Insulated composite aluminum enamelled wire

A technology of enameled wire and composite aluminum, which is applied in the direction of insulated cables, insulated conductors, conductors, etc., and can solve problems such as potential safety hazards, erosion, and uneven thickness of insulated wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

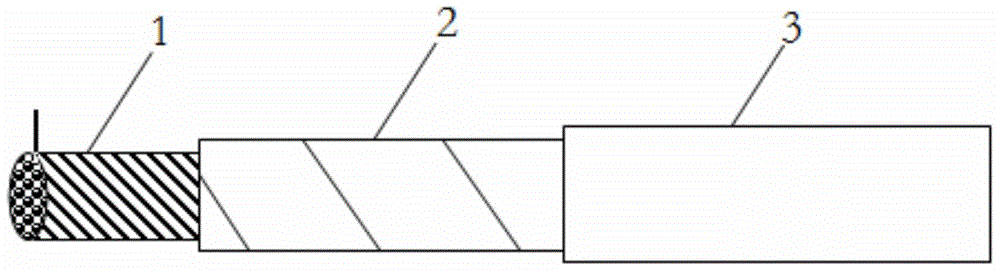

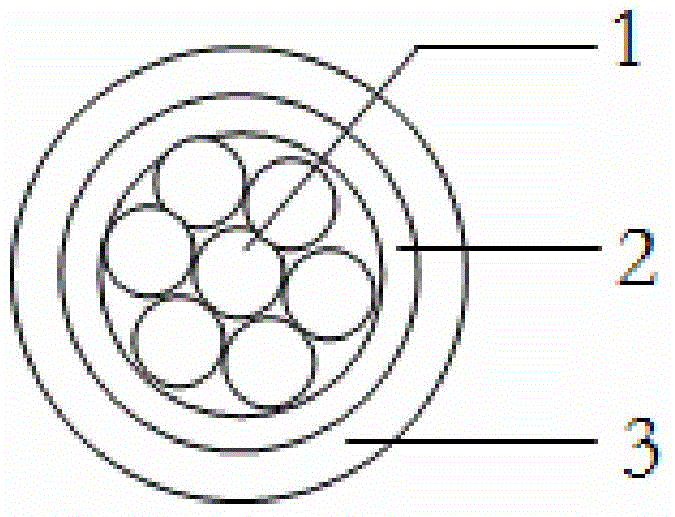

[0015] An insulated composite aluminum enameled wire, including a conductor 1, a composite paint film layer (not shown in the figure), a Teflon tape 2, a nylon modified glass fiber layer 3, the conductor 1 is a composite aluminum wire, and its outer layer is coated with Composite paint film layer (not shown in the figure), the composite paint film layer is composed of primer and top coat according to process requirements, both primer and top coat are made of polyesterimide paint, insulation thickness is 2-5 microns, which can withstand 4KV pulse high voltage.

[0016] The Teflon tape 2 is wrapped on the outside of the enamelled wire 1, the specification of the Teflon tape 2 is 8*0.05, and it has the function of high pressure resistance and water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com