Patents

Literature

101results about How to "No pinholes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical deplating solution and deplating method suitable for removing tin-nickel coating on surface of brass

InactiveCN101775601AImprove the status quo of low dissolution rateImprove work efficiencyWater bathsTin

The invention discloses a deplating solution and a deplating method thereof for tin-nickel coating (commonly called plated scrap) on the surface of brass. The deplating solution comprises oxidizer, accelerator, complexing agent and inhibitor, and the deplating solution is prepared by adding water to the reagents, stirring, dissolving, then putting in a water bath and slowly heating. The oxidizer adopts 65-68% nitric acid, the accelerator adopts 36-38% hydrochloric acid, the complexing agent adopts citric acid and the inhibitor adopts benzotriazole. After being deplated by the deplating solution of the invention, the surface of the brass is bright, the color of the substrate is basically unchanged, and the brass has no pinholes and small corrosion amount.

Owner:HEFEI UNIV OF TECH

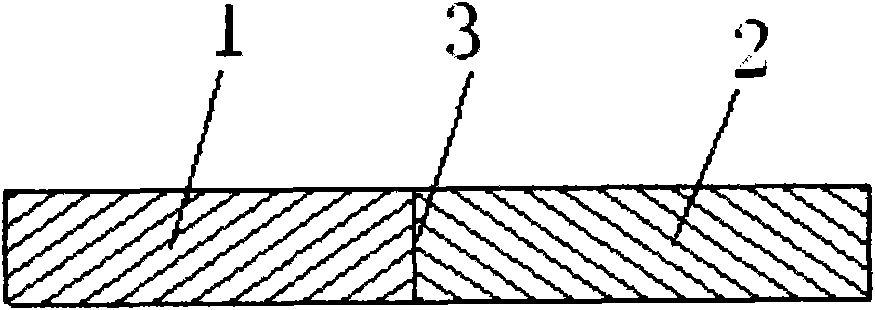

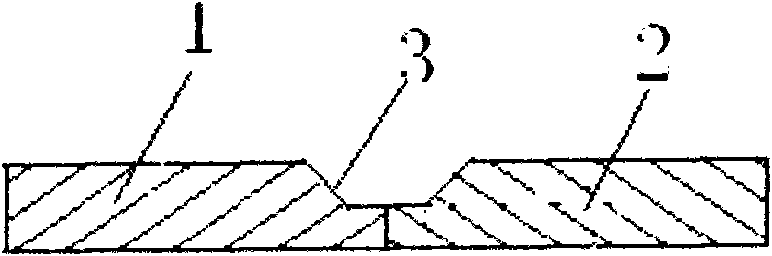

Automatic TIG gasket-free single-side welding and double-side molding process for aluminum alloy

InactiveCN102079003AReduce distortionImprove welding qualityArc welding apparatusWorkpiece edge portionsUltimate tensile strengthStainless steel wire

The invention discloses an automatic tungsten inert gas (TIG) gasket-free single-side welding and double-side molding process for aluminum alloy, which comprises the following steps of: selecting welding equipment and materials, performing assembly and clearing, performing tack welding, clearing grease dirt and oxide films in 50 millimeters of two sides of a groove by using acetone and a stainless steel wire wheel, placing a shell on a welding operation rack, regulating a welding gun to be aligned with the groove, preheating, welding a first layer without adding welding wires, clearing the oxide film on the surface of the seam by using the stainless steel wire wheel after the first layer is welded to expose metal luster, welding a second layer, adding the welding wires for covering the surface, and making the welding direction of the welding gun and a cylinder swing vertically to form a seam. The process has the advantages of high efficiency, low labor intensity, high welding quality, attractive appearance, no undercut or arc crater cracks, workpiece deformation resistance and high seam qualification rate.

Owner:陕西国德电气制造有限公司

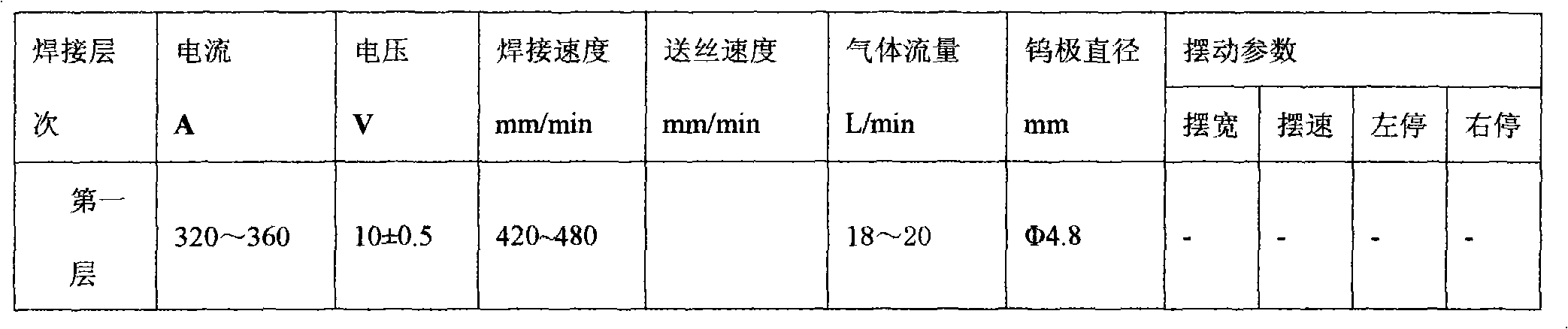

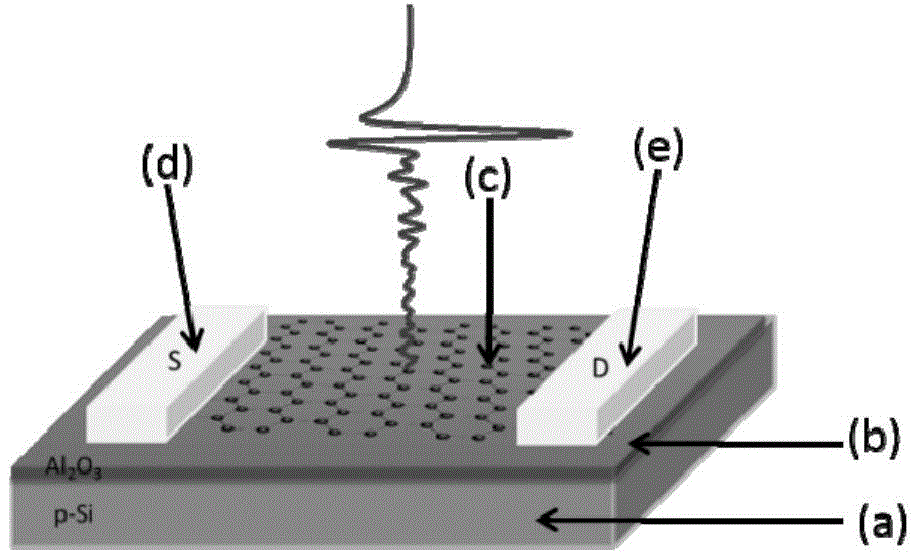

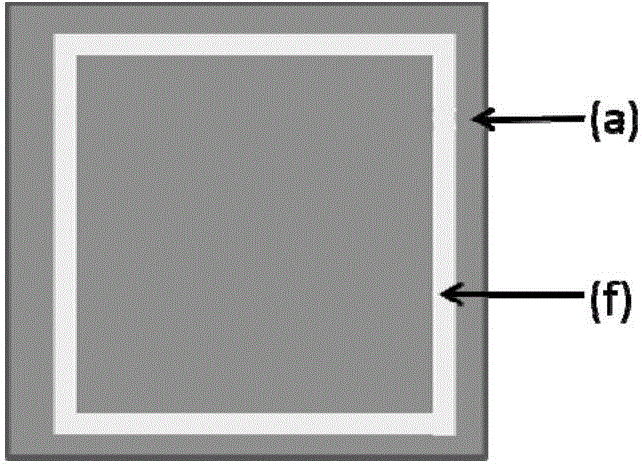

Graphene field effect transistor terahertz wave modulator and manufacture method thereof

InactiveCN104678597AReduce thicknessReduce leakage currentNon-linear opticsCommunications systemGrating

The invention provides a graphene field effect transistor terahertz wave modulator and a manufacture method thereof and aims to increase the modulating speed and depth of the graphene field effect transistor terahertz wave modulator. The graphene field effect transistor terahertz wave modulator comprises a semiconductor substrate, and a medium layer, a graphene film and source and drain electrodes which are arranged on the substrate, and an annular grating electrode which is arranged on the back of the substrate. The terahertz wave modulator is characterized in that the medium layer is an Al2O3 layer, and the thickness ranges from 5 to 100nm; the Al2O3 is deposited by the ALD (atomic layer deposition) method, and the Al2O3 is high in evenness, is free of defects and pores and has better voltage resistance; the leakage current is reduced greatly. The modulating speed of the terahertz wave modulator can be 178 KHz, the corresponded modulating depth is larger than 22%, and the modulating speed and depth are increased significantly; the terahertz wave modulator can be widely applied to the fields of terahertz wave communication systems, terahertz wave detection and terahertz wave imaging.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its prepn

InactiveCN1887996AImprove physicsGood chemical propertiesInorganic pigment treatmentAnti-corrosive paintsEpoxyHigh intensity

The present invention discloses one kind of heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its preparation process. The anticorrosive paint consists of primer, finishing paint and intercoat paint. The primer consists of polyphenylene sulfide, epoxy resin, glass scale and cyanamide dimmer. The finishing paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, 4, 4'-diamino diphenyl sulphone and cyanamide dimmer. The intercoat paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, glass scale, dihydrazide sebacate and 4, 4'-diamino diphenyl sulphone. The anticorrosive paint produces no sag, and can form homogeneous and smooth coating with excellent physical and chemical performance, high heat resistance, high corrosion resistance, high impact strength, and high insulating performance.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

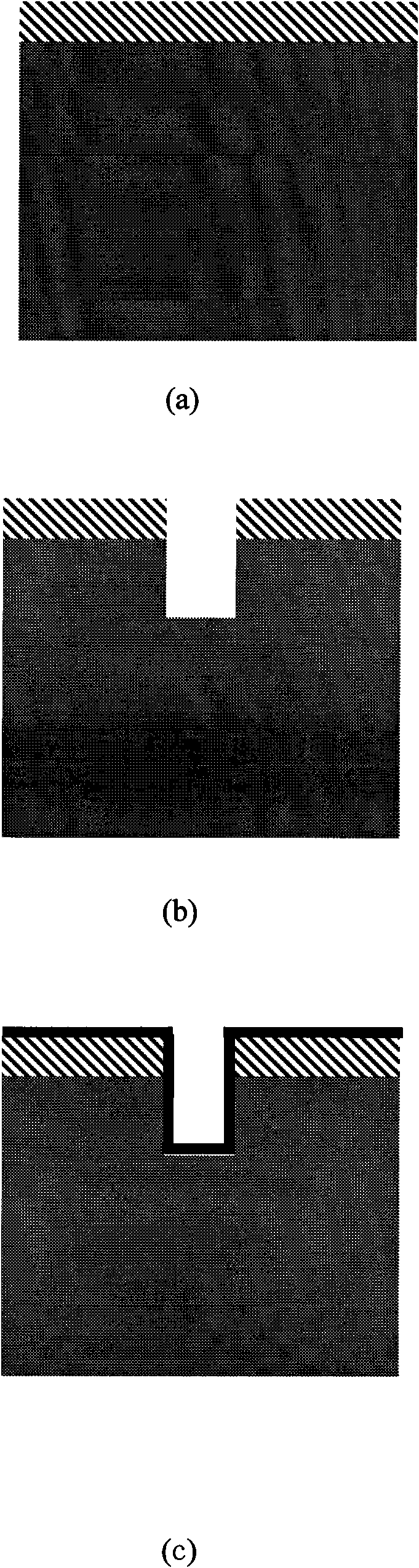

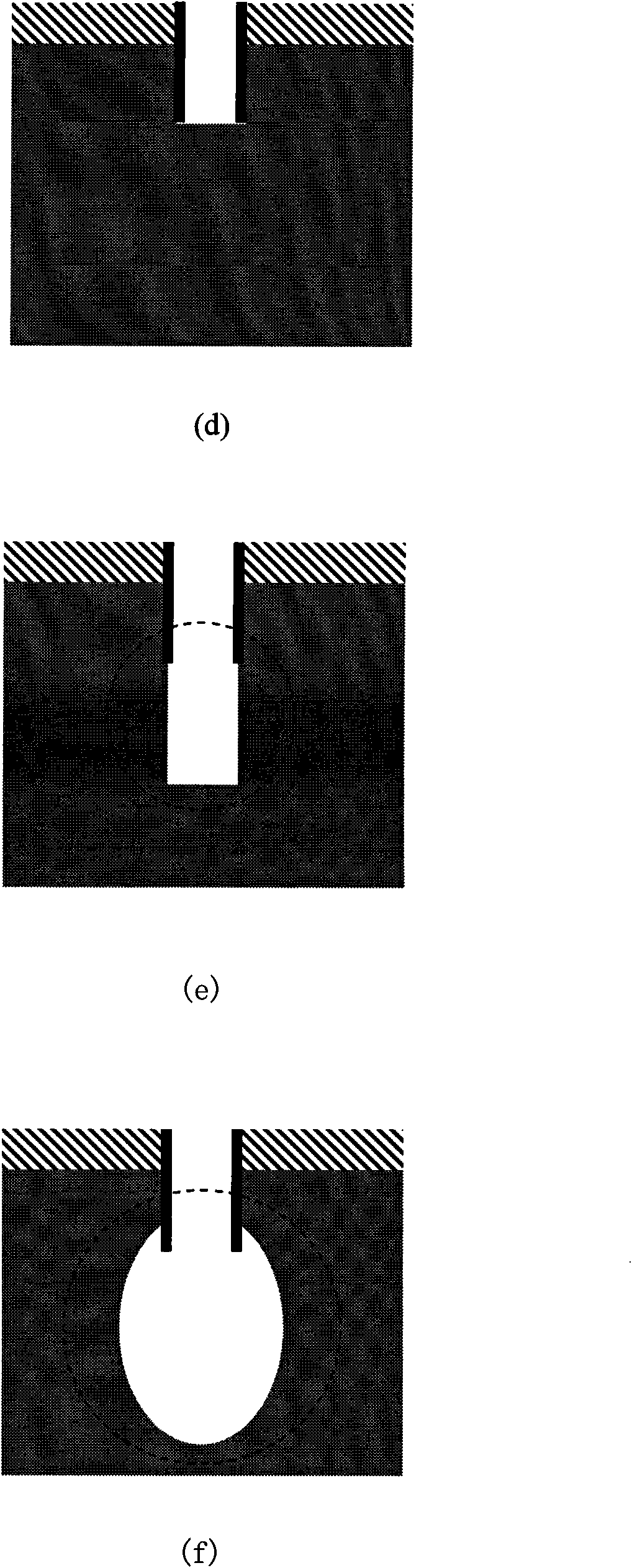

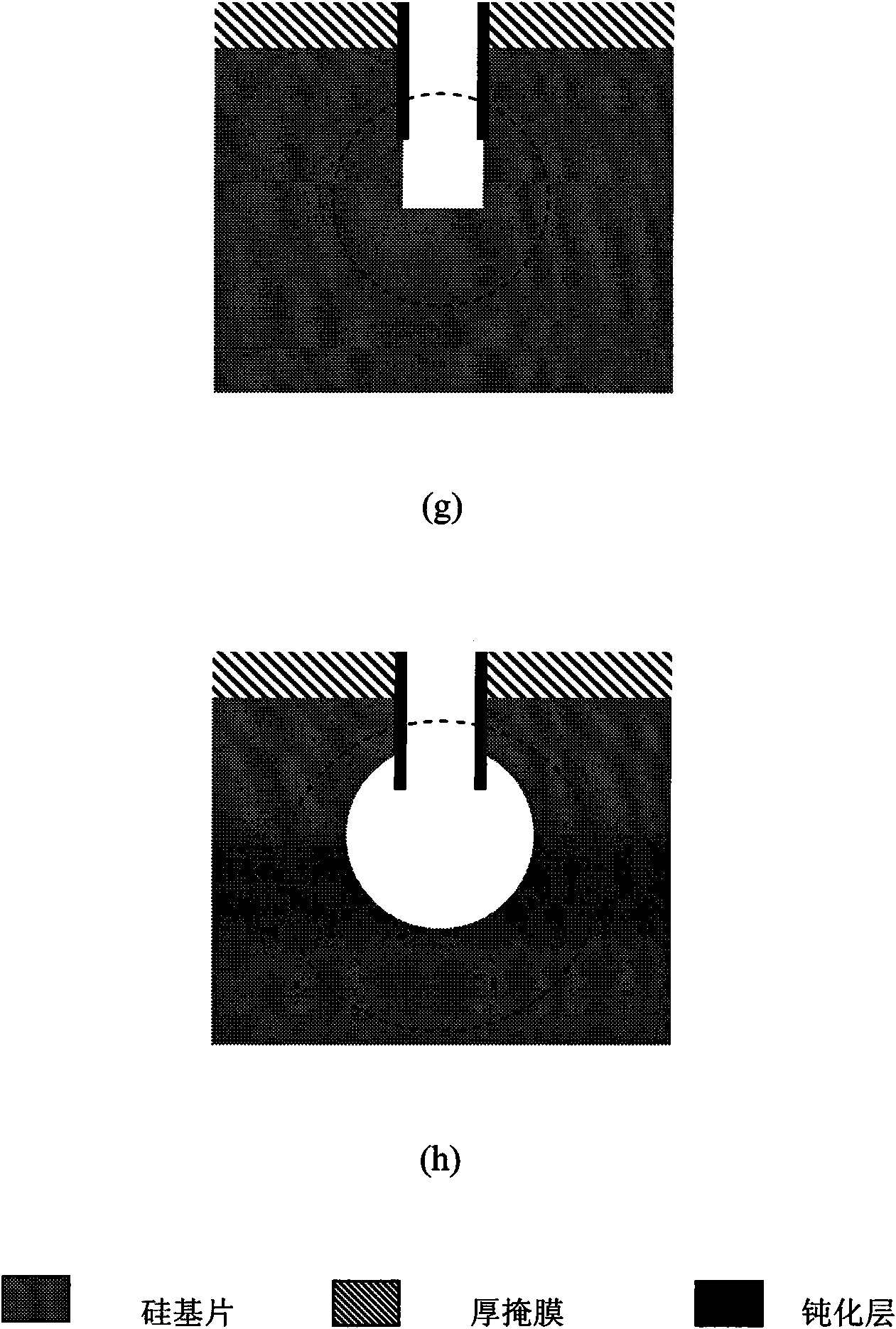

Method for preparing masking microstructure

InactiveCN101559916AImprove protectionOptimize passivation processDecorative surface effectsChemical vapor deposition coatingSilicon dioxideIsotropic etching

The invention discloses a method for preparing a masking microstructure, and belongs to the technical field of microelectronic mechanical systems. The method comprises the following steps: preparing a silicon dioxide mask of which thickness is 1 to 2mu m on the surface of a silicon substrate, patterning the mask, and deeply etching silicon to form a micro-groove or micro-opening structure; carrying out surface passivation for the micro-groove or micro-opening structure; removing a bottom passivation layer of the micro-groove or micro-opening structure by etching, and pre-etching the bottom of the micro-groove or micro-opening structure; next, continuously carrying out isotropic etching to form a microstructure; then, removing the mask on the surface of the silicon substrate and the passivation layer on the side wall of the micro-groove or micro-opening structure; and backfilling the microstructure to form the masking microstructure. The method uses the thick mask to well protect the surface of the silicon substrate so as to avoid the phenomenon of pinholes and under etching. Because the isotropic etching of the masking microstructure is carried out after the pre-etching, the section shape of the masking microstructure can be controlled, the complex process parameter adjustment is avoided, and the dependency on precision etching equipment is also avoided.

Owner:PEKING UNIV

Sulfamic acid nickel plating solution and method

The invention relates to a nickel sulfamate electroplating solution which comprises nickel sulfamate, boric acid and nickelous chloride. A formed nickel-plated layer which has favorable stability and is continuous and complete without pinholes, bubble shedding and residual stress is formed after a metal surface is plated by the electroplating solution. The smoothness and the brightness of the obtained plated layer are improved after a certain amount of brightener is added to the electroplating solution so that the metal surface is smoother and more attractive.

Owner:嘉兴中科亚美合金技术有限责任公司

Sulfate trivalent-chromium chromeplate electroplating solution and application method thereof

The invention provides a sulfate trivalent-chromium chromeplate electroplating solution and an application method thereof. Amine compounds and organic compounds containing nitrogen, sulfur, acetylenicalcohol and the like, which are used as brighteners, are added into a basic electroplating solution containing chromium sulfate and conducting salt; hydroxylamine hydrochloride or ascorbic acid is added for stabilizing trivalent chromium in the electroplating solution, substances such as polyethers and polyalcohols are added as surfactants, and low carbon chain material complexing agents such asoxalic acid, propionic acid, glycine and succinic acid are added for complexing trivalent chromium ions, so that the cathodic reduction of the trivalent chromium complex ions is greatly promoted, andthe tolerance of the electroplating solution to impurities and the stability of the electroplating solution are further improved; the brighteners and the surfactants also can promote the cathodic reduction of the trivalent chromium ions, and appropriate processing parameters are cooperatively set, so that the reaction effects of all components can be greatly improved; the sulfate trivalent-chromium chromeplate electroplating solution can enable plating to have excellent appearance, morphology, structure, binding force and corrosion resistance, and enables the plating not to have surface defects such as pinholes and stripes.

Owner:MINNAN NORMAL UNIV +1

Coten base enamel and glazeslip thereof

The invention relates to coten base enamel and glazeslip thereof. The contents of some ingredients in the chemical component of coten are excessive for production of the enamel and are unbeneficial to the quality of a product; the key for overcoming the adverse factors is to determine suitable special base enamel capable of ensuring the enamel quality and the physicochemical property. The coten base enamel comprises the following components: 57.80-59.30 parts of SiO2, 32.06-2.70 parts of Al2O3, 1.80-2.80 parts of K2O, 10.98-11.35 parts of Na2O, 12.76-16.05 parts of B2O3, 2.80-1.00 parts of Li2O2, 3.80-4.80 parts of CaO, 0.60-1.50 parts of CoO, 1.401-2.00 parts of NiO, 0.20-0.80 part of Fe2O3 and 1.40-2.00 parts of MnO. The coten base enamel is utilized as an acid resistant and anticorrosive coten heat transfer element coating.

Owner:HARBIN TIANLU ENAMEL

Daily use ceramics and preparation method thereof

The invention relates to the field of daily use ceramics, in particular to daily use ceramics and a preparation method thereof, wherein, the blank for the daily use ceramics comprises 7-10wt% Li2O, 30-33wt% Al2O3, and 58-62wt% SiO2; the glaze comprises 48-52% SiO2, 28-31wt% Al2O3, 6-9wt% Li2O, 1-2wt% ZrO2, 2-3wt% P2O5, 2-3wt% TiO2, 0.5-1.5wt% Na2O, 0.5-1.5wt% K2O, 2-4wt% B2O3, and 0.5-1.5wt% PbO;and 4-6 wt% clay is added into the glaze in addition before glazing. Compared with the prior art, the preparation method in the invention, by improving the formulas of the blank and the glaze and thefiring process, allows the water absorption to be changed from 3.5% to less than 15%, meeting the requirement of users, improving the heat preservation of the products, reducing the sintering temperature to about 40 DEG C, and reducing the cost greatly.

Owner:福建省德化县全丰陶瓷有限公司

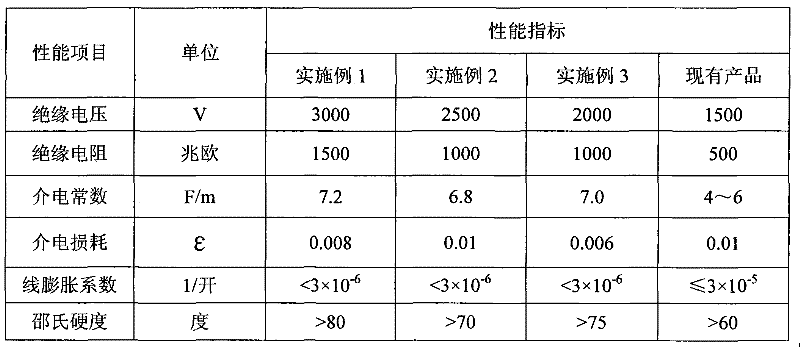

Organic silicon modified phenolic resin encapsulating material and preparation method and usage thereof

InactiveCN102337002ASimple processLess investmentFixed capacitor housing/encapsulationNegative temperature coefficient thermistorsHigh pressureThermistor

The invention discloses an organic silicone modified phenolic resin encapsulating material and a preparation method and usage thereof. The encapsulating material comprises the following components in parts by weight: 15-19 parts of modified phenolic resin, 3-5 parts of titanium white, 1-2 parts of organic silicon, 50-64 parts of silicon micro powder, 5 parts of pigment, 3 parts of thixotropic agent, 5 parts of drying agent and 4-7 parts of curing agent. The preparation method of the encapsulating material comprises the following steps: spraying, extrusion, crushing and ball milling. The encapsulating material has the advantages of high pressure resistance, temperature difference resistance, good insulating property, good moisture proof performance, high mechanical strength, quick natural drying, stable electric property, good adhesion, no cracking before and after curing, no color variation and the like, the production efficiency is increased by 20%, the output rate is improved by 10%, the manufacturing cost is reduced, the encapsulated product has a bright and attractive surface, is green and environment-friendly, and can replace an imported encapsulating material. The organic silicone modified phenolic resin encapsulating material is mainly used for the dipping encapsulation of porcelain medium capacitors, ceramic filters, thermistors and other electronic components.

Owner:LAIZHOU SHUNLIDA ELECTRONICS MATERIAL

Production technology for nodular cast iron pipe lining epoxy ceramic

InactiveCN104728557ANo leakageNo segregationCorrosion preventionPipe protection against corrosion/incrustationCeramic coatingFirming agent

The invention belongs to the field of nodular cast iron pipe corrosion prevention, and particularly relates to a production technology for nodular cast iron pipe lining epoxy ceramic. The production technology comprises the steps that after being preheated, a nodular cast iron pipe metal base body rotates at high speed under the drive of a carrier roller, a coating machine coats the interior of the pipe body with liquid A and liquid B at uniform speed, an antifoaming agent with the weight being 3% of the total weight of the liquid A and the liquid B is added into the liquid A and the liquid B for synchronous coating, and an epoxy ceramic coating layer is formed on the inner surface of the pipe body after cooling and solidification. The liquid A is formed by mixing, by mass, 20-30% of quartz powder and 70-80% of epoxy resin. The liquid B is formed by mixing, by mass, 20-30% of quartz powder and 70-80% of polyamide curing agent. The weight ratio of the liquid A to the liquid B ranges from 1:1 to 1:1.2. By the adoption of the production technology, pin hole and bubble phenomena produced on the surface of epoxy ceramic are avoided, the surface of the epoxy ceramic is smooth and flat, and no electric leakage phenomenon exists through electric spark detection.

Owner:BENGANG STEEL PLATES +1

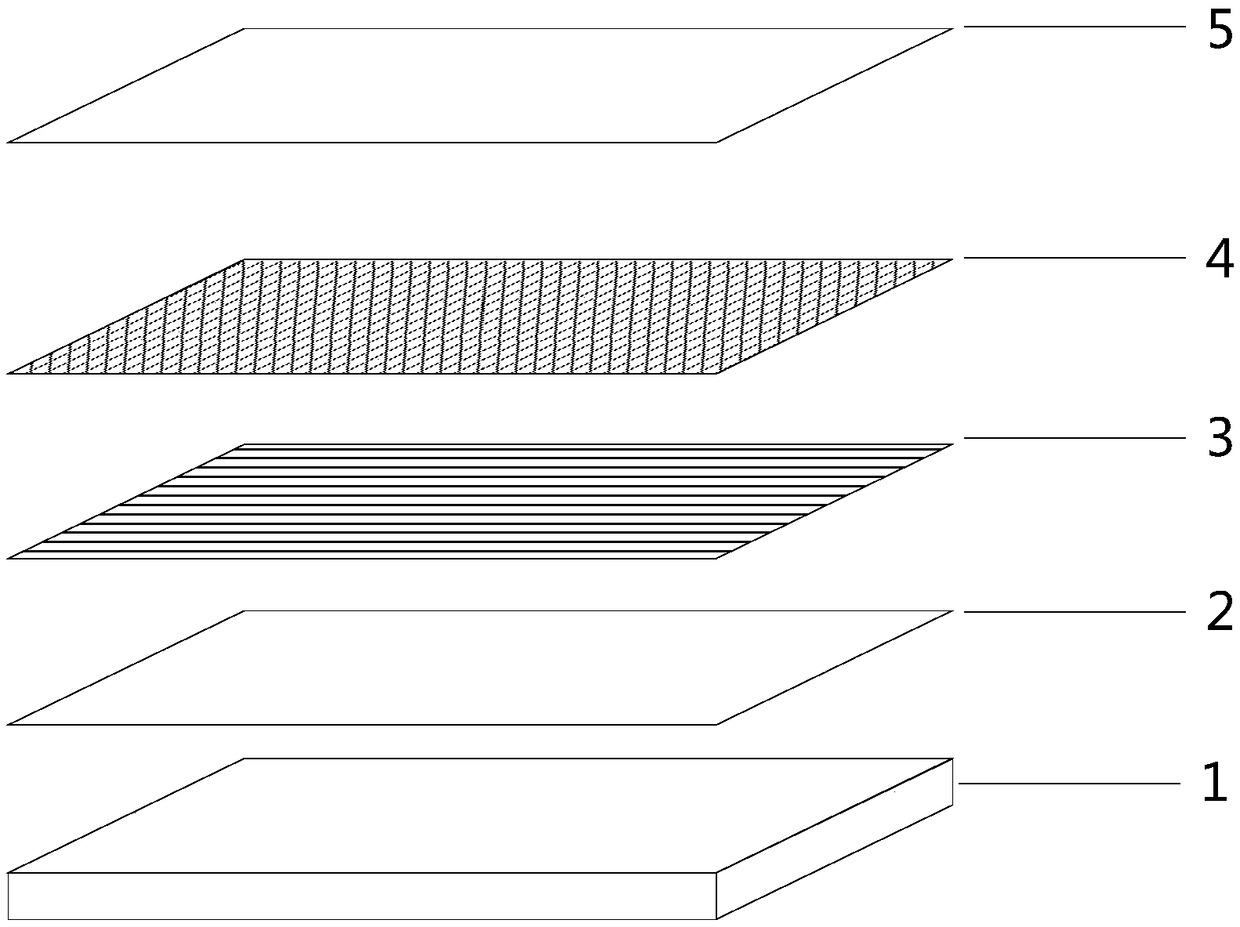

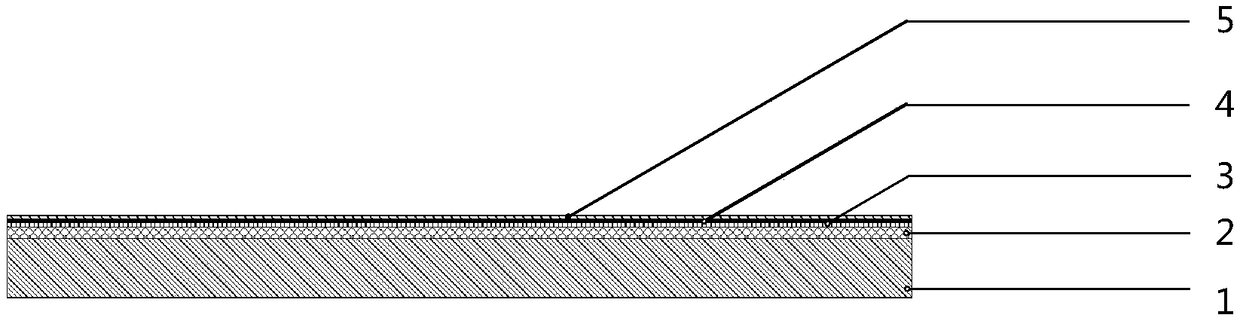

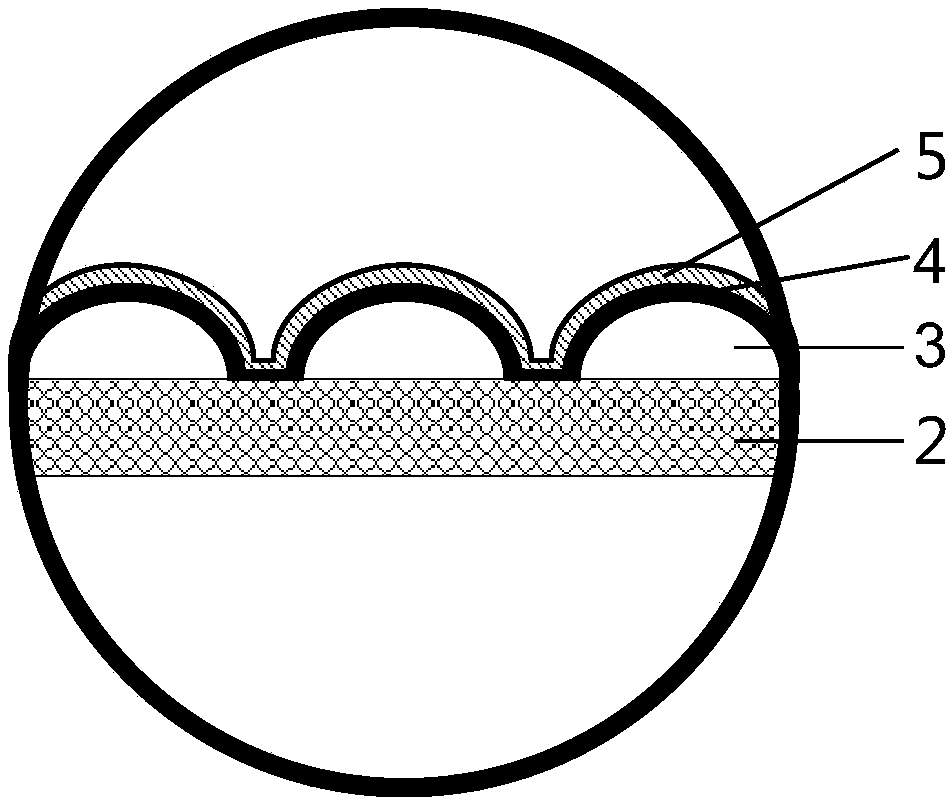

Stereoscopic surface woodgrained ceramic tile, stereoscopic surface woodgrained ceramic tile emboss effect glaze layer and decoration technology

InactiveCN109291723AGood printing performance and firing performanceEasy to operateSpecial ornamental structuresCalciteCeramic glaze

The invention relates to a stereoscopic surface woodgrained ceramic tile, a stereoscopic surface woodgrained ceramic tile emboss effect glaze layer and a decoration technology. The ceramic tile is composed of a green body layer, a cover glaze layer, an emboss effect glaze layer, a pattern decoration layer and a surface protective glaze layer which are sequentially compounded. The stereoscopic surface woodgrained ceramic tile emboss effect glaze layer comprises the following materials including, by weight, 2.5-3 parts of zinc oxide, 20-30 parts of feldspar, 15-20 parts of frit, 10-12 parts of washed kaolin, 8-10 parts of calcite, 8-10 parts of burning talc and 20-30 parts of home-made quartz. The decoration technology comprises the steps that (1) long-strip-shaped green bodies are obtainedby pressing woodgrained brick powder, the surfaces of the green bodies are coated with cover glaze, and formulated emboss effect glaze materials are printed on the surfaces of the green bodies, coatedwith the cover glaze, in a rubber covered roller engraving mode; (2) decoration is performed by means of ink jet patterns, and the ink jet patterns cover the glaze surface and the printed emboss effect glaze on the whole; and (3) the green bodies are coated with clear protective glaze, and then kiln firing is performed.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +3

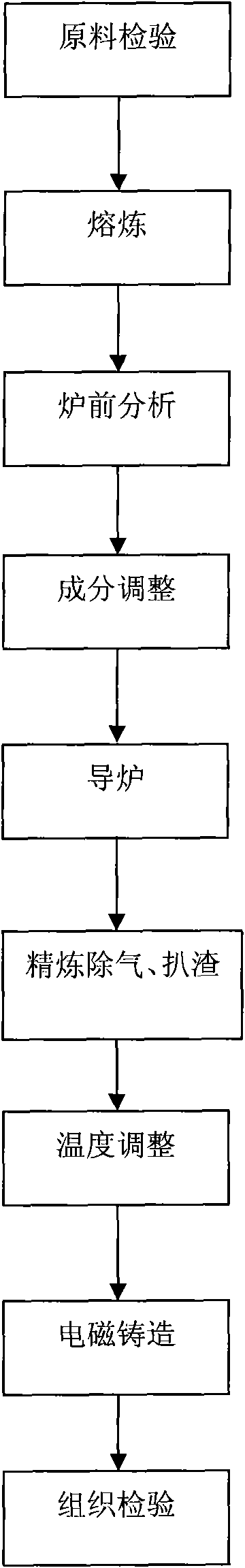

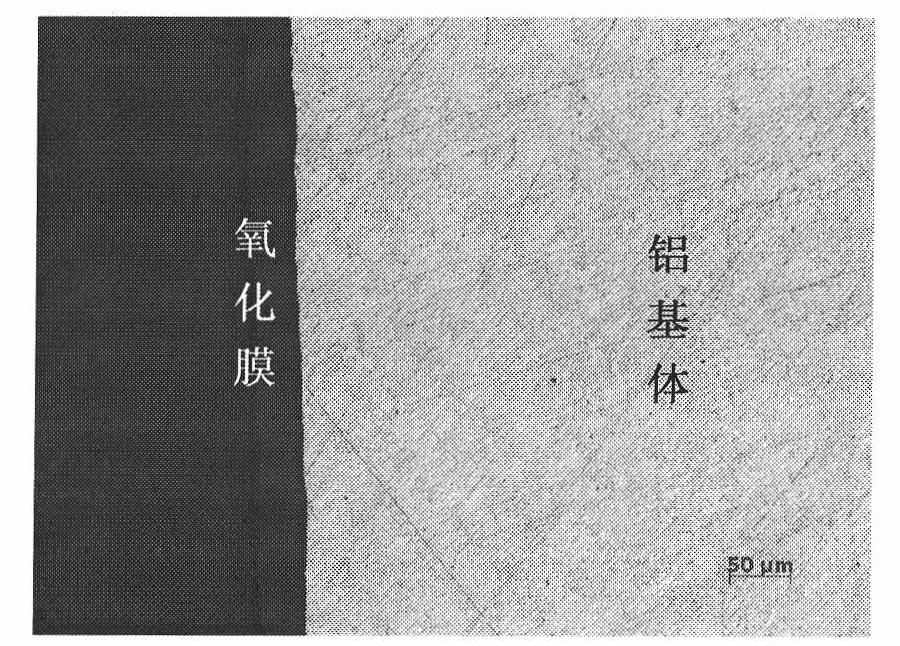

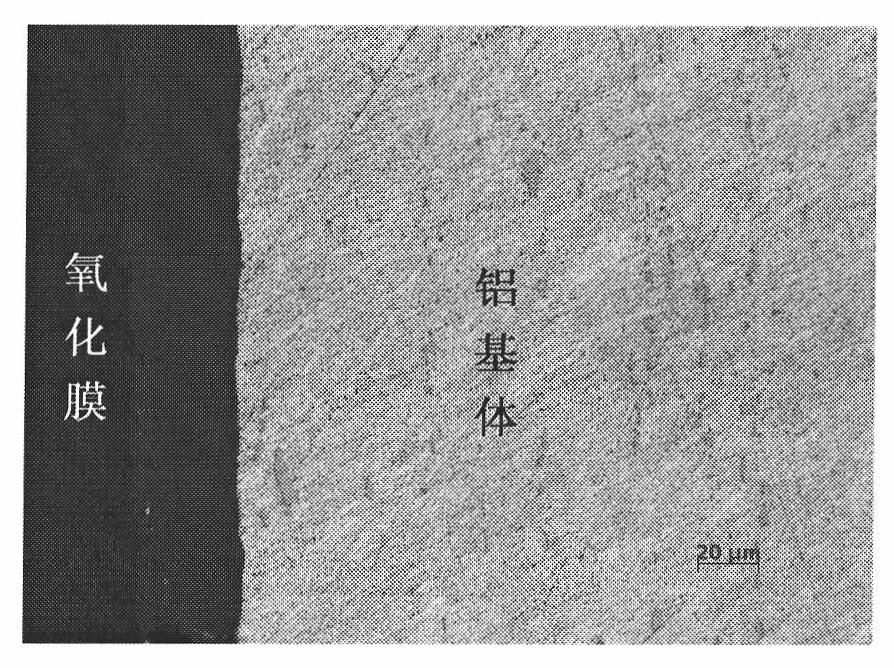

Aluminum alloy for semiconductor equipment and preparation method thereof

The invention relates to an aluminum alloy for semiconductor equipment and a preparation method thereof, and belongs to non-ferrous metal processing technology. The aluminum alloy material for the semiconductor equipment consists of the following components in percentage by weight: 1.00 to 1.20 percent of Mg, 0.58 to 0.75 percent of Si, 1.6 to 1.73 percent of Mg / Si, 0.10 to 0.15 percent of Cu, 0.04 to 0.20 percent of Cr, 0.10 to 0.40 percent of Mn, 0.015 to 0.02 percent of Ti, less than or equal to 0.3 percent of Fe and the balance of Al. The texture of the aluminum alloy material for the semiconductor equipment is improved and becomes uniform by optimizing and controlling alloy elements, and all second-phase precipitates are distributed in crystals with the size of within 5 microns. After the alloy with the components is oxidized, an oxide film is uniform and has good quality without the defects of pinholes and the like.

Owner:GRIMAT ENG INST CO LTD

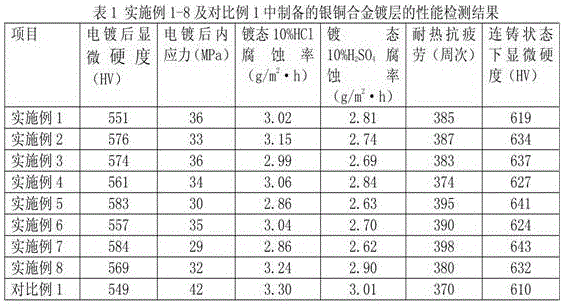

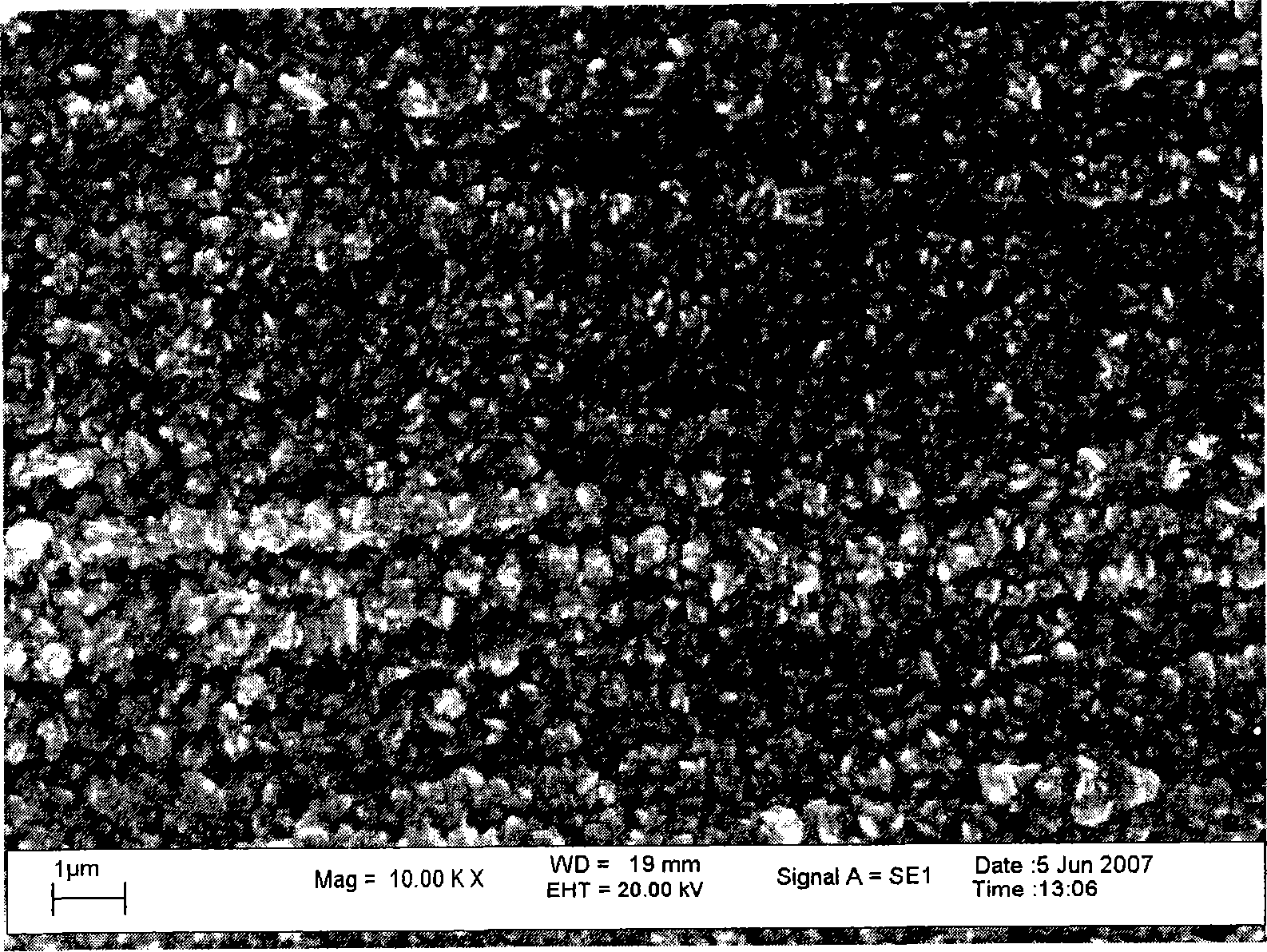

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

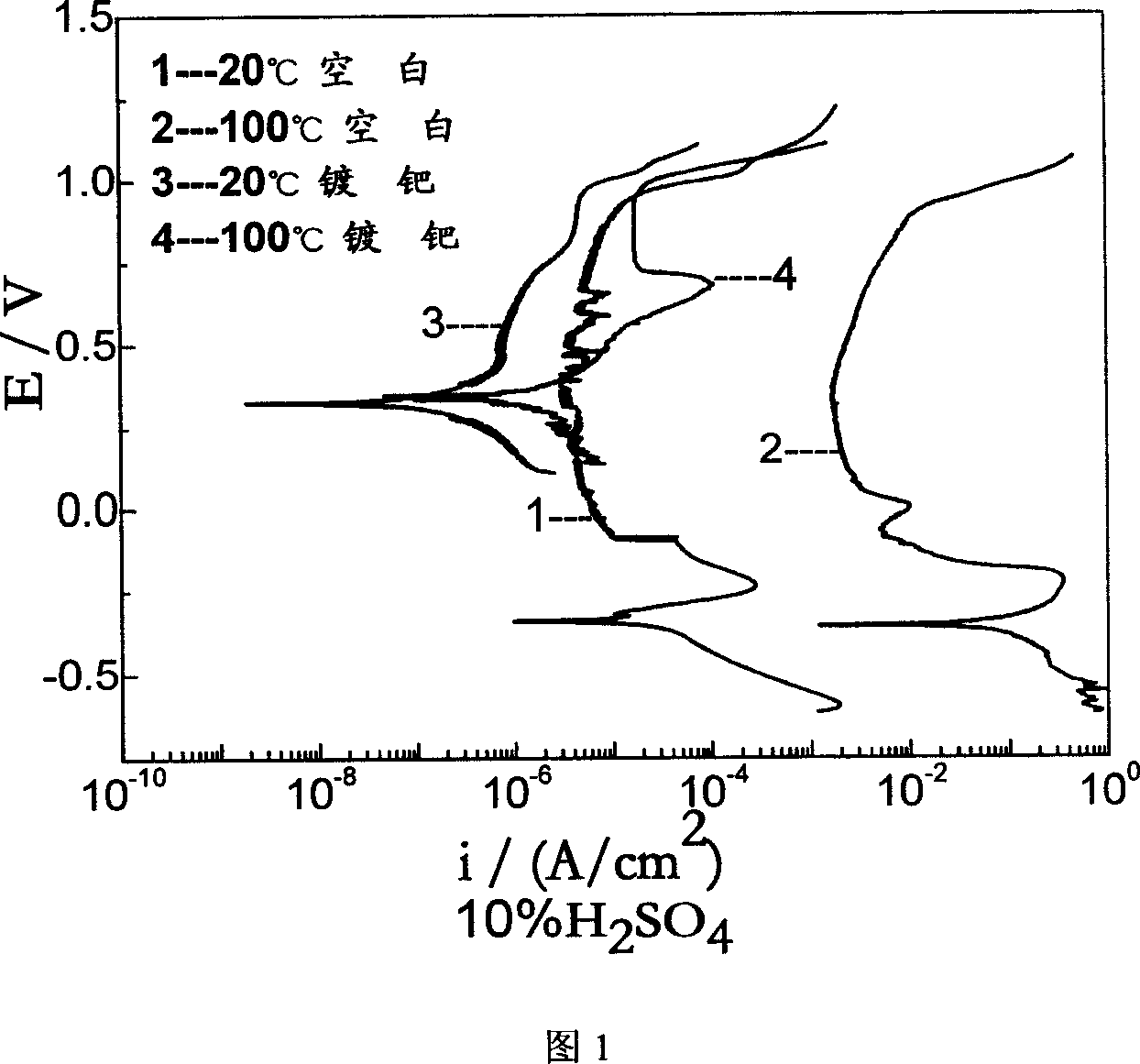

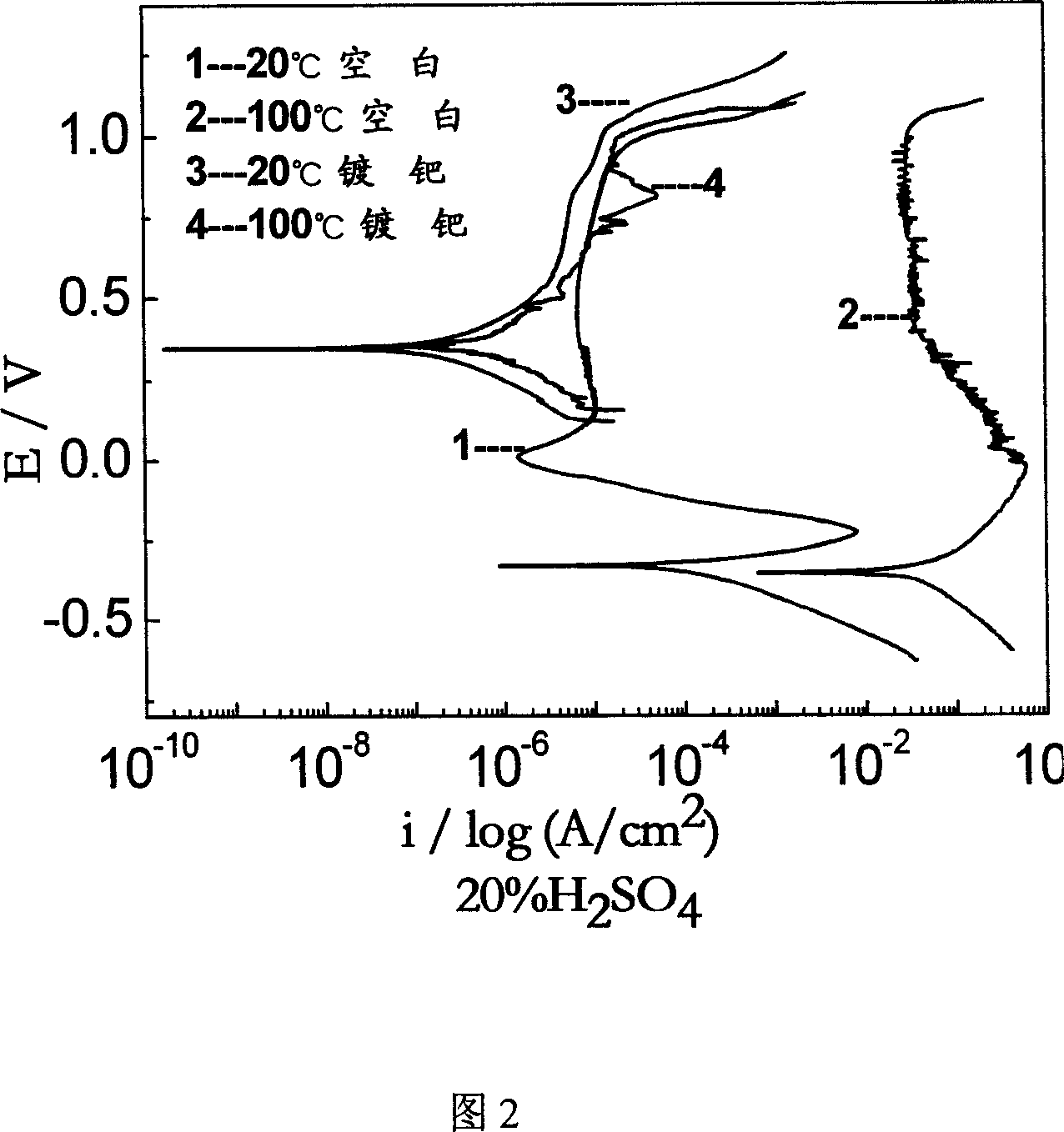

Stainless steel surface large area brush Pd-electroplating process

Disclosed is a large area electric brush palladium plating technique on the surface of stainless steel, which belongs to special electroplating field. The shortcomings of electroless palladium plating are that the electroless palladium plating is unsuitable to plate in large area and unsuitable to construct and repair in the spot. The technique of the invention comprises surface preliminary treatment and electric brush plating steps, which is characterized in that plating solution comprises palladium salt Pd (NH3)4C12. The measure of the plating solution is measured by quality of Pd: 5-12g / L, NH4C1: 50-125G / l, (NH4)2PO4: 50-100g / L, polyoxyethylene sorbitol anhydride single laurate: 0-0.002ml / L, NH3,H2O: 10ml-80ml / L, the left is water, and the pH measure of the water is 7-8. Processing parameter is as follows: voltage: 5V-10V, plating pen is utilized as anode, work piece is utilized as cathode, the speed which the plating pen relates to the work piece is 8-12cm / s, and the temperature is normal temperature. The invention has the advantages of large area plating in the spot, fast speed of plating, simple operation, low cost respectively, and good environmental protection performance, and furthermore the invention can immensely improve anti-corrosion capability of the stainless steel after being plated.

Owner:BEIJING UNIV OF CHEM TECH

Antiskid polyurethane paint and its prepn

InactiveCN1453319ASolve self-leveling problemsShorten drying timePolyurea/polyurethane coatingsSolventTolylene Diisocyanate

The antiskid polyurethane paint is prepared with tolylene diisocyanate, polyether N210, trihydroxymethyl propane, butyl acetate, acetone, dibutyltin dilaurate, benzoyl chloride, antioxidant, 1,2-propylene glycol and water absorbent, and through dewatering butyl acetate, acetone and polyether N210 in reactor at 90-100 deg.c; adding trihydroxymethyl propane into the reactor before heating and stirring to dewater; adding benzoyl chloride, antioxidant and tolylene diisocyanate, heating and adding dibutyltin dilauratel; reflux evaporating solvent butyl acetate or acetone; packing the prepolymer into paint tank; and mixing prepolymer, xylene or butyl acetate or acetone, 1,2-propylene glycol and water absorbent in certain proportion to obtain the paint. The paint has simple preparation process,strong adhesive force, high wear resistance, high weather resistance and other advantages.

Owner:INST OF AQUATIC LIFE ACAD SINICA

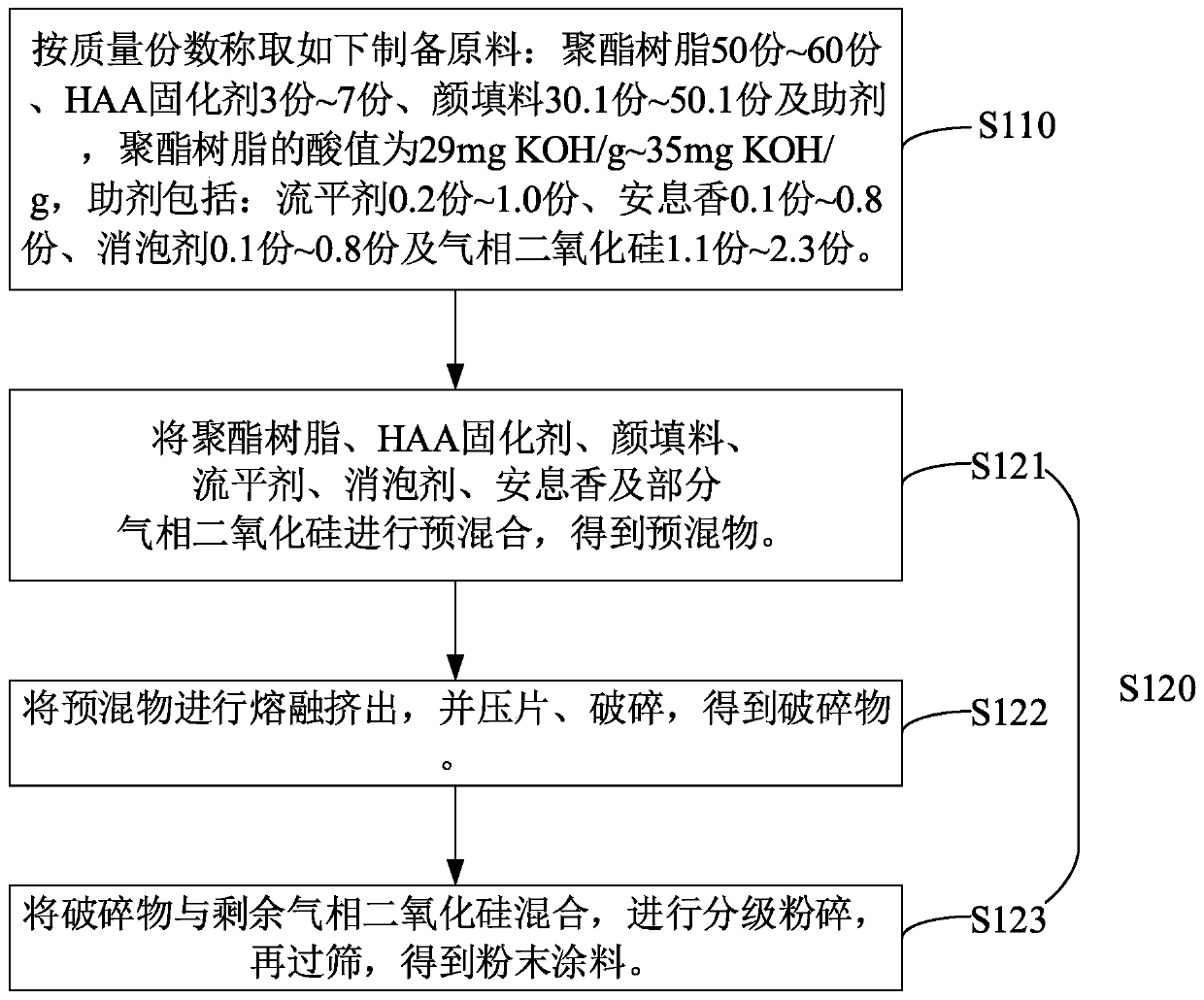

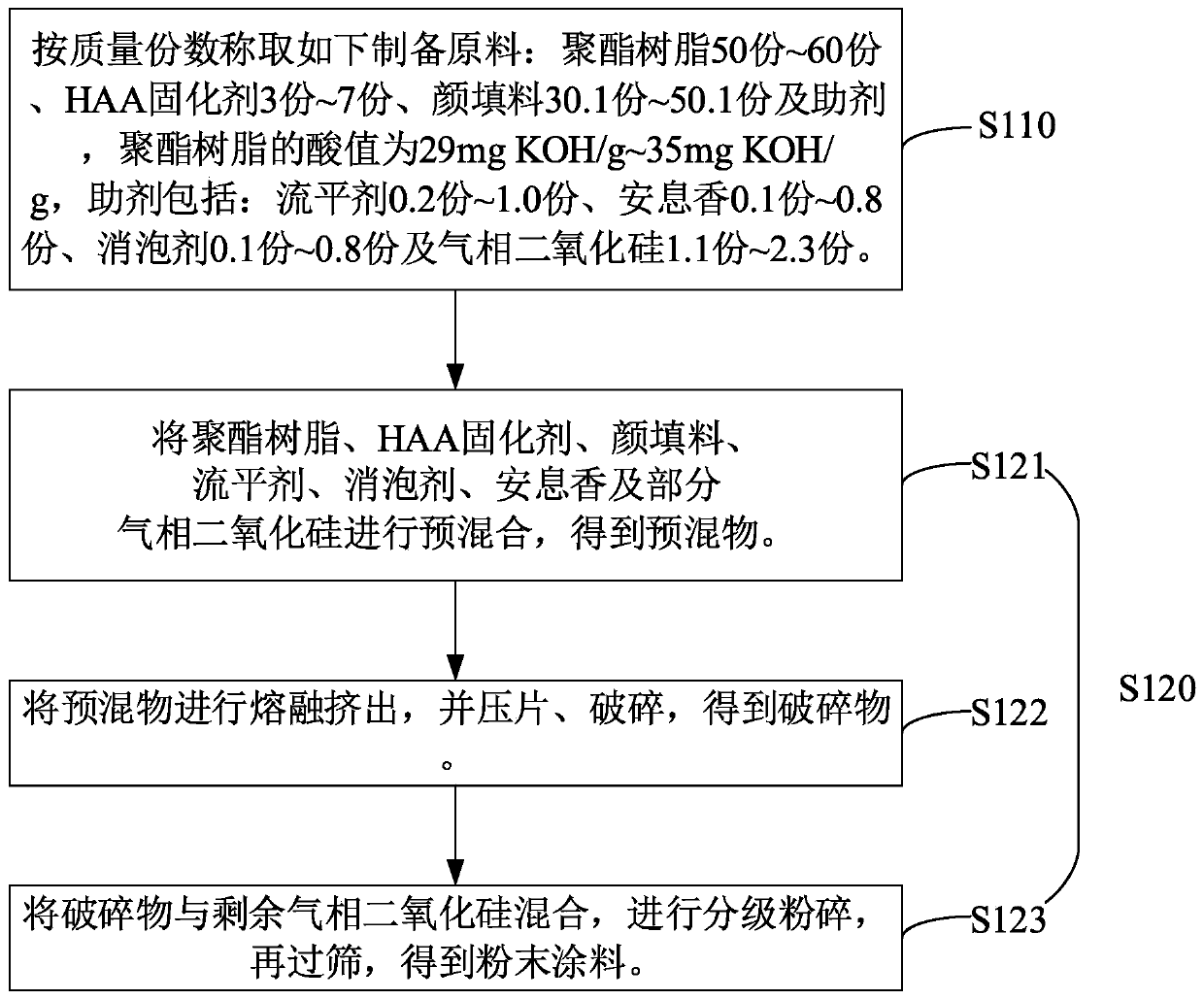

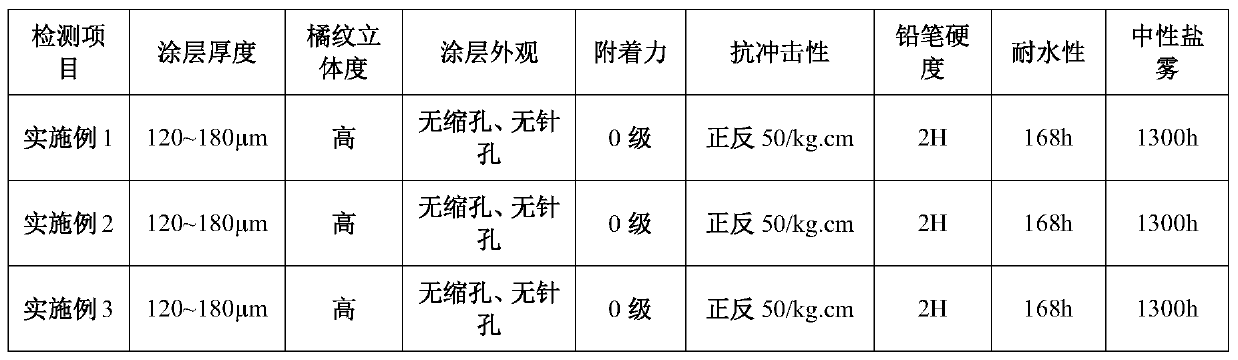

Powder paint and production method and application thereof

InactiveCN109988489AReduce surface tensionNo pinholesAnti-corrosive paintsPowdery paintsSalt spray testAcid value

The invention relates to powder paint and a production method and application thereof. Raw materials for producing the powder paint comprise, in parts by mass, 50-60 parts of polyester resin, 3-7 parts of an HAA curing agent, 30.1-50.1 parts of pigment and filler and assistants, wherein an acid value of the polyester resin is 29-35 mg OKH / g, and the assistants comprise 0.2-1.0 part of a flatting agent, 0.1-0.8 part of benzoin, 0.1-0.8 part of a defoaming agent and 1.1-2.3 parts of fumed silica. During use of the powder paint, when an obtained coating is thick, the phenomena of shrinkage and pin-holes are avoided, and a natural salt spray test reaches 1000 h or longer, so that the corrosion resistance is good.

Owner:SHENZHEN WAVE TELECOMM TECH CO LTD

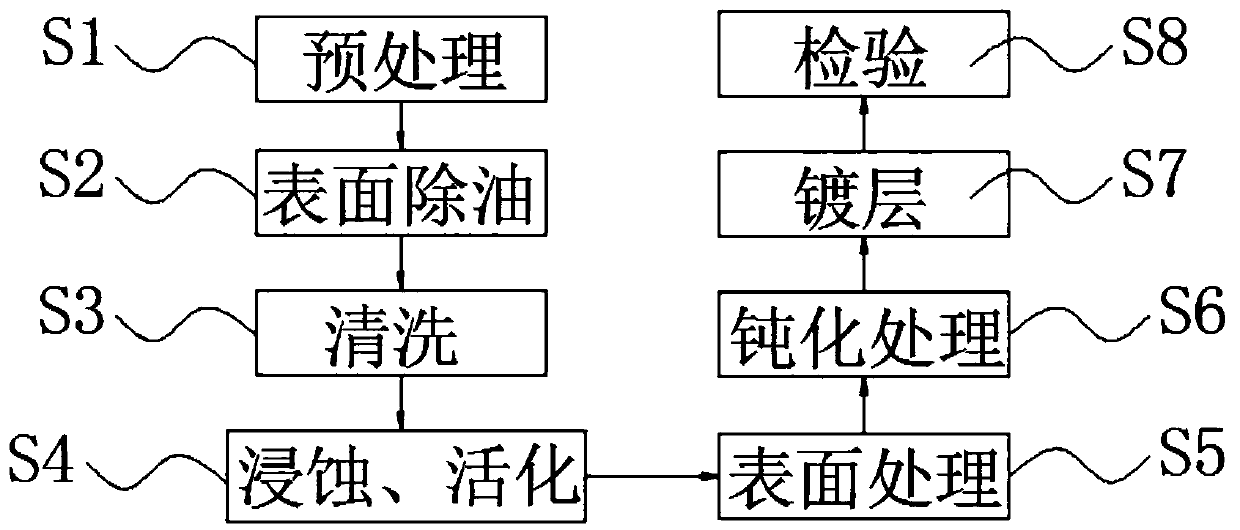

Processing technology of zinc-nickel plating alloy

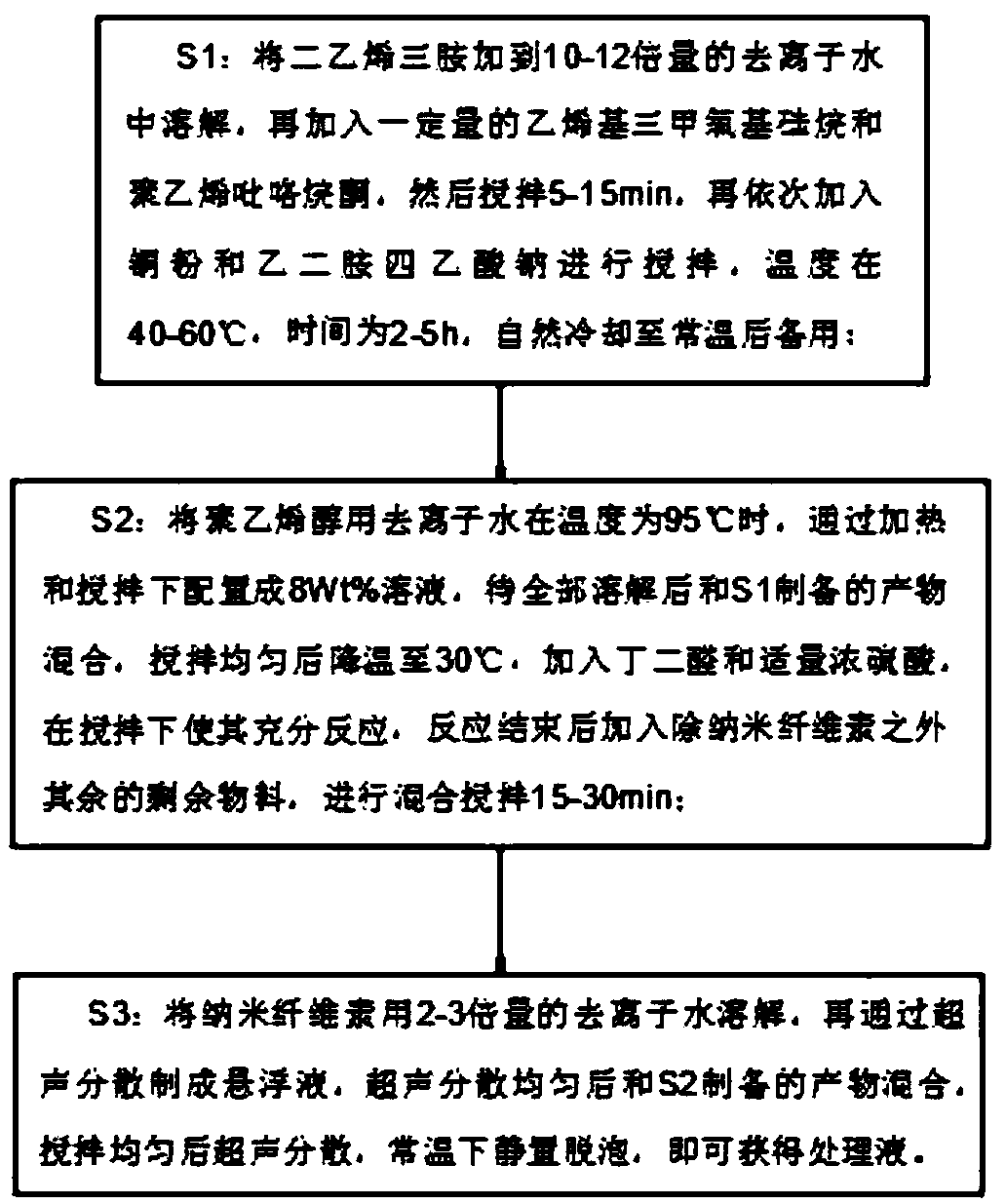

The invention discloses a processing technology of a zinc-nickel plating alloy. The processing technology comprises the following steps: S1, pretreatment; S2, surface oil removal; S3, cleaning; S4, etching and activation; S5, plating; S6, passivation treatment; S7, surface treatment; and S8, inspection. During actual use, a zinc-nickel alloy coating layer is plated on the surface of a workpiece; the high-strength bonding force with a workpiece can be realized; the zinc-nickel plating alloy plating layer is fine in appearance, free of pinholes and free of blistering; the attractiveness of the workpiece is further improved; meanwhile, after the workpiece plating is finished, the surface is treated by a treatment liquid; the surface of the workpiece can be further protected, so that the workpiece has good thermal stability, corrosion resistance and oxidation resistance, the surface of the workpiece soaked in the treatment liquid is smooth and complete, and holes and redundant parts are avoided; the process is easy to operate, and the corrosion resistance of the plating layer is still superior to that of a pure zinc plating layer after the plating layer is processed.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

Polyurethane waterproof flame-retardant paint and preparation method thereof

InactiveCN104745071AImprove waterproof performanceExtend your lifeFireproof paintsPolyurea/polyurethane coatingsDiacetonaminePolymer science

The invention discloses a polyurethane waterproof flame-retardant paint and a preparation method thereof. The paint comprises polyurethane prepolymers, diacetone acryloamide, buty stearate, titanate coupling agent TMC-311 and titanium pigment. The paint further comprises polydimethyl siloxane, white carbon black, mixed solvent and flame-retardant materials. The preparation method comprises the following steps: dissolving the diacetone acrylamide by ethanol of which the volume concentration is 65-80%, wherein the adding amount of the ethanol is 1.5 kilograms in per kilogram of diacetone acrylamide on the basis of weight; mixing the dissolved diacetone acrylamide with the polyurethane prepolymers in a reaction kettle, wherein the reaction temperature is 75-119 DEG C and the reaction time is 1.2-1.5 hours; adding the titanate coupling agent TMC-311 into the mixture and further reacting for 3-6 hours; then adding buty stearate, the rutile-type titanium pigment, polydimethyl siloxane, the flame-retardant materials, the white carbon black and the mixed solvent into the mixture and uniformly mixing, so that the polyurethane waterproof flame-retardant paint product is obtained. The paint prepared by the preparation method is good in waterproof and flame-retardant effects, friendly to the environment and not easy to age.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP +1

Polyurea elastic body pipeline anti-rot protection material

InactiveCN101033335AExcellent physical and chemical propertiesHigh strengthCorrosion preventionPipe protection against corrosion/incrustationElastomerChemical storage

This invention relates to a pipeline anti-corrosion protective material of polyurea elastomer. Its technical program is: A component is isocyanate, and B includes the weight components of following materials: 45-55% of amid-capped propylene oxide compound, 6-15% of diethyl toluenediamine, 5-7% of 2,4-diamido-3,5- methylthio chlorobenzene, 3-8% of DMS toluenediamine, 5-7% of N, N'-dialkyl diamine, 4-6% of N, N'- dialkyl methyl diamine, 2-5% of phosphite triester, 1-2% of fumed silica, 1-3% of organobentonites, 1-2% of silica. This invention advantages: fast setting, influence-free of temperature and humidity, strength, flexibility, high wear-resistance, anti-aging, anti-corrosion. It is particularly applicable to overhead and buried pipes, municipal sewage pipes, oil pipelines, gas pipelines and a variety of steel chemical storage tank.

Owner:山东斯泰普力高新建材有限公司

Chemical pd-plating process for stainless steel surface with excellent anticossive performance in non-oxidant medium

InactiveCN1932078AImprove passivation effectIncreased durabilityLiquid/solution decomposition chemical coatingChemical platingCompound (substance)

The present invention belongs to the field of surface treatment technology, and is especially chemical Pd-plating process for stainless steel surface with excellent anticorrosive performance in non-oxidant medium. The Pd-plated stainless steel is suitable for use in high temperature non-oxidant acidic medium environment. The chemical Pd-plating process includes surface pre-treatment and chemical plating, the surface pre-treatment includes deoiling and acid pickling, and chemical plating uses the plating solution comprising Pd salt Pd(NH3)4Cl2 in 1.5-5g / L accounting in PdCl2, stabilizer NH4Cl in 20-30 g / L, auxiliary complexing agent EDTA in 0-20g / L, surfactant Tween-20 in 0-0.002 ml / L, NH3 .H2O in 80-160 ml / L, reductant NaH2PO2 .H2O in 10-20g / L and water for the rest, of pH 9-10, for 30-60 min at 30-50 deg.c. The chemical Pd-plating process is simple.

Owner:BEIJING UNIV OF CHEM TECH

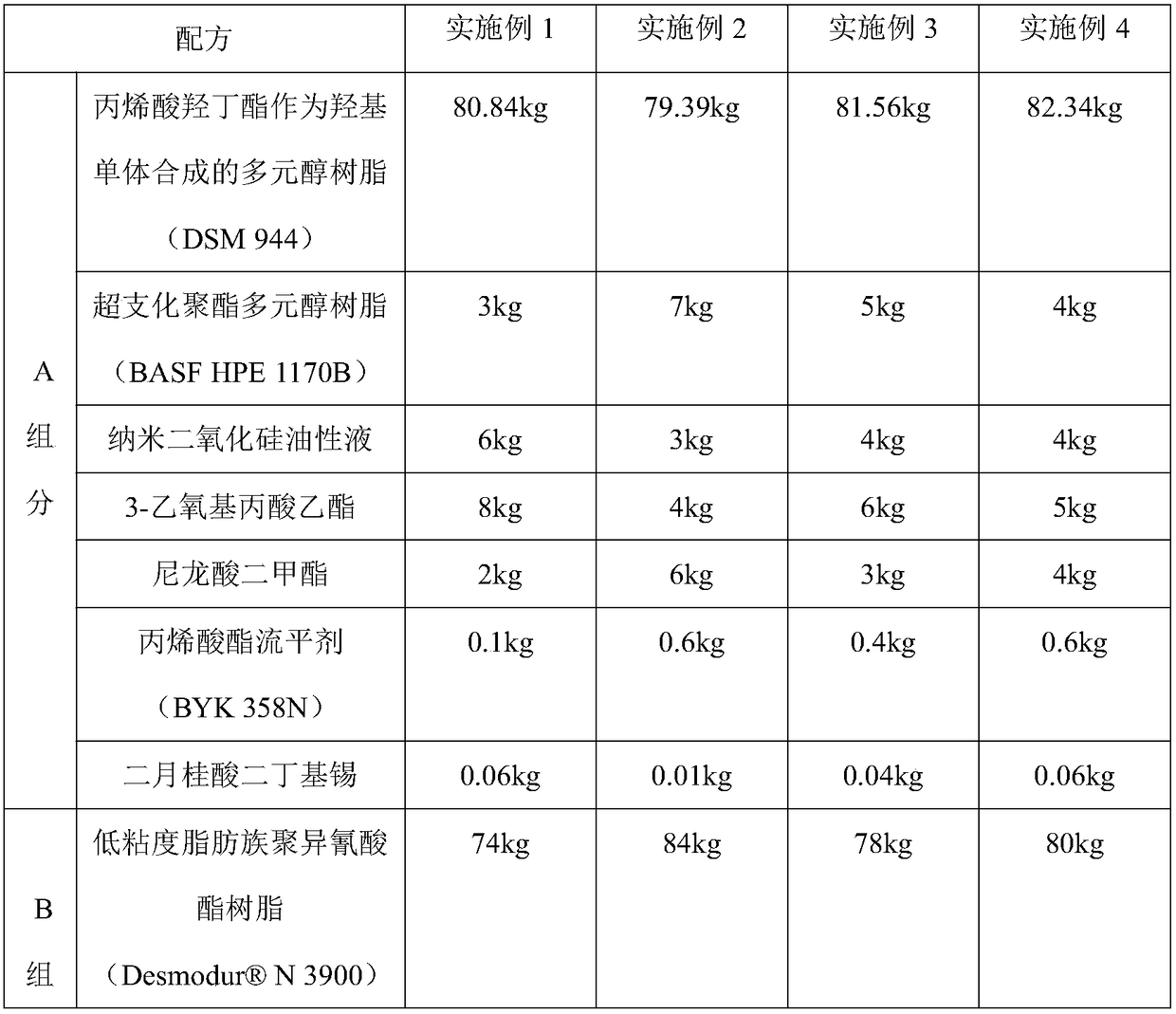

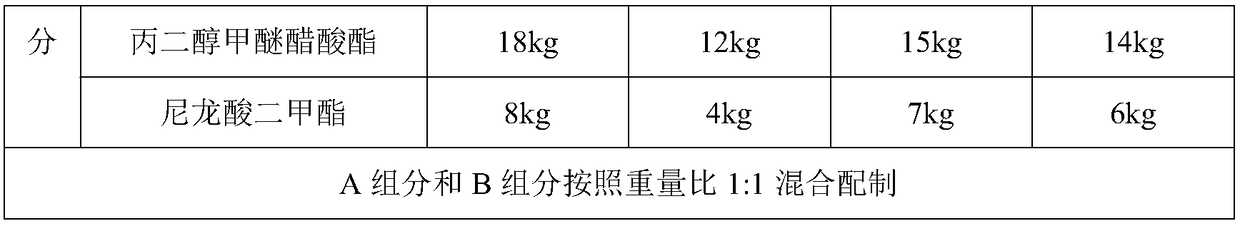

Low-VOC automobile varnish and preparation method thereof

The invention belongs to the technical field of coatings, and concretely relates to a low-VOC automobile varnish and a preparation method thereof. The low-VOC automobile varnish is prepared by mixinga component A with a component B according to a weight ratio of 1:1; the component A comprises 78-84% of polyol resin synthesized by using hydroxybutyl acrylate as a hydroxy monomer, 3-7% of hyperbranched polyester polyol resin, 3-6% of a nano-silica oily liquid, 4-8% of ethyl 3-ethoxypropionate, 2-6% of dimethyl nylon acid, 0.1-0.6% of a leveling agent and 0.01-0.06% of an organotin drier; and the component B includes 74-84% of a curing agent and 16-26% of a solvent. The varnish has a construction viscosity of 20 s / 25 DEG C (Tu-4 cup) or less and a construction solid content of 80% or above,meets the requirement of the VOC content being equal to or less than 200 g / L during construction, and also has the advantages of simple formula, low cost, and high performances of a paint film.

Owner:GUANGDONG YATU CHEM

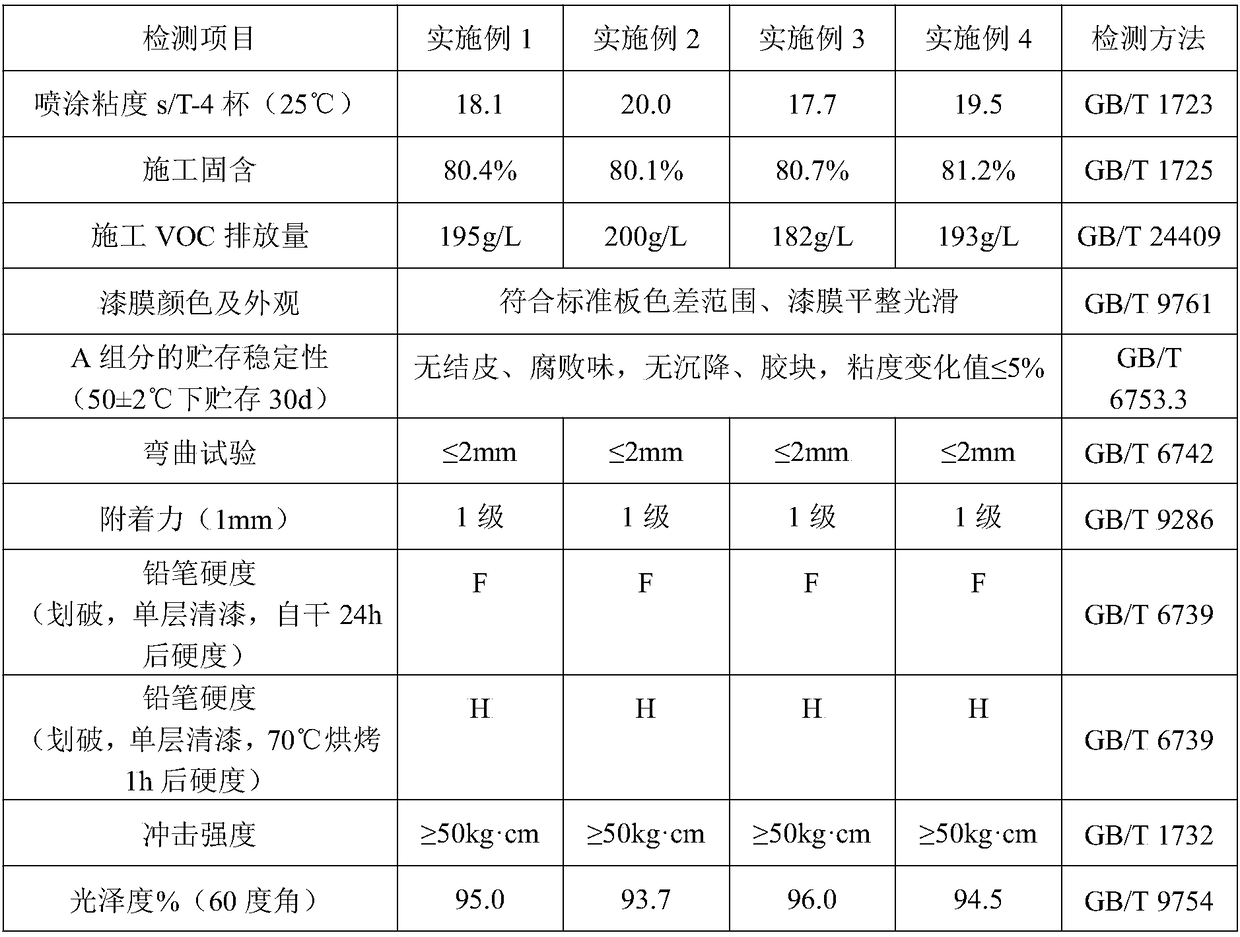

High-performance water-based single-component automobile finish paint applicable to a compression process and preparation method thereof

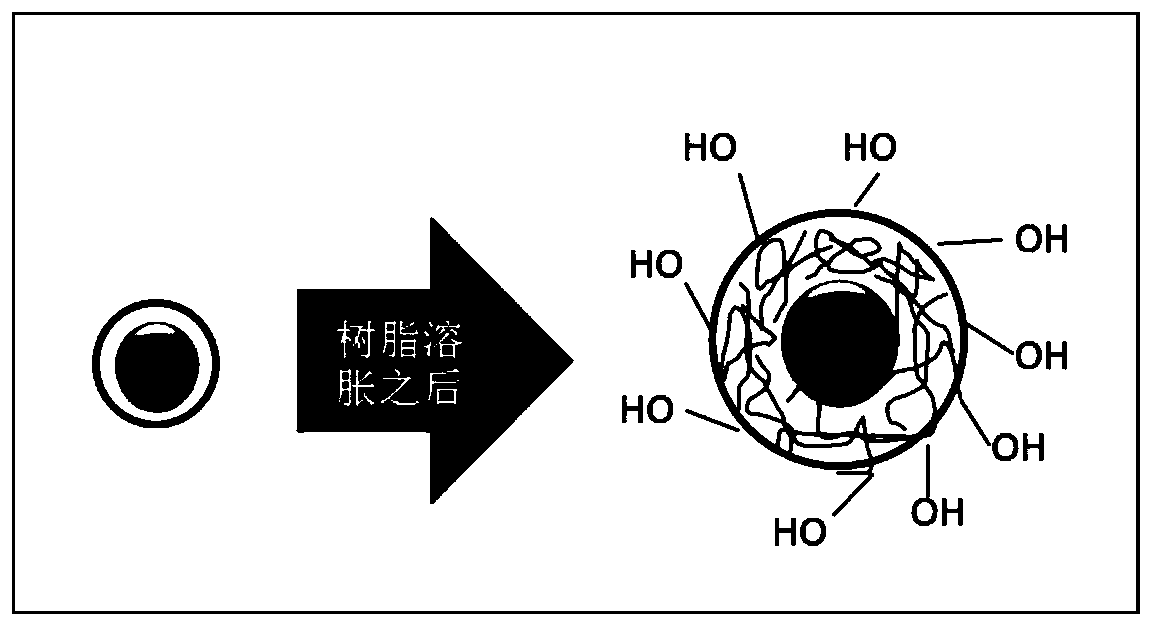

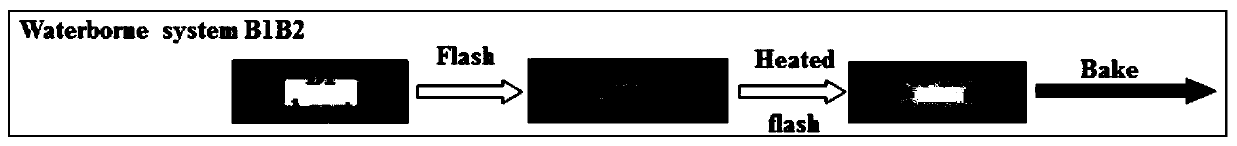

ActiveCN110982368AEasy constructionReduce mixed layer phenomenonPolyurea/polyurethane coatingsMechanical engineeringCoating

The invention discloses a high-performance water-based single-component automobile finish paint applicable to a compression process. The automobile finish paint consists of two parts, namely a finishpaint B1 and a finish paint B2. The invention also discloses a preparation method of the automobile finish paint. According to the invention, the automobile finish paint can meet the requirements of along mainstream B1B2 spraying process (a compression process) used for main engines of various automobiles at present and has excellent workability; due to the fact that a core-shell structure micro-gel emulsion is used, the automobile finish paint has extremely high drainage capacity and is free of paint film defects such as pinholes and miliaria under wet spraying process conditions; and the finish paint B1 has a high-humidity film Tg which has a strong supporting effect on the later coating B2, and therefore, the phenomenon of paint film layer mixing can be effectively reduced, and the appearance of the paint film is improved.

Owner:上海金力泰化工股份有限公司

Method for coating plastic products

InactiveCN102049378ACoating quality is stable and reliableNo pinholesPretreated surfacesCoatingsVarnishChemistry

The invention discloses a method for coating plastic products, comprising the following steps of treating a surface by a nonionic surfactant, drying the surface, spraying adhesive primer, spraying plain colored paint and polyurethane varnish and the like. The nonionic surfactant is sprayed and washed, therefore, the quality of a coating is more stable and reliable, no pinholes and dulling situation exist, and uniform luster is provided on the surface; in addition, the coating construction process is simple with mild conditions.

Owner:张栋

Marine condenser with carbon steel and polyethylene hot-melted combined pipe box

InactiveCN102914207AImprove bindingNot easy to delaminateEvaporators/condensersCorrosion preventionEngineeringHot melt

The invention relates to the field of refrigeration and especially relates to a marine condenser with a carbon steel and polyethylene hot-melted combined pipe box. The marine condenser is mainly used for solving the technical problems of the prior art that a zinc block is corroded when the zinc block is adopted by the condenser for protecting a pipe box, the pipe box is detached and overhauled, a gasket is manufactured again, the operation is troublesome, the position and the construction of the zinc block are specially designed, the parts of the pipe box are increased, the structure of the equipment is more complex, and the like. The marine condenser comprises a cylinder, wherein a front pipe plate and a rear pipe plate are respectively arranged at front and rear two ends of the cylinder; a front pipe box and a rear pipe box are respectively connected with the front and rear pipe plates; a water inlet and a water outlet are arranged on the front pipe box; a plurality of heat exchange pipes are arranged in the cylinder; a refrigerant inlet and a refrigerant outlet are connected with the exterior of the cylinder; plastic lining layers are arranged inside the front pipe box and the rear pipe box; and the plastic lining layers are plastic and steel substrate hot-melted combined layers.

Owner:HANGZHOU SAFETY EQUIP

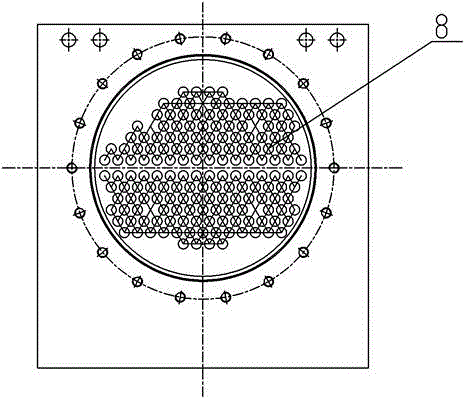

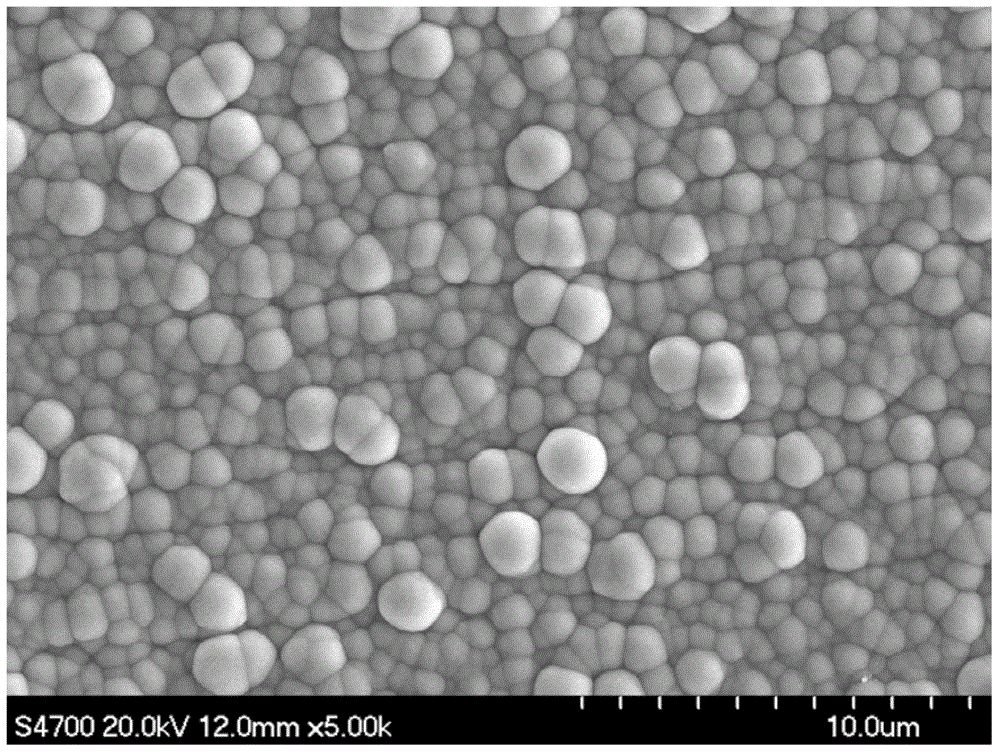

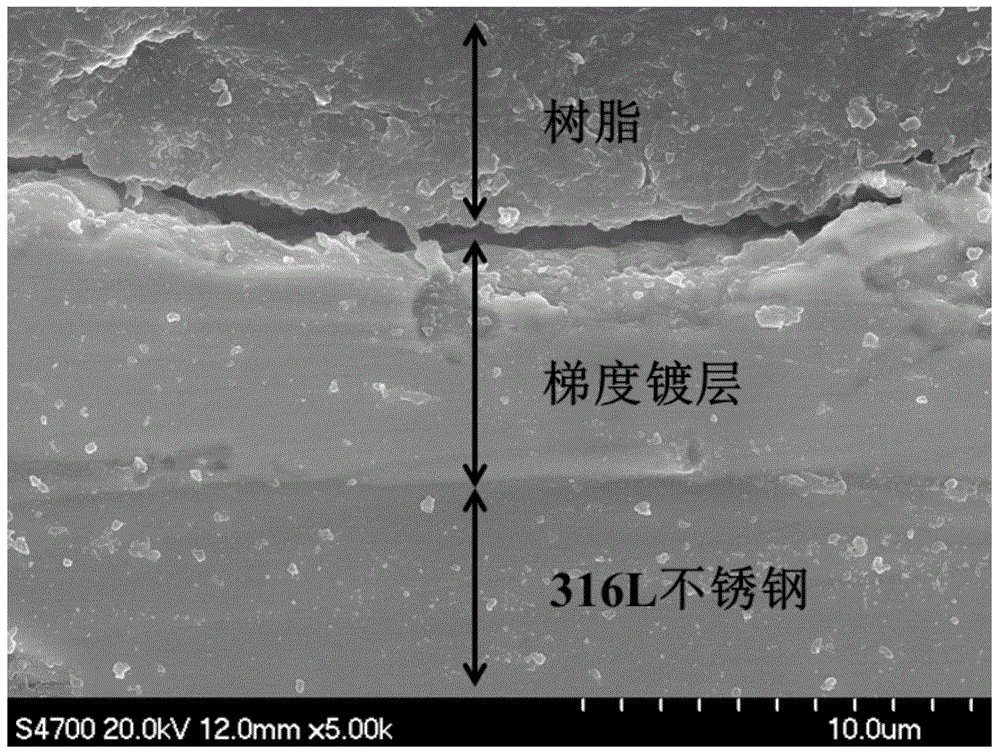

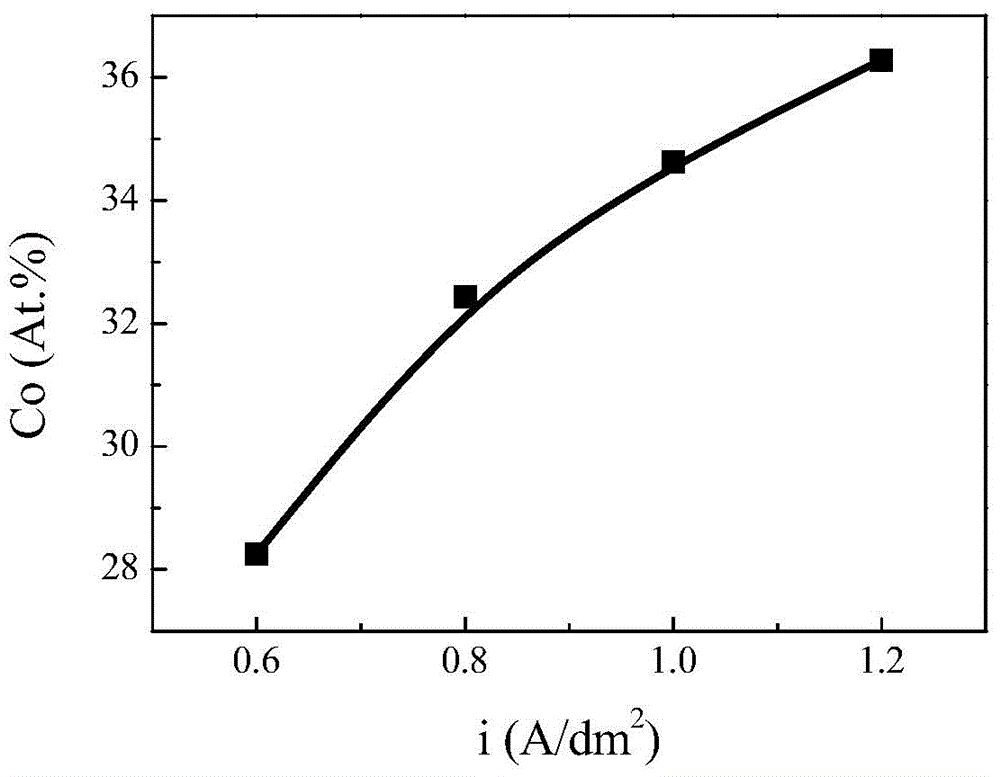

Electroplating process of high-abrasion resistance corrosion-resistance Pd-Co gradient alloy for stainless steel surface

The invention relates to an electroplating process of a high-abrasion resistance corrosion-resistance Pd-Co gradient alloy for a stainless steel surface. The electroplating process comprises a surface pre-treating step and an electroplating step, and is characterized in that an electroplating solution used in the electroplating step is composed of 5-12 g / L of palladium salt Pd (NH3)4Cl2 (measured by the mass of Pd), 50-125 g / L of NH4Cl, 50-100 ml / L of NH3.H2O with the mass percent concentration of 28%, 16-50 g / L of CoCl2.6H2O, 50-100 g / L of C2H5O2N, 1-5 g / L of saccharin and the balance of water, wherein the pH value is 7-8, and the temperature is 30-50 DEG C. In the electroplating step, electroplating is sequentially carried out for 2-3 min by adopting the current density of (0.5-0.6), (0.8-0.9), (1.0-1.1) and (1.2-1.4) A / dm<2>. The electroplating process is simple, and realizes the preparation of a gradient coating in a single trough; the obtained coating is excellent in washing resistance, excellent in corrosion resistance and capable of exerting the good protection effect on stainless steel in a solid-liquid two-phase scoured high-temperature non-oxidizing medium.

Owner:BEIJING UNIV OF CHEM TECH

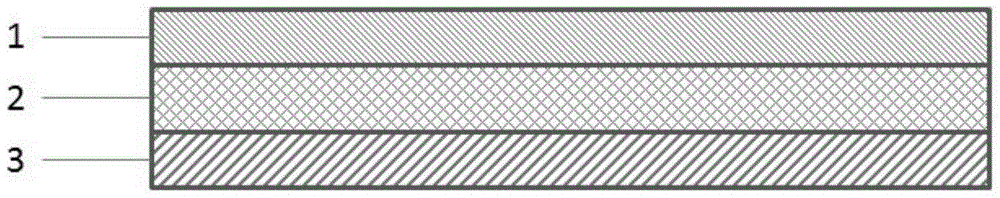

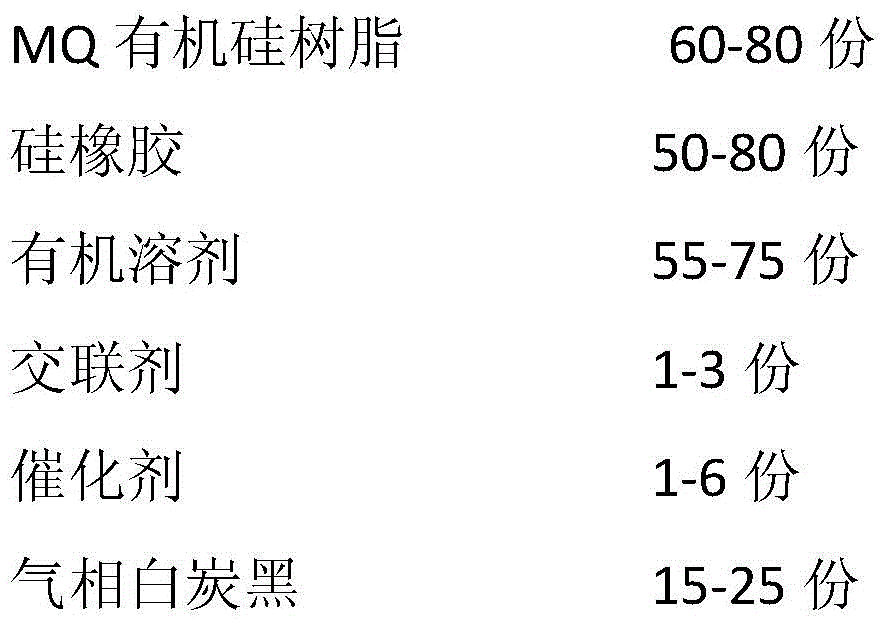

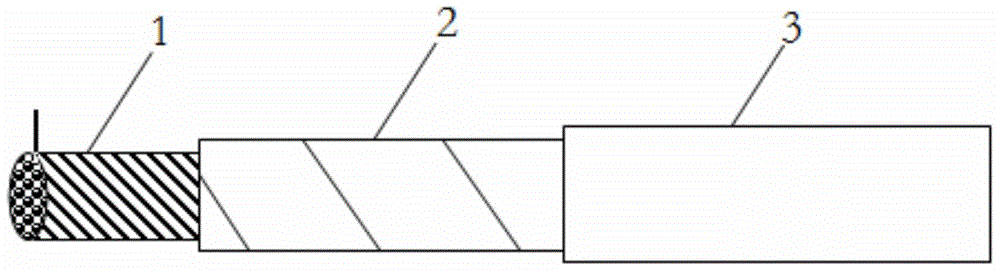

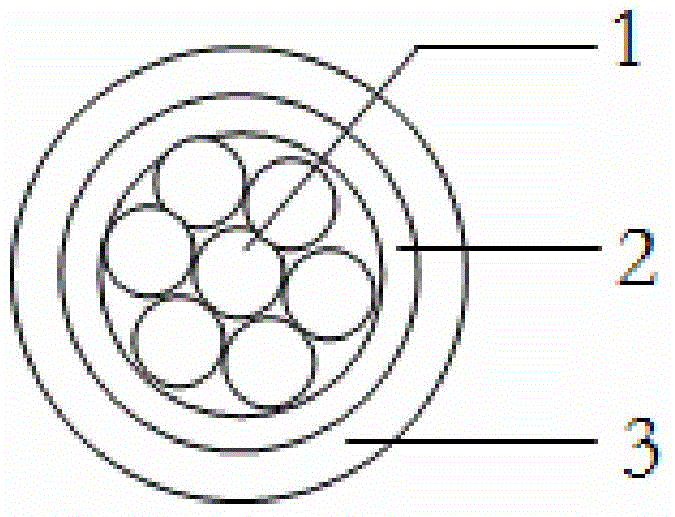

Adhesive high temperature-resistant demoulding cloth and preparation method thereof

ActiveCN105667017AExcellent high temperature peel resistanceStrong self-adhesiveNon-macromolecular adhesive additivesSynthetic resin layered productsGlass fiberEngineering

The invention provides an adhesive high temperature-resistant demoulding cloth and a preparation method thereof, which belong to the technical field of the demoulding cloth. The demoulding cloth comprises an antistick layer, a bearing fabric layer and a bonding layer from up to down, the antistick layer is a teflon film, the bearing fabric layer is glass fiber cloth, and the bonding layer is an organosilicon pressure-sensitive adhesive. The invention also provides the preparation method of the adhesive high temperature-resistant demoulding cloth, the method is characterized in that the teflon film and a glass fiber cloth round roller are subjected to hot pressing for compositing to prepare the glass fiber-enhanced antistick layer; then the glass fiber surface is coated with a stock solution of the organosilicon pressure-sensitive adhesive, and then is slaked at the high temperature to obtain the adhesive high temperature-resistant demoulding cloth. According to the invention, the surface of the demoulding cloth is integral without pin holes, the demoulding can be carried out at the high temperature of 80 DEG C, a production period is shortened, and efficiency is increased.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Novel environmental protection waterproof paint, and preparation method thereof

InactiveCN108676496AImprove waterproof performanceImprove adhesionChloropene polymer coatingsPolyether coatingsSilanesGlycerol

The invention provides a novel environmental protection waterproof paint, and a preparation method thereof. The novel environmental protection waterproof paint is prepared from a polymer emulsion, modified asphalt emulsion, titanium dioxide, hollow glass microsphere, a composite filling material, a polyether polyol, polyether modified silane, glycerol triacetate, a thickening agent, a dispersant,and water. The novel environmental protection waterproof paint possesses excellent water resistance; the coating film surface is smooth and flat; coating film is compact; no pin hole or foam is generated; coating film bonding performance is excellent; peeling from a base layer is not easily caused; the raw materials are low in cost, and are widely available; the preparation method is simple; and the preparation method is suitable for industrialized large scale production.

Owner:来安县森浩茂环保工程有限公司

Single-component polyurethane waterproof coating material

InactiveCN110835497AImprove adhesionNo pinholesPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses a single-component polyurethane waterproof coating material, and belongs to the technical field of waterproof coating materials, wherein the coating material comprises, by weight, 100-200 parts of polyester polyol, 50-100 parts of toluene diisocyanate, 40-90 parts of an organic solvent, 200-400 parts of a filler, 10-30 parts of an organic silicon defoamer, 20-50 parts of alatent curing agent and 50-80 parts of a dispersing agent. According to the invention, the single-component polyurethane waterproof coating material has advantages of high binding power with the layer, compact coating, no pinhole, no bubble and small water vapor permeability coefficient, is waterproof, can be used as a gas barrier layer, can be directly constructed on the surface of a humid base layer, and has high construction speed so as to shorten the construction period.

Owner:XIANGYANG JOYOUNG WATERPROOF MATERIAL

Insulated composite aluminum enamelled wire

InactiveCN105469865AImprove insulation voltageExcellent abrasion resistanceInsulated cablesInsulated conductorsAluminiumVoltage

The present invention discloses an insulated composite aluminum enamelled wire, belonging to the technical field of insulating conductive wire manufacturing. The insulated composite aluminum enamelled wire comprises a conductor, a composite film layer, a Teflon tape, and a nylon-modified glass fiber layer. The conductor is a composite aluminum conductive wire and is coated by the composite film layer. The enamelled wire is coated by the Teflon tape which is coated by the nylon-modified glass fiber layer. By using the design of combining the conductor, the composite film layer, the Teflon tape, and the nylon-modified glass fiber layer, the raw materials are easy to obtain, the operation is simple, compared with an extrusion type Teflon enamelled wire, the specific purchase of a high-temperature extrusion machine is not needed, the preparation can be completed in general equipment, and the industrialization is easily achieved. The insulating voltage of the three-layer insulating enamelled wire is high, since outer sheath composite nylon has superior abrasion resistance, high speed automatic winding is possible, at the same time, the insulation voltage is high, an insulating tape and an insulating space can be saved, three layers of insulation protection are used, and a pinhole phenomenon is avoided.

Owner:ANHUI JIUHUA KIMRUN COPPER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com