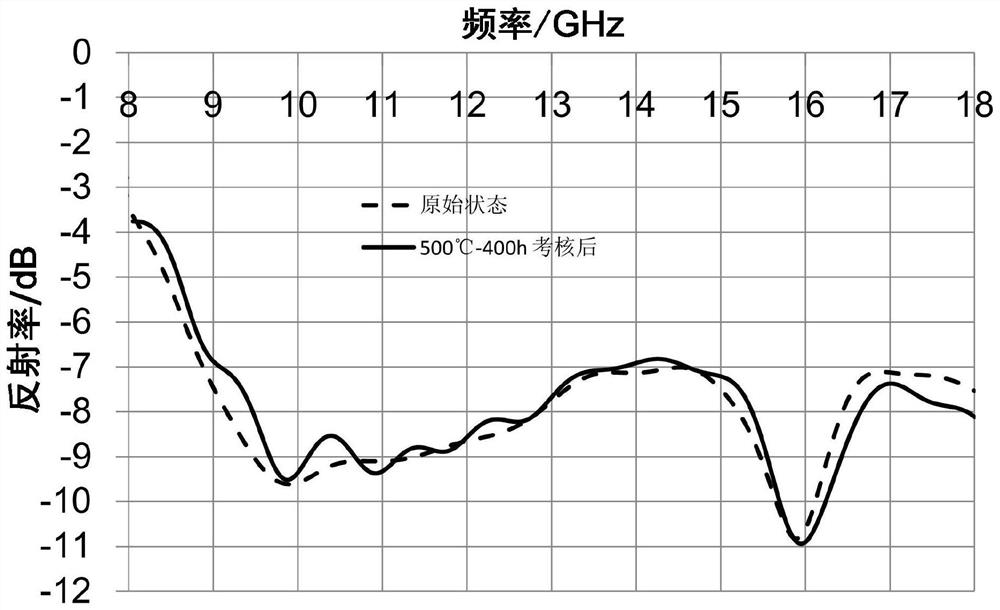

Functional gradient distribution high-temperature radar and infrared compatible stealth coating and preparation method thereof

ActiveCN112961531AImprove absorbing performanceHigh resistivityPowdery paintsSpecial surfacesThermal dilatationRadar

The invention relates to the technical field of high-temperature stealth coatings, and particularly discloses a functional gradient distribution high-temperature radar and infrared compatible stealth coating and a preparation method thereof. The surface of a metal base material is coated with the high-temperature radar and infrared compatible stealth coating, and from the surface of the metal base material, the coating sequentially comprises a metal bonding layer, a thermal matching ceramic layer, a dielectric ceramic layer, a first high-temperature electromagnetic periodic structure layer, a dielectric isolation layer, a second high-temperature electromagnetic periodic structure layer and an infrared stealth layer from bottom to top. The high-temperature radar and infrared compatible stealth coating disclosed by the invention has radar and infrared compatible stealth functions, adopts a multifunctional layer structure, realizes gradient distribution of thermal expansion coefficients of the coating, can realize better thermal matching with a metal substrate, and is good in thermal shock resistance; and the softening point temperature of the selected glass phase does not exceed 600 DEG C, so the coating has the advantages of low sintering temperature and short sintering time, and can reduce the influence of oxidation, damage, deformation and the like on the metal substrate.

Owner:NAT UNIV OF DEFENSE TECH

Catalyst, method of making, and reactions using the catalyst

InactiveUS7498001B2Reduce thermal expansion stressReduce corrosionCatalyst protectionOrganic chemistry methodsReagentLayered structure

The present invention includes a catalyst having a layered structure with, (1) a porous support, (2) a buffer layer, (3) an interfacial layer, and optionally (4) a catalyst layer. The invention also provides a process in which a reactant is converted to a product by passing through a reaction chamber containing the catalyst.

Owner:BATTELLE MEMORIAL INST

U-shaped heating element of silicon tetrachloride hydrogenation furnace and manufacturing process thereof

InactiveCN101541111BHigh in fiberThermally matched wellLiquid surface applicatorsFurnace heating elementsFiberCarbon fibers

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

A layered electrode matched with mg-si-sn-based thermoelectric elements and its connection process

ActiveCN104362249BThermally matched wellAvoid it happening againThermoelectric device manufacture/treatmentThermoelectric device junction materialsElectrical resistance and conductanceInternal resistance

The invention relates to a multi-layer electrode matching Mg-Si-Sn-based thermoelectric elements and a connection process thereof. The electrode is divided into a three-layer structure, in order: a first Ni-Al alloy layer, a second Ni-Al alloy layer and elemental Ag layer. The multilayer electrode of the present invention has good thermal matching with the Mg‑Si‑Sn based thermoelectric element, can reduce interface thermal stress and improve service life; has a small wetting angle and can be directly welded to the guide plate; and has Good electrical property transition, contact resistance is less than 5% of the internal resistance of Mg-Si-Sn-based thermoelectric elements, and the process of connecting Mg-Si-Sn-based thermoelectric elements and multi-layer electrodes is simple and reliable.

Owner:WUHAN UNIV OF TECH

Resistive heaters and uses thereof

InactiveUS20050236400A1Prevent bending and fractureImprove adhesionMolten spray coatingLinings repairBorideElectrical resistance and conductance

The present invention features a metallic resistive heater and uses thereof. The resistive heater includes a metallic component that is electrically conductive (i.e., has low resistivity) and an oxide, nitride, carbide, and / or boride derivative of the metallic component that is electrically insulating (i.e., has high resistivity). The resistivity is controlled in part by controlling the amount of oxide, nitride, carbide, and boride formation during the deposition of the metallic component and the derivative.

Owner:ABBOTT RICHARD C +2

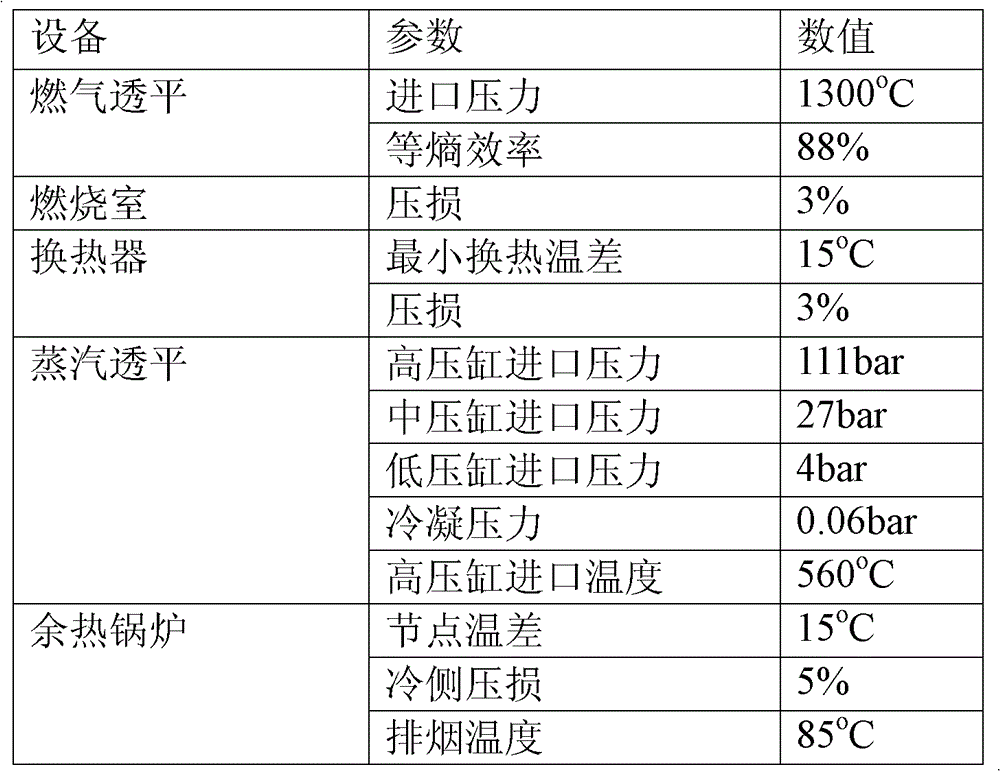

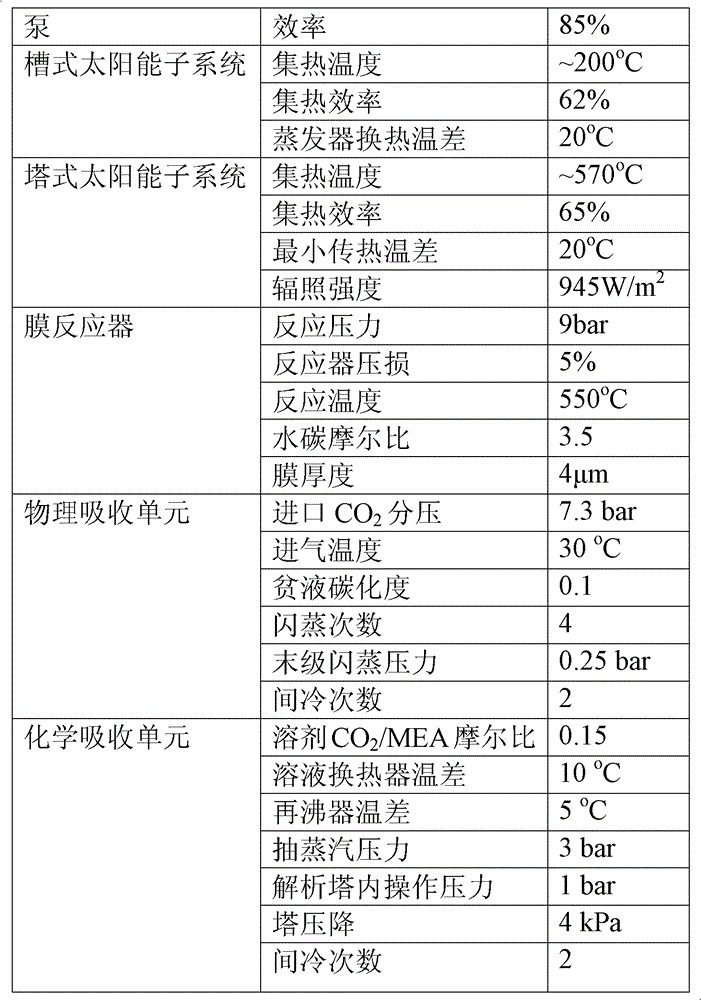

Method and device for improving grade of medium-and-low-temperature solar thermal power and integrally separating CO2

ActiveCN103373705BIntegrated Separation RealizationImprove reforming reaction conditionsHydrogenCarbon compoundsSteam reformingWater vapor

The invention discloses a method and a device for improving the grade of medium-and-low-temperature solar thermal power and integrally separating CO2. According to the method, a palladium base alloy membrane structure with very strong hydrogen permeation property is introduced into a methane / water vapor reforming reaction, thereby greatly improving reaction conditions, increasing percent conversion rate of methane and realizing CO2 separation. 200 DEG C cyclone separator trench type solar is used for providing latent heat of vaporization for reforming vapor, the latent heat of vaporization is converted into vapor internal energy, and the vapor internal energy is converted into synthesis gas chemical energy. 550 DEG C light-concentrating tower-type solar is used for providing reaction heat needed by the reforming reaction and the reaction heat is directly converted into synthesis gas chemical energy. Thus, grade is improved. Finally, conversion of heat into power is realized in a high-efficiency fuel gas-vapor combined circulating system. By the method and the device provided by the invention, the high-efficiency conversion of medium-and-low-temperature solar thermal power and comprehensive gradient utilization of medium-and-low-temperature solar thermal power and fossil fuel which are complementary to each other are realized; moreover, the integral separation of CO2 is also realized.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Rotary friction welding

ActiveUS20180029158A1Less timeLow variabilityTurbinesMetal working apparatusFriction weldingHeat flow

A rotary friction welding process is provided, including: providing a first axisymmetric workpiece having a first annular weld surface, and a second axisymmetric workpiece having a second annular weld surface; and rotationally welding the workpeices. On the longitudinal section through the aligned workpieces, each of the first and second annular weld surfaces is flanked by radially inner and outer side surfaces, the first weld surface and its side surfaces being shaped to thermally match the second weld surface and its side surfaces across a line of initial contact of the first and second weld surfaces such the heat flows from the weld at all the side surfaces are substantially equal.

Owner:ROLLS ROYCE PLC

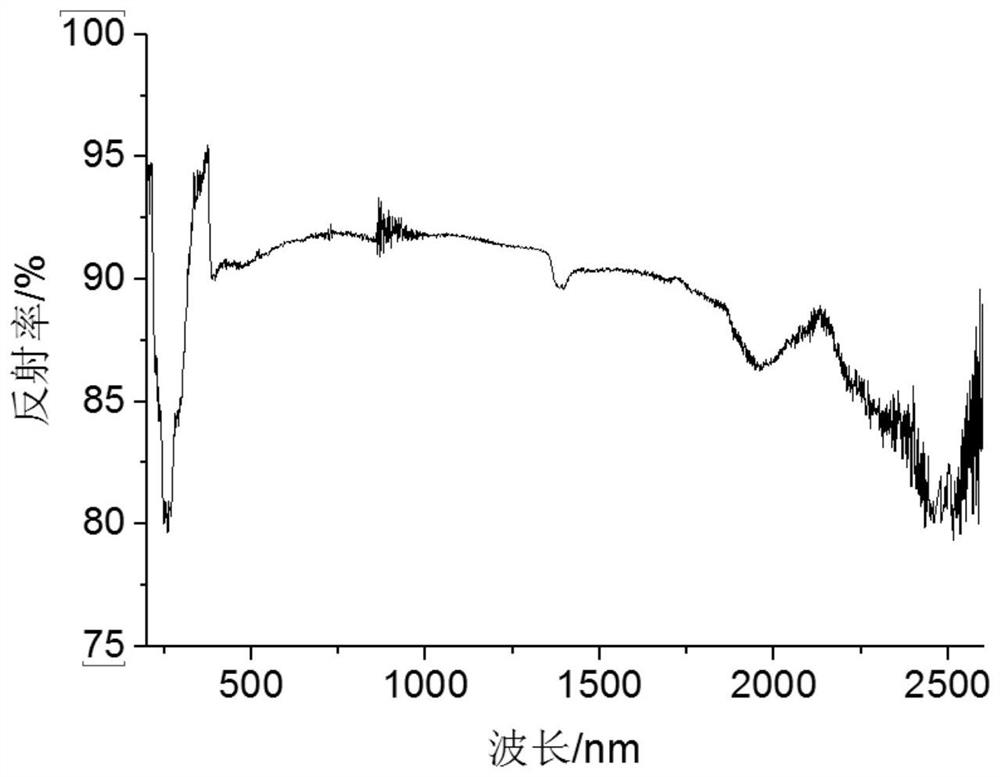

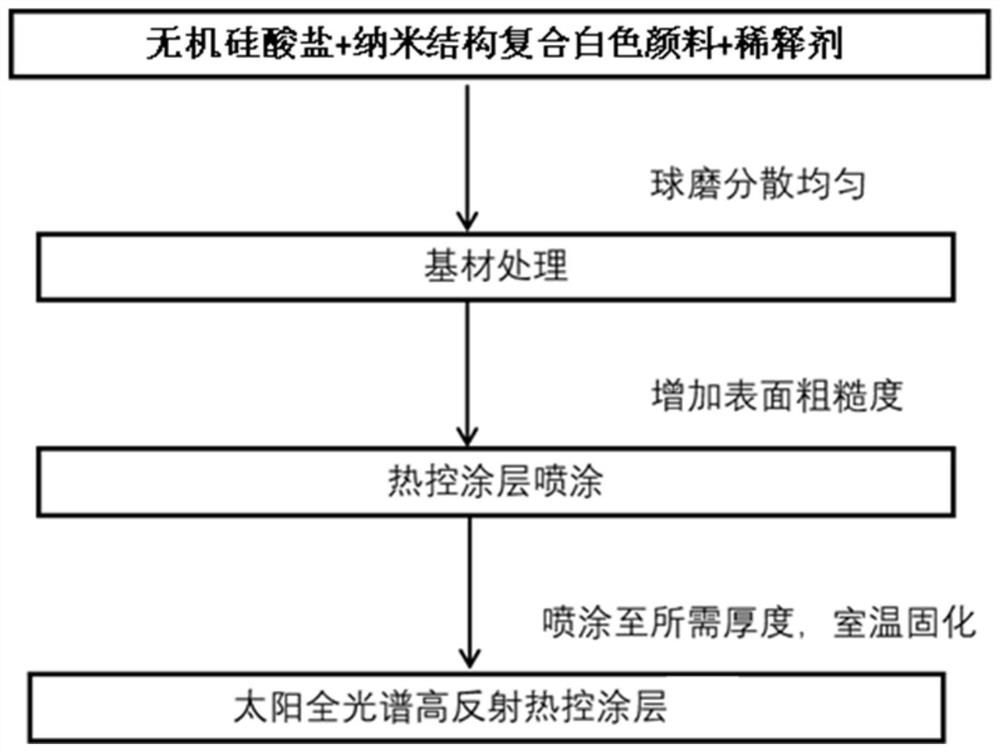

Pigment, preparation method, thermal control coating containing pigment and preparation method

The invention relates to a pigment, a preparation method, a thermal control coating containing the pigment and a preparation method. MgZnO / SiO2 core-shell nanostructure composite powder is used as the pigment, and after the pigment is mixed with inorganic silicate, a solar full-spectrum high-reflection thermal control coating is prepared. MgZnO is used as a core of the MgZnO / SiO2 core-shell composite powder, and the surface of the MgZnO / SiO2 core-shell composite powder is coated with a SiO2 shell layer, so that the high reflection of the thermal control coating in an ultraviolet band is realized, and meanwhile, the possibility is provided for improving the spatial stability of the coating. Through reasonable formula design and spraying process control, the prepared solar full-spectrum high-reflection thermal control coating is compact in paint film and good in binding force, and the engineering application technical problems that a coated product is rough in surface appearance, prone to powder falling and the like are solved. The bonding force of the thermal control coating and a non-metal base material is improved, good thermal matching of the coating and different types of base materials is achieved, the thermal control requirements of medium and low orbit long-life spacecraft model products are met, and the thermal control coating has potential application prospects in the civil field.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

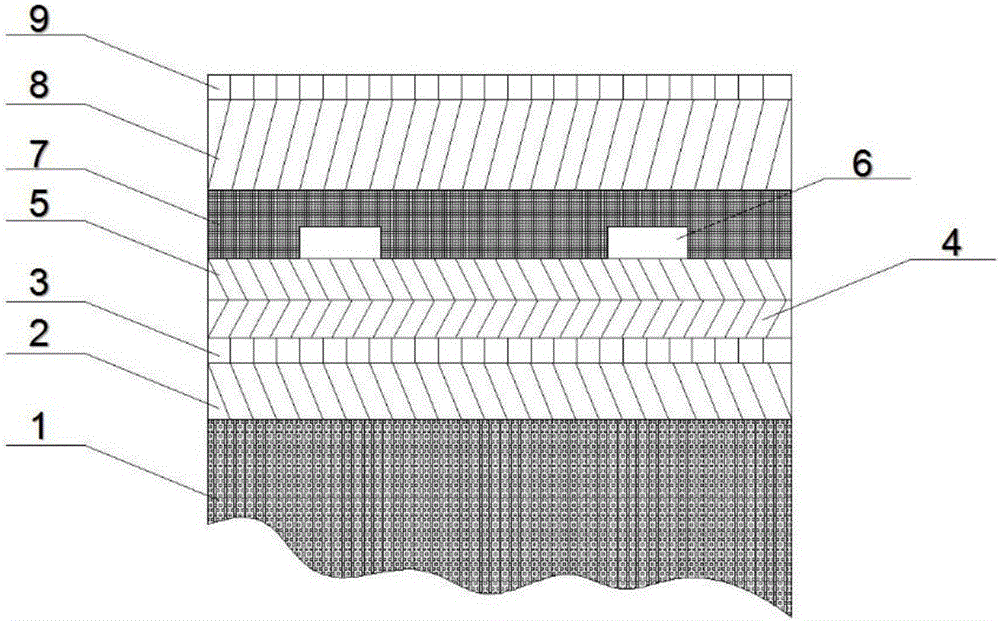

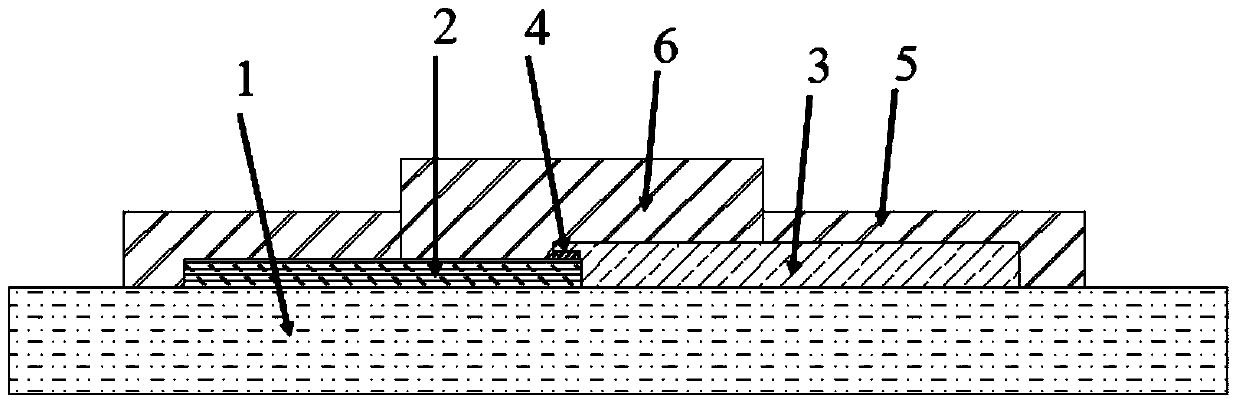

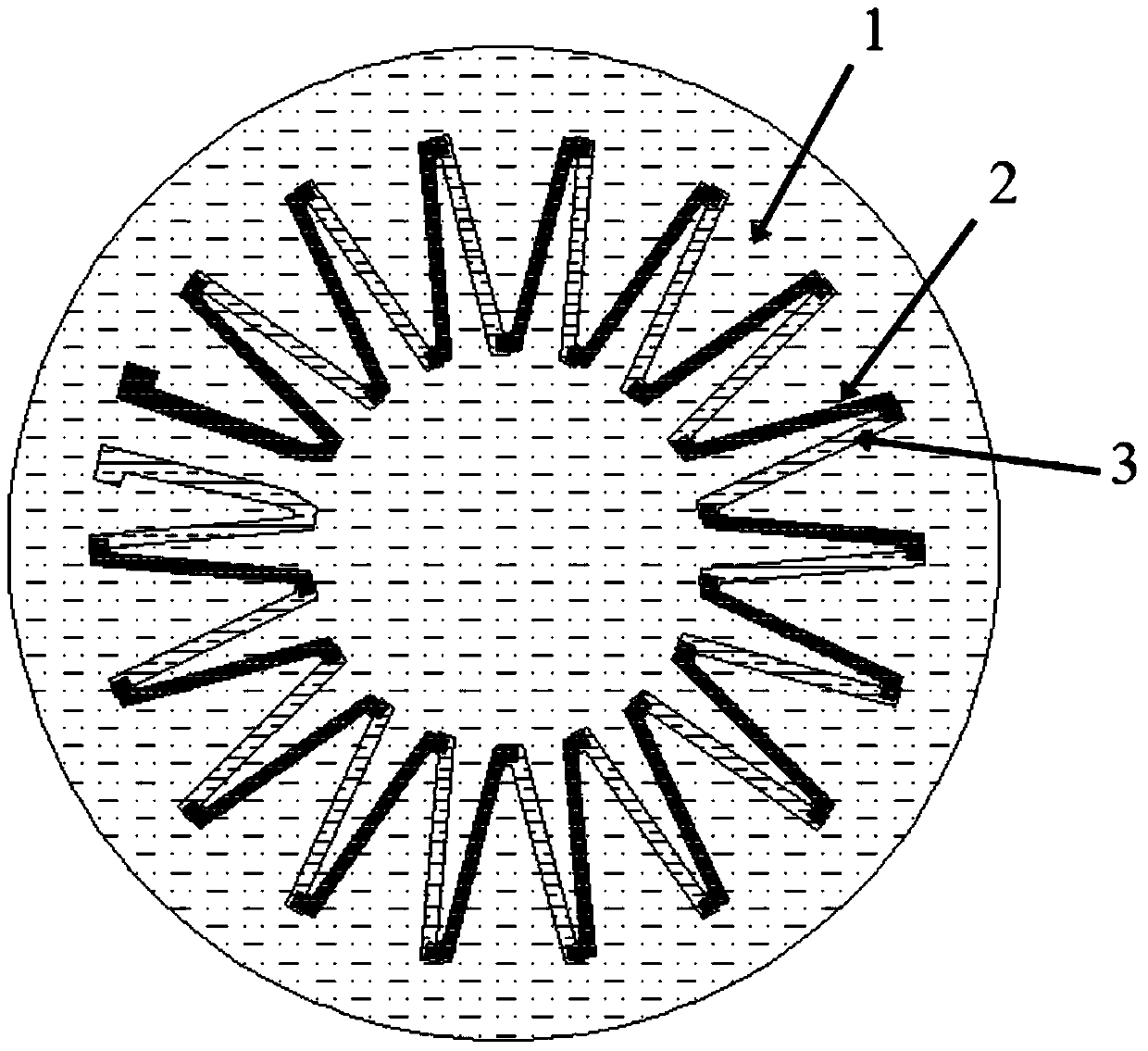

Thermal resistance thin film thermopile type transient heat flow meter and preparation method thereof

ActiveCN106017696BReduce volumeQuick responsePyrometry using electric radation detectorsHeat flowThermopile

The invention provides a thermal resistance-type thin film thermopile-type transient heat flow meter and a manufacturing method. The heat flow meter comprises a ceramic substrate, and a positive thermocouple, a negative thermocouple, a thermocouple connection layer, an outer thermal resistance layer and an inner thermal resistance layer arranged on the ceramic substrate, wherein the positive thermocouple and the negative thermocouple are in butt joint via the thermocouple connection layer; the outer thermal resistance layer and the inner thermal resistance layer cover the positive thermocouple and the negative thermocouple; when an external environment applies heat flow in a vertical direction to the heat flow meter, the outer thermal resistance layer and the inner thermal resistance layer have different thicknesses, the positive thermocouple and the negative thermocouple are connected to form hot and cold junctions, a temperature difference exists between adjacent two hot and cold junctions, corresponding electric potential output exists according to Seebeck effects, and the output electric potential is related to the heat flow density. Transient measurement on the heat flow density can be realized, and the thermal resistance-type thin film thermopile-type transient heat flow meter has the advantages of simple structure, small size, few influences on a measured field, quick response speed, large measurement temperature range and high measurement precision.

Owner:SHANGHAI JIAOTONG UNIV

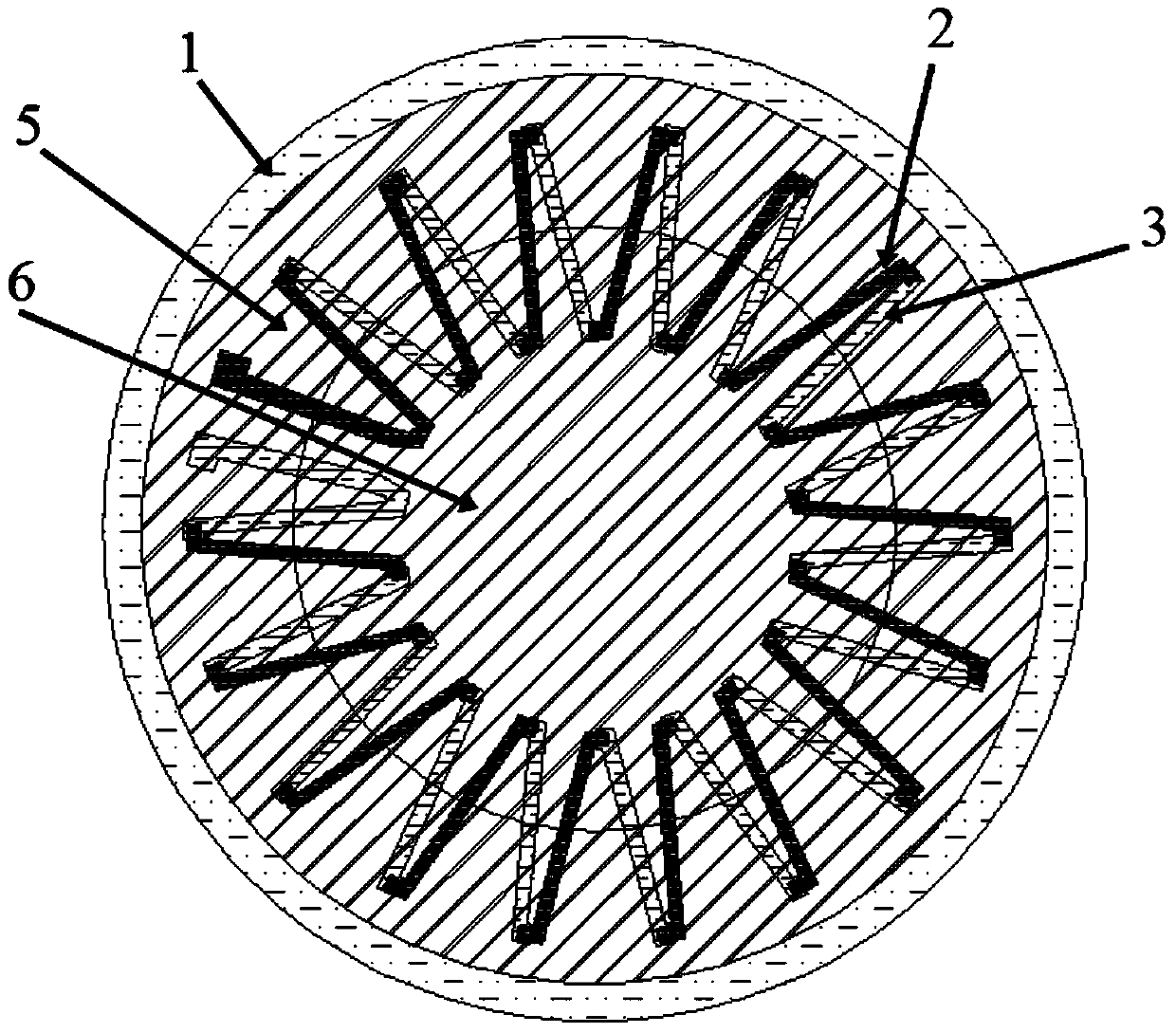

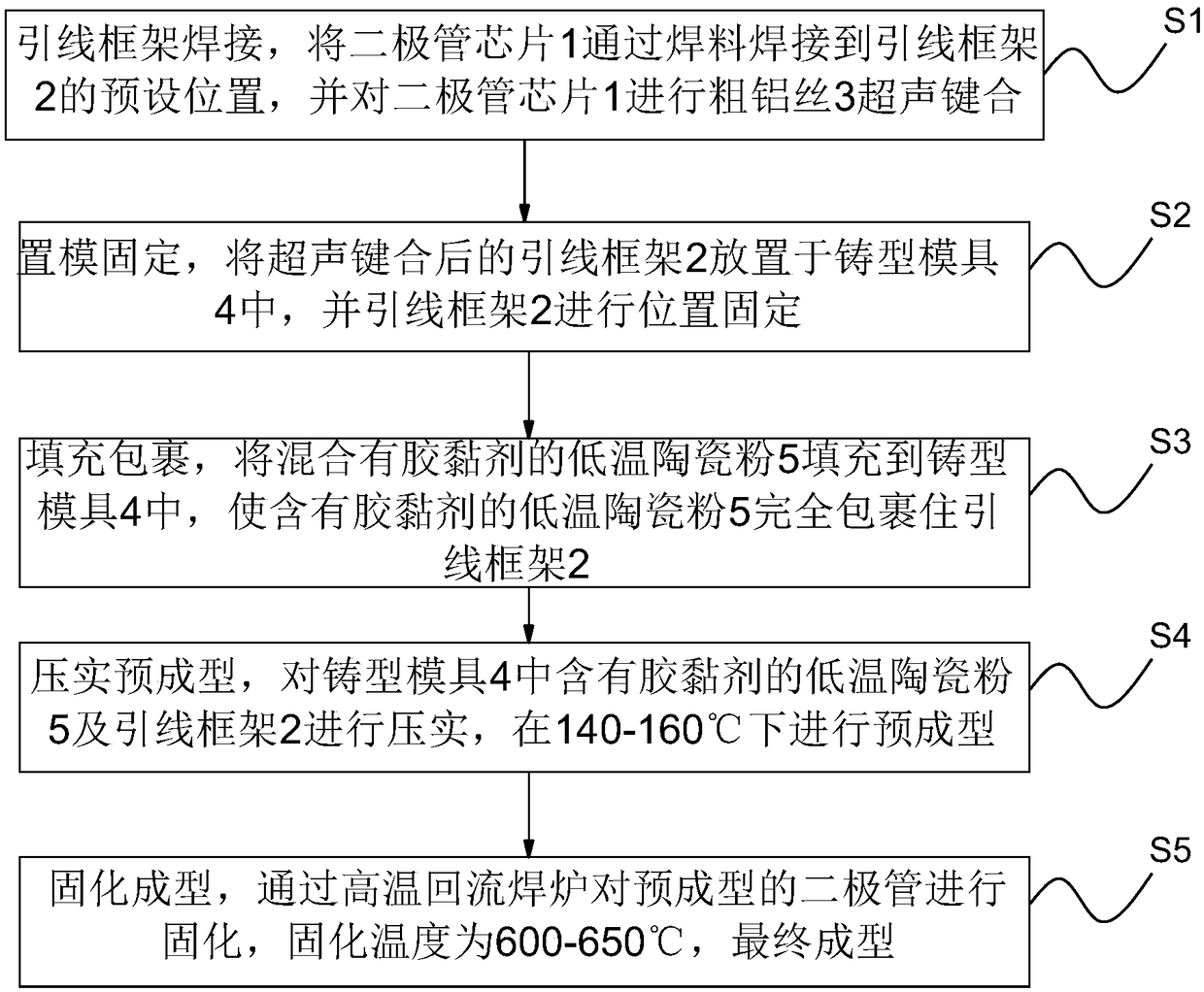

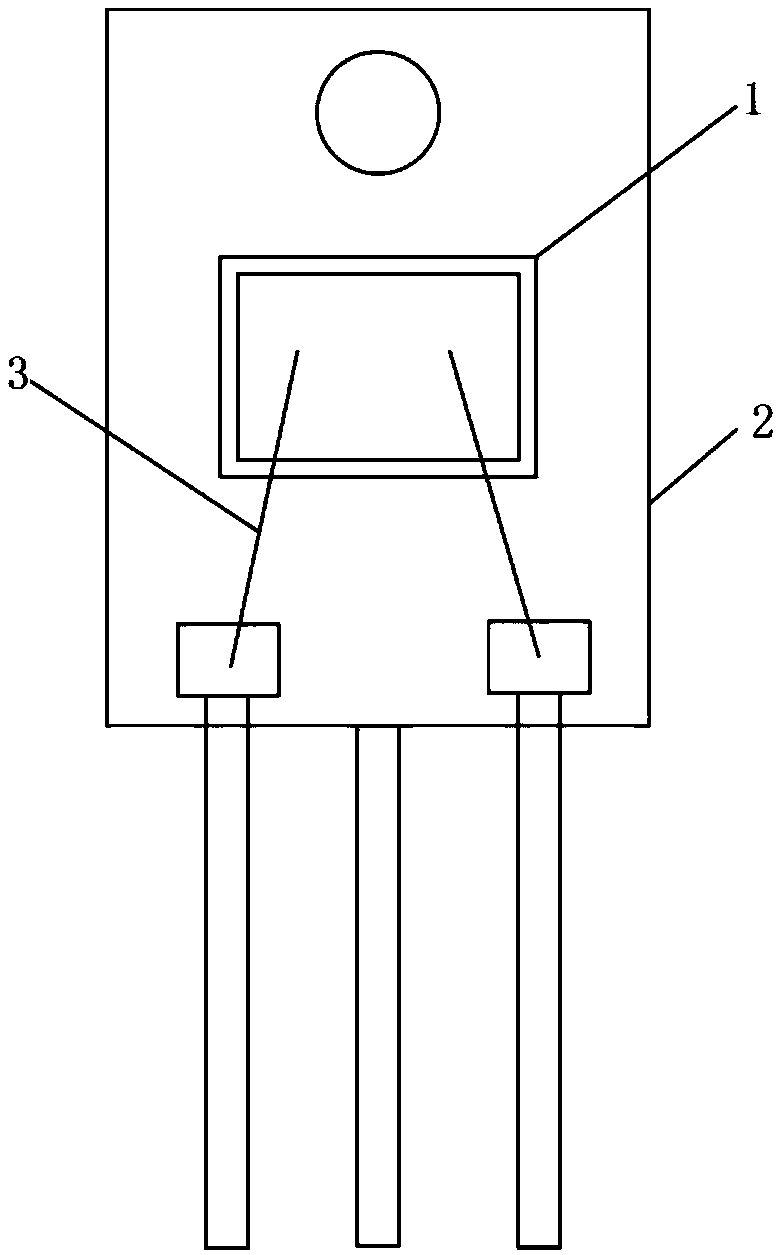

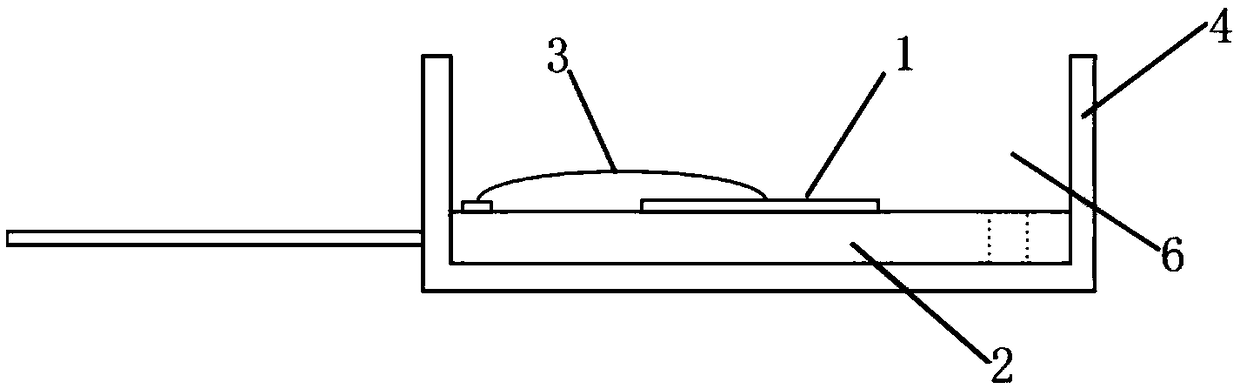

Low-temperature ceramic package process method of diode

InactiveCN108807171AFully filledReduce void rateSemiconductor/solid-state device manufacturingSemiconductor devicesPower flowAdhesive

The invention discloses a low-temperature ceramic package process method of a diode. The low-temperature ceramic package process method comprises the steps of welding a diode chip at a preset positionof a lead frame by a welding material, and performing rough aluminum wire ultrasonic bonding on the diode chip; placing the lead frame in a casting die after ultrasonic bonding, and fixing the position of the lead frame; filling low-temperature ceramic powder mixed with an adhesive in the casting die so that the lead frame is completely wrapped by the low-temperature ceramic powder mixed with theadhesive; compacting the adhesive-containing low-temperature ceramic powder and the lead frame in the casting die, and performing pre-formation under 140-160 DEG C; and curing the pre-formed diode bya high-temperature reflow soldering furnace, and finally forming the diode, wherein the curing temperature is 600-650 DEG C. The processing product can conform to higher temperature application range, is high in cooling ability, can bear larger current and voltage load and has good moisture-resistant and salt mist-resistant capability, and the application requirement of high-end field of new energy, power systems, military projects and the like is met.

Owner:YANTAI TAIXIN ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com