Ceramic substrate planarization manufacturing method

A production method and ceramic substrate technology, applied in the field of ceramic substrate production, can solve the problems of poor uniformity of substrate coating edges, adverse effects on the health of production personnel, poor coating uniformity, etc., and achieve controllable glaze layer thickness and fluidity Good, improve flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

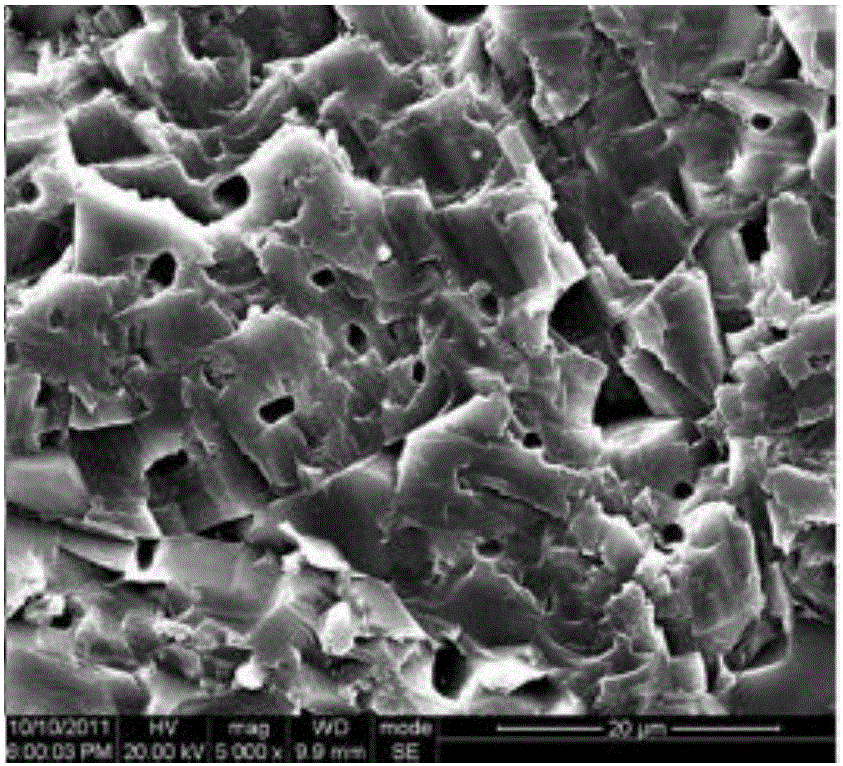

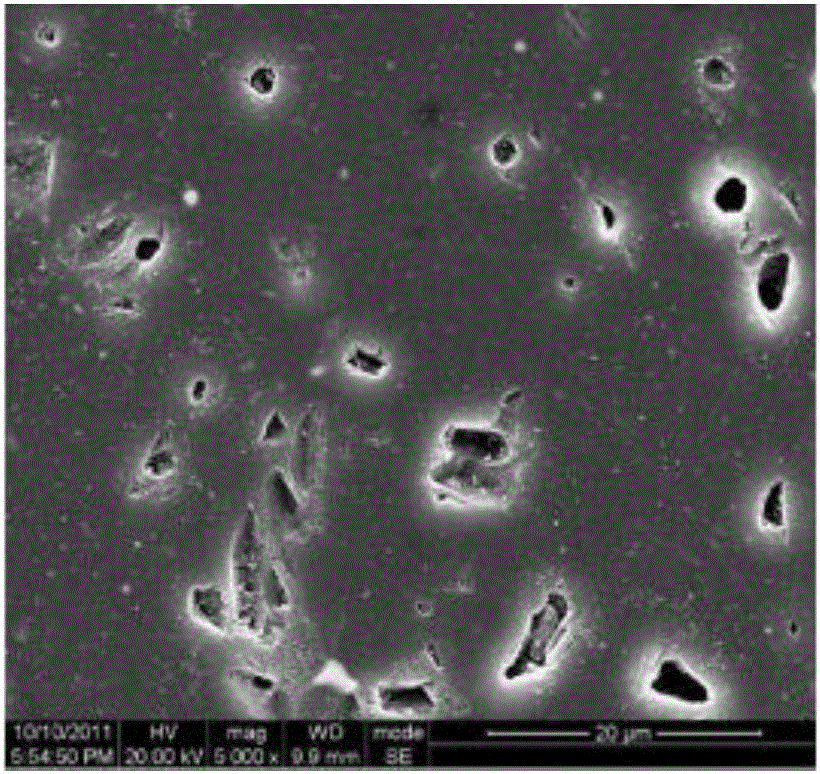

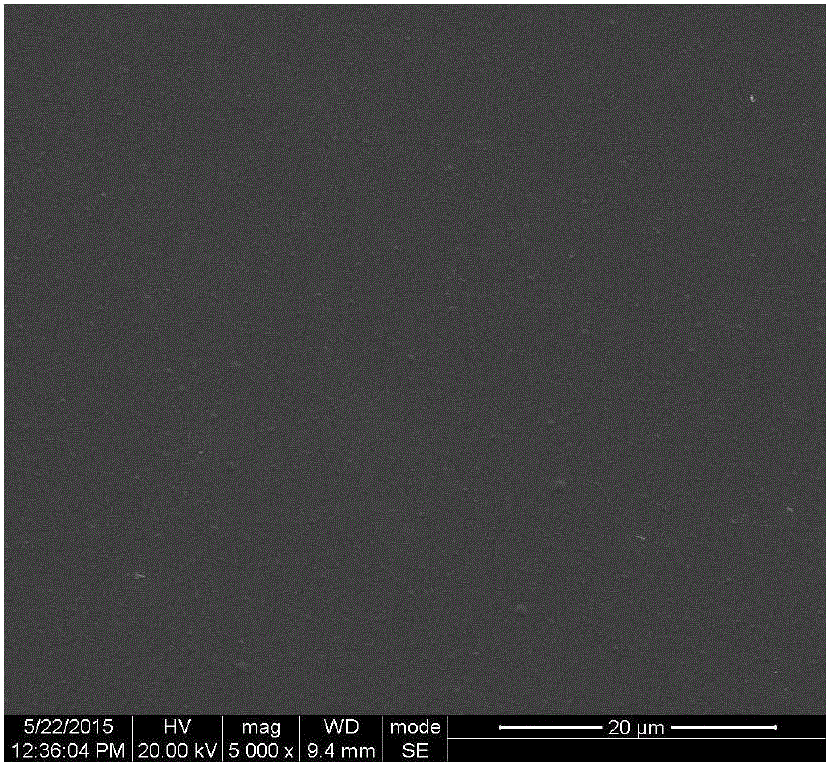

Image

Examples

Embodiment 1

[0023] (1) the mass percent SiO 2 41%, Al 2 o 3 13%, CaO17%, MgO4%, BaO10%, Na 2 O8% and K 2 O7% mixed evenly, ball milled for 24 hours.

[0024] (2) Dried in an oven, melted in a high-temperature electric furnace at 1390 degrees to a clear state, kept at the highest temperature for 15 minutes, and then quenched with deionized water.

[0025] (3) Grind the quenched glass clinker to the size of salt particles, and then ball mill for 72 hours.

[0026] (4) Sieve through a 300-mesh sieve, and then mix with the organic carrier at a mass percentage of 1:1. The organic carrier consists of 110ml terpineol, 2g hydrogenated castor oil, 8g ethyl cellulose, and 30ml dimethyl phthalate and 2g of Tween 80 were uniformly mixed, and stirred in an 85°C water bath atmosphere for 8 hours to form a slurry.

[0027] (5) Using the screen printing method, a 300-mesh screen plate was used to print three times on the surface of the substrate to obtain a glaze with a thickness of 60 um, and sint...

Embodiment 2

[0029] (1) the mass percent SiO 2 62%, Al 2 o 3 13%, CaO11%, MgO4%, BaO4%, Na 2 O2% and K 2 O4% mixed evenly, ball milled for 24 hours.

[0030] (2) Dried in an oven, melted in a high-temperature electric furnace at 1450°C to a clear state, kept at the highest temperature for 30 minutes, and then quenched with deionized water.

[0031] (3) Grind the quenched glass clinker to the size of salt particles, and then ball mill for 72 hours.

[0032] (4) Sieve through a 300-mesh sieve, and then mix with the organic carrier at a mass percentage of 1:1. The organic carrier consists of 110ml terpineol, 2g hydrogenated castor oil, 8g ethyl cellulose, and 30ml dimethyl phthalate Esters and 2g of Tween 80 were evenly mixed, and stirred in an 85°C water bath atmosphere for 8 hours to make a slurry.

[0033] (5) Using the screen printing method, a 300-mesh screen plate was used to print three times on the surface of the substrate to obtain a glaze with a thickness of 60 um, and sintere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com